Lithium-Ion Cell Charging and Discharging During Life Cycle Testing Versus Formation

Lithium-ion cells get charged and discharged, both during life cycle testing and during formation. However, the goals for life cycle testing versus formation are very different. Correspondingly, the charging and discharging, and associated activities, are also very different. Here we will explore the charging and discharging, and associated activities, for life cycle testing and for formation of lithium-ion cells, and how they are different. We will see how this affects the definition of the system solutions for each, making them distinctly different.

Standard Charging and Discharging Protocols for Lithium-Ion Cells

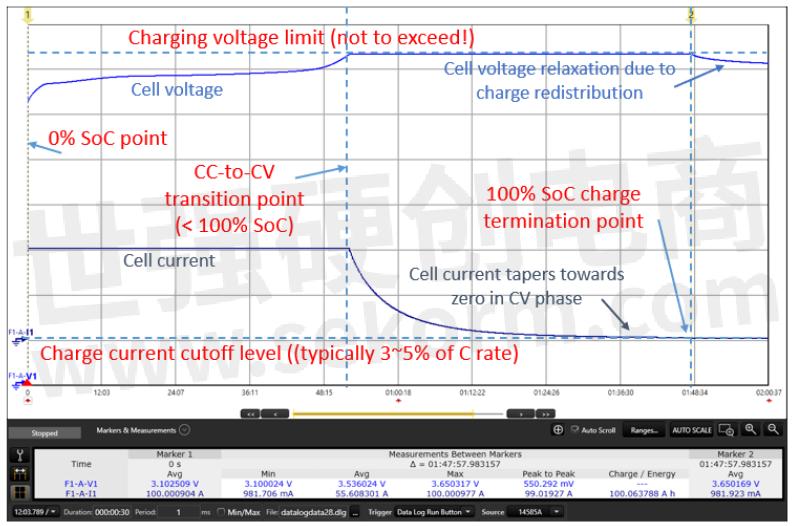

In normal use the standard charging for lithium-ion cells is referred to as CCCV charging. This is illustrated in Figure 1.

Figure 1: Standard lithium-ion cell CCCV charging

In CCCV charging the cell is first charge by a constant current (CC) at a desired rate, followed by float charging with a constant voltage (CV), equal to the maximum recommended cell voltage. The charging equipment is a constant current power source set to the desired charging current, with a voltage limit set to the maximum recommended cell voltage. A cell's current charging rate is typically specified in terms of its C rate, where 1C would be the constant current rate in amps, equal to the cell's capacity in amp-hours. Thus, 2C would be a charge current set to twice the cell's amp-hour capacity, and so on.

When the cell starts out at a low state of charge (SoC), its voltage is low. As a result, the charger starts out in CC mode during the first phase of the cell's charging. As the cell's SoC increases, so does its voltage. When the cell initially reaches its maximum voltage level, it is usually about 70 to 80% charged, depending on what the C rate is. But because the cell voltage has reached the charger's CV limit setting, the charger automatically transitions to CV mode. During the CV float charging phase the charge current drops exponentially as the remaining charge accumulates in the cell. Full charge, or 100% SoC, is typically defined as when the charge current drops down to about 3 to 5% of the cell's 1C charge rate. When charge current has dropped to this level, the charging is terminated.

