How Over-provisioning Improves NAND-based ATP SSDs’Endurance and Performance

Abstract

Over-provisioning (OP) provides additional space for garbage collection process of solid-state drives (SSDs), aids in improving the performance, and increases their endurance, hence contributing to extended drive life. This article provides an in-depth view of OP and how its size affects the terabytes written (TBW), along with random write performance of SSDs.

Introduction to Over-Provisioning

In the past few decades, flash-based SSDs have sparked a revolution in storage devices. Unlike traditional electro-mechanical hard disk drives (HDDs) that use magnetic disks for storage, SSDs are made from an array of solid-state electronic storage chips, consisting of control units and storage cells (i.e., NAND flash chips, DRAM chips), thereby offering higher data transfer rates, area storage density, and reliability, as well as lower latency and access times.

In the scope of this article, it is worth elaborating the function of HDDs and SSDs. While the HDDs write and overwrite data by magnetizing sectors on the magnetic disks, the data on SSDs cannot be overwritten directly. Instead of overwriting old data, SSDs update data by programing, in the NAND flash, a new copy and invalidating previous copy of the same data.

Key and fundamental operations allowing to write data in the NAND flash are Program (P) and Erase (E). One P and E process is called one P/E cycle. The number of P/E cycles is used to describe the NAND flash endurance. Since every P/E cycle will lead to slight wear to the flash, NAND flash has finite P/E cycles before it is worn out. Various techniques and algorithms are implemented to manage the NAND to extend the lifespan of SSDs. The OP is one of them and is the focus of this article. It is actually a feature closely related to the working principle of NAND-based SSD storage.

It is important to have some basic knowledge regarding the physical structure of NAND memory to understand the P and E processes of SSDs. The NAND memory can be divided into blocks. One block usually consists of many pages and the page size varies with the NAND technology. In a programing process, data can only be written into one page at a time. However, Erase happens only to one block. Due to this limitation, a Garbage Collection process has been introduced to make full use of the flash memory.

Garbage Collection (GC)

The SSD controller uses Flash Translation Layer (FTL) to manage the mapping of the logical block address (LBA) from the host space and physical block addresses (PBA) of the flash memory. This mapping is in the form of a linking/mapping table. The Host addresses the physical blocks by using the linking table.

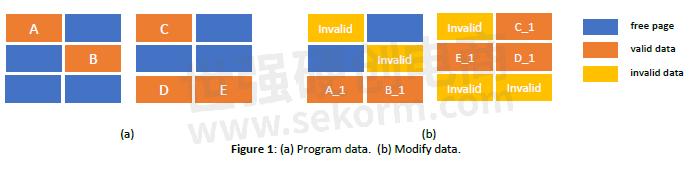

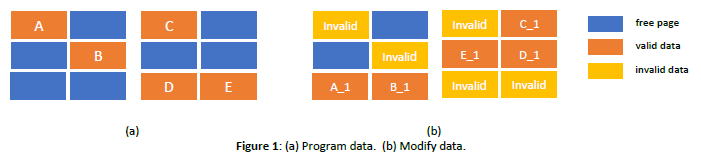

To clarify the GC process in simple terms, a flash memory is simplified into two physical blocks, each containing six pages, as shown in Figure 1. When writing the data to memory, with the help of wear-leveling algorithm, the data is distributed fairly evenly across all physical blocks as shown in Figure1(a), thus preventing repeated programming on specific areas. Since it is not possible to directly overwrite data on flash, the updated data needs to be written to free pages, while the original data is marked as invalid, as shown in Figure 1(b). The FTL will simply redirect the logical addresses of the updated data to the new physical addresses.

Invalid pages need to be freed up to allow more data to be added to the memory. Given the fact that erase can only be done at the block level to free the invalid pages in the blocks above, the valid data need to be read and written to free pages in another block. At the same time, the data in original pages are marked as invalid and the whole block containing only invalid data can be erased. The process of collecting valid data and erasing entire blocks of invalid data is called GC.

as shown in Figure 2.

