Overcome the Challenges of Using Sub-Milliohm SMD Chip Resistors--part 1

In this article, you’ll learn:

How to treat sub-milliohm chips as a separate class of component.

Strategies to avoid pitfalls during component selection and PCB layout design.

Uncover opportunities to quantify and minimize error and variation at every stage.

The simplest and most cost-effective way of converting a measured current to a voltage signal is to use a low-ohmic-value current-sense resistor. The upswing in products containing batteries, motors, or actuators that call for current monitoring or control has led to huge market growth for current-sense chip resistors with values below one ohm over the last two decades.

More recently, though, driven by power-efficiency demands and enabled by low-noise voltage-sense amplifiers, the value range has extended downward from milliohms to hundreds of microhms. Such low ohmic values present challenges to the user at many stages in their design and manufacturing processes.

This two-part series considers the nature of these challenges and suggests strategies to overcome them at various stages, including component selection, PCB layout design, verification of the ohmic value of unmounted components, and critical assembly processes. Each stage features potential pitfalls but also opportunities to quantify and minimize error and variation.

Although sub-milliohm chip resistors are still just chip resistors, ideal design strategies treat them as a separate class of component, embracing considerations and techniques that enable their successful use.

Component Selection

Termination Styles

When restricting the temperature sensitivity of a resistor-based current-sensing circuit, it’s well-known that the total terminal resistance from copper, common to both the current-carrying circuit and the voltage-sense circuit, must be restricted as well. That’s because this element of the total measured resistance has a temperature coefficient of resistance (TCR) of +3900 ppm/°C, which contributes to the total TCR in proportion to the resistance ratio.

For example, a total terminal resistance of 100 µΩ, i.e., 50 µΩ at each end, for a 1-mΩ resistor contributes 100 µΩ/1000 µΩ × 3900 ppm/°C = 390 ppm/°C to the TCR. This contrasts with the TCR of the resistance element itself, which is typically better than ±30 ppm/°C. Such separation between the current-carrying and voltage-sense circuits is referred to as a Kelvin connection, an issue that becomes clearly more important as the nominal ohmic value is reduced.

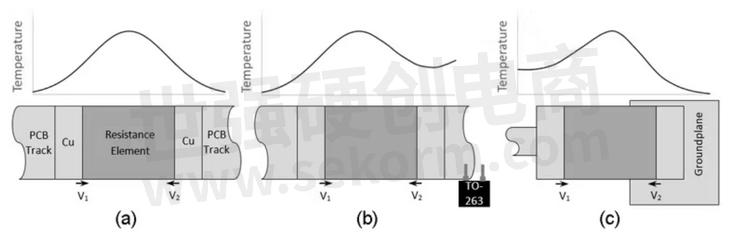

There’s a spectrum of termination styles to address this problem. The most common is the Kelvin connectable two-terminal resistor (Fig. 1a). While this is often the lowest-cost option, it places the onus on the PCB designer to realize a Kelvin connection in the PCB track layout (later we’ll look in detail at how this may best be achieved). Such a component must have a low termination resistance since the Kelvin connection strategy necessarily ends at the surface of the termination.

(1) A Kelvin connection, or separation between the current-carrying and voltage-sense circuit, becomes increasingly important as nominal ohmic value is reduced. The most common option is a Kelvin connectable two-terminal style. (a) There’s also an intermediate option, a semi-Kelvin four-terminal style (b), and a true Kelvin four-terminal style.

Figure 1b shows an intermediate component type where four solder terminals are provided, but the separation of circuits doesn’t extend all the way into the resistor element. Figure 1c shows a true Kelvin format where there’s no current-carrying termination whatsoever within the voltage-sense circuit. The latter two types offer error-proof PCB layout design and the lowest achievable magnitude of TCR, but generally it comes at a higher cost.

Element Materials

Low-value resistors can be made from both thick- and thin-film materials, but the lowest values available in these technologies are in the multiple-milliohm range. Both types are relatively susceptible to damage from high-current surges. In the case of thick-film technology, the lowest values are associated with high TCR values of several hundred ppm/°C and thus are suited only to low precision use.

For these reasons, most current-sense chip resistors are based on a bulk metal element. This may be either a foil supported on a substrate or a self-supporting metal element. Though the former option allows for the use of thin metal layers to achieve higher values, the latter lends itself to sub-milliohm values.

