Rogers curamik® Ceramic Substrates offer superior thermal properties and have applications in many of the world‘s most advanced electronic systems

Ceramic substrates are materials typically used in Power Modules with unique thermal, mechanical and electrical properties that make them ideal for demanding power electronics applications. These substrates enable the electrical function of a system providing mechanical stability and a superior thermal performance to meet the requirements of each unique design.

Ceramic Substrate Advantages

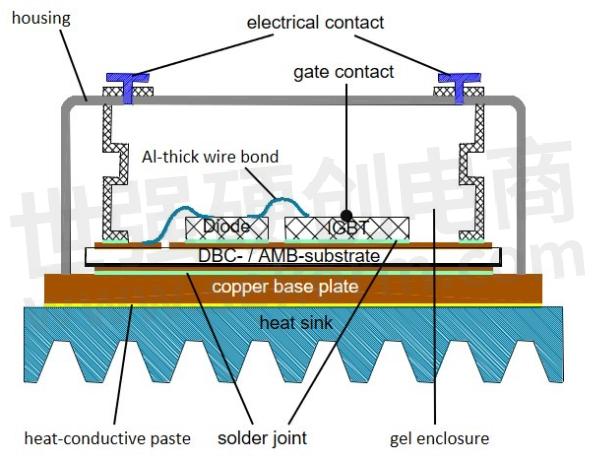

Ceramic substrates are usually found within the copper/metal layers of a Power Module as part of a power electronics circuit. They assist in the function similar like a PCB, allowing it to best perform its desired purpose. The diagram below shows a typical representation of the location and function of the substrate.

There are many advantages in choosing a ceramic substrate over other substrates based on metal or plastic. ROGERS curamik® Ceramic Substrates offer superior thermal properties such as high-heat conductivity, extended heat capacity and enhanced thermal spreading. Their low coefficient of thermal expansion enables a range of mechanical benefits making them suitable for the most critical applications. On top of this, they provide a rugged electrical insulation protecting the users from the electrical system.

Types of Ceramic Substrates

Choosing the right substrate for your application is a key factor in optimizing the performance of your system. Our Advanced Electronics Solutions team is available to help you select the ideal substrate and find the best trade off among mechanical parameters, thermal performance and cost.

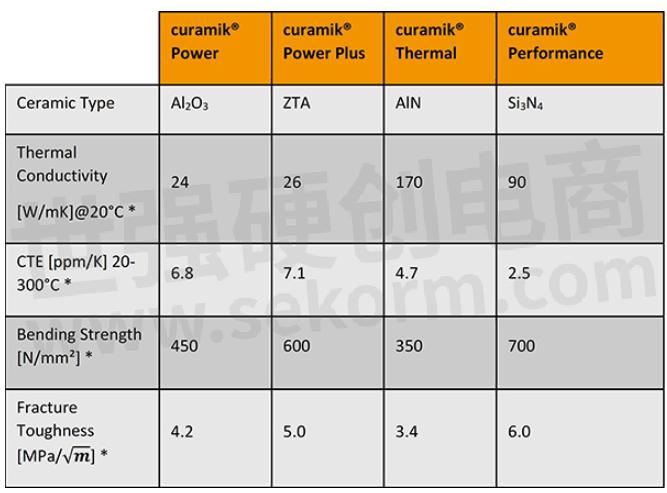

Rogers' curamik® portfolio includes curamik® Power, curamik® Power Plus, curamik® Thermal and curamik® Performance substrates.

*Values are valid for bare ceramics

Applications for Rogers Substrates

Ceramic substrates have applications in many of the world's most advanced electronic systems, including the expanding renewable energy and vehicle electrification industries. Below are just a few notable markets and applications that can benefit from the implementation of curamik® substrates.

Electric and Hybrid Vehicles and Vehicle Electrification

Many upgrades in automotive comfort and safety features are driven by advances in vehicle electrification. Automakers are also notably interested in electrifying cars’ powertrains from mild hybrid into full electric vehicles to meet growing market demand for low emissions vehicles.

More electrification requires more power. High-current, high-voltage solutions are needed to drive all-new electric functionalities within strict mechanical boundaries. Because of their superior qualities, Rogers substrates are found in market applications including electric power steering, electrical braking systems, integrated starter alternators, diesel and water-pump controls, motor and engine controls, and converters/inverters for HEV/ EV, LED lighting and alternators.