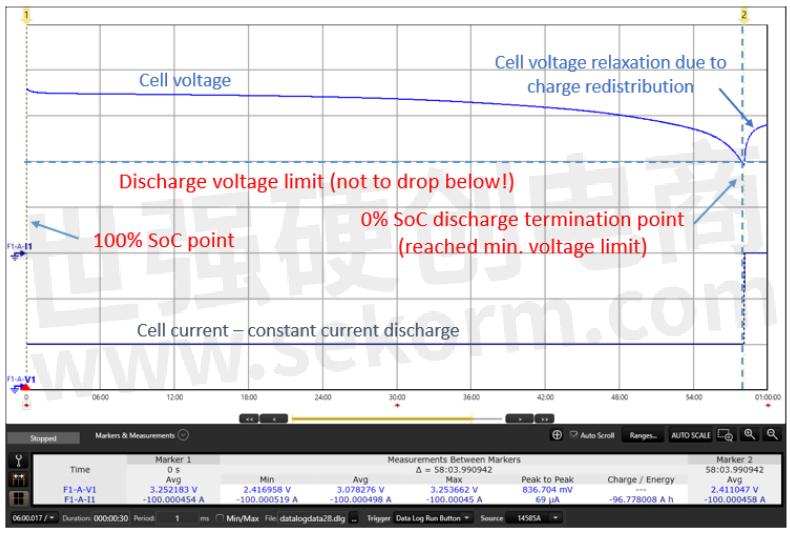

Standard discharging is referred to as constant current (CC) discharging. (Of course, for most cases in real life use, the discharging current is typically anything but constant!) CC discharging for a lithium-ion cell is illustrated in Figure 2.

Figure 2: Standard lithium-ion cell CC discharging

Starting at 100% SoC, in CC discharging, current is drawn from the cell at a constant rate until the cell reaches its minimum recommended voltage. This is the point at which the cell is defined to be fully discharge, or at 0% SoC. Any further discharging is terminated. Lithium-ion cells must not be discharged below their minimum recommended voltage as it can cause irreversible damage to them.

Now that the details of the standard charging and discharging protocols have been reviewed, let's look at how charging and discharging is applied in life cycle testing and in formation.

Charging and Discharging During Life Cycle Testing

In lithium-ion cell life cycle testing, a sample group of cells are subjected to many hundreds of charge-discharge cycles over an extended period of typically many months or longer, to predict the cells' charge-discharge cycle end-of-life. The charge and discharge rates may range from 0.5 to several C. Most often standard charging and discharging protocols are used, as described in the previous section. Life cycling is most always performed at elevated temperatures using a temperature chamber, to further accelerate aging.

During the life cycling, the cells are periodically tested for capacity, DC internal resistance (DC-IR), AC internal resistance (AC-IR), and possibly other parameters of specific interest. Very basically, capacity loss over life is the primary concern, where 20% capacity loss is defined the end of (first) life for the cells. The end-of-life number of cycles is predicted by extrapolating from the actual capacity loss measured after exercising the cells hundreds of cycles. This is illustrated in Figure 3. Life cycling may also reveal other things that may lead to premature end-of-life, such as electrode delamination, shorts, and so on. These typically reveal themselves as an abrupt drop in capacity, instead of a gradual loss.

Figure 3: Predicting cells' end-of-cycle-life by extrapolation

System Solutions for Cell Life Cycle Testing

Cycling a large sample of cells at charge and discharge rates from 0.5 to several C requires tens to hundreds of channels of high power, high efficiency regenerative equipment, able to source and sink up to hundreds of amps per channel for today's large format lithium-ion cells. An example of a solution for cell testing and cycling is depicted in Figure 4.

Figure 4: Scienlab SL1007A Cell Level Battery Test System

The KEYSIGHT Scienlab SL1007A Battery Test System for cells provides up to 64 independent channels that operate from 0 to 6V. Channels can be configured for 8 output current levels ranging from +/-25A to +/-600A. The SL1007A is very efficient and regenerative, so that it puts the energy back on the AC line when discharging the cells, minimizing electrical consumption and waste heat generation. More importantly, coupled with the SL1091A Scienlab Energy Storage Discover software, it provides a complete, turn-key solution for testing and cycling cells. The Energy Storage Discover software performs and keeps track of cell cycling and performs the required periodic measurements. It supports integrating additional equipment including the climatic chamber and alternative measurement equipment to meet specific customer requirements. Additional features making it a complete solution include:

◆ A flexible and complete database.

◆ Report generation and analytics.

◆ Redundant safety capabilities.

◆ Remote access.

◆ Maintenance and service tracking.

◆ Error handling.

◆ Startup assistance and training.

◆ And much more.

