Vincotech Helps Realize Integrating Power ICs into Chargers with No Development or Production Cost in 3 Months

The market for electric vehicles (EVs) has entered a phase of fast growth, boosted by a combination of vigorous support from governments and growing consumer appreciation for electric passenger vehicles. The latest forecasts suggest that EVs (that is, hybrid electric, plug-in hybrids, and fully electric vehicles) will account for 30 % of new car sales by the year 2021.

A consequence of this growth in EV numbers on the road is that the number of public and private charging points will also grow fast. EV drivers will see a rapid build-out of charging infrastructure, including charging posts on-street and at workplaces and other public locations, low-power charging units at drivers’ homes, and very high-power fast-charge units at fuel filling stations. These static charging points to which a driver can connect their EV are also called off-board chargers, in contrast to the onboard chargers mounted inside a vehicle, which may be supplied with power by an ordinary 120 V/240 V wall socket or by a charging point.

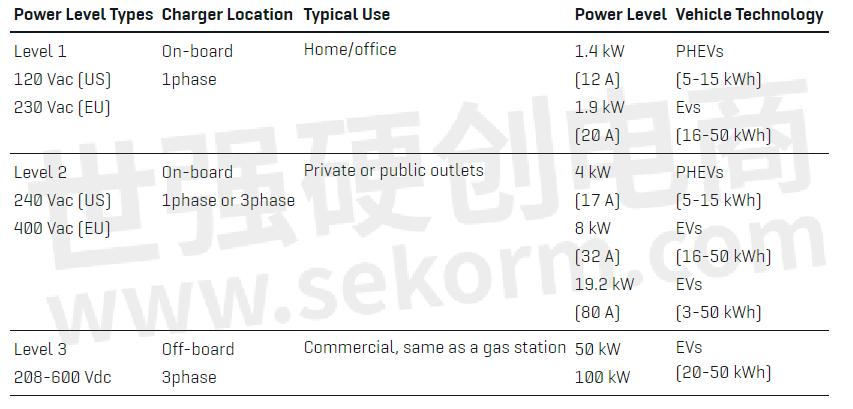

The power delivery capability of charging points is commonly classed by reference to levels, with level 1 being the lowest-power charger, and level 3 the highest.

The growth forecast (figure) has given rise to a huge, and global, opportunity for manufacturers of off-board EV chargers. Still, in its infancy, this market is today highly fragmented and supports a large number of manufacturers. Over time, consolidation is inevitable. So which factors will determine which companies are the winners and which the losers in the battle for market share?

At least in part, this will be a matter of which suppliers respond best and quickest to customers’ requirements. The customers for high-value off-board chargers are, for the most part, large organizations:

/ Highway authorities or other governmental organizations responsible for sponsoring the build-out of EV infrastructure

/ Vehicle service providers such as fuel (gas) station operators and highway (motorway) service station operators

/ Electric utilities

These customers' primary requirements are for:

/ High power efficiency. By maximizing efficiency and minimizing conversion losses, customers can control their energy cost, which makes up a large proportion of their operating expenses, and minimize the CO2 emissions associated with generating the electricity they provide.

/ The lowest possible purchase (capital) cost while maintaining a specified level of quality and reliability.

These requirements define the ground on which the battle between charger manufacturers will be fought. And this brings into the spotlight a strategic decision of crucial importance to the engineering teams designing the next generations of EV chargers. This decision is over the best way to implement the power circuit in each of the three power stages of an off-board EV charger: the input PFC (power factor correction) stage, the converter stage, and the output rectifier stage.

Continual innovation in power semiconductors

If a priority for customers is high power efficiency, the principal driver of efficiency improvements in all types of power systems is semiconductor technology.

Advanced power semiconductor manufacturers such as Infineon, STMicroelectronics, Fairchild, ROHM Semiconductor, and Wolfspeed are constantly innovating both in the fields of semiconductor materials and of circuit topologies, and continually introduce new products – such as IGBTs, MOSFETs, and diodes – which offer incremental improvements in efficiency, as well as in other operating parameters.

