Wevo Develops Liquid Battery Adhesive Systems for High-performance EVs

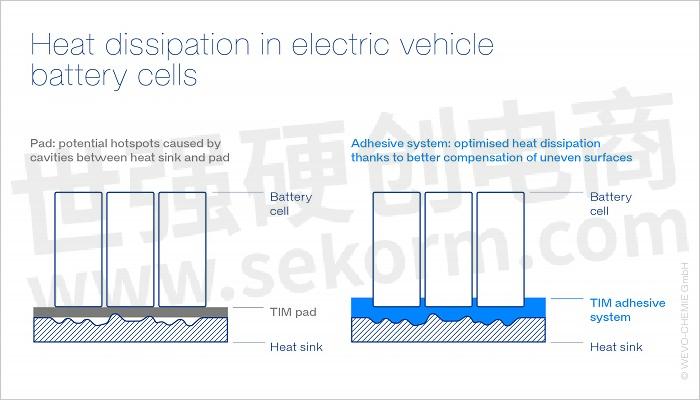

High temperatures are generated in the battery cells of electric vehicles (EVs) during charging and these have to be dissipated. Until now, this has mostly been achieved by inserting silicone-based pads between the cells and the cooling system. However, the manufacturing process of batteries is increasingly demanding that “thermal interface materials” (TIMs) with adhesive properties be used – something silicone pads are not able to provide. Wevo-CHEMIE GmbH has therefore developed liquid adhesive systems that offer better surface wetting and can also be used as structural adhesives. In addition to optimized heat dissipation, these customizable polyurethanes also open up new possibilities in the design process.

Wevo adhesive systems reliably dissipate the heat generated during the charging process from the battery cells to the heat sink

The ongoing upgrade of the liquid battery adhesive systems voltage of EVs from 400V to 800V is leading, among other things, to an increase in the efficiency of the battery charging process. However, this results in high temperatures – also in the battery cells. TIM pads no longer provide adequate heat dissipation in these cases. That’s because the inlaid solutions that are inserted between the cells and the cooling system do not fully compensate for the uneven surfaces of the cells and cooling system (see figure). This can lead to hotspots and damage to the cells.

What’s more, insertion solutions such as pads can no longer satisfy the complex geometries of modern battery design concepts. The customized liquid adhesive systems developed by Wevo are the perfect solution for the job. They are flexible and are applied directly to the cooling system – three-dimensional if required – and pressed together with the battery cells. This prevents air voids from forming and ensures immediate dissipation of the heat generated by the cooling system.

Properties matched to state-of-the-art battery designs

Wevo has set the thixotropy and therefore the rheological properties of these adhesive systems such that they can be applied as a vertical bead that doesn’t collapse even if the components are tilted or rotated as part of the manufacturing process. At the same time, the corresponding special fillers ensure that the viscosity of the potting compound doesn’t rise disproportionately to the thermal conductivity. This enables trouble-free processing in standard dosing systems despite the compound’s high thermal conductivity. The reactivity of the materials is individually adjusted to the customer’s particular process – for fast downstream processing and short production cycles.

What’s more, these Wevo products can be used as structural adhesives for durable and dimensionally stable bonding applications. This makes it easier for battery manufacturers to overcome the challenges they come up against in the design process. That’s because the polyurethane adhesives make it possible, for example, to dispense with certain screwed connections, helping to reduce the overall weight of the battery and increase the range it offers.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由玄子转载自Wevo News,原文标题为:Liquid battery adhesive systems for high-performance EVs,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Custom Design And Efficient Production: Wevo Products for Automotive Lighting Systems

In order to meet the high quality standards laid down by HELLA GmbH & Co. KGaA for the bonding and sealing of its headlamps and rear lights, WEVO-CHEMIE GmbH has developed products that facilitate both freedom in design and efficient production.

Temperature-resistant and Flame-retardant: Wevo Potting Compounds Materials with High UL Ratings

The polyurethane- and epoxy-based Wevo solutions are therefore suitable for use in electrical and electronic components that are operated continuously at higher temperatures and require flame retardancy.

Wevo Silicones Mitigate Thermal Runaway Propagation and Offer More Safety for Lithium-ion Batteries

WEVOSIL 27001 FL has been proven in field tests to be a highly efficient mechanical and thermal barrier that can be applied both above and between cells, depending on the cell type. It achieves high heat and flame resistance without any mineral or metallic fillers having to be incorporated.