Renewable Energy

Rogers substrates can be found in diverse applications throughout the renewable energy industry, including technologies used for wind and solar energy production and storage, such as inverters for photovoltaic solar (PV) and wind as well as concentrators for concentrator photovoltaics (CPV).

Industrial

Our curamik® substrates have shown excellent performance in broad applications under the umbrella of the general industry. Some industrial applications for ceramic substrates include pump controls, variable frequency drives, traction drives, power supplies, Peltier coolers, customized motor controls, standardized semiconductor modules with chips on board, DC/DC converters and AC/DC converters.

Major Home Appliances

Demand for large electrical home appliances (also known as white goods) is influenced by customer preference for energy efficiency, noise control, maintenance accessibly and safety features. Rogers substrates have a number of applications in major home appliances, including the intelligent power modules that drive appliance motors.

Contact Us About curamik® Metalized Ceramic Substrates

With almost 40 years of expertise in joining metal and ceramic technologies, Rogers is a trusted, leading manufacturer of Direct Bonded Copper (DBC) and Active Metal Brazing (AMB) substrates under the curamik® brand.

Rogers offers full access to our team to customize a product design to match your design's unique needs. Contact us for additional information or assistance on your project.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由翊翊所思转载自ROGERS,原文标题为:Overview of Ceramic Substrates,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

ROGERS正在大规模生产可用于更高功率密度的新型Si3N4 AMB 基板

随着功率半导体在诸如电动汽车和储能等应用中的重要性日益增加,面临的成本和性能压力也不断加大,这需要不断地创新来满足市场的需求。幸运的是,新的Si3N4陶瓷原料现已上市,ROGERS正在利用其强大的合作伙伴网络大规模生产更高性能的Si3N4 AMB 基板。

罗杰斯curamik®金属化陶瓷基板具有出色热性能和机械性能,可用于可再生能源和汽车电气化行业等

陶瓷基板在世界许多最先进的电子系统中都有应用,包括汽车电气化、可再生能源、工业、大型家用电器等诸多领域。罗杰斯陶瓷基板具有出色机械参数和热性能,以上各应用均可以从curamik®基板的实施中受益。

罗杰斯高功率半导体陶瓷基板苏州新生产基地喜迎首批员工入驻,开启公司历史新篇章

在中国节气“芒种”之际,罗杰斯电子材料(苏州)有限公司迎来了其高功率半导体陶瓷基板新生产基地的重要里程碑:首批员工正式入驻。该项目体现了罗杰斯提升产能、服务全球的战略理念。自项目签约以来,团队全力推进设施建设、设备安装及安全监管,确保项目顺利进行。投产后将缩短交付周期,深化与亚洲客户的技术合作,满足电动车和可再生能源等领域对金属化陶瓷基板的增长需求。

ITW(依工聚合)粘合剂/密封剂/点胶设备/耐磨化合物/环氧树脂/聚氨酯 选型指南

ITW Performance Polymers offers a wide range of products to the mining, coal-fired power, alternative energy (wind), transportation, marine,composites, engineered construction and general industrial markets.