Write Amplification Factor (WAF)

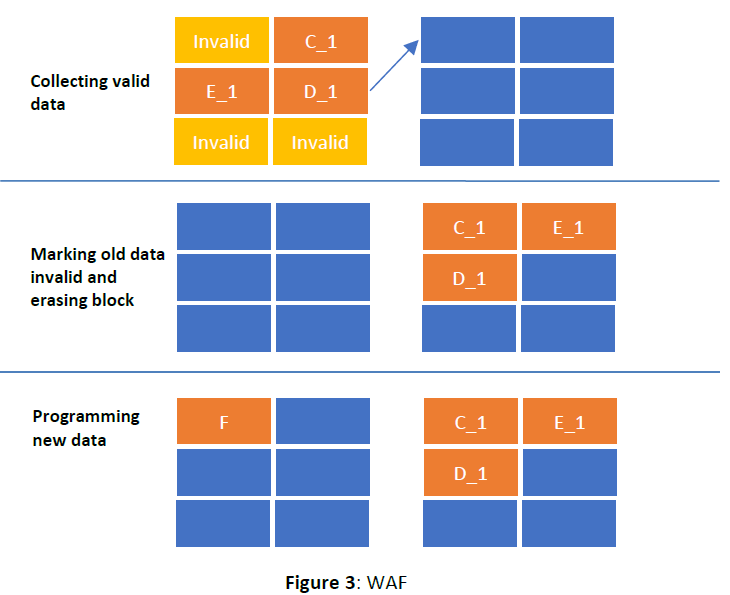

Suppose the Host wants to write data while there are very few free blocks available in the SSD, the SSD controller should start performing the GC process to free up the blocks containing invalid data. As shown in Figure 3, during the “GC – Write data” process, the SSD actually wrote four pages to the flash, in order to write data “F” on one page, as requested by the Host.

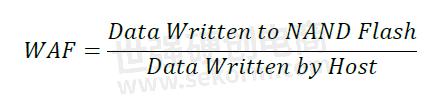

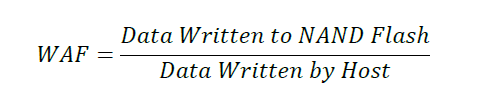

This kind of phenomenon is called Write Amplification, which means the amount of data written to the NAND exceeds the amount of data the host requires to be written. The WAF can be calculated as the ratio of the data written to flash (including copying the valid data during GC) to the amount of data to be written as requested by Host.

Taking the example, as shown in Figure 3, and assuming the data size of C_1, D_1, E_1 and F are all 4 KiB, the WAF of this write process can be calculated as 4. This also illustrates that the efficiency of GC will have a heavy impact on WAF. A high WAF will exacerbate the degradation of the flash memory and reduce the lifetime of the drive.

The WAF varies significantly by applying different workloads. In general, small-chunk random write will result in a much higher WAF than big-chunk sequential write. For instance, when writing 4 KiB chunk size data to the SSD with 16 KiB page size, in the case of sequential write, four chunks can be sequentially written to one physical page. While in terms of random write, every 4 KiB data will be randomly distributed to different pages or/and blocks. The data on the drive will be highly fragmented compared to a sequential write, which will result in highly fragmented invalid data during data replacement. Thus, the SSD controller will need to perform intensive GC to relocate the valid data and erase all the invalid data. This can lead to a significant drop in drive performance and a rise in WAF.