A range of alloys, each with differing resistivities, are selected by device designers to provide the required ohmic value within the dimensional constraints of the product. From the point of view of the user, the material choice is often unimportant, but there are two exceptions: one is the control of thermally generated errors, and the other is application for non-dc circuits.

A copper-terminated metal-element chip resistor contains at least two boundaries between dissimilar metals. These act as thermocouples and generate a thermoelectric voltage in the presence of a temperature gradient. Furthermore, they’re connected in series, and because of the component’s symmetry, they’re of opposite polarity when the resistor element itself is the main heat source. As a result, if the temperature distribution across the chip resistor is symmetrical, any generated thermoelectric voltages will be cancelled out.

Figure 2a illustrates this balanced state in which the thermal voltages V1 and V2 are equal. Figures 2b and 2c show an example of imbalance due to the external influence of a heat source and a heatsink, respectively. This would lead to a finite value of V1 − V2, which would sum with the measured sense voltage and create a source of error.

(2) Shown is a balanced state in which the thermal voltages V1 and V2 are equal (a), and examples of imbalance due to the external influence of a heat source (b) and a heatsink (c).

In many designs, it’s simply not possible to guarantee thermal symmetry under all operating conditions. In such a case, a chosen part should employ a resistance alloy with a low thermoelectric voltage against copper. These alloys contain manganese in a copper nickel alloy in which the proportion of copper exceeds 80%. The thermoelectric voltages generated across a junction with copper can be as low as 3 µV/°C, which is an order of magnitude lower than for a copper nickel alloy.

The second application-specific driver for resistance alloy selection is the need to avoid iron-bearing alloys in circuits where ac or rapid step changes in dc need to be tracked accurately, as this is not possible with ferromagnetic alloys.

Thermal Design Format

An inherent problem with resistive current sensing is heat, generated at a rate proportional to the square of the current. This may need to be restricted for one of two reasons. First, the design must reduce the effect of temperature increase on the linearity of the component, which can stem from TCR or from thermoelectric voltage errors. Second, it’s necessary to avoid overheating the resistance alloy, which can lead to irreversible ohmic-value change.

This consideration calls for careful thermal design of the assembly. It begins at the component selection stage in response to the basic decision as to where the heat generated should be dissipated; for example, in the air or in the copper PCB tracks. The answer to this depends on the overall thermal-management strategy.

A well-ventilated assembly—with either a high thermal loading already on the PCB or with temperature-sensitive components—would benefit from a resistor that dissipates heat into the air. Conversely, a PCB that’s heatsinked, or has no excess of heat generation and no temperature-sensitive parts, can employ a resistor which dissipates heat mainly to the PCB tracks.

An example of a primarily air-dissipating open-air format is shown in Figure 3a. This can sustain a temperature rise of the hotspot above the solder joints well in excess of 100°C. Its flexible nature makes it virtually immune to temperature cycling or board flex stresses on the solder joints. An example of the primarily PCB dissipating flat-chip format is shown in Figure 3b. The design benefits from its low profile and is generally the lower-cost option.

(3) Illustrated are an open-air format metal-alloy resistor (a), and a flat-chip format metal-alloy resistor (b).

Most Common Type

After considering the many options of termination style, element

material, and thermal design format, the most common type of

sub-milliohm resistor is a two-terminal metal-element chip resistor.

This resistor type will be considered hereafter in this article.

PCB Layout Design

Near-Kelvin Connection

The PCB layout design around a very-low-value resistor is critical to its performance. The most important aspect of this design is the fact that four rather than two tracks must be provided to form a Kelvin connection, even where the component itself has only two terminals.

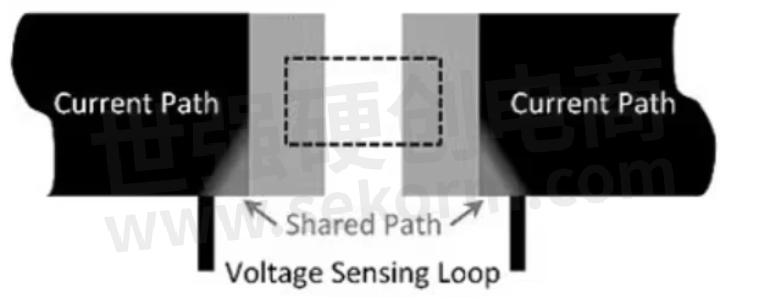

The aim is to minimize the conductive path shared between the current path and the voltage-sensing loop (Fig. 4), which would increase both the effective ohmic value and the TCR of the mounted part. This may be achieved by connecting the voltage-sense tracks to the inner edges of the solder pads (Fig. 5).