ITW - 快速固化腻子,LARGE DIAMETER THREADLOCKER,EZ-SPRAY药筒系统,可刷陶瓷,阻挡涂层,粘合剂,HIGH PERFORMANCE SHRINK CONTROLLED FILLED TOOLING RESIN,静态混合喷嘴,硅树脂RTV,点胶设备,硅酮脱模剂,磨损化合物,TROWELABLE PREMIUM FLOOR PATCHING SYSTEM,厌氧法兰密封胶,可喷涂合成材料,CERAMIC REPAIR COMPOUND,CERAMIC BEAD-FILLED WEAR AND ABRASION RESISTANT EPOXY,双组分甲基丙烯酸酯结构胶,滞留化合物,铜防卡润滑剂,螺纹锁紧器,环氧树脂灌封料,非导电双组分甲基丙烯酸酯胶粘剂,RADIUS COMPOUND,POURABLE STEEL-FILLED EPOXY,性能聚合物,NON-VOC CLEAR EPOXY SEALER,通用型瞬间粘合剂,FLOOR REPAIR COMPOUNDS,BLACK SILICONE ADHESIVE SEALANT,URETHANE ADHESIVES,RAPID-CURING ANAEROBIC ADHESIVE,三组分填充环氧树脂体系,FLOOR PATCHING COMPOUNDS,衬垫化合物,大直径螺纹锁固剂,树脂基体,BEARING MOUNT,TITANIUM PUTTY,CORROSION REPAIR COMPOUNDS,HIGH TEMPERATURE THREAD SEALANT,STEEL-FILLED EPOXY,可浇注的钢填充环氧树脂,铝填充环氧腻子,HIGH STRENGTH ADHESIVE,硅酮密封剂,PASTE-LIKE GASKET COATING,护发素,90 分钟垫片制造机,可刷环氧化合物,TWO-PART METHACRYLATE ADHESIVE,PLASTIC STEEL® PUTTY,陶瓷微珠填充环氧树脂体系,SEAL + LOCK THREAD COMPOUND,陶瓷修补腻子,铝填充可浇注环氧树脂,MICRO BALLOON FILLED RESIN MATRIX,ANAEROBIC GASKET MAKER,THIXOTROPIC EPOXY GEL SYSTEM,CERAMIC REPAIR PUTTY,SILICONES,BEAD-FILLED EPOXY COMPOUND,陶瓷修补化合物,HIGH-TEMP RED RTV SILICONE GASKET MAKER,CERAMIC COMPOUNDED VINYLESTER RESIN,HIGH STRENGTH THREADLOCKER RED GEL,PREMIUM QUALITY COPPER ANTI-SEIZE AND THREAD LUBRICANT,LIQUID RELEASE AGENT,CYANOACRYLATES,膏状垫片密封剂,地板修补化合物,氧化铝填充环氧树脂,无VOC透明环氧封闭漆,膏状垫片涂层,ANTI-SEIZE LUBRICANTS,低粘度螺纹防松,DISPENSING EQUIPMENT,ADHESIVE PUTTIES,NON-RUSTING TITANIUM-REINFORCED EPOXY PUTTY,重负荷混合,GASKETING COMPOUNDS,METAL-FILLED EPOXY PUTTY,VINYLESTER LAMINATING RESIN,通用密封剂,WET SURFACE REPAIR PUTTY,THREADLOCKERS,RTV硅胶密封垫制造商,CERAMIC COMPOUNDED POLYESTER RESIN,WEAR-RESISTANT EPOXY,陶瓷微珠填充耐磨环氧树脂,HI-TEMP RTV SILICONE GASKET,可喷涂聚酯树脂基体,GENERAL-PURPOSE ADHESIVE,GENERAL-PURPOSE FITTING SEALANT,铝腻子,SELF-LEVELING URETHANE KIT,双组分快速固化甲基丙烯酸酯胶粘剂,氧化铝陶瓷微珠填充环氧树脂体系,陶瓷复合聚酯树脂,100% SOLIDS EPOXY-BASED POLYMERS,RESIN MATRIX,防卡密封剂,LIGHTNING FAST CURING GEL ADHESIVE,SPRAYABLE FILLER,NON-CONDUCTIVE TWO-PART METHACRYLATE ADHESIVE,PNEUMATIC CARTRIDGE DISPENSING GUN,表面润湿剂,HEAVY-DUTY BLEND,NON-TRICHLOROETHANE BASED DEGREASER,TWO-PART RAPID-CURING METHACRYLATE ADHESIVE,穿透级螺纹锁固剂,PERMANENT STRENGTH THREADLOCKER,钛腻子,COPPER ANTI-SEIZE LUBRICANT,URETHANES CERAMIC FILLED EPOXY,双组分聚氨酯粘合剂,GENERAL-PURPOSE ENCAPSULANT,ANAEROBIC FLANGE SEALANT,LOCK THREAD COMPOUND,双环戊二烯层压树脂,CORROSION RESISTANT EPOXIES,EZ-SPRAY可刷陶瓷,THREE-PART FILLED EPOXY SYSTEM,金属修补环氧树脂,橡胶增韧结构胶,高强度螺纹锁固剂红色凝胶,聚氨酯陶瓷填充环氧树脂,SPRAYABLE TWO-PART POLYESTER BASED FILLER,SENSOR-SAFE BLUE RTV SILICONE GASKET