Over-Provisioning

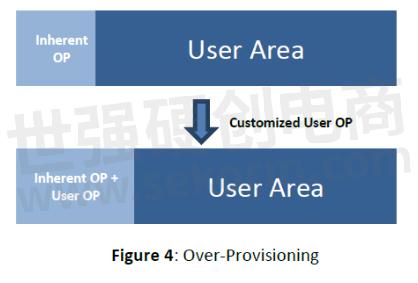

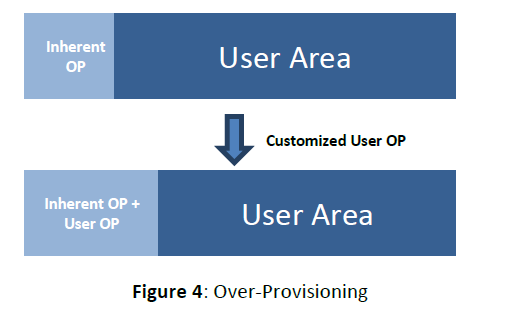

Foreseeably, when the SSD is almost full, there will not be enough free space for garbage collection. The approach to solve this dilemma is over-provisioning, which is the process of allocating extra free space into the SSD to ensure that there is always enough room for GC process. This extra area, called over-provisioned space, is inaccessible to the Host and is only accessible to the SSD controller, allowing the GC process to proceed smoothly.

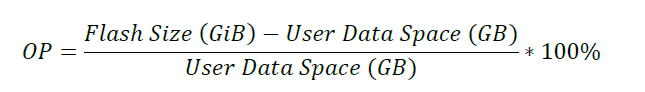

OP can be calculated using the following formula:

*GiB: unit symbol of Gibibyte: 230 bytes

*GB: unit symbol of Gigabyte: 109 bytes

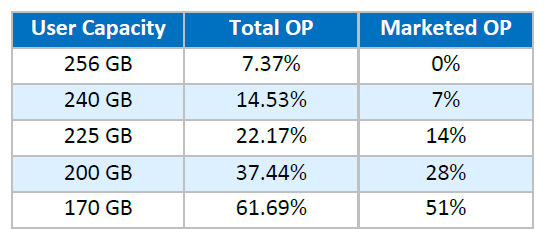

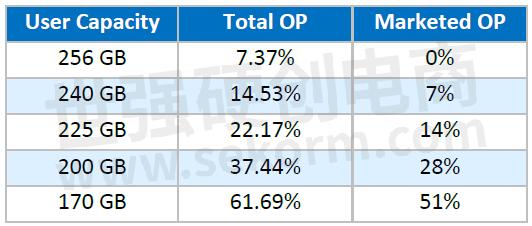

Notice that the flash capacity is always 2 to the nth power (in the unit of GiB), while the capacity advertised by the SSD manufactures is decimal (GB). For instance, using 256 GiB Flash to build a 256 GB SSD, the SSD has an inherent OP of (256*(2^30)-256*(10^9))/(256*(10^9)) = 7.37%.

On top of the inherent OP, additional user OP can be configured depending on different application requests. For example, a 240 GB SSD built by 256 GiB flash has a total OP of (256*(2^30)-240*(10^9))/(240*(10^9)) = 14.53%.

However, in order to make it simpler, the marketing description usually refers only to the user OP. So for a 240 GB SSD, the marketed OP is (256*(10^9)-240*(10^9))/(240*(10^9)) ≈ 7%. While the marketed OP for a 256 GB SSD is 0%, according to the calculation.

In summary, if we configure the SSD to different User Capacities, the OP will be like:

Regardless of which definition is used, OP refers to the portion of the SSD capacity that is reserved for FW algorithms like GC, wear leveling, and bad block replacement. It is inaccessible to the users.

How Over-Provisioning Impacts the TBW

Workload

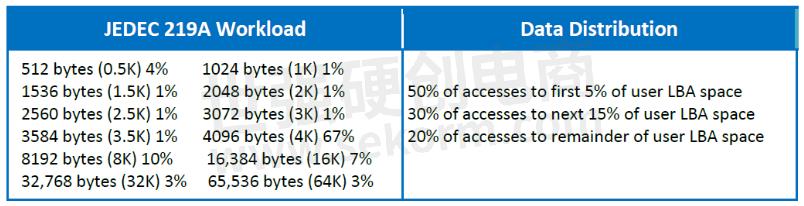

WAF can vary significantly depending on the workload from the Host. In this article, a series of tests have been performed to figure out the impact of the OP size on TBW and drive performance. The workload used for testing is the Enterprise workload JEDEC 219A, with the specific parameter settings shown in the table below.