(4) Minimizing the conductive path shared between the current path

and the voltage-sensing loop increases both the effective ohmic value

and the TCR of the mounted part.

(5) To achieve what’s illustrated in Figure 4, connect the voltage-sense tracks to the inner edges of the solder pads.

Designers also can take this a step further and split the voltage-sense pads from the current-path pads, so that the solder joints themselves are removed from the shared path, too (Fig. 6). By using this method, it’s possible to approach the accuracy obtained from a true four-terminal resistor.

(6) By splitting the voltage-sense pads from the current-path pads, the solder joints themselves also are removed from the shared path.

Furthermore, a study by Analog Devices based on TT Electronics’ ULR3 0.5-mΩ mounting-pad options has shown that a mounted value tolerance close to 1% may be achieved on a 1% tolerance component. This indicates low additional error due to mounting effects, using a centralized, isolated sense-pad design similar to that of Figure 4c.

Minimization of Sense-Loop Area

A source of error involving high currents that are ac or changing dc is due to the voltage-sensing loop linking with changing magnetic fields. This can induce a noise signal superimposed on the desired voltage sense signal.

To reduce the noise, the loop area contained within the sense resistor, the two voltage-sense tracks, and the sense circuit input should be minimized. This means keeping the sense circuitry as close as possible to the sense resistor and running the voltage-sense tracks close to each other.

A good way to keep these tracks very close is to superimpose them in different PCB layers. Where long track runs are unavoidable, it’s also possible to use periodic vias to cross over the tracks into alternate layers. On a PCB, this replicates the effect of a twisted-pair cable, which, by means of cancellation of induced voltages, allows the circuit to withstand the effect of any changing magnetic fields that have small variations across the spatial periodicity of the twisting.

Connecting Multiple Resistors in Parallel

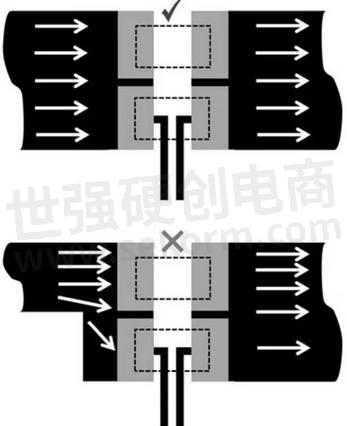

Sometimes, designers are forced to use more than one current-sense resistor connected in parallel, either to meet a high power or surge rating, or to achieve an ohmic value lower than the minimum available. This is problematic but possible. Resistors may be connected in parallel with voltage-sense connections made to just one of the resistors, provided the track layout ensures equal distribution of current between all resistors.

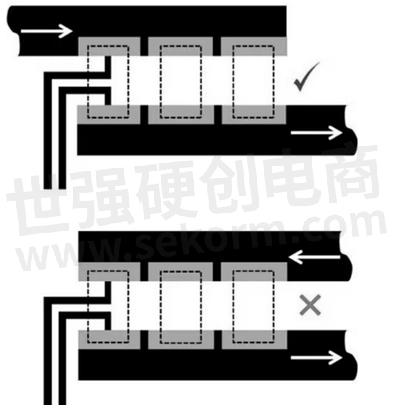

For example, the position in the current trace where the resistors are placed should be well clear of bends or constrictions that could affect the distribution of current density (Fig. 7). The goal is to ensure that the total track resistance in series with each resistor should be the same (Fig. 8), so that the sensed resistor carries the required fraction of the total current.

(7) Parallel connection requires equal distribution of current.

(8) The total series track resistance should match for all resistors.

Moreover, this ensures that the proportion of the total current carried by the sensed resistor doesn’t vary with temperature. This would otherwise be the case with unequal series track resistances due to the high TCR of the copper PCB tracks.

