The Necessary Sensors for an Ev Battery Pack & Cell Connection System

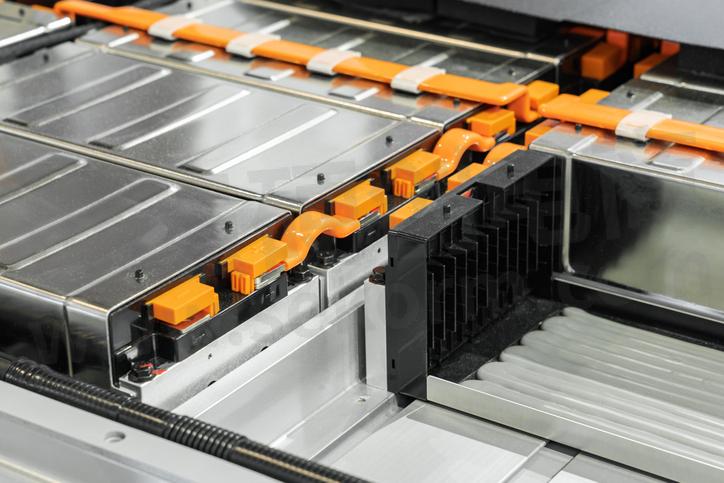

The heart of an electric vehicle (EV) is its battery pack, and the module cell connection system is infrastructure that connects the individual cells to the high voltage output of the pack.

Without either functioning properly, an EV may experience a host of issues -- from poor performance to an outright failure.

Inside the battery pack, the cell connection system combines individual cells in parallel and series configuration to create both energy and power for the pack, as well as providing critical sensor data to the Battery Management System (BMS) to control the pack functions.

sensors TO INCLUDE IN AN EV BATTERY PACK CELL CONNECTION DESIGN

In addition to providing the busbars that connect the cells and allow current to flow from and to the individual cells, the cell connection system incorporates temperature sensors for measuring the battery cell and busbar temperatures, which are critical for controlling cell temperature within their optimum performance range for best performance and life. Lithium-ion cells perform best between temperatures of 10 deg C and 45 degrees C, and the battery thermal management system can provide both heat and cooling to the cells, but must have highly accurate temperature measurements to properly maintain proper temperature management of the cells during the dynamics of driving and charging.

EV Batteries experience substantially greater stress than traditional Internal Combustion Engine battery systems. In a typical Electric Vehicle, the battery pack may experience thousands of charge and discharge cycles throughout its life. The pack Battery Management System monitors voltage, current, and temperature of cells.

Sensors that should be considered within the pack and module assembly systems:

1,temperature

2,Voltage & current

3,Gas Detection

4,Water intrusion/coolant breach

1. TEMPERATURE

Temperature sensors are critical for electric vehicle battery and cell connection system applications. Put simply, both parts of an EV require constant thermal management for optimal performance and vehicle occupant safety.

The need for temperature monitoring for electric vehicle batteries is two-fold:

1, When in use -- be it powering the vehicle or acting as a source for electricity -- batteries give off heat. If left unchecked, high temperatures will damage cells, causing them to degrade and lose charging ability or capacity (SOH and SOC). In extreme cases, the cells decompose, starting a chain reaction of thermal runaway. In addition, in extreme cold conditions, charging cells can result in lithium dendrite growth, which can cause an internal short circuit in the cell, which can also result in thermal runaway.

2, If not being driven (think: recharging), temperature sensors allow the BMS to control the thermal management system to keep the battery in the optimum temperature range to maintain long life. In addition, if there are any issues with a battery cell, temperature sensors can provide critical safety data to the BMS, which can immediately notify the vehicle’s owner if the pack is in an unsafe state.

Like the battery itself, an EV’s cell connection system is not immune to the effects of excessive heat. EV vehicle battery components, such as a busbar, get hot when in use. The part of the battery which power flows through and is connected to each battery cell, heat from the cell connection system can transfer to each individual battery cell. Busbar design for proper thermal management is an essential element of engineering robust battery systems.