MAKER,乙烯基酯层压树脂,氧化铝填充环氧化合物,CORING PRINT BLOCKER,METAL REPAIR EPOXIES,增韧型用途瞬间胶粘剂,SPRAYABLE RESIN BASED MATRIX,青铜腻子,SURFACE INSENSITIVE THREADLOCKER,SEAL THREAD COMPOUND,90 MINUTE GASKET MAKER,TWO-PART URETHANE ADHESIVE,手动点胶枪,高温红色RTV硅胶垫片制造机,EPOXY CONCRETE SEALER,PENETRATING GRADE THREADLOCKER,CLEAR RTV SEALANT,可喷涂填料,BRONZE PUTTY,传感器安全蓝色RTV硅胶垫圈制造商,液压密封胶,中等强度蓝色螺纹锁固剂凝胶,高温螺纹锁固剂,高性能收缩控制填充模具树脂,RTV SILICONE GASKET MAKER,CONCRETE PATCHING COMPOUND,湿面修补腻子,闪电快速固化凝胶胶粘剂,高性能陶瓷复合树脂,柔性衬垫材料,CHEMICAL CLEANER,ALUMINA CERAMIC BEAD-FILLED EPOXY SYSTEM,螺纹密封剂,无锈钛增强环氧腻子,MANUAL CARTRIDGE DISPENSING GUN,BRONZE-FILLED EPOXY PUTTY,洗手液,MEDIUM VISCOSITY ANAEROBIC ADHESIVE,通用环氧腻子,硅酮,ALUMINA-FILLED EPOXY,高强度螺纹锁固剂,WEAR RESISTANT PUTTY,组合气窗取芯材料,THREAD SEALANTS,RETAINING COMPOUNDS,珠粒填充环氧化合物,自流平聚氨酯套件,氨基甲酸乙酯,100%固体环氧基聚合物,黑色RTV密封剂,耐腐蚀环氧树脂,NON-HARDENING LIQUID GASKET SEALANT,FAST CURE PUTTY,GASKET MAKER,POLYESTER ADHESIVE,聚酯粘合剂,ANTI-SEIZE SEALANTS,无铜防卡润滑剂,批量打印拦截器,耐磨腻子,FLOOR COATINGS,TROWELABLE URETHANE,FLEXIBLE EPOXY,混合复合,双组分甲基丙烯酸酯粘合剂,触变性环氧凝胶体系,SILICONE RELEASE AGENT,SPRAYABLE POLYESTER MATRIX,可喷涂双组分聚酯基填料,THREAD SEALANT,低收缩树脂,金属填充环氧腻子,ELASTOMERIC RUBBER,THREADED JOINTS,气动药筒点胶枪,ANTI-SEIZE & GASKET SEALANTS,优质铜防卡死和螺纹润滑剂,SINGLE-COMPONENT SEALANT,陶瓷复合乙烯基酯树脂,耐溶剂密封剂,中等强度螺纹锁固剂,SOLVENT RESISTANT SEALANT,ALUMINUM-FILLED POURABLE EPOXY,HIGH STRENGTH THREADLOCKER,密封螺纹油,VINYLESTER BLENDED PREMIUM MOLD BUILDING RESIN,BLACK RTV SEALANT,非硬化液体垫片敷料,非硬化液体垫片涂层,PASTE-LIKE GASKET DRESSING,ALUMINUM PUTTY,NICKEL ANTI-SEIZE LUBRICANT,凝胶粘合剂,PIPE JOINT COMPOUND,氰基丙烯酸酯,可喷涂双组分聚酯基玻璃化合物,高强度粘合剂,液体脱模剂,塑钢®腻子,快速固化厌氧胶,WEARING COMPOUNDS,WEARING COMPOUND,HIGH PERFORMANCE PUTTY,STATIC MIX NOZZLE,LOW SHRINK RESIN,COPPER-FREE ANTI-SEIZE LUBRICANT,BLENDED COMPOUNDED,ADHESIVE,RUBBER-TOUGHENED STRUCTURAL ADHESIVE,清洁护发素,环氧地坪涂料,通用接头密封剂,密封+锁紧螺纹油,HIGH TEMPERATURE THREADLOCKER,STAINLESS STEEL PUTTY,柔性环氧树脂,PRIMERLESS ADHESIVES,CERAMIC COMPOUND RESIN,MAXIMUM TEMPERATURE THREAD SEALANT,CLEAR RTV SILICONE ADHESIVE SEALANT,凝胶,中粘度厌氧胶,防卡&垫片密封剂,高温RTV硅胶垫片,易于使用的粘性贴片套件,高温螺纹密封剂,可抹平的氨基甲酸乙酯,WEAR AND ABRASION ALUMINA CERAMIC BEAD-FILLED NOVALAC EPOXY COMPOUND,管道接合剂,膏状垫圈敷料,100% SOLIDS SELF-LEVELING COATING,PNEUMATIC SEALANT,TWO-PART METHACRYLATE STRUCTURAL ADHESIVES,油灰,SPRAYABLE SYNTACTIC MATERIALS,环氧树脂凝胶,黑色硅酮粘合密封胶,厌氧密封垫制造商,HIGH-PERFORMANCE CERAMIC COMPOUND RESIN,ALUMINUM-FILLED EPOXY PUTTY,气动密封剂,BARRIER COAT,PLUG BUILDING,锁紧螺纹油,HYDRAULIC SEALANT,URETHANES,TOUGHENED STRUCTURAL ADHESIVE,DCPD LAMINATING RESIN,ALL-PURPOSE EPOXY PUTTY,MANUAL DISPENSING