Breakthroughs such as the commercialization of the high-performance silicon carbide (SiC) semiconductor material are bringing rapid improvement to the operation of MOSFETs and diodes. SiC is a near-ideal semiconductor material for the manufacturers of Power ICs. Compared to silicon, it:

/ Enables devices to switch faster, enabling the use of smaller, cheaper passive components

/ Suffers from lower switching losses, resulting in more efficient power-conversion operation

/ Withstands higher operating temperatures, which enables the user of smaller heat sinks, reducing the host system’s size and bill-of-materials cost

The semiconductor manufacturers' continual innovation in materials such as SiC, and their many new product introductions provide charger manufacturers with a means to meet customers’ demand for ever-higher power efficiency. But the question for the manufacturers is, what is the best way to take advantage of the stream of new, improved power ICs that continually come on to the market, while maintaining tight cost control?

Rapid, low-cost implementation of new charger designs

This is a strategic question for charger OEMs: they will benefit from a long-term commitment to a specific plan for upgrading their products.

The problem for the charger OEM is that technology leadership in power ICs is not in the grip of a single supplier. At any given time, the most efficient power IC for any given application may be manufactured by STMicroelectronics, by Infineon, or by another semiconductor manufacturer.

In order to optimize the efficiency of their products, then, charger manufacturers need to continually modify and upgrade their designs to incorporate the latest new components. But the development and production costs associated with the introduction of brand-new product designs are very high. Normally, this limits the frequency with which OEMs can introduce new products to the market.

But what if new power ICs could be integrated into a charger’s design as often as every three months, at almost no development or production cost?

This is the promise of the VINCOTECH family of Power Modules, which includes products supporting various topologies used in each of the three power stages in a high-power off-board charger. The use of power modules is already common among charger OEMs. By implementing power circuits with modules, rather than ‘home-grown’ circuits developed by the OEM itself with discrete ICs and other components, OEMs gain several benefits:

Efficiency up and cost down in the PFC stage

The new symmetric three-phase PFC power module, flowSPFC 0, is designed to deliver extremely high efficiency of up to 99.2% and is marketed at a remarkably low price. This PFC module is the first building block in an EV charger application: optimal specifications at this stage can help the whole system design benefit from cost savings. It enables operation at fast switching frequencies of up to 75 kHz and is based on ultra-fast and efficient IGBTs built with the latest bipolar transistor technology.

It comes in a compact, low-inductance flow 0 housing, and offers various maximum current ratings, making this one module suitable for many applications.

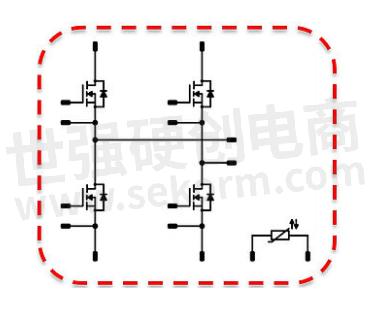

New H-bridge helps applications switch faster

The new fastPACK 0 SiC power module is the fastest representative of a new family of H-bridge products designed to be faster, cooler, and more efficient. In this module, Vincotech has integrated a 900 V SiC MOSFET, which has better switching performance than 1200 V SiC MOSFETs and a higher safety margin than 650 V MOSFETs. This power module supports applications switching at up to 400 kHz. It also achieves much higher efficiency than comparable IGBT solutions, offering an 8 % increase in efficiency at light loads and a 3 % increase at full load.

It comes in a compact, low-inductance flow 0 housing with press-fit pins for high electrical performance, reduced EMI, and easy assembly on the production line.

Alongside this flagship 900 V power module, Vincotech offers a complete portfolio of 650 V and 1200 V IGBT, silicon MOS and SiC MOS modules, to cover all operating conditions and designs.

/ Modules allow OEMs to get to market faster since they provide a complete, ready-made power circuit that can be dropped into a product design

/ A module is supplied with full documentation and is tested and verified, so it offers guaranteed performance in the application and eliminates development risk

/ A module combines multiple power components in a single, thermally-efficient package. This makes tooling and production simpler and cheaper than a system populated with multiple discrete components. It also simplifies the manufacturer’s supply chain, dramatically reducing vendor and component count.

Charger OEMs derive all of these benefits when they use modules from Vincotech or from any other reputable module manufacturer. But Vincotech solves the crucial question for charger manufacturers: how to implement the latest, most efficient power semiconductors in charger designs rapidly, and at low cost?