2.VOLTAGE & CURRENT

Maintaining an electric vehicle’s power is a balancing act of sorts.

A cell’s State of Charge is a calculated metric that describes the amount of charge it can hold. 100% SOC is a fully charged cell, and a 20% SOC cell has very little energy left. If a lithium-ion cell’s state of charge drops below 20%, the copper in the current collector can go into solution in the electrolyte, which can cause a short circuit and fire. If a cell is overcharged beyond 100% SOC, it can also undergo thermal runaway. To calculate SOC, highly accurate voltage, current, and temperature measurements are necessary.

When designing the circuits that provide the signals to voltage and current sensors mounted on the BMS, it is important to ensure there is minimum resistance in the sense circuits, regardless of where the cell is and the sense lead length. Of the hundreds of sensor connections between bus locations and the BMS, every one must be properly designed and manufactured to accommodate the thermal, intercalation, and pack stresses as batteries swell and shrink with the effects of charging and discharging. To accommodate this, sense circuits must be flexible without losing function and must be securely soldered to the contact points on the busbars.

With hundreds or thousands of individual cells providing power to the vehicle, each can have different states of health (SOH) after prolonged use. SOH is another calculated metric that approximates the remaining useful life in a cell. As with SOC, the calculation is very dependent upon reliable voltage, current, and voltage measurements over time.

In the case of EV batteries, they are generally considered to be no longer useful when their SOH value falls much below 80%.The batteries within a module act as a team, where the module performance is governed by the weakest cell in the string. To manage this, the BMS must perform cell balancing, to make certain that individual cells are neither overcharged or drop below certain SOC values to keep the SOH as high as possible across all the cells. As even a single cell performing poorly can degrade the performance of the module and hence the pack, it is critical to obtain the best available information from the embedded sensors.

New technologies, such as impedance spectroscopy, are also emerging as techniques to obtain the best information available on lithium-ion battery cell health. As the new control electronics for this technique are developing, the cell connection systems will grow organically to include more of this sensor intelligence close to the cells.

Balance between the cells comprising an electric vehicle’s battery maintains:

Charging capacity and charge rates

Vehicle range

Battery health & life

3. GAS

One of the most damaging -- and dangerous -- events in a battery-powered vehicle is thermal runaway. A process started by overheating, thermal runaway moves quickly through a battery pack as battery cells deteriorate.

Next to abnormally high battery pack temperatures, a sure sign that thermal runaway has started is the presence of vented flammable gases, including:

Hydrogen

Volatile hydrocarbons

Carbon monoxide & dioxide

Dimethyl carbonate

Hydrogen fluoride

Acetonitrile

The best time to stop thermal runaway from overtaking an EV battery is the second a single cell starts to vent the flammable gasses. The sooner you’re able to stop the process, the less damage it causes and the danger it poses. New cell connection systems designs can incorporate these gas sensor technologies directly onto their surface, providing the fastest response to a failed cell.

With gas sensors embedded close to the cells, early detection for thermal runway is built-in to the part of an electric vehicle closest to the potential failure point.

4. WATER INTRUSION AND COOLANT LEAK DETECTION

Like any vehicle, even a small leak can be a big problem for an EV. In an electric vehicle, coolant and humidity-based condensation, and water intrusion within the battery pack’s case are particularly problematic for two main reasons:

The presence of water or condensation from humidity can cause a short circuit. For an EV, a short circuit can have a minimal effect, such as a blown fuse or the vehicle entering safe mode, or cause much bigger issues, such as system failures or thermal runaway. Even in small amounts, water can also cause corrosion issues in critical electronics that can result in failure as well.