As a basis for an economical cell life-cycling solution, Keysight introduced the BT2205A dual +/-100A, 6V channel module, which is part of the BT2200 Charge-Discharge System. The BT2205A is shown in Figure 5.

Figure 5: The BT2205A dual +/-100A channel module

The BT2200 Charge-Discharge System mainframes can hold up to eight BT2205A modules, providing 16 +/-100A channels. Channels can be paralleled to provide up to +/-800A. Customers can opt to use the BT2200 Charge-Discharge system with the BT2205A module. Multiple BT2200 Charge-Discharge systems can be integrated into a solution for performing cell life cycle testing. This can then be coupled with a cell measurement system, or with a high-performance system such as the Scienlab SL1007A shown in Figure 4, for a hybrid system that uses lower cost equipment for the actual charge-discharge system, for a more economical overall solution.

Cell Charging and Discharging During Formation

Unlike cell life cycle testing, the purpose of formation is to grow a high-quality solid electrolyte interface (SEI) layer on the anodes of all freshly assembled cells in the manufacturing process. Also, in contrast to cell life cycle testing, formation takes place at very low C rates, typically on the order of C/20 to C/10, to produce a high-quality SEI layer that assures long cell life and high performance.

During formation, some of the lithium and electrolyte in the cells are consumed to form the SEI layer. A high-quality SEI layer allows lithium ions to freely pass through, while being electrically non-conductive so that no more electrolyte and lithium can be consumed at the surface of the anode.

If done properly, very little to no additional lithium and electrolyte is consumed in subsequent charge-discharge cycles. However, if the SEI layer is not done properly, additional electrolyte and lithium continues to be consumed, reducing the capacity of the cell over time.

Not only is formation performed at very low C rates, but there are other aspects of formation that make it very different from the standard charge-discharge protocol used for cell life cycle testing. The objective is to form a high-quality SEI layer providing high performance and long life while at the same time minimizing formation time and cost. As I had pointed out in my previous article, the charge-discharge profiles used in formation are a closely guarded company trade secret, considered to provide a competitive advantage over other companies. Also, a protocol that may work well for one cell design may not be well suited for another cell design. Additional unique things about charging and discharging cells during formation that differentiate it from standard cell charge-discharge cycling include:

◆ Some manufacturers may apply a pre-charge step as prelude to the main formation process, to raise the cell potential high enough to prevent corrosion of the copper foil substrate of the negative electrode. They would then let the cell rest for a period before continuing the formation process.

◆ Cells are generally subjected to just a few charge-discharge cycles during formation. Many times, the cells are not fully discharged during formation, as SEI formation primarily takes place at relatively high SoC levels. Manufacturers experiment with a myriad of complex multi-cycle profiles with one cycle being different from the next, to minimize formation time while still assuring a high-performance SEI layer is formed.

◆ The charging and discharging may often be interlaced with different rest periods and fixed-voltage dwell periods, to optimize the SEI formation.

◆ As with cell wetting, formation may be performed at elevated temperatures to help accelerate SEI formation to reduce time. This contrasts with cell life cycling, where higher temperature may be used to accelerate cell wear-out mechanisms.

After cell assembly and filling, an illustrative example of a formation procedure may be as follows:

1. Allow cells to rest 1 hour for wetting.

2. Move cells to a pre-charge station or formation station. Apply a pre-charge at C/30 with 3V limit for 5 minutes.

3. Move cells to a temperature chamber for a 30 degree C soak for 8 hours for full wetting.

4. Move to a formation station:

◆ Apply a CC/CV charge of C/20 with a 4.2V limit. (About 1 day)

◆ Apply a CC discharge of C/20 with a 2.7V cutoff. (About 20 hours)

◆ Apply a C/10 charge to bring the cells to 80% SoC (About 8 hours)

5. Move cells to storage to rest for 1 day.

6. Move cells to a measure station, measure OCV.

7. Move cells to storage to rest for 7 days.

8. Move cells to a measure station, measure OCV and AC-IR.

9. Move cells to a formation station:

◆ Apply a CC/CV charge of C/5 with a 4.2V limit to bring to 100% SoC. (About 2 hours)

◆ Apply a CC discharge of C/5 with a 2.7V limit to bring to 0% SoC, to measure capacity (about 5 hours).