Source: www.jedec.org

The workload was used to measure the performance with the random read/write mix ratio of 40%/60%. The total amount of data being continuously and randomly written to the drive was 12x the user capacity of the drives.

OP Factor vs. WAF

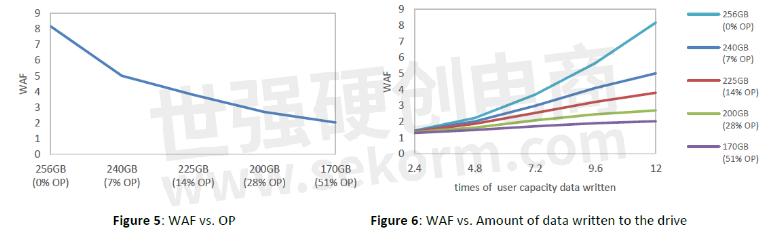

Figure 5 shows the overall WAF after writing data in the amount of 12x the user capacity size to the drive. As expected, the overall WAF decreases as the OP size increases.

Figure 6 shows how the WAF changes as data is written to drives with different OP settings. As data continues to be written, the data fragmentation within the drive becomes more and more significant, requiring more frequent GC process. With 0% OP (256 GB), the WAF increases very quickly as more and more data is written. Instead, increasing the OP can optimize the WAF as it ensures that there is enough space for GC to be carried out more efficiently.

OP Factor vs. TBW

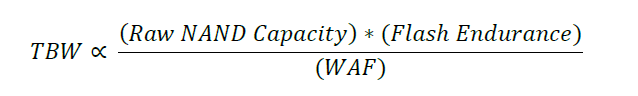

The TBW shown in the following graph is estimated based on the relationship:

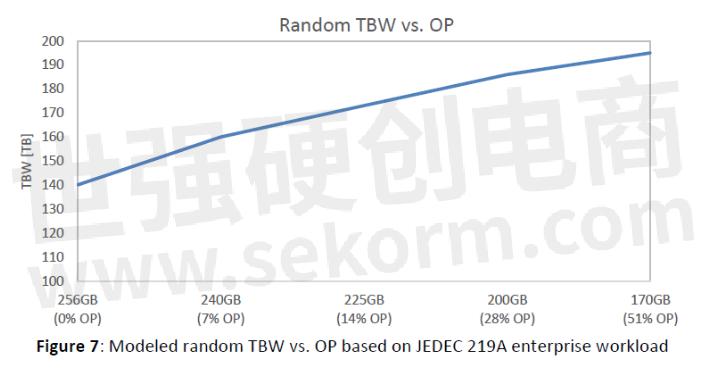

The TBW varies significantly depending on application. The following random write endurance has been calculated based on the test results in above session using JEDEC 219A enterprise workload and is not guaranteed value.

From the curve shown in Figure 7, it can be observed that TBW and OP are positively correlated, but in a non-linear fashion. After a certain point, increasing the OP does not significantly increase the TBW, but rather reduces user capacity. The customer therefore needs to choose an appropriate OP size for the actual application.

How Over-Provisioning Impacts SSD’s Performance

The garbage collection can severely impact SSD performance when it is near saturation with writes. To cope with this problem, over-provisioning provides additional space for the garbage collection process without heavily impacting the performance.