There are two key elements to this proposition:

First, Vincotech is supplier-independent. Unlike module manufacturers such as STMicroelectronics, Fairchild, and ROHM Semiconductor, it is not tied to the use of just the house brand of power ICs. Instead, it can use the best semiconductors available on the market, from any manufacturer.

Second, Vincotech maintains long-term, strategic product platforms. Within each platform, every module shares a common footprint and pin-out. This means that users of Vincotech modules can replace an older module with a new, upgraded module in an existing design with little or no requirement for a board re-spin or for new tooling or assembly modifications.

To enable rapid implementation of new semiconductor technology by-charger manufacturers, Vincotech follows a quarterly product upgrade schedule, integrating new ICs into its module product families almost as soon as manufacturers release these ICs. As a dedicated power module manufacturer, Vincotech can bear the costs associated with this short product-development cycle, amortizing them over a broad customer base and high production volumes.

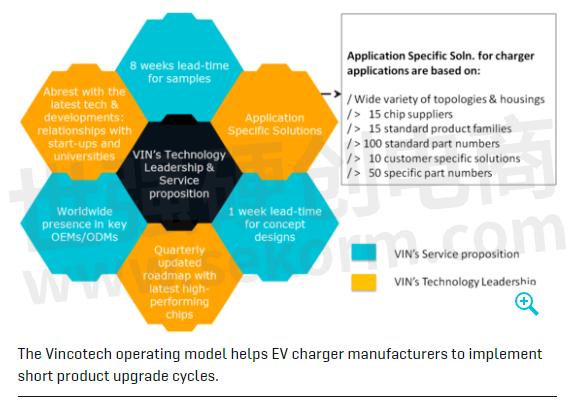

And as a specialist in the design and implementation of highly integrated power systems, Vincotech has the experience and expertise to optimize the performance of popular power topologies and to take advantage of new topologies developed by semiconductor manufacturers. The elements of its service and technology leadership are illustrated (figure).

This operating model enables Vincotech to offer the newest semiconductor technology in modules with market-leading efficiency. This is demonstrated by the specifications of the latest Vincotech modules aimed at off-board EV chargers, which are described below:

Conclusion

By basing new product designs on a strategic platform provided by Vincotech, charger OEMs can benefit from constantly upgraded products using the latest, most efficient semiconductor technology, without incurring the high development and production costs normally associated with a short product lifecycle. New Vincotech modules featuring the latest SiC and silicon semiconductor technology are described above.

The Vincotech platform gives the charger OEM an edge over slower-moving competitors who offer products based on older technology.

By standardizing on Vincotech modules, a charger OEM can maximize its design, production, and supply-chain efficiency and expect to benefit from the wave of consolidation that the charger manufacturing market is set to experience in the coming years.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由Batman转载自Vincotech,原文标题为:Chargers for Electric Vehicles,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

电源模块包装盖形状变更(FLOW0,FLOW90 0)(2024-009)

描述- Vincotech发布产品变更通知,宣布对部分功率模块的包装盖形状进行微小调整,以优化包装过程。此次变更不影响产品功能,仅涉及包装设计。受影响的型号包括所有*flow*0和*flow*90 0尺寸的功率模块。新修订版本将于2024年4月10日发布,首批样品预计于2024年8月5日前提供。客户无需确认此变更,但应在收到通知后30天内知悉。

10-FZ12NMA080SH01-M260F电源模块规格书

描述- 该资料为Vincotech公司生产的10-FZ12NMA080SH01-M260F模块的技术规格书。文档详细介绍了该模块的最大额定值、特性值、开关特性曲线等,适用于太阳能逆变器(Solar Inverter)和不间断电源(UPS)等领域。

型号- 10-FZ12NMA080SH01-M260F-7,10-FZ12NMA080SH01-M260F,10-FZ12NMA080SH01-M260F-3

Valeo & ROHM Semiconductor Co-develop the Next Generation of Power Electronics TRCDRIVE pack™

Valeo and ROHM collaborate to propose and optimize the next generation of power modules for electric motor inverters using their combined expertise in power electronics management. As a first step, ROHM will provide its 2-in-1 Silicon Carbide (SiC) molded module TRCDRIVE pack™ to Valeo for future powertrain solutions.

