Consider Adding a Pre-Charge Step to Your Lithium-Ion Cell Manufacturing Process

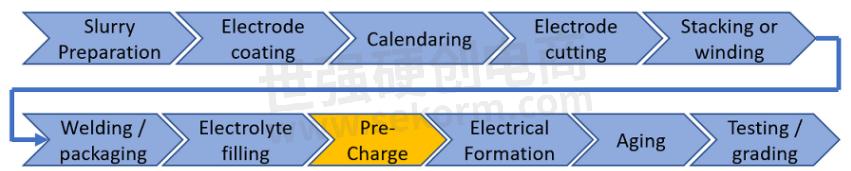

Last year Ed Brorein posted an article "The ABCs of Lithium-Ion Cell Manufacturing" (click on title to access) that provides an overview of the lithium-ion cell manufacturing process. In my article I walked through 10 main steps of the manufacturing process, starting with preparing the materials that go into the cell's construction and ending with final testing and grading. While these 10-steps are comprehensive, manufacturers are always looking at ways to enhance their process to better suit their specific needs. One way to consider enhancing the cell manufacturing process is adding a pre-charge step, as illustrated in Figure 1. As shown, pre-charge is a step that takes place before formation.

Figure 1: Adding a pre-charge step to the lithium-ion cell manufacturing process

What is pre-charge? Why add it into the manufacturing process?

Traditionally, after the cell is assembled and filled with electrolyte, the formation step then adds electrical charge to the cell, taking typically on the order of a day to perform. A portion of this charge is consumed to form the solid electrolyte interface layer (or SEI layer) on the surface of the cell's anode. Hence the term formation. A properly formed SEI layer is paramount to a cell's performance and long-term life. Additional electrical charge applied is stored as energy in the cell.

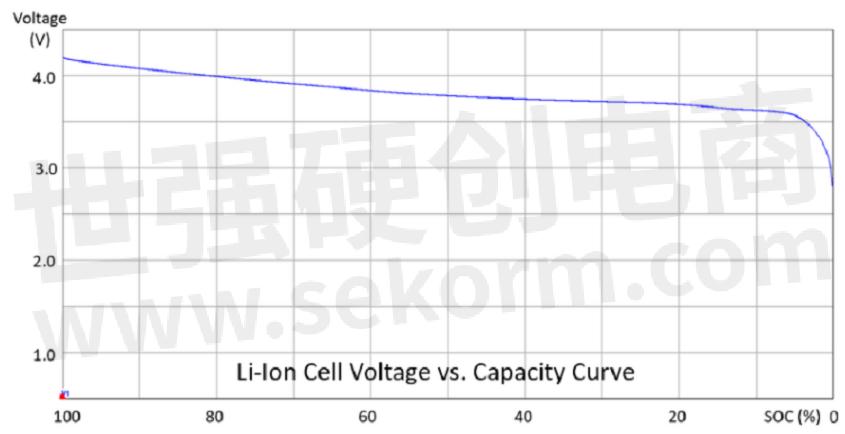

A lithium-ion cell's state of charge (SoC) characteristic is depicted in Figure 2. As expected, the cell's voltage varies with its % SoC. For this lithium ion cell type, the voltage is at 4.2 volts for 100% SoC (fully charged) and drops down to 2.5 volts for 0% SoC (fully discharged). This is not to say there is no charge left in the cell at 0% SoC, as there is a slight amount left. Instead, 0% SoC is defined by the minimum voltage level that the cell can remain at without risk of causing damage. Over-discharging the cell below its minimum voltage can cause internal corrosion and irreversible damage. This makes the cell potentially dangerous to recharge again.

After the step of filling a cell with electrolyte, it becomes electro-chemically active but still does not have any charge. Some time is allotted for the electrolyte to fully soak into the porous active materials of the electrodes, referred to as wetting. After this time however, the filled but uncharged cell may be sitting somewhere near 0 volts and subject to start corroding internally. It is imperative to apply some charge to the cell at this point to prevent this internal corroding from starting. Not enough charge to start forming the SEI layer or charge the cell, but just enough to "pre-charge" the cell to get it up to 2 to 3 volts, to prevent internal corrosion caused by too low of a cell voltage.