Design for Heatsinking

A flat-chip resistor dissipates more than 80% of its heat by conduction into PCB tracks, making it important to provide sufficient copper area to act as a heatsink. Copper area is, for this purpose, defined as the total area directly surrounding the solder pads, including the first two squares of connected tracks. Figure 9 indicates the general relationship between effective power rating and PCB copper area.

(9) The general relationship between effective power rating and PCB copper area can be divided into three distinct regions.

In region (A), there’s relatively low thermal conduction through copper connected to the pads, and conduction by substrate and convection to air predominate. In region (B), the copper connected to the pads acts as a heatsink to raise the effective power rating. In region (C), further increase in copper area gives diminishing returns, as the internal thermal impedance of the chip restricts the rating.

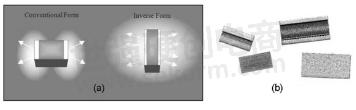

This limiting factor of the internal thermal impedance can be lowered significantly by changing the resistor’s orientation. If the terminations are formed on the longer edges of the chip rather than the shorter edges, the solder joint width is approximately doubled and the maximum distance from film center to termination is approximately halved (Fig. 10a). TT Electronics' ULR2N and ULR3N (Fig. 10b) are examples of products that use this enhanced cooling method.

(10) The limiting factor of the internal thermal impedance may be lowered significantly by changing the orientation of the resistor. If the terminations are formed on the longer edges of the chip rather than the shorter edges, the solder joint width is approximately doubled and the maximum distance from film center to termination is approximately halved (a). TT Electronics ULR2N and ULR3N are examples of products that make use of this enhanced cooling method (b).

The resistor datasheet should contain information on the mounting conditions used to obtain the rated power. This indicates the minimum copper area that should be provided by the designer.

Summary

The growing use of sub-milliohm chip resistors for current sensing creates a spectrum of challenges for the designer and the process engineer. The component format should first be selected to support the chosen thermal-management approach, with metal-element flat-chip resistors having two terminals being the most cost-effective solution. It’s then essential to design the PCB tracks and pads to meet the needs of the Kelvin connection, heat dissipation, and avoidance of induced noise.

Part 2 of this series will address additional stages, including verification of the ohmic value of unmounted components and critical assembly processes.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由咪猫转载自TT Electronics,原文标题为:Overcome the Challenges of Using Sub-Milliohm SMD Chip Resistors (Part 1),本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Overcome the Challenges of Using Sub-Milliohm SMD Chip Resistors--part 2

For TT Electronics’ LRMAP2512-R0005FT4, 500 µΩ ±1% in a 2512 footprint, the value of A is approximately 8.32 mm2. And for SAC305 alloy solder, the value of ρ is 1.4 x 10-7 Ωm.

【经验】简述TT Electronics CWS和EBW系列固定电阻器的电气特性和焊接示例

TT Electronics的CWS和EBW系列固定电阻器在传统或电子束焊接结构中具有广泛的高电流分流特性。由于CWS和EBW系列固定电阻器的焊接部分是由高纯度铜的接头制成,它的安装方式可以根据定制配置的要求冲压成端子或母线。开尔文检测连接片提供校准的电压输出,可以根据客户要求预先安装终端引线。它主要应用于电表、电机驱动、电池充电、汽车、能量监测器、发电机和UPS等。

【经验】TT ELECTRONICS 光电开关的设计原则及注意事项

OPB系列光学传感器是TT Electronics推出的一款开槽和反射开关,该款光开关在非接触式物体感应、装配线自动化、机械自动化等领域有着十分广泛的应用。本文将介绍OPB系列开关的设计原则及注意事项:静电放电灵敏度(ESD),焊接,清洁和去渗,化学暴露,安装和湿度敏感性。

【成功案例】TT Electronics非接触式流体传感器成功应用于气泡检测

TT Electronics的非接触式流体传感器具有免受环境照明影响的优点,具有电路板安装和电线安装两种方式,兼容多种管径尺寸,能够实现对液体的非接触式测量。本文应用于医疗器械体外诊断行业,通过选择合适尺寸的TT Electronics的非接触式流体传感器OPB350W125Z,设计恒流源驱动等硬件电路,实现稳定的气泡检测功能。

