8610 Battery Pack Integrated Testbed for Testing New Energy Vehicle Battery Systems and Subparts | Chroma

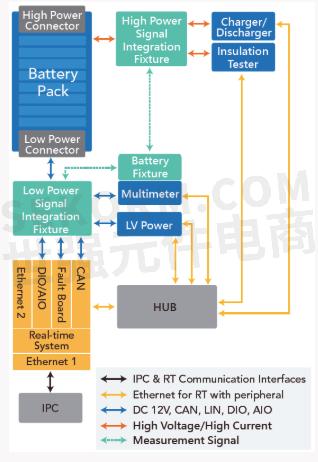

CHROMA ATE launches the 8610 Battery Pack Integrated Testbed for testing new energy vehicle battery systems and their subparts, including battery modules, battery management systems, cooling/heating systems, and other related components. Various hardware options are available for integration, such as DC power supply, battery charger/discharge system, digital meter, insulation measurement equipment, and short circuit and overvoltage protection devices.

Key Features:

· Support upper-level automated test software through ASAM XIL and ASAM XIL-MA

· Extensive modular hardware to fulfill test accuracy and repeatability; expandable according to users' needs

· Support CAN, CAN FD, and LIN communication interfaces

· Independent PLC real-time monitoring to ensure safety during battery pack charging and discharging tests

· Built-in AC/DC EVSE charge interfaces, including CAN Bus and PLC communication and related control signals for GB/T, CHAdeMO, and CCS compatibility tests

· Real-time monitoring of timing sequences, including high power relay open/close, initial power output, and CAN signals

· Integrated with Fault Injection Unit to combine fault signals and simulate fault injection

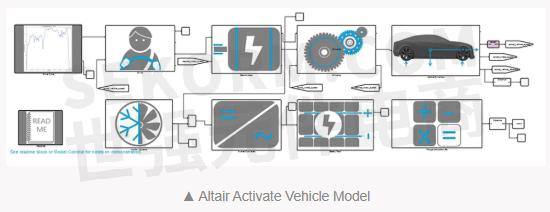

· Support Altair Activate and various Simulink-based real-time models for import to simulate on-road test conditions

· Integrated with Hipot safety analyzer to measure and compare battery insulation and grounding status

Applications:

· Battery pack calibration and verification

· Reliability and durability tests

· Simulation of vehicle driving conditions

· System integration tests

The 8610 system integrated with Chroma’s 17040 Regenerative Battery Pack Test System can simulate the charging and discharging of battery pack using the power system under various driving conditions to increase the test reliability when testing a whole vehicle.

The 8610 Battery Pack Integrated Testbed is designed for research and development of battery modules and packs. The open software architecture offers users powerful dynamics and flexibility while implementing various test items. Besides basic functions like vehicle driving cycle import, CAN signal monitoring, fault injection, insulation measurement, and EVSE charging simulation, this testbed can execute the most complex scenarios of a real vehicle and composite operation conditions with the highest risk of failure (e.g. physical and communication signal errors during cyclic discharge).

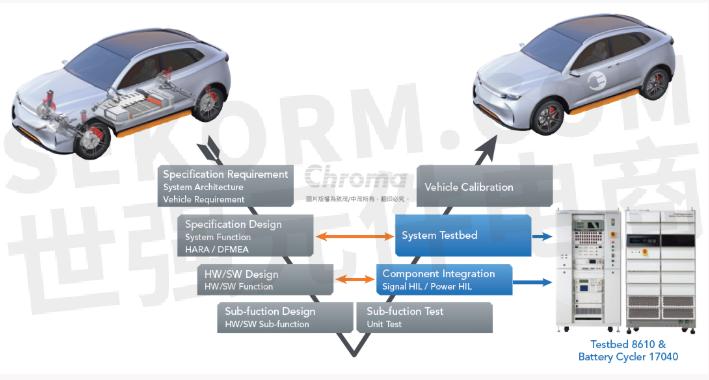

The 8610 highly supports the testing requirements on the right side of the vehicle’s standard development, V-shape process, from the integration of battery pack components to the system-level functions. This testbed system can implement various composite and simulated vehicle scenarios in advance before entering a real vehicle test. Users can also discover and correct problems early to reduce development costs and improve test efficiency.