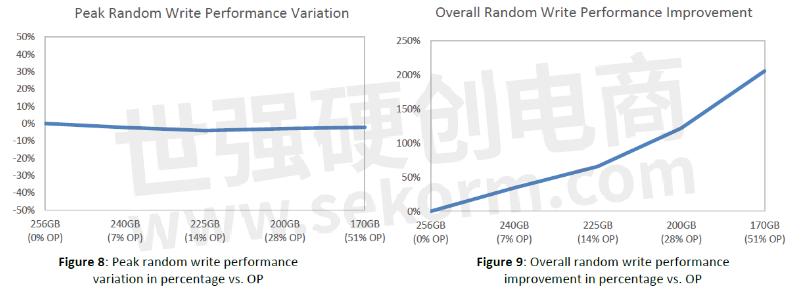

The following two graphs show the variation in peak performance and overall performance of a 256 GB SATA drive by allocating different OP sizes. These performances were measured by using the JEDEC 219 workload described in the above section, with 2.4x the user capacity size for continuous random writes.

The random write performance is at its best when writing to a brand-new drive, as there is no garbage collection action yet and the OP size therefore has no impact on peak performance, like shown in Figure 8. As the drive fills up with data, the data inside the drive becomes more and more fragmented. The drive's controller must constantly mark invalid data and garbage collect them. At this point GC becomes a major factor in slowing down the performance of the drive. As you can see from the graph in Figure 9, garbage collection has less and less impact on performance as the OP size increases. And in fact, the overall random write performance increases significantly with the increase in the OP.

Conclusion

Over-provisioning contributes to improving the endurance and write performance of the SSD, but it will reduce the user capacity; therefore, it is important to allocate an optimum amount of OP depending on the application. For write-intensive workloads, it is beneficial to compromise a certain portion of capacity for a significantly improved endurance. Instead, for read-intensive workload, a lower OP can allow the customer to take the best advantage of the user capacity.

As the global leader in specialized storage and memory solutions, ATP provides unique, custom-configured solutions to meet unique requirements. ATP customizes the OP to adapt to different real-world application environments, delivering the most benefit of drive endurance, user capacity, and performance product for the customer.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由电子人生转载自ATP ELECTRONICS,原文标题为:How over-provisioning improves NAND-based ATP SSDs’ endurance and performance,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

【经验】什么是SSD的M.2标准?M.2 SSD和mSATA SSD之间又具体有哪些差异?

近年来发布的固态驱动器(SSD)变得更快,并且能够处理大量数据。但是,它们的全部功能受到与其连接的接口的阻碍或限制。Mini-SATA(mSATA)接口虽然专为提供最小的SSD尺寸而设计,但受到SATA 6 Gb / s的限制。M.2标准是内部安装的计算机附加卡的规范,旨在解决mSATA的局限性,并为小型卡(包括不同大小和容量的SSD)提供更多选择。

【经验】过度配置如何提高基于NAND的ATP SSD的耐用性和性能介绍

过度配置(overprovisioning, OP)为固态硬盘(SSD)的垃圾收集过程提供了额外的空间,有助于提高性能,并增加其耐久性,从而有助于延长驱动器寿命。本文ATP ELECTRONICS深入介绍OP及其大小如何影响写入(TBW),以及SSD的随机写入性能。

ATP NVMe BGA pSLC SSD符合AFSSI-5020数据安全清除销毁要求

AFSSI-5020是一种基于软件的数据清除销毁方法,它通过永久覆盖已有信息来让存储设备中删除文件和文件夹。使用此方法擦除存储设备数据可防止基于软件和硬件的文件恢复方法来提取和/或重新创建以前存储在设备上的信息。

PCIe®Gen 3 NVMe M.2 2280/2242/2230 SSD专业存储和内存解决方案的全球领导者

描述- ATP推出PCIe Gen 3 NVMe M.2 SSD,具备数据保护、加密和散热解决方案。产品支持多种容量和温度范围,提供高性能和可靠性,适用于嵌入式和工业应用。

