ATP Industrial e.MMC Employs Configurable SRAM Soft Error Detector and Recovery Mechanism, Robust Durability

The ATP industrial e.MMC (Embedded MultiMediaCard) solution is designed to meet the high-performance data transfer and storage requirements of industrial and embedded applications in space-constrained systems requiring rugged reliability and very high endurance.

Compliant with the latest JEDEC e.MMC v5.1 specifications, the ATP e.MMC is an embedded storage solution consisting of an MMC interface, flash memory and controller integrated in the same IC package and offered in a 153-ball fine pitch ball grid array (FBGA) package. The integrated package simplifies the application interface design, making the ATP e.MMC suitable for industrial applications requiring rugged endurance, reliability and durability in challenging operating environments.

While several module houses and manufacturers already have their own versions of industrial e.MMC, each one claiming to offer the best features and benefits, the ATP e.MMC is backed by over 25 years of ATP's pioneering expertise in manufacturing flash memory and storage products.

As shown in the figure below, ATP e.MMC's strengths are not only about the product itself, but the ATP name that backs it up.

Figure 1. The ATP e.MMC promises data integrity, quality and reliability, along with ATP services that are tailor-fitted according to customers' needs. As a true manufacturer, ATP is fully in charge of the manufacturing processes after the wafers are received and can therefore control quality, product support and longevity.

Data Integrity

Data integrity refers to the reliability and accuracy of data over the entire usage life of the storage device. To ensure that there is no loss in data quality when using an ATP e.MMC device, it employs the following built-in technologies.

Configurable SRAM Soft Error Detector and Recovery Mechanism

Soft errors in the static random access memory (SRAM) corrupt memory bits and alter stored data or change instructions in a program. They do not cause physical damage to the memory or storage device, but will cause damage to the data.

Although usually remedied by a system cold boot, unattended SRAM soft errors can significantly jeopardize data accuracy because these errors cannot be detected nor solved by ECC engines, so the system will keep using the error data to run the system until catastrophic damage occurs. These errors are of great concern especially in mission-critical applications, where high levels of data integrity and availability are required.

The ATP e.MMC features an advanced SRAM Soft Error Detector and Recovery mechanism, which maximizes data integrity by providing timely error detection, logging, and configurable* action to address the error. If, after assessing the risk, the user opts to continue running the device, an error log will be created and a system reboot should be performed to avoid unpredictable events that could damage the system, or worse, cause personal safety risks in critical autonomous applications.

Note: The configuration setting is predetermined by the customer with ATP and is done before product shipment. Configuration cannot be changed on the field.

Read Disturb Prevention

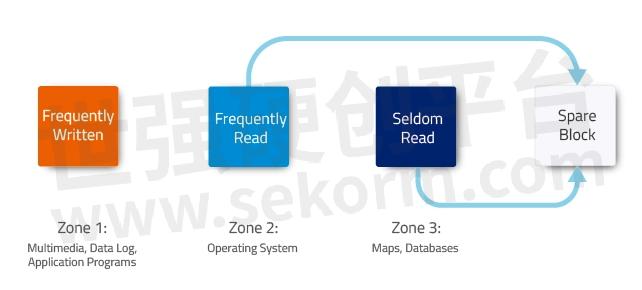

AutoRefresh Technology improves the data integrity of read-only areas by monitoring the error bit level and read- counts in every read operation. It detects when the read count is about to exceed the threshold. Before the limit is reached, data in the affected block is copied to a healthy block, thus preventing the controller from reading blocks with too many error bits. With this technology, the ATP e.MMC performs reliably and prevents uncorrectable data damage.

Dynamic Data Refresh Technology reduces the risks of read disturb and sustains data integrity in seldom-accessed areas. Read disturb happens when frequent reading of a cell causes adjacent cells to change or be programmed. Dynamic Data Refresh runs automatically in the background, sequentially scanning the user area flag record while the ATP e.MMC is free from host commands, thus keeping data safely stored without affecting the read/write operation.

Figure 2. Data refresh algorithm prevents Read Disturb errors by moving data to a healthy block when the read count exceeds the threshold.

Product Quality and Reliability

Industry-Leading NAND Screening Capability

With over 25 years' experience in the NAND flash product industry, ATP is thoroughly knowledgeable in NAND characterization. ATP believes that high-quality components are the building blocks to high-quality products and makes sure that screening begins at the integrated circuits (IC) level, where NAND flash is screened for temperature tolerance, data retention, disturbance, and other attributes.

Extreme Endurance: 2-3X Higher than Standard e.MMC

One reliable way of measuring flash storage endurance is by the number of write and erase operations, also called program/erase (P/E) cycles. At mass production stage, Rapid Diagnostic Test (RDT) is performed to screen out weak ICs for early life failure and to ensure long endurance with robust components. Stringent NAND flash sorting and screening during thermal cycling tests, functional tests, robust product design, and high-quality wafer packaging ensure high P/E cycles, healthy memory storage, and the long product service life of the ATP e.MMC.