E-MOBILITY

型号- WEVOSIL 28002,WEVOSIL 28001,WEVOPUR 9251 FL,WEVOSIL 26009 FL,WEVOPUR 60910 FL,WEVOPOX 32702,WEVOSIL 22006 FL,WEVOSIL 26009 FLB,WEVODUR 32702,WEVOSIL 22002 FL,WEVONAT 600,WEVOPOX 2513,WEVOPUR 56003 FL,WEVOSIL 27015 FLB,WEVODUR 5008,WEVOPUR 600,WEVOSIL 27015 FLA,WEVONAT 552 FL,WEVOPUR 56093 FL,WEVOPUR 552 FL,WEVODUR 5001,WEVOPUR 300 RE,WEVOSIL 26010 FL,WEVONAT 56003 FL,WEVOPUR 56002 FL,WEVOSIL 22005 FLA,WEVOSIL 26020 FL,WEVOPUR 60515 FL/40,WEVOPOX 1003/07,WEVOPUR 895,WEVOPUR PD 445,WEVONAT 507 L,WEVODUR 1003/07,WEVOSIL 20201,WEVOSIL 27015 FL,WEVONAT 512 FL,WEVOPUR PD 52,WEVOSIL 26020 FLB,WEVOSIL 26020 FLA,WEVONAT 403 FL,WEVONAT 78901,WEVONAT 507,WEVONAT 7210 FL,WEVONAT PD 79952,WEVONAT 900,WEVOPUR 56005 FL,WEVOPUR 68389 FL,WEVOSIL 22005 FLB,WEVOPOX 5008,WEVOPUR 900,WEVOPUR PD 79952,WEVONAT 56093 FL,WEVONAT 300,WEVOPOX 5001,WEVONAT 385,WEVOPUR 403 FL,WEVOPUR 512 FL,WEVOPUR 300,WEVOPUR 78901,WEVOSIL 22002 FLB,WEVOPUR 385,WEVONAT PD 52,WEVOSIL 22002 FLA,WEVONAT 300 RE,WEVOPOX 36001 FL,WEVODUR 2513,WEVOPUR 56992,WEVONAT 56992,WEVOSIL 22006 FLB,WEVOSIL 22006 FLA,WEVODUR 34020,WEVONAT PD 445,WEVOSIL 28002B,WEVOSIL 28002A,WEVONAT 68389 FL,WEVOSIL 22005 FL,WEVONAT 56005 FL,WEVOPUR 507,WEVOSIL 20201B,WEVOSIL 20201A,WEVOPUR 67210 FL,WEVONAT 67210FL,WEVONAT 895,WEVOPOX 34020,WEVOSIL 26009 FLA,WEVODUR 36001 FL,WEVOPUR 7210 FL,WEVONAT 9251 FL

Wevo Lannched a Battery Adhesive Systems for High-Performance EVs

High temperatures are generated in the battery cells of electric vehicles (EVs) during charging and these have to be dissipated. WEVO-CHEMIE GmbH has therefore developed liquid adhesive systems that offer better surface wetting and can also be used as structural adhesives.

Wevo(威孚)WEVOPUR聚氨酯(PU)产品选型指南

描述- WEVOPUR products are the number one choice for a wide range of applications – especially owing to their great versatility in terms of formulation options and the product properties that can be achieved with them.

型号- 300 RE,300 M,9251 FL,390,801 G,PD 52,895,139,PD 445,923 M,552 FL,512 FL,PD 4,3050,385,300,500 MT/40,403 FL/33,600,403,930 M,900,801,507,7210 FL

Structural Adhesives & Sprayable Syntactics for Recreational Marine

型号- 2000-CM,MA8120 GB,MA2045,4055,MA2245,MA320,PDR 9000,MA8110 GB,MA8105 GB,MA560-1,SC-4500,VELR 4000,7315,MA2230,2000-HS,MA590,6000,MA530,MA2015,2045,1500-LS,2000-OS LS,1050,1070,4000 HDT,PDR 6000,1800-LS,ALPHACOAT 1700,SC-4750,900,MA2290

Coherent ARM Fiber Laser and SmartWeld+ Surpass Traditional Remote Welding Systems is Reinventing Laser Processing for EVs

Meeting the challenge of EV manufacturing often requires novel and innovative solutions. Traditional tools which have performed well in the past for other uses sometimes don’t possess the capabilities needed for these highly exacting processes.

电子商城

登录 | 立即注册

提交评论