Wate /glycol-based coolants are typically used in the cod plate or cooling passages within EV battery packs to extract heat from the cells. If the connections or cooling lines inside a battery pack fail, coolant breaches into the battery space places conductive fluid in areas that can create short circuits. In addition to creating the opportunity for shorting the control or high voltage electronics, water from either condensation or coolant can hydrolyze when exposed to the current conductors in the pack, generating hydrogen and oxygen, which can also create issues For this reason it is also critical to protect circuit traces in the cell connection system from moisture and corrosion.

Regardless of the source, fluids inside an EV battery pack require immediate attention to preserve the functionality of the power unit.

UPGRADING EV BATTERY PACK & CELL CONNECTION SYSTEM CASES WITH SENSOR TECHNOLOGY

The defining component of an electric vehicle, a battery pack -- and its cell connection system -- require constant sensing of many critical parameters for robust life.

AMPHENOL SENSORS with sensor technology strategically placed throughout the cell connection system, maintaining battery EV health and performance happens reliably and in real-time.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由微笑向前转载自Amphenol Sensors,原文标题为:THE NECESSARY SENSORS FOR AN EV BATTERY PACK & CELL CONNECTION SYSTEM,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

HVAC System Upgrades and Optimization Via Sensors + 2 Checklists

Remote Monitoring and Control: In a certain respect, HVAC control system optimization strategies are no different than what we‘re seeing with other building management systems – you no longer need to be in the same room or even continent to control the system. Thanks to IoT (Internet of Things) technology, HVAC system managers can give the system attention no matter where they are.

Optimizing Fast Charging with Electric Vehicle Sensors

Fast-charging technology is making this shift possible as it meets a major concern head-on. Electric vehicle sensors are the unsung hero in making EV charging as uneventful as filling up a gas tank.

7 Places For Electric Car Temperature Sensors In Vehicle Design

Car temperature sensors are a key component of EV design -- on par with those that monitor battery power. When it comes to monitoring temperatures throughout the vehicle, there are seven places where sensors are a necessity.

Amphenol Sensors(安费诺)/Thermometrics 温度传感器选型指南

目录- 温度传感器产品介绍及应用领域 NTC热敏电阻/PTC热敏电阻 探针和组件 其他技术和附件

型号- T5D,HM,YA,YB,YC,P60,YD,YF,P65,YG,YH,RL40,YK,YL,YP,YR,EC95,GC32,YS,RL45,GC16,B35,UD20,RL30,3006,AB6,MELF,JA,YS4019,JB,JTC,JC,JD,RL35,JE,JF,MF65,SP85,JS2945,JI,B43,JL,JM,JP,FP10,JR,JTR,CTR100,FP14,P85,JW,M,NDK,T,NDM,CTR65,NDL,ZTP,BB07,PT1000,0706,BB05,NDP,YS4020,NDU,YSM 4021,CL,CTR85,BR16,KU,BR14,KY,BR11,TC,FP07,1403,NHQM,YSM,TH,R100,TM,MA400,PTSM,TP,1803,BB11,EVAP,P100,MA100,DK,SC30,R60,BR23,P20,R65,HVAC,P25,YM120,PT200,EVAPA1450,MS,DKM,MT,CTR60,P30,RL1004,BR32,A1447-A1450,ND,PTA,NK,EVAPA1447,1703,PTE,PTD,SP100,PTF,DC95,PTH,B05,B07,PTO,EVAP A1424,SC50,R85,BR42,C100,2006,JYA,NHQ,NHQMM,GC11,GC14,GE,RL20,M2000,B10,PT100,B14,GT,BR55,MC65,SP60,TK95,SP65,RL14,RL060628,RL10