Figure 2: One type of lithium ion cell discharge characteristic.

Normally all the cells need to move immediately to formation after filling and wetting to prevent internal corrosion from starting, but this may not be the ideal situation for several reasons:

Formation typically takes on the order of a day to perform.

Formation equipment is typically high power to charge and discharge cells at higher power levels. This is more than what is needed for putting a small initial charge on the cells.

In some cases, the formation equipment may not be well suited for applying charge to cells down near, or slightly below 0 volts.

Having to form the cells right after electrolyte filling and wetting reduces scheduling flexibility.

Adding a pre-charge step before formation may be a better alternative. Pre-charge consists of setting up stations like formation, but with differences:

Pre-charge channels can be lower power, only needing to apply a small charge over a couple of minutes, to bring the cell up to a safe minimum voltage level of 2 to 3 volts.

Being dedicated to performing pre-charge, the equipment can be better tailored to the task, such as charging cells starting at or below 0 volts and optimized for throughput for applying a charge cycle of only minutes, instead of up to a day.

Pre-charge channels can be more economical with the equipment providing many more lower power channels in much less space, making it more cost-effective to process greater numbers of cells all at once.

Pre-charge can provide greater flexibility in the manufacturing process. There is no longer the immediate need to put all the cells through formation after electrolyte filling and wetting. This can provide greater flexibility in scheduling, putting the pre-charged cells through formation when it is opportune to do so.

Using the KEYSIGHT BT2200 Charge-Discharge System for Pre-charge:

The Keysight BT2200 Charge-Discharge System is well suited for both pre-charge and formation. The BT2202A or BT2203B mainframe, along with eight BT2204B modules provides 256 6-amp channels. For formation these channels can be connected in parallel for higher power and current as required, depending on the cell size. Individual channels are well suited for applying lower voltage and current typically required for pre-charge. The BT2200 also incorporates other specific capabilities uniquely needed for pre-charge, including operation down to or below 0 volts and short charge cycles, among other things. A BT2200 mainframe and BT2204B modules are pictured in Figure 3.

Figure 3: Keysight BT2200 Mainframe with BT2204B modules

- |

- +1 赞 0

- 收藏

- 评论 0

本文由董慧转载自Keysight,原文标题为:Consider Adding a Pre-Charge Step to Your Lithium-Ion Cell Manufacturing Process,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

Keysight Enables First O-RAN Open Distributed Unit Fronthaul Certificate for ArrayComm through APOP

Keysight Technologies has enabled ArrayComm to obtain the first O-RAN ALLIANCE Fronthaul Certificate of Conformance for its open distributed unit (O-DU) with the Keysight Open RAN Architect (KORA) solutions. The certification was issued by the Asia & Pacific OTIC in PRC (APOP).

原厂动态 发布时间 : 2023-03-30

Keysight Brings Keysight Open RAN Architect (KORA) to AWS Outposts

Keysight Technologies announced that the company‘s open radio access network (O-RAN) test solutions are now available on AWS Outposts. AWS Outposts is a fully managed service that offers the same AWS infrastructure, AWS services, APIs and tools to virtually any datacenter, co-location space, or on-premises facility for a consistent hybrid experience. It delivers a flexible 5G test environment that simplifies interoperability challenges and validates performance.

原厂动态 发布时间 : 2021-08-18

Keysight Enables Microamp Solutions to Accelerate Development of mmWave Radio Units for Private 5G Networks

Keysight Technologies announced that Microamp Solutions has selected Keysight Open Radio Architect (KORA) solutions to meet increasing demand for mmWave radio units in private 5G networks.