型号- FT960GP38AG8BPC,N750PI,FT480GP38ANDBFC,FT120GP38AG8BPC,FT480GP38AG8BPC,FT480GP34ANDBFC,FT960GP38AG8BPI,FT240GP38AG8BPC,FT120GP38ANDBFC,N700PC,FT240GP38AG8BPI,FT120GP38AG8BPI,N600SC,N650SI,N600VI,FT960GP34ANDBFC,N700PI,FT240GP38ANDBFC,N600SI,FT120GP34ANDBFC,N650SC,FT240GP34ANDBFC,N600VC,FT480GP38AG8BPI

笔记本需要更换大容量硬盘,求推荐性价比更的SSD固态硬盘。

您好,推荐ATP(华腾国际)的SSD固态硬盘,M.2 NVMe接口最高容量可达1TB,M.2 2280接口最高容量1TB,SATA接口最高容量1TB,具体可参考【选型】ATP(华腾国际)内存及存储产品选型指南

ATP工业企业SSD系列产品宣传单

描述- ATP Industrial Enterprise SSD系列结合了工业级和企业级存储解决方案的优点,适用于边缘计算环境。该系列SSD采用NVMe PCIe Gen4x4接口,提供M.2、U.2和E1.S三种形态,适用于数据中心向边缘计算转移的趋势。产品具备高耐用性、数据保留能力、一致性能、高质量服务和高可靠性,同时支持宽温度范围和硬件电源丢失保护。ATP还提供固件定制服务,以满足不同企业客户的需求。

型号- FT400GP48APHBSI-ERS2,FT480GP48APHBSI-ERS3,N651SIE SERIES,FT800GP48APHBSI-ERS2,FT240GP48APHBSI-ERS3,FT800GES4APHBSI-ERS2,FT1T60ES4APHBSI-ERS2,FT240GP48APHBSI-ERS1,FT120GP48APHBSI-ERS3,FT6T40U24APHBSI-ERS2,FT3T20ES4APHBSI-ERS2,FT3T84ES4APHBSI-ERS1,FT7T86ES4APHBSI-ERS1,FT1T60P48APHBSI-ERS2,FT3T20U24APHBSI-ERS2,FT480GP48APHBSI-ERS1,FT1T92P48APHBSI-ERS1,FT960GES4APHBSI-ERS1,FT960GES4APHBSI-ERS3,FT1T60U24APHBSI-ERS2,FT960GU24APHBSI-ERS1,N651SIE,FT960GU24APHBSI-ERS3,FT200GP48APHBSI-ERS2,FT7T86U24APHBSI-ERS1,FT3T84ES4APHBSI-ERS3,FT3T84U24APHBSI-ERS3,FT3T84U24APHBSI-ERS1,FT960GP48APHBSI-ERS3,FT800GU24APHBSI-ERS2,FT1T92U24APHBSI-ERS3,FT480GU24APHBSI-ERS3,FT6T40ES4APHBSI-ERS2,FT1T92U24APHBSI-ERS1,FT480GES4APHBSI-ERS3,FT1T92ES4APHBSI-ERS3,FT960GP48APHBSI-ERS1,FT1T92ES4APHBSI-ERS1

ATP对所有SSD进行数千小时RDT测试,确保产品严格遵守最高质量标准

可靠性验证试验(RDT)是对ATP固态驱动器(SSD)进行的一项长期严格测试,旨在证明每个SSD符合最严格的质量要求。ATP在较长时间内对其 SSD执行完整的实际驱动器级别测试,以验证额定MTBF值,而不是依赖可靠性预测系统。

ATP NVMe BGA pSLC SSD安全保护及加密功能特点

硬件写保护* 写保护功能将ATP NVMe BGA SSD置于“只读”模式,以防止数据写入设备,并保护重要数据不被意外删除、移动或修改。通过在控制器印电路板(PCB)上的通用输入/输出(GPIO)信号引脚的特定引脚上放置跳线,在存储设备上启用写保护。硬件快速擦除*对于特定应用,主机可以使用GPIO连接器触发“擦除数据”行动。

The Doctor is in: ATP PLP Diag Offers Proactive Capacitor Health Checks to Avert PLP Failures

As more industries and enterprises rely on SSDs for reliable data storage under all circumstances, especially during unpredictable power loss events, ATP Electronics strengthens its SSDs‘ MCU-based HW PLP design with PLP Diag. By proactively monitoring the health of its polymer tantalum capacitors and responding to potential failures that expose the in-flight data to risks, PLP Diag offers fail-safe protection to ensure uncompromised data integrity and device reliability.