Robust Durability

ATP e.MMC is available in industrial temperature-rated operating range, performing dependably in sub-freezing -40°C to searing 85°C. Sturdy and resilient, the ATP e.MMC can withstand harsh environments and extreme temperatures, as well as power and thermal cycling in demanding operation scenarios.

Figure 3. ATP e.MMC operates within full industrial temperature range.

ATP as a True Manufacturer: Full Process Ownership

ATP maintains complete control of all stages of the manufacturing process — from the time the wafers are received all the way up to the finished product. ATP performs in-house testing, quality control, Rapid Diagnostic Test (RDT) and in-house field application (FA) to provide customers nothing less than the best products. By taking charge and ownership of the processes, ATP also maintains control of its supply and value chains. We implement controlled bill of materials (BOM) with longevity planning and maintain buffer inventory to prevent stock outs.

Figure 4. ATP Process Ownership

ATP-Owned Manufacturing Facilities

The ATP e.MMC is designed, produced and tested thoroughly at ATP's own purpose-built factory with top-notch engineers and highly skilled production staff using the most modern equipment along with exclusive ATP-designed firmware and testing platforms.

Post-Manufacturing Process Excellence

No doubt, each ATP e.MMC is manufactured to the highest and most stringent standards to make sure that it meets the rigid requirements of industrial applications. The ATP culture of excellence, however, extends after the product is finished. Further processes are taken to ensure that each product coming out of ATP's manufacturing facilities meet and even exceed expectations.

Below is a sneak peek into the meticulous processes that the ATP e.MMC goes through before it is shipped out.

Ensuring Product Traceability

Laser imprints important information to identify each piece for accurate tracking and efficient inventory management.

Rapid Diagnostic Test (RDT)

RDT is performed to evaluate product reliability under extreme temperatures and to catch early and latent defects.

ATP e.MMC devices are loaded into a specially designed RDT chamber for thermal cycling tests at both low (-40°C) and high (85°C) temperatures. ATP can perform high-volume testing according to customer request.

Automated Final Screening

A special machine performs high-speed automated initialization and screening to make sure that errors and failed parts not caught during the production stage are effectively screened out before the product is packaged.

Protective Packaging

Finally, the ATP e.MMC is vacuum-sealed, removing all the air from the packaging, including humidity and moisture that could cause corrosion. Vacuum packaging also safeguards the ATP e.MMC against environmental hazards that could cause damage while the devices are stored or in transit.

Service

ATP delivers total solutions by manufacturing not only best-in-class products, but also offering top-notch services. By project support and customer request, ATP offers value-added services such as Joint Validation, where ATP conducts compatibility and function tests with client-supplied host devices and systems to proactively detect and minimize failures that may not have been caught in production tests. ATP also guarantees long product cycles with a longevity commitment of over 5 years for MLC NAND-based e.MMC.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由涂抹转载自ATP Blogs,原文标题为:Why ATP Industrial e.MMC?,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

ATP e.MMC集成数据刷新技术,确保数据在使用寿命期间的可靠性和准确性,对2D NAND e.MMC提供长期供货支持

ATP Electronics的e.MMC解决方案集成了数据刷新技术,专为空间受限的系统而设计和制造,可确保数据在整个使用寿命期间的可靠性和准确性。为了满足对基于2D NAND闪存的e.MMC的持续需求,ATP Electronics致力于长期向客户提供低容量e.MMC,产品容量包括MLC 8GB/16GB,pSLC模式的4GB/8GB。

Extensive Reliability Tests Prove the Suitability of 3D e.MMC MLC and SLC Mode for Demanding Industrial Automotive Application

Based on the results of the reliability tests, the ATP e.MMC with 3D SLC Mode and MLC NAND flash deliver reliable performance for industrial and automotive applications requiring high density and long endurance.

ATP’s Obsolescence Management Strategy Drives Long-Term Supply Stability and Flexibility

Despite its tiny size, which is smaller than a typical postage stamp, the ATP embedded multimedia card or e.MMC packs many premium features for industrial and automotive applications. The ATP e.MMC provides ultra-high endurance and trustworthy performance even under the most rigid operating scenarios.

Alliance Memory Expands Serial NOR Flash Portfolio With New High-Density Devices, Offering Increased Storage and Performance for a Wide Range of Applications

Alliance Memory today announced the expansion of its Serial NOR Flash product line with the introduction of three new 3.3V families with density of 128Mb, 256Mb, and 512Mb. The devices are now available for embedded applications that require reliable, high-performance code storage and execution.

