Busbars for e-Aviation and High Altitude Applications

During the past years, electric automobiles have evolved from conceptual prototypes to a booming trend, overcoming great challenges on the way and occupying a growing portion of the automotive market. E-aircrafts are now in the concept phase, getting ready to take off. Several companies, ranging from small start-ups to large traditional aircraft manufacturers, are developing the next generation of flying machines.

Due to operating conditions, airborne components must comply with strict reliability and safety requirements. Atmospheric conditions at 8000 meters are very different than at sea level and not all components are inside the pressurized volumes of the aircraft. The low density of air at high altitudes has two main negative effects on electric systems. First, it reduces the cooling properties of air, and second, it decreases the dielectric strength of air, following the Paschen curve. Both phenomena have a strong influence on the performance and lifetime of insulated electrical conductors, such as laminated Busbars.

Laminated busbars represent the best solution for most solid-state power converters. In e-aircraft, it applies to the main inverter which powers the electric motors. ROGERS also offers ROLINX® CapLink Solutions that combine capacitors with ROLINX laminated busbars for low inductance and high-power density specially designed for high power inverters.

Rogers Corporation, ROLINX CapLink Solutions

Design Constraints for High Altitude Busbars

As air density decreases, so do its heat transfer capability. This is the reason why many electric components must be adapted and/or derated for operating altitudes above 2000 meters. ROLINX busbars are custom designed for each project and optimized based on operating conditions, including ambient air temperature and density.

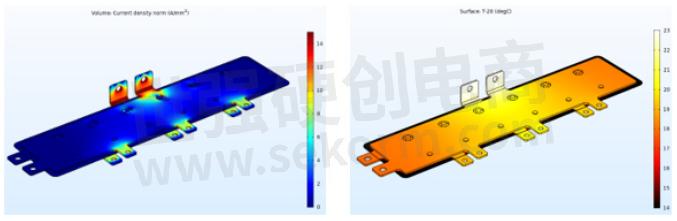

Rogers engineers' most powerful tools are their design experience and FEM simulations. In the case of high-altitude designs, FEM simulates the busbar's power dissipation and heat transfer to the environment at different ambient conditions. Once a 3D model is developed, its thermal response to outside temperatures and pressures can be studied virtually. This allows a quick iterative design that leads to the optimal conductor thickness while preventing overheating in all operating scenarios.

Rogers Corporation, ROLINX Busbars, FEM simulations

The FEM simulation above shows the current thermal distribution for a busbar model (on the left). For given ambient conditions (temperature, density, …) it is possible to obtain the busbar´s operating temperature, in order to, as necessary, optimize the design.

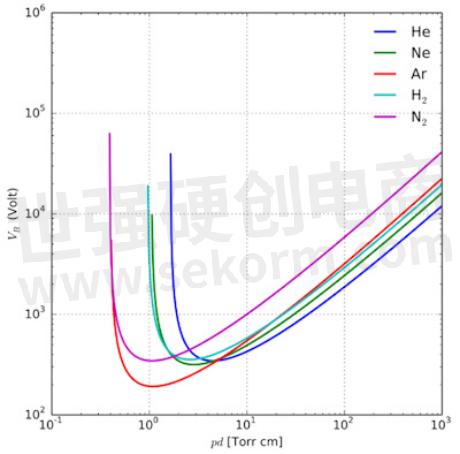

Another challenge for airborne electrical equipment is the decreasing dielectric strength of gases at lower pressures. This relationship was experimentally discovered by Friedrich Paschen who created the law that bears his name.

Paschen curves for different gases

In the case of air, the breakdown voltage is 3.1kV/mm at sea level pressure but decreases to 2.0 kV/mm at 0.5bar (pressure corresponding to 5500m) and even lower at higher altitudes. This phenomenon has two main implications:

If any transient voltage on the equipment becomes higher than the air´s breakdown voltage at the operating altitude, a flashover will occur if creepage and clearance distances are not respected. In the creation of a busbar at Rogers, this factor is considered and compensated during the design phase. In the prototype and manufacturing stages, all parts are electrically tested with a corrected voltage to account for this risk.

Film and rigid insulation are very sensitive to gaps in the interfaces, either between insulation layers or between the insulation and the conductors. These gaps are filled by air, which density depends on the operating altitude. These air bubbles can create a partial discharge. Partial discharge (PD) is defined in IEC60270 (section 3.1) as a “localized electrical discharge that only partially bridges the insulation between conductors […] Partial discharges are in general a consequence of local electrical stress concentrations in the insulation or on the surface of the insulation. Generally, such discharges appear as pulses having a duration of much less than 1 µs.” Although intermittent partial discharge does not affect the performance of the insulation, constant partial discharge higher than 10pC can degrade insulation properties and eventually lead to a short-circuit in the component. To achieve the maximum lifetime of ROLINX busbars without failures, each project is individually studied and designed, based on all environmental conditions, including high altitude effects on the insulation. Besides, partial discharge is measured in all busbars before delivery to verify that it keeps below 10pC, even at voltages higher than operating ones.