Vincotech‘s 1200V flowIPM 1C Power Modules with Higher Integration and more Sophisticated Subsystems

Catering to manufacturers seeking higher integration and more sophisticated subsystems to cut systems‘ cost and assembly time, Vincotech‘s 1200V IPM achieves the deepest level of integration of any power module available on the market today.

Vincotech’s Power Modules‘ Current Carrying Capability of a Standard Solder Able Pin and a Press-fit Pin

This application note investigates the current carrying capability of a standard solder able pin and a Press-fit pin for Vincotech’s power modules.

Save up to 15% on System Costs with Vincotech‘s MiniSKiiP®DUAL Power Modules Product Line

With the addition of the MiniSKiiP®DUAL to our line of standard MiniSKiiP® power modules, a single platform now covers a very wide power range extending all the way up to 90kW for 650V and 1200V applications.

Vincotech Offers Power Modules for 3 Main Photovoltaic (PV) Applications/Inverters

VINco X modules meet the demanding requirements for central inverters, while retaining the string inverter‘s speed and flexibility. Add-ons such as integrated snubber capacitors and asymmetric inductance are available to make this an even more persuasive package. The terminal connection allows DC and AC stages to be split, which makes busbar design that much easier.

30-P2126PA150M7-L280F79Y flowPACK 2 1200V/150A电源模块数据表

描述- 本资料为Vincotech公司生产的30-P2126PA150M7-L280F79Y模块型功率器件的数据手册。该模块包含一个1200V/150A的IGBT和一个反向并联二极管,适用于工业驱动、电源和UPS等领域。

型号- 30-P2126PA150M7-L280F79Y-/3/,30-P2126PA150M7-L280F79Y

Vincotech’s 650, 900, and 1200V Versions H-bridges Power Modules are Engineered to Fit Your Tech Specs and Business Needs

Vincotech’s 650, 900, and 1200V versions featuring multi-sourced IGBTs, Si-MOSFETs, and SiC-MOSFETs satisfy your voltage level, current rating, and component technology needs.

Faster, Cooler & More Efficient DC EV Charging:Vincotech’s FlowANPFC and Flow3xANPFC Power Modules

All Vincotech‘s power modules come in industry-standard compact, low-inductive packages with press-fit pins. They now also feature the latest advance in die-attach technology.

Highly Integrated and Ultra Compact Power Modules for Embedded Drive Applications

The outstanding level of integration achieved by Vincotech’s intelligent power modules enables system engineers to come up with more compact designs and to take advantage of a proven combination of power components and gate drive circuits, which happen to be the most critical elements in the inverter’s design. This mitigates the risk associated with circuit design, speeds up development, and dramatically reduces time to market.

Real Chip-level Multi Sourcing - The Multi-sourced Power Modules Featuring IGBT M7 for Motion Control Applications

Vincotech‘s range of multi-sourced power modules for motion control applications just got bigger with a set of products featuring IGBT M7 chips. Featuring sixpack and PIM topologies these product families not only offer superior performance but also multiple sourcing for the highest supply chain safety.

Vinco E3电源模块可靠性报告

描述- 本报告详细介绍了VINco E3系列功率模块的可靠性测试。测试包括温度循环、高温反向偏置、高温高湿反向偏置、高温高湿绝缘、振动、低温存储、功率循环、压接技术和热膏涂抹等,所有测试均符合标准,并通过了验收标准。无异常情况在视觉检查中被发现。

30-PT07NIA450S501-PD68F58Y电源模块规格书

描述- 本资料为Vincotech公司生产的30-PT07NIA450S501-PD68F58Y模块的详细数据手册。该模块包含一个650V/450A的NPC IGBT和一个650V的快恢复二极管,适用于工业驱动、太阳能逆变器、不间断电源等领域。

型号- 30-PT07NIA450S501-PD68F58Y,30-PT07NIA450S501-PD68F58Y-/3/

Vincotech‘s PFC Module flowANPFC 0: Here To Gear Up Three-phase Applications

Vincotech‘s flowANPFC 0 power modules featuring an advanced neutral boost PFC topology are aimed to help vendors step up efficiency and drive down costs. This ultra-compact module packs a lot of power into a petit housing.

电子商城

现货市场

登录 | 立即注册

提交评论