The open software architecture of 8610 can integrate real-time systems, power equipment, measurement modules and simulation models for real-time and highly dynamic testing on battery packs. Compared with other battery test systems that need to obtain the actual on-road charge/discharge records in advance for loading and replay, the 8610 system integrates the driving cycle of vehicle model to directly perform tests on the dynamic battery pack.

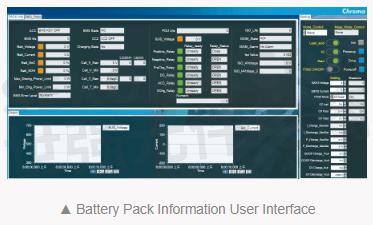

On the part of communication, the 8610 testbed supports the common CAN, CAN FD, and LIN interfaces and is capable of loading CAN communication DBC files. For manual testing, it has high flexibility to edit and modify the UI functions so that users can continuously optimize test items and procedures. For automated testing, it supports the upper-level testing software following ASAM XIL and after completion of test sequences, the system's monitoring parameters are recorded for subsequent analysis.

Warning and protection function for system safety

· Warning and protection mechanisms include overcurrent, overvoltage, under voltage, short circuit, power failure detection, system temperature monitoring and others can be expended by users.

· Implement warning, stop, and power cut-off functions through communication data which typically by CAN Bus from battery pack under test.

· Independent PLC real-time system which is capable of integrating monitoring and sensing signals existed already in user’s lab ascertaining the safety of battery pack charging and discharging tests

Highly flexible testing software with intuitive user interface

The software structure of 8610 testbed is based on real-time systems, which integrates diverse equipment to establish a control and test program development environment. While supporting the CAN, CAN FD, and LIN communication protocols, the 8610 is capable of setting the battery cycler behavior to interact with battery pack under test synchronously and customizing different testing functions defined by users. Testing engineers can also edit new test sequences based on existing source provided by Chroma and modify the UI to add additional functions. We adopt the Altair Activate vehicle model (depicted below) for vehicle dynamics simulation, for example, importing international standard driving cycles like NEDC, WLTP…etc. to implement dynamic battery pack discharge and regeneration tests.

Main features of user interface and control software

· The monitoring UI can digitally show all testing parameters and update the values in real time through plotting. Related information includes the battery charge/discharge status, voltage, current, SOC, temperature, protection alarm, and insulation level, etc.

· The parameter-control UI can change values or status in real time digitally through dragging or switching. Controlling parameters include battery charge/discharge start and stop, charge/discharge voltage, current and power settings, insulation measurement start, fault injection signal selection, and test condition selection, etc.

· Plot parameter curve while executing testing procedure, and generate report with graphic data after the test is finished. Related parameters include the battery charge/discharge status, voltage, current, SOC, temperature, protection alarm, and insulation level, etc.

· Support the adoption of Altair Activate vehicle model and various Simulink model-based real-time models.

· Sample data synchronously on assorted equipment and adjust sampling frequency by different testing requirements.

· Support manual execution and automatic sequence testing requirements.

Compound Vehicle Scenarios

Test functions for loading vehicle driving cycles such as charging/discharging, signal measurement and control, fault injection, insulation measurement, and simulated EVSE charging are included. Users can arrange and combine all of these test functions with high flexibility to achieve a variety of compound vehicle scenarios, for more comprehensive testing of battery packs. The example below illustrates charging and discharging after loading the real on-road profiles as well as simulation of charging changes right after a fault injection.

Diverse Test Items

Single Test Functions

(1) CC and CV charge/discharge tests

(2) Vehicle driving cycle discharge

(3) Arbitrary charge/discharge pattern reproduction

(4) Voltage measurement and voltage difference detection

(5) Current measurement and current difference detection

(6) High power ON/OFF control logic and timing (relay self-test mechanism confirmation)

(7) High voltage interlocking mechanism

(8) Battery protection function timing check

(9) Insulation resistance measurement

(10) AC/DC withstand voltage tests

(11) Dynamic leakage current

(12) GB/T, CHAdeMO, CCS AC/DC charging and interoperability tests

Compound Test Functions

(1) Checking insulation & withstand voltage status after fault injection while discharging with the imported vehicle driving cycle