◆ Apply a CC charge of C/5 to bring to 30% SoC for shipping (about 1.5 hours).

10. Move cells to grading, marking, and shipping.

System Solutions for Cell Formation Cycling

Because formation is performed at a much lower C-rate and is done for 100% of the cells in manufacturing, this dictates the need for up to thousands of channels that can charge and discharge cells typically from a couple of amps up to tens of amps. High efficiency, regenerative capabilities, and space savings are all top priorities for the formation electronics used in manufacturing. To address the need, Keysight provides the BT2200 Charge-Discharge System with BT2204B module having 32 +/-6.25A channels, for performing cell formation in manufacturing. A BT2200 Charge-Discharge mainframe holds up to eight BT2204B modules, providing a total of 256 channels per mainframe. Channels can be paralleled for higher current. A BT200 Charge-Discharge System is energy efficient, regenerative, and space efficient. Multiple mainframes are then integrated into production systems to address the needs of the factory formation floor. The BT2200 Charge-Discharge System with BT2204B modules is shown in Figure 6.

Figure 6: BT2200 Charge-Discharge System with BT2204B modules

Every bit as important for a complete formation solution are the supporting software system and factory floor automation. As can be seen from the example formation process, there are many different types of steps and corresponding stations intermixed with the actual charging and discharging that takes place at the formation station. Lots of cells and associated data and measurement results need to be tracked at each step of the process. The handful of formation charging and discharging cycles performed, while essential, is a smaller part of the integrated formation solution that needs to be considered for the complete formation process. This is in sharp contrast to cell life cycle testing, where the charging and discharging is most of the process.

In addition to providing the BT2200 Charge-Discharge System, Keysight provides tailored software solutions and works with several partners around the world, to help customers implement their factory formation floors for their lithium-ion cell manufacturing facilities.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由Vicky转载自Keysight,原文标题为:Lithium-Ion Cell Charging and Discharging During Life Cycle Testing Versus Formation,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

Keysight(是德科技)数字万用表选型指南(详细版)

目录- Digital Multimeter Index Accessories Compatibility Chart Linking up your instruments to the PC BenchVue Software Handheld meter logger software GPIB and instrument

型号- U1191A,U1272A,34460A,34133A,34420A,34161A,U1210,10833F,10833G,34307A,10833A,10833B,10833C,10833D,U1232A,U1583B,3458A,U1163A,3446MEMU,U1175A,U1595A,3446SECU,U1180A,3446DIGU,U1192A,U8202A,34398A,U2741A,34172B,U1280 SERIES,34104A,U1176A,U1273A,U1164A,U1233A,34171B,3446ACCU,U1282A,U1173B,U1161A,U1173A,34470A,34131A,U1270,U1240B SERIES,U1240C SERIES,U1117A,E3600A-100,34103A,U1242C,U1185A,U1242B,U1169A,U1190 SERIES,U1271A,U1162A,3446LANU,U1230 SERIES,3446GPBU,U1280,11059A,34194A,34465A,34102A,34138A,U3606B,U1231A,U1174A,U1594A,U1186A,U1270 SERIES,U1240C,U1183A,U1240B,U5404A,U1171A,3445MEMU,82350A,11062A,U1250,34137A,U1252B,U1115A,U1212A,U1179A,U1273AX,Y1133A,82357B,U1172A,U1241C,E2308A,U1184A,U1281A,U1580A,34330A,34136A,U1241B,U1253B,M9181A,U1213A,U1168B,34191A,U1181A,U1193A,U1190,U8201A,34450A,11060A,U1230,U1210 SERIES,U1177A,M9182A,34190A,U1194A,U1251B,U1170A,U1182A,34134A,U1250 SERIES,34162A,34461A,3445GPBU,34308A,U1586B,M9183A,U1211A,U1178A

Keysight Launches Scienlab Battery Pack Test System with High Voltage Silicon Carbide Technology

Keysight Technologies, Inc. (NYSE: KEYS), a leading technology company that delivers advanced design and validation solutions to help accelerate innovation to connect and secure the world, announced the Scienlab SL1700A Series, the next generation battery pack test system for high voltage battery packs - up to 1500 V for automotive and industrial application.