ATP推出工业宽温企业级SSD系列产品N651Sie,包含U.2,M.2,E1.S三种接口类型

ATP推出工业宽温企业级SSD系列产品N651Sie,结合了工业级固态硬盘和企业解决方案的优点,专为在不受控制的恶劣环境中处理企业级工作负载而设计。

ATP AcuCurrent: Innovative Signal Integrity Optimization Technology

ATP‘s AcuCurrent Technology is an innovative signal optimization technology, enabling dynamic, real-time temperature-responsive drive setting adjustments across a wide operating range, up to 125℃. AcuCurrent Technology is temperature-responsive, dynamically adjusting settings in real time to ensure that the SSD operates at great efficiency across various scenarios, effectively minimizing unnecessary read-retry cycles, and substantially reducing error rates.

ATP推出业界最高擦写寿命的工业级固态硬盘(SSD),具有出色的耐久性和在极端温度下工作的能力

ATP推出N751Pi系列PCIe Gen4 NVMe M.2 2280 SSD,该SSD在配置了pSLC NAND的工业级固态硬盘(SSD)中具有出色的耐久性和在极端温度下工作的能力,是恶劣环境、恶劣条件和高负荷工作负载下关键任务和写入密集型应用的理想选择。

【电气】ATP推出业界最佳工业级宽温8TB E1.S固态硬盘N651Si系列,专为1U边缘服务器设计

ATP推出N651Si系列工业级宽温E1.S固态硬盘,支持工业温度工作范围(-40°C至85°C)以及硬件断电保护,在恶劣环境中提供最高级别的可靠性和总拥有成本价值,使其特别适用于在极端温度下运行的关键任务应用,如汽车、数据记录仪、数据中心和国防/航空航天,为要求最苛刻的应用提供一流的性能、耐用性和数据保持能力。

PCIe®Gen 3 NVMe M.2 2280/2242/2230固态硬盘

描述- ATP推出的PCIe Gen 3 NVMe M.2 2280/2242/2230 SSD,基于NVMe协议和PCIe Gen3 x4接口,提供高速、可靠和持久的性能,满足嵌入式和工业应用日益增长的数据存储需求。这些模块采用3D TLC NAND闪存,容量从40GB到960GB不等,适用于不同的数据存储需求。

型号- FT960GP38AG8BPC,N750PI,FT480GP38ANDBFC,FT120GP38AG8BPC,FT480GP38AG8BPC,FT480GP34ANDBFC,FT960GP38AG8BPI,FT240GP38AG8BPC,FT120GP38ANDBFC,N700PC,FT240GP38AG8BPI,FT120GP38AG8BPI,N600SC,N650SI,N600VI,FT960GP34ANDBFC,N700PI,FT240GP38ANDBFC,N600SI,FT120GP34ANDBFC,N650SC,FT240GP34ANDBFC,N600VC,FT480GP38AG8BPI

ATP‘s Power Loss Protection Just Got Smarter with MCU-based SSD Design

ATP customers want constant assurance that power loss events will not cause massive downtime or lost data that could affect business operations and lead to higher operating costs. The MCU intelligently monitors sudden power failure conditions from a glitch to a surge or a complete outage...

电子商城

服务

可定制ATP TE Cooler的冷却功率:40~200W;运行电压:12/24/48V(DC);控温精度:≤±0.1℃; 尺寸:冷面:20*20~500*300;热面:60*60~540*400 (长*宽;单位mm)。

最小起订量: 1 提交需求>

登录 | 立即注册

提交评论