TT Electronics激光二极管选型表

提供TT Electronics激光二极管选型,具有高稳定性,多种封装选择,波长850nm,正向电压2.2V,正向电流7mA。

|

产品型号

|

品类

|

Package

|

Wavelength(nm)

|

Forward Voltage(V)

|

IF(mA)

|

Total Power Out(mW)

|

|

OPR2800V

|

Infrared Light Emitting VCSEL

|

4-SMD

|

850nm

|

2.2V

|

7mA

|

1.5mW

|

选型表 - TT Electronics 立即选型

TT Electronics传感器选型表

提供TT Electronics开槽开关,流体传感器,霍尔效应传感器,高可靠性传感器,光发射器,微型SMD反射式传感器以及晶体管等各种传感器选型,产品类型有模拟、数字和逻辑输出,工作温度范围大,紧公差,小尺寸高,可用于精密设备,封装方式有紧凑型SMD封装、微型封装、表面贴装等。

|

产品型号

|

品类

|

Operating Temperature(℃)

|

Operating DC Supply Voltage(V)

|

Supply Current(mA)

|

Slot Width(mm)

|

Wavelength(nm)

|

|

OCB100AZ

|

Automatic Calibration Circuitry

|

-40℃~85℃

|

4.5V~5.5V

|

35mA

|

0.320''~0.474''(8.13mm~12.04mm)

|

935nm

|

选型表 - TT Electronics 立即选型

TT Electronics光电二极管选型表

提供TT Electronics PIN硅光电二极管,SMD光电二极管,表面贴装光电二极管选型,多种温度以及封装选择,峰值响应波长850nm/890nm,光视角18°~128°

|

产品型号

|

品类

|

Package

|

Operating Temperature(℃)

|

Peak Response Wavelength(nm)

|

Maximum Reverse Voltage(V)

|

Dark Current(nA、pA、uA)

|

Viewing Angle(°)

|

Output Rise Time(ns、us)

|

|

OP900SL

|

PN Silicon Photodiode

|

T-1(3mm)

|

-65℃~125℃

|

890nm

|

50V

|

10nA

|

35°

|

100ns

|

选型表 - TT Electronics 立即选型

TT Electronics光纤选型表

提供TT Electronics光纤发射器,光纤接收器,光纤探测器选型,波长涵盖840nm/850nm/860nm,温度高达125℃。

|

产品型号

|

品类

|

Wavelength(nm)

|

Operating Temperature(℃)

|

Continuous Forward Current(mA)

|

Maximum Reverse Voltage(V)

|

Forward Voltage(V)

|

|

OPF1414

|

High Speed Fiber Optic Transmitter

|

840nm

|

-40℃~85℃

|

100mA

|

1.8V

|

2.09V

|

选型表 - TT Electronics 立即选型

TT Electronics光电LED传感器选型表

提供TT Electronics红外发射二极管,可见LED,光电传感器,高可靠性GaAIA红外发射二极管,塑料红外线发射二极管选型,多种温度以及封装选择,LED峰值波长高达940nm,光束角范围4.5°~150°

|

产品型号

|

品类

|

Package

|

Continuous Forward Current(mA)

|

LED Peak Wavelength(nm)

|

Forward Voltage(V)

|

Total Beam Angle(°)

|

Operating Temperature(℃)

|

EE(APT)(Min.)(mW/cm²)

|

|

OP123

|

Hermetic Infrared Emitting Diode

|

Pill

|

100mA

|

935nm

|

1.5V

|

24°

|

-65℃~125℃

|

0.4mW/cm²@50mA

|

选型表 - TT Electronics 立即选型

TT Electronics光隔离器选型表

提供TT Electronics轴向光纤隔离器,高压隔离器,光耦合隔离器,RAD功能光隔离器,表面贴装光耦合隔离器选型,多种温度以及封装选择,隔离电压高达50000V。

|

产品型号

|

品类

|

Package

|

Isolation Voltage(V)

|

Forward Voltage(V)

|

Forward DC Current(mA)

|

Collector Saturation Voltage(V)

|

Collector-Emitter Breakdown Voltage(V)

|

On-State Collector Current(mA)

|

CTR Min(%)

|

CTR Max(%)

|

Operating Temperature(℃)