GUN,不锈钢腻子,透明RTV硅酮粘合密封剂,通用粘合剂,不锈钢填充环氧腻子,PRIMER,CONDITIONER,GASKET SEALANTS,SPRAYABLE POLYESTER RESIN MATRIX,混凝土修补剂,底漆,化学清洁剂,MEDIUM STRENGTH THREADLOCKER,双组分聚氨酯胶粘剂,单组份密封胶,GELS,插入式建筑,环氧树脂粘合剂,HI-STRENGTH THREADLOCKER,青铜填充环氧腻子,镍防卡润滑剂,STRUCTURAL ADHESIVES,螺纹接头,PASTE-LIKE GASKET SEALANT,MICRO-ALUMINA CERAMIC BEAD-FILLED EPOXY SYSTEM,BRUSHABLE CERAMIC,腐蚀修复化合物,EPOXY POTTING COMPOUND,环氧混凝土密封剂,微球填充树脂基体,EZ-SPRAY CARTRIDGE SYSTEM,可喷涂树脂基基体,永久强度螺纹锁固剂,FLEXIBLE GASKETING MATERIAL,MEDIUM STRENGTH BLUE THREADLOCKER GEL,混合喷嘴,高性能可刷聚氨酯,EZ-SPRAY BRUSHABLE CERAMIC,SYNTACTIC TRANSOM CORING MATERIAL,喷嘴,BULK PRINT BLOCKER,SURFACE WETTING AGENT,结构胶粘剂,弹性半结构双组分混合胶粘剂,半径化合物,ALUMINA-FILLED EPOXY COMPOUND,LOW VISCOSITY THREADLOCKING,HIGH-PERFORMANCE BRUSHABLE URETHANE,可抹平的高级地板修补系统,CLEANER CONDITIONER,铝填充环氧树脂粘合剂,HAND CLEANERS,EPOXY FLOOR COATINGS,可喷涂聚酯基体,EASY-TO-USE ADHESIVE PATCH KIT,NOZZLES,HIGH PERFORMANCE THREAD SEALANT,NON-VOC EPOXY COATING,高强度可拆卸橙色螺纹锁固剂,MIX NOZZLE,垫片密封剂,HI-TEMP THREADLOCKER,SPRAYABLE TWO-PART POLYESTER BASED GLAZING COMPOUND,TWO-PART POLYURETHANE ADHESIVE,无底漆粘合剂,SILICONE SEALANTS,基于非三氯乙烷的脱脂剂,钢填充环氧树脂,HIGH STRENGTH REMOVABLE ORANGE THREADLOCKER,BRUSHABLE EPOXY COMPOUND,PUTTY,无VOC环氧涂料,螺纹锁固剂凝胶,100%固体自流平涂料,粘性油灰,CERAMIC BEAD-FILLED EPOXY SYSTEM,NON-HARDENING LIQUID GASKET DRESSING,垫圈制造商,耐磨化合物,可喷涂材料,透明RTV密封剂,取芯印刷阻滞剂,乙烯基酯混合高级模具建筑树脂,THREADLOCKER GELS,GENERAL PURPOSE INSTANT ADHESIVES,高性能螺纹密封剂,GEL ADHESIVE,STAINLESS STEEL-FILLED EPOXY PUTTY,轴承底座,地板涂料,表面不敏感螺纹锁固剂,EPOXY GEL,NON-HARDENING LIQUID GASKET COATING,最高温度螺纹密封剂,ELASTIC SEMI STRUCTURAL TWO-PART HYBRID ADHESIVE,ALUMINUM-FILLED EPOXY ADHESIVE,TOUGHENED PURPOSE INSTANT ADHESIVES,增韧结构胶,耐磨环氧树脂,SPRAYABLE MATERIAL,非硬化液体垫片密封剂,SILICONE RTV,陶瓷复合树脂,手动药筒分配枪,聚氨酯粘合剂,高性能腻子,PERFORMANCE POLYMERS,EPOXY ADHESIVES,氧化铝陶瓷珠粒填充酚醛环氧树脂复合物的耐磨性能,弹性橡胶,防卡润滑剂,DEVCON® HP 250,MA8120 GB,MA300,MA420,SC VELR 4000,SC 7315,PLEXUS® MA2000 SERIES,PDR 9000,PLEXUS® MA420W,MA8105 GB,SC PDR 9000,SC 1050,SC 1500-LS,PC-120,PLEXUS® MA2030,PLEXUS® MA2045,MA1020,MA2230,PLEXUS® PU2105,MA310,MA1025,MA550,PLEXUS® MA832,SC 2000-OS LS,PLEXUS® MA830,GPE 30,PLEXUS® MA205HV,PLEXUS® MA320,TE 2400,SC PDR 6000,MA425,SC 4055,SC 1060,MA422,AO420,SC ALPHACOA® 1700,PU2105,PLEXUS® MA8105 GB,MA2245,PLEXUS® MA420FS,SC 900,PLEXUS® MA422,PLEXUS® MA300,PLEXUS® MA425,ALPHACOAT® 1710,MA560-1,PLEXUS® MA550,PLEXUS® MA8000 SERIES,PLEXUS® MA310,EPOXY PLUS™ 25,PLEXUS® MA2290,MA530,MA2015,F-2,SC 2000-CM,PDR 6000,PLEXUS® MA560-1,PLEXUS® MA420,GPE 100,SC 4000 HDT,ALPHACOAT 1700,MA920,PLEXUS® H4110,SC