ATP e.MMC v5.1 Embedded Flash Storage Solution

型号- E600SI,E650SC,E600SAA,E700PI,E600SA,E650SI,E600VC,E700PIA,E600SIA,E700PA,E750PI,E700PAA,E750PC,E700PC

E600Saa Series AF016GEC5X-2001A2/AF032GEC5X-2001A2/AF064GEC5X-2001A2/AF128GEC5X-2001A2 Automotive-Gradee.MMC Data Sheet

型号- AF128GEC5X-2001A2,AF032GEC5X-2001A2,AF064GEC5X-2001A2,E600SAA,AF016GEC5X-2001A2

e.MMC MLC Solutions The Global Leader in Specialized Storage and Memory Solutions

型号- E700PI,E600SA,E700PIA,E600SIA,E700PA,E600SI,E600SC,E700PAA,E600SAA,E700PC

【产品】采用153-ball FBGA封装的e.MMC,具备超强耐用性和可靠性,满足严苛的工业应用要求

ATP ELECTRONICS工业级 e.MMC 解决方案是一种先进的存储解决方案,它将NAND闪存、先进的闪存控制器和快速多媒体卡(MMC)接口集成在同一个封装中。ATP e.MMC在内部管理所有后台操作,使主机不必处理低级别的闪存操作,从而实现更快、更高效的处理效率。

【经验】随机发生的软错误损害存储设备,ATP e.MMC具有先进的SRAM软错误检测器和恢复机制保障数据完整性

对于金融交易、交通管理、安全/监视等关键任务来说,即使是很小的故障也会造成灾难性的影响。无人值守的软错误会导致功能损失、系统故障和其他不利影响。ATP e.MMC先进的SRAM软错误检测器和恢复机制通过提供及时的错误检测,日志记录和可配置的操作来解决错误,最大化了数据完整性。

ATP(华腾国际)固态硬盘选型指南

描述- Since 1991, we have consistently distinguished ourselves as one of the world’s leading original equipment manufacturers (OEM) of high-performance, high-quality and high-endurance NAND flash products and DRAM modules.

型号- A750PI,S600SC,B800PI,S750 SERIES,S600SI,B600SC,N700PC,A750 SERIES,E650SC,N601,N651SI,A600VI,S800PI,E600VC,I800PI,A600VC,A650SI,A650SC,N651SC,N750,S650SI,A600VI SERIES,N750PI,N651SIE,A800PI,N601 SERIES,A700PI,N651SIA,N650 SERIES,E600SAA,A750,A600VC SERIES,N600SC,E600SA,E650SI,N750 SERIES,E700PIA,N600SI,S650,S650SC,N651SI SERIES,E700PAA,B600SC SERIES,E600SI,N600VI SERIES,I700SC,N600VI,N650SI,E600SIA,N650SC,E750PI,N600VC,I600SC,E750PC,N651,S700PI,A650 SERIES,N650,N751PI,S700PC,N600VC SERIES,N651 SERIES,S650 SERIES,A650,N601SC,S750PC,E700PI,A600SI,N700PI,E700PA,S750,S750PI,E700PC,N651SCE,A600SC

【应用】ATP的e.MMC、工业SD卡和工业microSD卡用于汽车领域,提供超大容量内存和宽温度支持

针对汽车智能化发展的需求,ATP拥有一系列内存和存储解决方案,包括e.MMC、工业SD卡、工业microSD卡等产品,其防护性、坚固性设计使其能够承受各种环境条件;紧凑的尺寸允许放置在小型嵌入式车辆系统中;而且,不同的容量和性能还确保了能够满足特定汽车需求。

L-Series e.MMC The Global Leader in Specialized Storage and Memory Solutions

型号- L-SERIES,E700PI,E600SA,E600VC,E700PIA,E600SIA,E700PA,E600SI,E700PAA,E600SAA,E700PC

Tiny ATP e.MMC with Over 50K Endurance Rating Delivers Huge Benefits for Handheld Computers

Through stringent RDT testing and the use of SLC Mode NAND flash, ATP successfully achieved an average of 50K P/E cycles to meet the customer’s high-endurance requirement. This is significantly higher than the endurance ratings of other standard NAND flash technologies such as 2D/3D MLC (25-30K).

e.MMC The Global Leader in Specialized Storage and Memory Solutions

型号- E600SI,E650SC,E600SAA,E700PI,E600SA,E650SI,E600VC,E700PIA,E600SIA,E700PA,E750PI,E700PAA,E750PC,E700PC

电子商城

服务

可烧录IC封装SOP/MSOP/SSOP/TSOP/TSSOP/PLCC/QFP/QFN/MLP/MLF/BGA/CSP/SOT/DFN;IC包装Tray/Tube/Tape;IC厂商不限,交期1-3天。支持IC测试(FT/SLT),管装、托盘装、卷带装包装转换,IC打印标记加工。

最小起订量: 1pcs 提交需求>

提供语音芯片、MP3芯片、录音芯片、音频蓝牙芯片等IC定制,语音时长:40秒~3小时(外挂flash),可以外挂TF卡或U盘扩容。

最小起订量: 1pcs 提交需求>

登录 | 立即注册

提交评论