原厂动态 发布时间 : 2021-10-15

Advancing the E-Mobility Ecosystem

型号- EP1150A,SL1800A,SL1700A,BT2200,SL1550A,PD1550A,RP7900,SL1040A,SL1041B,SL1010A,SL1001A,SL1200A,SL1047A,EV1003A,SL113XA,PV8900,EV2000,BT2152B,SL100XA

Consider Adding a Pre-Charge Step to Your Lithium-Ion Cell Manufacturing Process

Pre-charge can provide greater flexibility in the manufacturing process. The Keysight BT2200 Charge-Discharge System is well suited for both pre-charge and formation.

原厂动态 发布时间 : 2022-02-12

N1000A DCA-X Wide Bandwidth Oscilloscope Mainframe and Modules DATA SHEET

型号- N1000AU-PLK,N1077B-SMM,N1030A-65U,R1282A,N1060A-E33,N1076B-JSA,N1000A-GPI,N1060A-264,N1046A,N1046A-71F,861XX-SERIES,N1091BACA,N1091BMCA,N1077B-JSA,N1078A-216,N1077B-232,N1055A-34M,N1091APCA,N1000A-UK6,N1046A-84F,N1045A,N1000AU-PTB,N1046A-72F,N1045B,N1078A-EVA,N1032B-IRC,N1055A-34F,N1077A-SXT,N1055A-FS1,N1091CKCA,N109212CA,N1077B-264,N1032B-13U,N1010100A,N109310CA,D9010UDAA,N1032B-09U,N1060A-085,N10XX-SERIES,N1060A-JSA,86115D,N1078A-SXT,8348X,N1032B,N1030B-IRC,N1032A,N1094BS1A,N1046A-81F,N1000AU-LOJ,N1060A,N1030B-490,54XXX,N1076B-264,N1000A-LOJ,N1060A-A1X,N1077B-253,N1055A-32M,54754A,N1046A-14F,N1032A-112,N1077A-216,86116C,N1046A-82F,N1030A-280,N1055A,N1060A-A1F,N1078A-264,N1030A-560,N1055A-32F,N1040A-033,8348X-SERIES,N1060A-A1M,N1091BSCB,N1010300A,N1077B-EVA,N1000A-STD,N1000A-STB,N1045B-02M,N1030B-65U,N1046A-11F,54XXX-SERIES,N1060A-216,N1078A,86105D,N1030A,86105C,N1060AU-264,N1045B-02F,86117A,N1078A-253,N1030B,N1076B-EVA,N1055A-54M,N1000A DCA-X,N1032A-IRC,N1060A-232,54752A,N1000A-AX4,N1077B-SXT,N1046A-12F,N1077A-JSA,N1077A-232,N1078A-S50,N1077B,N1077A,86118A,N1055A-54F,N1000A-AXE,N109256CB,R1280A,N1076B-216,N1030A-IRC,N1077B-225,N1060A-EVA,N1000A-PTB,N1045B-04M,N109228CA,N1032A-13U,N1060AU-085,N1040A-060,N1095BSCA,N1030A-490,N1060A-CA1,N1060A-DC2,N1060A-CA2,N1076B,N1078A-232,N1000A,N1045B-04F,86107A,N1000A-PLK,N1040A,N1000A-AFP,N1091BJCA,N1030A-EC1,N1032A-09U,N1078A-JSA,N1055A-52M,N1032B-112,N1077B-216,N1055A-52F,N1046A-74F,N1010200A,N1060A-050,N1077A-SMS,86100D,86112A,N1030B-560,N1060AU-232,86108B,86108A,83484A,83496B,N1030B-280,N1078A-225,83496A,N1060A-PTB,N1076B-232