ALPHACOAT® 1700,SC 5000,PLEXUS® MA2230,PLEXUS® MA1020,GPE 3,PLEXUS® MA1025,PLEXUS® MA920,MA8110 GB,TE 1000,PLEXUS® MA530,DEVCON® FLEXANE® 80,ALPHACOAT 1710,MA590,PLEXUS® MA2000,PLEXUS® MA2245,MA420W,H4110,PLEXUS® MA8110 GB,SC 4600 HTT,2000-OS LS,ALPHACOAT® 1700,MA420FS,DEVCON® FLEXANE® 94,MA2030,MA2045,SC 4500,MA320,PLEXUS® MA2015,FLEXANE® FL-10,DEVCON® EPOXY COAT™ 7000 AR,SC 2000-HS,PLEXUS® MA590,DEVCON® CLEANER BLEND 300,DEVCON® EPOXY COAT™ 7000 NON-VOC,MA832,PLEXUS® MA8120 GB,MA830,DEVCON® WEAR GUARD™ 300RTC,DEVCON® EPOXY PLUS™ 25,SC 2045,SC 1070,SC 6000,SC1070,SC 1800-LS,DEVCON® EPOXY COAT™ 7000,GPE 15,WR-2,FLEXANE® FL-20,DEVCON® DEV-THANE™ 5,MA205HV,1800-LS,SC 2000-OS,MA2290,SC 4750,PLEXUS® MA8000,电子组件,胶合板,VALVES,加工设备,砖块,COMPOSITE,TRANSPORTATION INDUSTRY,ALTERNATIVE ENERGY,ASSEMBLIES,FLOAT CELLS,SBR CONVEYOR BELTS,复合粘接,ENGINEERED CONSTRUCTION,鼓声,燃煤发电,螺旋输送机,PLASTIC,SHOWER MARKETS,采矿设备,DRUMS,CHEMICAL STORAGE TANKS,高温,CONCRETE FLOORS,ALUMINUM,MARINE,SCREW CONVEYORS,不锈钢,ABS,MECHANICAL ASSEMBLIES,TANKS,传送带,恶劣的化学环境,橡皮,BINS,QUARRIES,HIGH VIBRATION APPLICATIONS,漏斗,基质,PLASTICS,管道弯头,TRANSPORTATION,旋风,竖井,CEMENT,具体的,STRUCTURAL BONDING,灰泥,TUB MARKETS,HEAVY-DUTY APPLICATIONS,BALSA,COAL-FIRED POWER,尿烷,RUBBER,工程建设行业,PLUG BUILDING,玻璃纤维,WOOD,POWER PLANT,钢,COMPOSITE BONDING,橡胶衬里设备,热塑性塑料,WEATHERPROOFING,衬垫,坦克,化学品储罐,MINES,玻璃钢,金属,工厂地板,铁,GASKETING,暖通空调,粘合垫圈,车载,开模过程,CONVEYOR BELTS,FIBERGLASS,RAMPS,PIPES,SCRUBBERS,COMPOSITE ASSEMBLIES,ELECTRONIC ASSEMBLIES,EPOXY,HIGH TEMPERATURE,防风雨的,走道,PIPE ELBOWS,IRON,风扇叶片,堤墙,SLIP FIT ASSEMBLIES,FRP,STAINLESS STEEL,MEAT PLANTS,PROCESSING EQUIPMENT,混凝土地板,潮湿环境,滑动配合组件,浴缸市场,THERMOPLASTICS,HARSH CHEMICAL ENVIRONMENTS,坡道,BLOCK,FAN BLADES,BOND GASKETS,轻木,SHAFTS,URETHANE,DIKE WALLS,木材,插入式建筑,合成物,聚酯填料,加工车床床身,METAL,COAL-FIRED POWER PLANTS,结构粘结,发电厂,装配,洗涤器,水泥,CLOSED MOLD PROCESSES,CERAMIC TILE,STEEL,滑槽,RUBBER LINED EQUIPMENT,复合组件,水泵,水雷,PLANT FLOORS,VEHICLE,COMPOSITES,CYCLONES,环氧树脂,块,浮法细胞,WINDOW PLATES,高振动应用,镀锌金属,塑料,一般工业,重型应用,PUMPS,粮食加工设备,THERMOPLASTIC,MINING EQUIPMENT,机械组件,防抱死制动系统,POULTRY PLANTS,螺旋钻,封印,CORING MATERIALS,家禽植物,METALS,SEALING,STUCCO,PLATFORMS,CHUTES,HVAC,结合,采石场,ENGINEERING CONSTRUCTION INDUSTRIES,垃圾箱,MINING,OPEN MOLD PROCESSES,海军陆战队,取芯材料,铝铝,紧急抢修,围堵区域,WET ENVIRONMENTS,GENERAL INDUSTRIAL,CONCRETE,管子,肉类植物,燃煤电厂,SBR输送带,窗板,闭模工艺,PLYWOOD,工程建设,淋浴市场,FOOD PROCESSING EQUIPMENT,平台,交通运输,SUBSTRATES,BRICK,交通业,GALVANIZED METAL,WALKWAYS,CONTAINMENT AREAS,复合材料,HOPPERS,POLYESTER FILLERS,EMERGENCY REPAIR,瓷砖,MACHINE LATHE BEDS,AUGERS,矿业,BONDING,阀门,替代能源