(2) Checking insulation & withstand voltage status after fault injection during arbitrary charge/discharge pattern reproduction

(3) Impact of fault injection on SOC calculation and protection functions

(4) Checking insulation & withstand voltage status after fault injection when performing AC and DC charge

(5) Charging energy and strategy verification with different SOC, cell & total voltage and fault signals

(6) Fully charged calibration mechanism test

- |

- +1 赞 0

- 收藏

- 评论 0

本文由宝丁转载自Chroma,原文标题为:Battery Pack Integrated Testbed Model 8610,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

【产品】Chroma结合UDS与BMS通讯全面自动化验证电池包

Chroma 17020/ 17020E是多通道的电池充放电测试系统,实现所有作业流程为全自动与各自独立,替使用者省掉逐一解锁与接线上的困扰。17020/ 17020E 能源回收式电池模组测试系统是专门为二次电池组测试而开发的高精密设备,透过Chroma的系统整合能力结合UDS服务内的服务ID(SID),达到全自动的充放电测试。

Chroma‘s New battery simulation software Validate EV Devices in Real Time

Chroma will continue developing flexible EV, EVSE, and Battery test solutions, including the 8610 Battery Pack Power HIL testbed for verification, reliability, and durability testing of electric vehicle battery systems and components to ISO 26262.

【产品】专为高功率二次电池组测试而开发的能源回收式电池模组测试系统17040

Chroma的17040大功率能源回收式电池模组测试系统,将电池组放电产生的电能回收再利用,解决放电时能量虚耗的问题,除了为使用者带来庞大的经济效应,也解决作业空间热处理不易的问题,并符合环保需求。具备动态电流/功率工况模拟功能,提供实际路况电流波形模拟测试。

储能与电力转换系统测试解决方案:储能逆变器/光伏逆变器/电池包

描述- Chroma ATE Inc. 提供全面的储能与电力转换系统测试解决方案,包括储能逆变器、光伏逆变器、电池包等设备的性能验证。公司产品涵盖自动化测试系统、电网/电池模拟器、电池模拟器等,满足研发、项目验证、法规测试及大规模生产测试需求。Chroma ATE 的解决方案专注于提高测试精度、可靠性和独特性,助力客户实现系统性能验证。

型号- 62000H-S,8630,19501,17020,17040E,61800-100HF,63800系列,17020E,61860,61800-100,63700,17040,63800,19055-C,61800,61845,61815,63700系列,62000H-S系列,63800R,8900,62000D 系列,8000,63800R系列,8700,17020E系列,8720,61830,19501-K001,62000D,19501系列,61812,61800系列,17020系列,61809,19032-P,87001

CHROMA电动车直流快充测试方案:支持全球主流直流充电标准通讯协议,多元测试的理想选择

直流充电过程中,电动车和充电桩透过通讯交握的方式进行讯息交换,以确保充电的安全性。然而,由于市场上存在不同品牌的电动汽车和直流供电设备,因两者分属不同的产业链,常因对标准通讯协议解读不同,而发生无法充电的囧境,为确保两者之间的互操作性必须进行广泛的测试,测试系统的多元性与灵活性是重要的评估考虑。Chroma电动车直流快充测试方案:多元测试的理想选择。

Chroma携手运算智能全球领导者Altair和创奕能源,展开先进的动态电池充放电测试合作

Chroma携手运算智能全球领导者Altair和创奕能源,展开了一项先进的动态电池充放电测试合作,旨在透过先进设备和精密模拟技术,验证并提升电池使用性能寿命。此次测试计划结合了Chroma Battery Pack Power HIL系统、Altair车辆动态与电池精准模型以及创奕电动巴士的实际运行数据,在实验室台架中模拟创奕电巴的行驶工况,进行多次动态充放电与循环测试。

Chroma携新型电驱动总成测试系统1210等产品重点亮相2024上海汽车测试及质量监控博览会

Chroma推出新型电驱动总成测试系统1210,应用在纯电动乘用或商用车与氢燃料电池混合等车型之动力系统,提供新能源汽车动力系统模拟测试,试验件涵盖电机、电机控制器、变速箱及电力驱动系统等。Chroma携一系列新热产品重点参展2024上海汽车测试及质量监控博览会。

Chroma ATE Presents Electric Vehicle Test Solutions for a Sustainable Future

Chroma 61800 grid simulator and 17040/17040E battery simulator have energy recovery capability, reducing equipment power consumption as well as environmental temperatures. This array of features helps users save on costs and contributes to energy conservation and carbon reduction goals.