Amphenol Sensors(安费诺)温度传感器/MEMS压力传感器/C〇2、湿度、灰尘传感器选型指南

目录- Sensors Temperature Sensors Pressure Sensors CO2, Humidity & Dust Sensors

型号- DK SERIES,NDP SERIES,NHQ SERIES,AAS-AQS-UNO-RH-CO2,RL40,T5D SERIES,FMA SERIES,GC32,EC95,AB6 SERIES,RL45,GC16,GT SERIES,DKM SERIES,CTP65,M SERIES,UD20,S SERIES,CTP60,RL30,AIT SERIES,GE-1935,TH SERIES,NDL SERIES,3006,MELF,YS4019,RL35,HM SERIES,GE-2102,GE-2103,JS2945,T6715,T6613-X,AAS-AQS-UNO,TM SERIES,R85 SERIES,SM-UART-04L,YSM SERIES,FP10,NPI-15,T6715-X,FP14,NPC-120,HS12SP,NPI-19,B35 SERIES,T6713,BB07,SUF SERIES,NK SERIES,BB05,YS4020,T6703,YSM 4021,YR SERIES,BR16,A-1737,BR14,T6700,BR11,T SERIES,FP07,1403,NHQM,P85 SERIES,ZTP SERIES,JF SERIES,NDK SERIES,JS8741,NPH SERIES,JS8746,R100,JR SERIES,PTSM,MA400,SM-PWM-01C,JB SERIES,1803,BB11,B05 SERIES,T6616,EVAP,YF SERIES,JA SERIES,P100,YD SERIES,YH SERIES,MF65 SERIES,YG SERIES,MA100,JIC SERIES,YB SERIES,B43 SERIES,T9602,NPC-100,YA SERIES,YC SERIES,SC30,CTP100,BR23,T6613,PTD SERIES,PTE SERIES,YM120,HVAC,JTC SERIES,JTR SERIES,MS SERIES,YK SERIES,WTF083B001,P30 SERIES,YL SERIES,YP SERIES,PTA SERIES,PTH SERIES,ND SERIES,B07 SERIES,PTF SERIES,PTO SERIES,P60 SERIES,JM SERIES,YS SERIES,T6600,RL1004,BR32,JS6780,JI SERIES,HS30P,JW SERIES,A1447-A1450,JS SERIES,TP SERIES,JE SERIES,JC SERIES,GE-1856,1703,B14 SERIES,T6615-X,GE SERIES,R65 SERIES,DC95,JYA SERIES,T3000,EVAP A1424,SC50,BR42,A-1266,C100,GE-1923,NPP-301,706 SERIES,2006,NKA SERIES,AS SERIES,B10 SERIES,P25 SERIES,NHQMM,GC11,RL20,CL SERIES,P20 SERIES,GC14,GE-1920,NPC-1220,JP SERIES,P65 SERIES,ES SERIES,CTP85,T6713-X SERIES,BR55,MC65,KU SERIES,TK95,NDM SERIES,R60 SERIES,NDU SERIES,NPC-1210,TC SERIES,JL SERIES,RL14,JD SERIES,RL060628,RL10

Amphenol Sensors(安费诺)/All Sensors 压力传感器选型指南(简版)

目录- 传感器解决方案及产品优势介绍 传感器技术介绍 单芯片压力传感器 双芯电路交叉耦合补偿压力传感器 双芯电路和气路交叉耦合补偿压力传感器 传感器应用领域介绍 压力单位换算 传感器通用名词解释

型号- DLH,ADCX,ACPC-C,AXCA,ACPC,BLV,DLV,ACPC-H,AXCA-PRIME,AXCA-MIDDLE,MAMP,MLV,SAMP,ACPC-P,BLC,ADUX,BLVR,MAMP-/P,ADCA,DLH,DLVR,DLVR,BLCR,MAMP-P,MDCX,ADO,BLV,AXCX-PRIME-INCH,DLHR,DLHR,AXCX,MLV,AXCA-MIL,BLC,DLC,ADO-MIL

NPA系列|压力传感器应用指南

描述- 本指南详细介绍了Amphenol Advanced Sensors的NPA系列压力传感器的应用。内容涵盖传感器的一般描述、输出特性、模拟和数字输出选项、未校准版本、封装尺寸、压力端口连接、PCB焊盘布局、焊接和设备标识。指南重点介绍了传感器的压力测量功能、输出特性、数字输出协议、诊断功能和睡眠模式,为用户提供了全面的应用指导。