【材料】罗杰斯curamik®金属化陶瓷基板使能高效可靠的电力分配方式,最大程度地降低传导损耗

大型家用电器以及空调和供暖系统都需要高效可靠的电力分配方式,罗杰斯的curamik®金属化陶瓷基板让变频驱动器和高效转矩电机以及IGBT 和 MOSFET 模块得以实现,将电力分配到更广泛的功能区,同时最大程度地降低传导损耗。

罗杰斯curamik®金属化陶瓷基板助力eVTOL电子系统可靠运行

eVTOL在纯电驱动下低空飞行,其电动化推进系统类似新能源汽车的大三电系统,但又具有更高的性能挑战,包括高功率密度、轻量化、高耐压、续航能力、高安全标准等方面。随之带来的,则是对推进系统中所采用的功率模块实现更高的性能要求。ROGERS罗杰斯curamik®陶瓷基板凭借在轨道交通、新能源汽车等行业40余年的经验积累,积极应对eVTOL电动化系统的独特挑战,助力电动化推进系统的效率和安全保障。

散热解决方案专家 | 罗杰斯激光二极管curamik®散热解决方案重量更轻、体积更小,冷却效率比传统模块结构高出4倍以上

罗杰斯提供了两种用于激光二极管的散热解决方案,分别是液冷散热器与被动散热。

罗杰斯curamik®陶瓷基板常见问题解答(第一期)

近年来,随着电力电子行业的迅猛发展,金属化陶瓷基板作为应用于该领域的重要材料也被越来越多的从业人员熟知。为此,ROGERS特推出两期关于陶瓷基板的常见问题汇总,内容涵盖陶瓷基板基础常识、材料信息、设计选型、工艺解读、市场应用及罗杰斯产品订购等相关内容。本文为第一期,主要涉及陶瓷基板的基础常识和材料信息等问题,欢迎您持续关注!