原厂动态 发布时间 : 2022-10-18

电动交通:用于电动动力传动系统和HEV/EV生态系统的创新设计和测试解决方案

型号- SL106XA系列,SL101XA系列,BT2200,18650,RP7900,21700,PT-100,PT-1000,SL1040A,PT-500,SL1000A,EV1003A,SL106XA,SL1002A,PA2203,SL1004A,SL101XA,SL1006A,BT2192A,BT2152B,N8900APV,SD1000A,SL 1005A,RP7900系列,BT2191A,SL1001A,SL1003A,SL104XA系列,BT2155A,PA2203系列,SL104XA

Advancing the E-Mobility Ecosystem

型号- EP1150A,SL1800A,SL1700A,BT2200,SL1550A,PD1550A,RP7900,SL1040A,SL1041B,SL1010A,SL1001A,SL1200A,SL1047A,EV1003A,SL113XA,PV8900,EV2000,BT2152B,SL100XA

电动动力传动系统和HEV/EV生态系统的创新设计和测试解决方案

型号- EP1150A,BT2200,PA2203 系列,RP7900,SL101XA 系列,SL1040A,SL1133A,SL1000A,SL1200A,SL1002A,SL1200A 系列,SL106XA,EV1003A,SL1004A,PA2203,SL101XA,SL1006A,BT2152B,SL106XA 系列,SD1000A,PD1500A,SL1091A,SL104XA 系列,RP7900 系列,SL1132A,SL1001A,SL1003A,SL1047A,BT2155A,SL1005A,SL104XA,SL1007A

Lithium-Ion Cell Charging and Discharging During Life Cycle Testing Versus Formation

Keysight has System Solutions for Cell Formation Cycling,induling Battery Test System Scienlab SL1007A,dual +/-100A channel module BT2205A,Charge-Discharge System BT2200 .

技术探讨 发布时间 : 2022-09-03

设计与测试解决方案: 汽车和能源行业

型号- N8900APV,N9038A,BT2200,EESOF,N8900APV 系列,E8740A,N7611B,E6640A,U8903B,BT2191A,X 系列,M8190A,E5071C,N8957APV,EV1003A,BT2152A,W1720,E8707A,EXM

How to Electrify Aerospace and Defense with State-of-the-Art Design and Test Solutions

型号- BT2205A,EP1150A,BT2200,BT2203B,SL101XA SERIES,SL104XX SERIES,RP7900,SL1040A,SL1133A,SL1000A,SL1200A,SL1002A,SL1004A,SL1006A,PA2200,BT2152B,SL106XX,SL104XX,RP7900 SERIES,BT2204B,SD1000A,BT2202A,PA2200 SERIES,PD1500A,SL1091A,SL106XX SERIES,BT2200 SERIES,SL1132A,SL1001A,SL1047A,SL1003A,PA2203A,SL1005A,PA2201A,BT2155A,SL1007A,SL101XA,SL1200A SERIES

【应用】Keysight BT2200充放电系统非常适合预充电和化成,可并联连接以获得更高的功率和电流

如今的锂离子电池制造商一直在试图改进锂离子生产工艺使之可以满足一些特定的需求,一种方法就是增加预充电步骤,添加预充电流程有利于提高电池的制造效率和质量,而Keysight BT2200充放电系统非常适合预充电和化成。

应用方案 发布时间 : 2022-03-02

BT2200 Charge-Discharge Platform DATA SHEET

型号- BT2204A,BT2206A,BT2200,BT2203A,BT2204B,18650,BT2202A,BT2152A,21700

【应用】利用电池形成解决方案,为电动自行车和电池储能系统供电

一家专业从事电动自行车制造的领先电池和电池合约制造商正准备扩大其生产能力,因为随着市场发展势头订单开始增加,但是很快就遇到了一些挑战,因此必须有一个快速而可靠的解决方案来确保生产和交付进度按计划进行BT2200平台平台具有高效的交流电源再生能力,在电池放电过程中将电能回收回电网,从而降低净能耗。 出于多种原因,选择了Keysight BT2200充放电平台。

应用方案 发布时间 : 2020-01-13

现货市场

服务

提供是德(Keysight),罗德(R&S)测试测量仪器租赁服务,包括网络分析仪、无线通讯综测仪、信号发生器、频谱分析仪、信号分析仪、电源等仪器租赁服务;租赁费用按月计算,租赁价格按仪器配置而定。

提交需求>

配备KEYSIGHT网络分析仪,可测量无线充电系统发射机/接收机线圈的阻抗,电感L、电阻R、电感C以及品质因数Q,仿真不同充电负载阻抗下的无线充电传输效率。支持到场/视频直播测试,资深专家全程指导。

实验室地址: 深圳 提交需求>

登录 | 立即注册

提交评论