|

|

3C91C

|

Hi-Reliability Optically Coupled Isolator

|

TO-72

|

1000V

|

1.2V

|

50mA

|

0.4V

|

50V

|

30mA

|

30%@10mA

|

200%@10mA

|

-55℃~125℃

|

选型表 - TT Electronics 立即选型

TT Electronics光电晶体管选型表

提供NPN硅光电晶体管,高可靠性NPN硅光电晶体管选型,多种温度以及封装选择,峰值波长890nm/930nm/935nm,功率高达250mW。

|

产品型号

|

品类

|

Package

|

Collector-Emitter Voltage(V)

|

On-State Collector Current(mA)

|

Collector-Dark Current(nA、µA)

|

Peak Wavelength(nm)

|

Power Dissipation(mW)

|

Operating Temperature(℃)

|

|

OP505A

|

NPN Silicon Phototransistor

|

T-1

|

30V

|

5.95mA

|

100nA

|

935nm

|

100mW

|

-40℃~100℃

|

选型表 - TT Electronics 立即选型

TT Electronics Welwyn电阻选型表

TT Electronics Welwyn电阻选型,包括精密电阻、金属合金功率电阻、电流检测电阻、MELF电阻、线绕高浪涌电阻、通用表面安装电阻等,提供多参数选择,最小尺寸达0204,最小电阻值达0.2mΩ,公差范围±0.01%~±10%

|

产品型号

|

品类

|

Size

|

Value(mΩ、Ω)

|

Tolerance(%)

|

|

HR0603F-100MJI

|

High Value Surface Mounted Resistors

|

0603

|

100MΩ

|

±5%

|

选型表 - TT Electronics 立即选型

【选型】TT Electronics(TT)ABCIRP模块化卡口锁连接器选型指南

目录- Company Profile and Modular Bayonet Lock Connector Introduction Technical Information and Part Number Explanation Insulators Seal Grommet Crimp Contacts Receptacle/Plug Connector Locking Backnut Adapter/Extender Cable Clamp and Bushing Gasket and Nut Plates Receptacle Mounting Detail Metal Protective Caps and Braid Strap Connector Supplementary Tooling Connector Safety Information