Rely On Rogers | 罗杰斯为提高光伏逆变器效率和可靠性提供陶瓷基板和母线排

太阳能逆变器或称光伏(PV)变流器,可将光伏太阳能电池板的直流(DC)输出转换为交流电(AC),以便馈入商业电网或供本地离网电网使用。逆变器是太阳能系统的关键元件,而且随着新半导体技术加快切换频率、提高功率密度,逆变器设计师需要不断创新,降低成本,同时还要保证太阳能系统的关键特征。罗杰斯的电力电子材料解决方案,在提高太阳能逆变器的效率、性能和可靠性方面有着出色的表现。

【材料】大功率应用专家——ROGERS罗杰斯推出DBC基板curamik® Endurance解决方案,拥有显著增强的可靠性

作为金属化陶瓷和全系列DBC、AMB基板的制造商, ROGERS罗杰斯拥有众多高性能的陶瓷基板产品。其中,curamik® Endurance解决方案是罗杰斯DBC基板家族中出色的一员,相较于其他带dimple设计的基板,Endurance拥有显著增强的可靠性。

Rely On Rogers | 罗杰斯电力电子产品解决牵引系统电气化的大功率挑战

罗杰斯的先进电子解决方案在配电领域拥有独特优势。牵引系统中功率模块发挥着核心作用,curamik®陶瓷基板有助于大功率模块有效散热及可靠性。对于配电,ROLINX®母线排可用作牵引系统的配电“高速路”。设计合理的叠层母线排可实现最低整体系统电感和最平衡的分布电容,成为高需求推进引擎的理想选择。

Rely On Rogers | 罗杰斯电力电子解决方案助力智能电网可靠高效运转

ROGERS罗杰斯在智能电网中,通过curamik®高效陶瓷基板和ROLINX®高可靠母线排,显著提升设备效率与可靠性。curamik®基板以卓越导热、高绝缘及低热膨胀特性,保障电力电子器件稳定运行;ROLINX®母线排则凭借低电感、高功率密度设计,实现高效配电。罗杰斯以创新技术助力智能电网发展,提供定制化解决方案,满足复杂电力需求。

聚焦奥运 | 罗杰斯curamik®陶瓷基板和ROLINX®母线排等产品助力可再生能源应用书写奥运新历史

罗杰斯公司提供多种材料解决方案,可提高可再生能源应用的效率、可靠性和性能。curamik®陶瓷基板用于逆变器的电源模块,旨在承载更高的电流,并在更广的工作温度范围内提供更高的电压绝缘性能。而我们定制化设计的ROLINX®母线排在风力涡轮机、太阳能发电场以及储能的整个生命周期内为各种电力电子元件之间提供了节能高效的连接。

罗杰斯curamik®陶瓷基板常见问题解答(第二期)

本文罗杰斯将分享curamik®陶瓷基板常见问题解答第二期,内容涵盖陶瓷基板设计选型、工艺解读及罗杰斯产品订购等相关内容。

Rogers Corporation’s Curamik® Ceramic Substrates, Low Inductive ROLINX® Laminated Busbars Power Renewable Energy Sources

The 2024 Paris Summer Olympic Games have captivated audiences worldwide, and part of that excitement has centered around the new and innovative technology applications utilized in this year’s games. Many of these technologies are enabled by materials that Rogers Corporation manufactures, including applications in footwear, 5G wireless infrastructure, renewable energy, and more.

电子商城

品牌:ROGERS

品类:High Frequency Circuit Materials

价格:¥550.8681

现货: 6,311

品牌:ROGERS

品类:High Frequency Laminates

价格:¥2,617.4106

现货: 4,017

品牌:ROGERS

品类:Circuit Materials

价格:¥2,479.9453

现货: 760

品牌:ROGERS

品类:Antenna Grade Laminates

价格:¥2,989.4355

现货: 429

品牌:ROGERS

品类:Liquid Crystalline Polymer Circuit Material

价格:¥1,485.0299

现货: 253

品牌:ROGERS

品类:Antenna Grade Laminates

价格:¥2,571.9097

现货: 250

品牌:ROGERS

品类:PTFE/Woven Fiberglass Laminates

价格:¥16,030.1502

现货: 201

品牌:ROGERS

品类:High Frequency Circuit Materials

价格:¥4,679.1859

现货: 180

登录 | 立即注册

提交评论