储能与电力转换系统测试解决方案

描述- Chroma ATE Inc. 提供全面的储能与电力转换系统测试解决方案,涵盖储能逆变器、光伏逆变器、电池包等设备的性能验证。产品包括针对不同标准和规范的测试设备,如GB/T 34120、IEC62933等,并提供自动化测试系统和软件平台,支持研发、项目验证和生产测试。此外,还提供定制化的生产线和电池管理系统(BMS)测试方案,确保产品质量和可靠性。

型号- 62000H-S,8630,19501,17020,17040E,61800-100HF,63800系列,17020E,61860,61800-100,63700,17040,63800,19055-C,61800,61845,61815,63700系列,62000H-S系列,63800R,8900,62000D 系列,8000,63800R系列,8700,8720,61830,62000D,19501系列,61812,61800系列,61809,19032-P,87001

Chroma的电池测试软件BatteryPro可实时接收BMS信息监测电池的温度和电压,提供准确的容量测量

电池容量测试(Capacity Test)是评价电池充放电能力的关键测试。一般的充放电机只能使用定流充电(CC),或是定流转定压(CC-CV)的方式做测试,但是实际的电池使用状况是电池管理系统(BMS)会依据当下温度、安全状态而去动态调整输出,因此为了让电池测试能更符合情况,电池测试期间依据BMS 讯息动态更改测试条件变得十分重要。Chroma的电池测试软件BatteryPro可以帮助解决此问题。

【技术】有关储能系统法规UL 9540电池包测试的重点介绍

Chroma 17040/Chroma 17040E能源回收式充放电设备,可对UL 9540、UL 1973法规验证项目进行测试,包含充放电循环测试、过充电测试、过放电保护测试、操作温度极限测试、电芯不平衡仿真测试、工作电压范围量测等六个主要测项。

8610型电池组电源HIL试验台

描述- 该资料介绍了Chroma ATE公司推出的8610电池包功率硬件在环测试平台(Power HIL Testbed)。该平台旨在为电动汽车(EV)电池系统提供全面的测试解决方案,支持实时模拟故障注入、动态充电和放电验证等功能。它集成了多种通信接口,并具备高可靠性的实时监控功能。

型号- MODEL 8610,8610

电力电子测试:电动车测试解决方案

描述- 致茂电子(Chroma ATE Inc.)提供全面的电动车辆电力电子测试解决方案,涵盖电池芯、电池模块、电池管理系统(BMS)、车载充电机、直流变换器、充电桩、无线充电器与电气安规等。公司专注于测试与自动化整合式解决方案,满足客户一次性购买的需求。产品包括电池模拟器、电动汽车充电测试系统、电气安规测试设备、电力电子测试仪器等,旨在提高测试的精准度、可靠性和独特性。

型号- 8630,17010 系列,63700 系列,19501,17020,17040E,63200A,8610,19200,61860,61800-100,17040,63700,61800,61845,63800R 系列,61815,63800 系列,1210,63800R,A170202,8900,RTSTAND LV124 PRO F24,62000D 系列,8000,17010,8700,8620,19036,8720,61830,62000D,19501系列,62000E,63200A 系列,17040 系列,61812,1920,17216M-10-6,61800 系列,61809,11210,62000E 系列,19032-P,87001,17208M-6-60

MODEL 17040E 能源回收式電池模組測試系統

描述- Chroma 17040E是一款专为高功率二次电池组测试设计的高精度、高安全与高效益充电放电设备。它具备能源回收功能,可节省放电过程所消耗的大量电能,并符合多种国际标准,如IEC、ISO、UL、GB/T等。

型号- 17040E,MODEL 17040E

电子商城

登录 | 立即注册

提交评论