Conclusions

The evolution to cleaner transportation is pushing the development of e-aircrafts and is already a reality in the development phase. Operation at high altitude and other demanding specifications creates many challenges, pushing all electrical components a step further in performance. Operating at a high altitude with low air density has many implications on the design of laminated busbars. Technical requirements, ambient conditions, and physical phenomena are studied case by case at Rogers to deliver the safest and most optimized ROLINX busbar solution.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由董慧转载自Rogers,原文标题为:Busbars for e-Aviation and High Altitude Applications,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Rogers Corporation’s Power Electronics Solutions Group to Showcase curamik® Ceramic Substrates & ROLINX® Eco Busbars at the PCIM 2023

Rogers Power Electronics Solutions (PES) group will be exhibiting at PCIM Europe and showcasing the whole curamik® ceramic substrate portfolio and ROLINX® Eco — a new generation aluminum busbar with unique features.

Rogers Corporation’s Curamik® Ceramic Substrates, Low Inductive ROLINX® Laminated Busbars Power Renewable Energy Sources

The 2024 Paris Summer Olympic Games have captivated audiences worldwide, and part of that excitement has centered around the new and innovative technology applications utilized in this year’s games. Many of these technologies are enabled by materials that Rogers Corporation manufactures, including applications in footwear, 5G wireless infrastructure, renewable energy, and more.

Rogers Corporation Has Become an Official Partner of the European Union´s €95B Innovation Program: Horizon Europe

Rogers Corporation‘s announced its participation in the European Union´s €95B innovation program, Horizon Europe, through the POWERDRIVE project: power electronics optimization for next-generation electric vehicle components.

ROLINX® Busbars General Overview

型号- ROLINX® COMPACT,ROLINX® EASY,ROLINX® THERMAL,ROLINX®,ROLINX® CAPPERFORMANCE,ROLINX® CAPEASY,ROLINX® HYBRID,ROLINX POWERCIRCUIT® SOLUTIONS,ROLINX® PERFORMANCE

Inductance Optimization for Laminated Busbars

Stray inductance of switching circuits is one of the most critical parameters in the design of power electronics and is becoming even more important for systems using wide-bandgap semiconductors, such as SiC and GaN. The inductance of a conductor depends on its shape, the proximity of the current paths and the lowest inductance geometry given by parallel planes: exactly the structure of a busbar. With the right tools, knowledge and experience FEM simulation is an ideal approach to optimize the inductance of a laminated busbar in order to boost the performance of any power electronics system.

Rogers Expands Capabilities and Services with New Application Laboratory

Rogers Corporation today announced that the new application laboratory was completed, expanding the company‘s assembly, testing and inspection capabilities and services at the curamik® production site in Eschenbach.

Rogers Announces New Factory in Monterrey, Mexico to Support Growing EV/HEV and Renewable Energy Demand in North America

Rogers Corporation (NYSE: ROG) announced today that it has signed a lease on a factory in Monterrey, Mexico for advanced busbar manufacturing and engineering services. The first phase of the new site is slated for completion in late 2024 and continues Rogers’ manufacturing footprint strategy of supporting customers in the regions where they operate.

Optimal Interconnection for Prismatic Battery Systems in Electric Vehicles

Many of the electrical, mechanical and thermal requirements are also applicable to prismatic cells. However, the manner in which a battery pack in the vehicle is designed depends on the OEM´s preference. To connect the prismatic cells manufacturers typically use high thickness aluminum conductors, compared to the cylindrical cell due to the cell´s higher Ah capacity. As a benefit, the Aluminum in the current collector busbar offers large weight and cost savings.

电子商城

服务

使用FloTHERM和Smart CFD软件,提供前期热仿真模拟、结构设计调整建议、中期样品测试和后期生产供应的一站式服务,热仿真技术团队专业指导。

实验室地址: 深圳 提交需求>

可加工PCB层数:1-30层;板材类型:FR4板/铝基板/铜基板/刚扰结合板/FPC板/高精密板/Rogers高频板;成品尺寸:5*5mm~53*84cm;板厚:0.1~5.0mm。

最小起订量: 1 提交需求>

登录 | 立即注册

提交评论