Investing in EV Battery Testing — Benefits for EV Battery Designers

型号- SL100XA SERIES,SL1700A SERIES,SL1700A,L113XA SERIES,L113XA,SL100XA

SL1132A Scienlab Battery Test Solution DATA SHEET

型号- EP1150A,SL1132A-A01,HS0002A-100,SL1132A-S11,SL1091A,SL1132A-S01,R9001A-201,SL1132A-S02,SL1132A-001,PS-XPS-100,R9001A-202,SL1132A,SL1000A,SL1050A-S07,SL1050A-S06

A Deeper Look at Lithium-Ion Cell Internal Resistance Measurements

This blog gives a deeper look at lithium-ion cell internal resistance measurements, then introduces one example of where Keysight provides EIS measurement capabilities in our Scienlab SL100xA series battery test systems for cell level testing.

新产品 发布时间 : 2022-06-13

电动交通:用于电动动力传动系统和HEV/EV生态系统的创新设计和测试解决方案

型号- SL106XA系列,SL101XA系列,BT2200,18650,RP7900,21700,PT-100,PT-1000,SL1040A,PT-500,SL1000A,EV1003A,SL106XA,SL1002A,PA2203,SL1004A,SL101XA,SL1006A,BT2192A,BT2152B,N8900APV,SD1000A,SL 1005A,RP7900系列,BT2191A,SL1001A,SL1003A,SL104XA系列,BT2155A,PA2203系列,SL104XA