型号- NPA SERIES,NPA-600 SERIES,NPA-601 SERIES,NPA-100 SERIES,NPA-500 SERIES,NPA-100,NPA-500M-001D,NPA-500,NPA-730,NPA-730 SERIES,NPA-300,NPA TYPES,NPA-600,NPA-700,NPA-601,NPA

Amphenol Sensors(安费诺)建筑及工业应用传感器选型指南

目录- Chip Cap 2完全校准的温湿度传感器 Telaire Ventostat®T8700壁挂式温湿度变送器 Telaire Ventostat®T8031 CO2小型风管式C02传感器 Telaire®T8041/T8042 分管式C02传感器 Telaire T8100-R系列挂壁式C02和温度变送器(带继电器) Telaire®7000室内空气品质监测器 Telaire VaporstatTM 9002红外露点变送器 Telaire®配件 Telaire HumiTrac™温湿度变送器 T9602湿度与温度传感器 AAS-53系列水管型温度变送器 ADT/AOT/AIT温湿度变送器使用说明书

型号- P40250128,CC2D265,P40250129,P40250126,P40250127,P40250125,P40250122,P40250123,DC95F302W,P40250120,P40250121,T8031,CC2D255,EHR-4,T8100-D-R,P40250139,K53,T8700,CC2A23,PT1000A,AIT,PT1000B,CC2A25,P40250133,P40250131,T2075NG,P40250130,T804K0-10V,T1508,T8200-D-5P,T8042-5VI0-5V,T9602-5-A-1,NI1000,9002,T9602-3-A-1,T5100,P40250149,CC2A35,T8700-E-D,P40250147,0-5000PPM,P40250144,PT100A,T7001I,P40250145,PT100B,P40250142,P40250143,T8100,S4B-EH,CC2A33,P40250141,CC2D235,CC2D355,T7001,PT1000,T2072,T7001D,CC2D25,T9602-3-A,T8042I0-10V,CC2D23,P40250156,T8041,T8100-R,P40250151,T8042,P40250150,T9602-3-D,NTC10K,CC2025,7000,T9602-3-D-1,CC2D35,T9602,CC2D33,ADT,NTC15K,T8200,CC2D335,CHIPCAP 2,NTC10K-II,T2090,T1551,T1552,MPNT3D03750M4,NTC20K,T2007,T8700-D,T8700-E,T8100,T2080,T8100-EC,P40250109,PA0250118,T8100-E-D-GN-5P-R,PA0250115,T1505,P40254275,P40254276,P40254277,P40250189,P40250186,P40250184,P40250185,T8300,P40250182,P40250183,P40250181,AAS-53,8000,PT100,T7001SK,P40250119,NTC10K-A,AOT,P40250117,T9602-5-A,P40250113,P40250114,P40250111,P40250112,DC95F103W,T2076NG,P40250110,P40250193,T9602-5-D,T8001,P40250191,7001D,P40250192,T8002,T9602-5-D-1,MPNV12R30M 16004616,B4B-EH-A,P40250190,T8041-5VI0-5V,RS485,NTC10K-III

Amphenol Sensors(安费诺) 汽车传感器选型指南

目录- 汽车传感器解决方案介绍 车厢空气质量系列传感器 排放处理系列传感器 新能源汽车传感器应用 测量汽车应用中最为关键的参数

型号- SM-UART-01L,PT200,T6703,TPMS,DPS,G-CAP2,SM-UART-01D,A2103,NPI-19,T6713,A-2102,EGR,A-2103,NPP-301,GE-1935,A-2121,ZTP,DPF,SM-UART-01L+,SM-PWM-01C,NPX1

Keeping Cool with Data Center Temperature Sensors

Data center temperature sensors are the eyes and ears of your climate control system. These tiny devices provide real-time data on temperature and some insight into potential humidity levels throughout your facility. They come in various forms, each suited to different applications.

Amphenol Sensors(安费诺) 医疗传感器选型指南

目录- NPA贴片式压力传感器系列 NTC AB6 型 "SC/MC"系列专为医疗设汁 MA100系列 ZTP-148SR系列 ZTP-101T系列 NPC-100系列一次性医疗压力传感器 NPC-1210系列 NPG-1220系列中压传感器 NPI-12卫生型压力传感器、不锈钢介质隔离压力传感器 NPI-15系列电流激励高压、介质隔离压力传感器 NPI-15VC系列电压激励、高压、介质隔离压力传感器 NPI-19系列电流激励、中压、介质隔离压力传感器 NPI-19系列电压激励、中压、介质隔离压力传感器 NPP-301系列贴片封装压力传感器

型号- NPP-301B-700AT,NPC-1001000,NPI-12-101G,MC65F103C,NPP-301A-100AT,NPI-19X-YYYZZ,NPI-15X-YYYZZ,NPI-19J-XXX,B35,ZTP-148SR,NPI-19A-XXX,MC65F103A,NPP-301A-200A,MC65F103B,AB6,NPA-300,NPI-19H-XXX,NPA-700,AB6E8,B43,NPP-301B-200A,NPI-12,NPI-19X-XXXXV,NPI-15,SC30F103W,NPP系列,NPP-301B-200AT,SC30F103V,MA100BF103C,NPI-19,SC30F103A,SC,MA100BF103B,MA100BF103A,NPI-15B-XXX,MA100GG232C,NPI-15C-C00903,NNP301B,NNP301A,MA100GG103CN,NPP-301B-700A,BR16,BR14,BR11,NPC-1210XXXX-YZ,ZTP-101T,NPC-100T,MA100GG103BN,MA100,NPP-301A-100A,NPC-100,NPI-19A-C01864,BR23,P20,P25,AB6B4,MC65F232A,MC,AB6B2,MC系列,NPI-19A-002GV,MA100GG103AN,AB6A8-BR16KA103N,NPI-15VC,NPP-301A-200AT,P30,BR32,NPA-100,NPC-1220XXXX-YZ,NPA-500,SC50F103W,NPP-301B-100A,NPA,NPP-301B-100AT,MC65F502B,NPI-15A-XXX,B05,B07,SC30Y103W,NPI-15J-XXX,NPP,NPP-301A-700A,BR42,NPP-301,MA100GG103B,NPI-19B-XXX,NPI-12-101GH,MA100GG103A,MC65G503B,MA100GG103C,NPC-1220,NPP-301A-700AT,B10,NPI-15H-XXX,B14,NPI-15XXXXXX,NTC AB6,BR55,NPC-1210,SC系列

Amphenol Sensors(安费诺)/Nova Sensor 压力传感器及敏感元件选型指南

目录- P1300低压硅压力传感器芯片 P1302低压硅压力传感器芯片 P111中压硅压力传感器芯片 P883(5~15000 PSI)硅压力传感器芯片 P1602硅压力传感器芯片 P122 高压硅压力传感器芯片 NPC-100系列一次性医疗压力传感器 NPC-1210系列低压系列固态压力传感器 NPC-1220系列中压传感器 NPH系列固态压力传感器(中低压) NPI-12卫生型压力传感器、不锈钢介质隔离压力传感器 NPI-15VC系列电压激励、高压、介质隔离压力传感器 NPI-15系列电流激励高压、介质隔离压力传感器 NPI-19系列电压激励、中压、介质隔离压力传感器 NPI-19系列电流激励、中压、介质隔离压力传感器 NPI-19低压不锈钢介质隔离压力传感器 NPP-301系列贴片封装压力传感器 NPA贴片式压力传感器 NPR-101系列复杂介质压力传感器 Modus T系列微差压力传感器 压力变送器IPT1000/2000系列