SL1007A Cell Level –Up to ±600 A Scienlab Battery Test System DATA SHEET

型号- EP1150A,SL1079A-CM1,PS-XENG-100-SL,SL1079A-CM2,SL1007A,PS-XCOM-100-SL,PS-XPM-100-SL,PS-XINS-100-SL,SL1070A,SL1091A

86100D DCA Wide-Bandwidth Oscilloscope Family

型号- 86100D-AX4,N1094X-FS1,86116C-025,N1076B-JSA,N1076A-C0C,86105C-200,N1090A-1CN,N1090A-1CM,86100D-061,86100D-062,N1046A,86100D-AXE,N1046A-71F,N1090A-UK6,86100D-500,N1090A-140,N1078A-216,N1090A,N1092X-9FP,86105D-141,N1092X-SIM,N1078A-CR1,N1046A-84F,N1081/2/3/4A,N1092X-168,N1045A,N1021B,N1046A-72F,N1078A-EVA,N1092X-280,N1094X-500,N1077A-SXT,IRC,86108B-HBW,N1055A-FS1,N1076B-1CN,N1076B-1CM,86108B-PT3,86108B-PT2,N1094X-9FP,86105C-300,N2092B,N2092A,86100C/D,N2092D,N1076B-UK6,N1094X-050,86115D,86108B-PTB,N1046A-81F,N1076B-264,N1090A-160,86116C-041,N1078A-C0C,86105D-281,86100D-090,54754A,86100D-092,N1046A-14F,86116C,N1046A-82F,N1092X-1CN,N1055A,N1092X-1CM,N1094X-SIM,86105D-168,N1092X-UK6,86100D-UK6,N1078A,N1094X-C0C,N4694A-HFF,N1055A-54M,86100D-GPI,N1092X-IRC,86100D-GPN,N1046A-XXF,86105C-195,86100D-BFP,86105C-193,N1077A-JSA,N1077A-232,N1078A-S50,SIM,N1077A,N1094X-300,N1055A-54F,N1092X-TFP,86105C-190,N1045A-LOJ,N1045A-XXM,86108B-400,N1077A-UK6,86100A/B,N1077A-1CM,N1077A-1CN,N1027A-X4X,N1076B,N1076A,N1078A-232,86100D-SIM,86105C-180,N1045A-XXF,N1092X-STB,N1078A-JSA,N1055A-52M,86100D-PTB,86100D-9FP,N1055A-52F,N1046A-74F,N1094X-LOJ,N1090A-IRC,86100D,86100D-AFP,86100C,N1076B-EQ9,86112A,86105C-170,N1076B-EQ6,N1076B-EQ3,N1094X-401,N1045A-02M,N1077A-CR1,86108B-300,N1094X-STB,N1092X-PLK,N1092X-EFP,86105C-160,N1045A-02F,N1092X-200,86118A-H11,86100DU-401,86108B-CA3,86100DU-400,86108B-CA2,86108B-DC3,N1055A-34M,86108B-DC2,N1092X-206,N1092X-201,86108B-LBW,N1076A-UK6,86105C-150,N1077A-C0C,N1076A-1CN,86100D-STR,N1076A-1CM,N1085A,N1055A-34F,86118A-H01,N1090A-C0C,86100D-TFP,N1092X-C0C,86116C-201,86105C-140,N1094X-PLK,N1094X-EFP,N1078A-SXT,N1090A-EEC,N1045A-04F,N1092X-30A,N1045A-04M,N1078A-1CM,N1090A-204,N1055A-32M,N1078A-1CN,N1090A-200,N1078A-UK6,N1055A-5XM,N1027A,N1092X-300,N1077A-216,300,N1094X-200,86105C-130,N1078A-264,N1094X-201,86105D-200,N1055A-32F,N1076A-JSA,N1076B-2P2,N1090A-PLK,N1076B-2P1,N1076B-C0C,86108B-216,N1076B-2P3,N1055A-5XF,86105D-206,86105C-IRC,N1076B-2P8,N1076B-CR1,N1046A-11F,N1076A-232,N1027A-45A,N1094X-030,N1014A,86105D,86105C,86105C-120,86100D-300,86117A,N1094B,N1094A,N1090A-180,N1076B-EVA,86108B-232,N1094X-UK6,N4694A-HMF,86100D-ETR,86118A-103,N1092X-401,86118A-102,86118A-101,N1046A-12F,200,201,N1092X-LOJ,86105C-110,86118A,86105D-100,86108B-JSA,N4694A-HMM,N1076B-216,N1076A-216,N1078A-EQ3,N1024B,N1012A,N1078A-EQ6,N1092X-FS1,N1078A-EQ9,86105C-100,86100D-200,86100D-201,86108B-A23,N1092A,86100D-202,86107A,N1092E,N1092D,N1092C,N1094X-1CN,N1092B,N1094X-1CM,N1094X-TFP,N1077A-SMS,N1092X-500,86118A-201,86105D-IRC,86100D-EFP,86108B,86108A,N1055A-3XM,83496B,N1076A-CR1,N1055A-3XF,N1076B-232

SL1000A Scienlab Battery Test System Pack Level 360 kW

型号- SL1000A-D02,SL1000A-D03,SL1000A-D00,SL1000A-D01,HS0002A-100,SL1000A-001,SL1000A-402,R9001A-201,SL1000A-501,SL1000A-403,SL1000A-502,SL1079A-BP1 BPT,PS-XPS-100,SL1000A-401,R9001A-202,SL1000A-506,SL1000A-404,SL1000A-701,SL1000A-503,SL1000A,SL1000A-702,SL1000A-504,SL1000A-507,SL1079A-BP2 BPT

SL1004A SL1005A Cell Sample Level Scienlab Battery Test System DATA SHEET

型号- R9001A-201,PS-XPS-100,R9001A-202,SL1005A-701,SL1005A,SL1005A-702,SL1004A,SL1004A-P01,HS0002A-100

现货市场

服务

可定制电感最大电流100A,尺寸最小7 x 7 x 3.0mm到最大35 x 34 x 15.5 mm,工作频率100KHZ ~ 2MHZ,感值范围:0.15 ~ 100uh;支持大功率电感,扁平线电感,大电流电感,高频电感,汽车电感器,车规电感,一体成型电感等定制。

最小起订量: 5000 提交需求>

登录 | 立即注册

提交评论