型号- NPP-301B-700AT,IPT1000,51243,51245,51003,51244,NPP-301A-100AT,51005,51367,51004,51007,51006,51009,NPI-19X-YYYZZ,51008,51407,51406,NPI-15X-YYYZZ,51409,51408,NPP-301A-200A,NPH-XYYY-ZZ,51010,51012,51254,51011,51253,51013,NPA-300,NPR-101,51137,NPA-700,NPH系列,NPP-301B-200A,NPI-12,NPI-19X-XXXXV,P1602,NPI-15,NPP-301B-200AT,NPI-19,NPA100,NPI-15X-XXXXX,51142,MODUS T,51421,NPI-15X-XXXXXX,51304,51303,NPI-15C-C00903,NPP-301B-700A,51391,NPC-1210XXXX-YZ,51151,51393,51392,51395,NPI-19A-031GH,T10,51394,51031,51397,51399,51313,51433,51314,NPC-100T,51317,51318,NPP-301A-100A,P1302,NPC-100,P1300,51041,51283,NPI-19A-021GH,51282,T20,51045,51322,51046,51445,51324,51444,51323,51326,51325,51328,51327,51329,NPI-19A-002GV,NPI-15VC,NPP-301A-200AT,IPT2000,T30,NPC-1220XXXX-YZ,51298,51331,NPA-500,51330,51333,51299,51332,51335,51334,NPI-19X-XXXXXV,51337,51336,51339,51338,NPP-301B-100A,NPP-301B-100AT,NPA,T系列,P122,P883,NPH,NPI-19A-C01841,NPI-19A-C01840,NPP-301A-700A,T40,51340,NPP-301,51342,51187,51341,NPI-12-101GH,NPI-1,NPC-1220,NPP-301A-700AT,P111,51076,NPC-1210,51114

EV Battery Pack Water Detection Sensor from Amphenol Sensors

With the sharp growth of electric vehicles, many OEMs are using a water cooling system for the EV battery system. When water escapes the system and leaks into the battery pack, dangerous conditions are created. Amphenol Advanced Sensors‘ Water Detection Sensor monitors for water leakage by constantly checking resistance values. If a leak is detected in the EV battery pack, this sensor technology provides immediate notification.

电子商城

品牌:AMPHENOL SENSORS

品类:Surface Mount Pressure Sensors

价格:¥97.5000

现货: 51

品牌:AMPHENOL SENSORS

品类:Air Quality Sensors IR LED Dust Sensor

价格:¥40.5000

现货: 35

品牌:AMPHENOL SENSORS

品类:Board Mount Pressure Sensors

价格:¥253.8839

现货: 30

品牌:AMPHENOL SENSORS

品类:Low Pressure Compact Sensors

价格:¥125.9778

现货: 25

品牌:AMPHENOL SENSORS

品类:Board Mount Pressure Sensors

价格:¥253.8839

现货: 25

品牌:AMPHENOL SENSORS

品类:Board Mount Pressure Sensors

价格:¥227.5314

现货: 25

品牌:AMPHENOL SENSORS

品类:Board Mount Pressure Sensors

价格:¥227.5314

现货: 25

品牌:AMPHENOL SENSORS

品类:Board Mount Pressure Sensors

价格:¥227.5314

现货: 25

品牌:AMPHENOL SENSORS

品类:Board Mount Pressure Sensors

价格:¥227.5314

现货: 25

现货市场

服务

可定制板装式压力传感器支持产品量程从5inch水柱到100 psi气压;数字输出压力传感器压力范围0.5~60inH2O,温度补偿范围-20~85ºС;模拟和数字低压传感器可以直接与微控制器通信,具备多种小型SIP和DIP封装可选择。

提交需求>

可定制温度范围-230℃~1150℃、精度可达±0.1°C;支持NTC传感器、PTC传感器、数字式温度传感器、热电堆温度传感器的额定量程和输出/外形尺寸/工作温度范围等参数定制。

提交需求>

登录 | 立即注册

提交评论