型号- ABCIRPSE22FS,P80 16 GET,ABCIRP12/14KPKP3,ABB-24-#GA-#M32,ABCIRP40-A60GSS,CMSP3057C**M32,ABBP8/16KSKP80,ABCIRP16/14KPKP3,ABCIRP40-A60GSL,ABCIRP16/22KLKP3,ABCIRP24-10PFS,ABCIRP28-21GSL,P8028GAT,ABBE**XPCAK,ABBP100KPKP80,ABCIRP12/40KLKP3,ABCIRP12/10KLKP3,ABCIRP18-19S,ABCIRP20-15GPL,ABCIRPPSE06T,ABCIRP03T,ABBMBS035015,ABCIRP40-A60S,ABCIRP24-10S,FT8,ABBP**/**KPKP80,ABCIRP20-15GPS,ABCIRP22-14PFS,ABCIRP32-A13GSL,ABBE**XPCA,ABCIRP22XR,ABCIRP36-A22S,ABCIRP32-A13S,ABCIRP12/18KLKP3,68-016-01,ABCIRP32-A13GSS,P80 8 ETA,ABCIRP18-19GPL,ABBP100KSKP80,ABCIRP22-14GPS,ABCIRP22-14GPL,ABCIRP32-A13GPS,ABCIRP36-A22GPS,ABCIRP12KLKP3,ABCIRP28XR,ABCIRP20-15S,ABCIRP24XR,SB ** RPGS,ABCIRP12/20KPKP3,ABCIRP36IC,ABCIRP36-A22GPL,P80 16 ITL,ABCIRP18-19PFS,ABB608109,ABCIRP20IC,ABCIRP28-21PFS,ABCIRP40-A35PFS,ABCIRP40-A60PFS,ABBD51,ABBMBS050015,ABCIRP**/**KLKP3,ABCIRP16/20KPKP3,ABB12KFPF80,ABBPL0550A1130,ABBP8/12KPKP80,ABCIRP16/18KLKP3,P80 16 ETA,ABCIRP32-A13GPL,ABB600061,6M3800644,ABCIRP28-21GSS,ABCIRP28IC,ABCIRP,6M3800645,ABBP100/60KPKP80,ABB-20-#GA-#M32,ABCIRP24IC,6M3800646,ABCIRP09T,ABBMKM1050,ABB600052,67-012-01,SBMSH554,ABB600057,ABCIRP24-10GPL,ABB600058,AB-CIRP03LBN2214GPSPFS****VON,WA27F,ABCIRPSE24FS,ABCIRP22-14S,ABBP100/60KSKP80,ABCIRP16/22KPKP3,P80 12 ITL,ABCIRPSE20FS,ABCIRP40-A35GSS,6M3800730,6M3800731,ABCIRPSE28FS,ABCIRP24-10GPS,ABCIRP18IC,ABB-18-#GA-#M32,ABMRP0925,ABB8KFPF80,ABBTH592,ABCIRP32XR,P80 12 ETA,ABCIRP18-19GSL,ABCIRP40IC,ABCIRP18-19GSS,P8018GAT,ABCIRP40-A35GSL,ABCIRP12/40KPKP3,ABBP**/**KSKP80,ABB16KFP,ABCIRP20-15PFS,ABCIRPSE36FS,ABCIRP16/18KPKP3,ABCIRPSE32FS,ABCIRP40-A60GPS,ABCIRP12/10KPKP3,ABCIRP36-A22PFS,ABCIRP40-A60GPL,SB ** FPGS,ABCIRP36XR,ABCIRP28-21S,ABCIRP20XR,ABCIRP32IC,ABBMBS025015,68-012-01,ABCIRP12/18KPKP3,SBMSH554**,ABB601200,ABCIRP8/40KPKP3,ABBP8KSKP80,SB ** FPG,ABCIRP20-15GSL,ABCIRPSE06T,ABCIRP18-19GPS,ABCIRP28-21GPS,ABCIRPSE40FS,ABCIRP20-15GSS,CMSP3057A,SB ** RPG,ABCIRP12/20KLKP3,CMSP3057C,ABCIRP28-21GPL,ABBP8KPKP80,CMSP3057A**M32,ABCIRP24-10GSL,ABCIRP12KPKP3,ABCIRP22IC,ABCIRP16/20KLKP3,ABBMBS020010,P80 12 GET,HT250-3,ABCIRP12/16KPKP3,ABCIRP16KPKP3,TH592,ABBP8/16KPKP80,ABCIRP22-14GSS,D51,ABCIRP36-A22GSS,ABBFT8,ABCIRP40-A35GPS,ABCIRP22-14GSL,ABCIRP**/**KPKP3,ABCIRP24-10GSS,ABWA27F,ABCIRP36-A22GSL,ABCIRP18XR,ABCIRPSE18FS,ABB**EPCA,ABB**EPCAK M32,ABCIRP40-A35S,ABBP8/40KSKP80,ABBP8/12KSKP80,ABCIRP32-A13PFS,ABB-32-#GA-#M32,ABCIRP40XR,ABCIRP12/14KLKP3,ABCIRP40-A35GPL,67-016-01,ABB600090

TT Electronics Opens New Manufacturing Facility in Mexico

TT Electronics proudly announces the grand opening of its newest manufacturing facility located in Mexicali, Mexico. This strategic expansion marks a significant milestone in the company‘s continued growth and commitment to serving customers worldwide.

电子商城

品牌:TT Electronics

品类:High Power MELF Resistors

价格:¥0.5375

现货: 9,000

品牌:TT Electronics

品类:High Power MELF Resistors

价格:¥0.5375

现货: 9,000

品牌:TT Electronics

品类:High Power MELF Resistors

价格:¥0.3305

现货: 9,000

品牌:TT Electronics

品类:High Power MELF Resistors

价格:¥0.3305

现货: 9,000

品牌:TT Electronics

品类:High Power MELF Resistors

价格:¥0.5375

现货: 9,000

品牌:TT Electronics

品类:High Power MELF Resistors

价格:¥0.3305

现货: 9,000

品牌:TT Electronics

品类:High Power MELF Resistors

价格:¥0.5375

现货: 9,000

品牌:TT Electronics

品类:High Power MELF Resistors

价格:¥0.5375

现货: 9,000

品牌:TT Electronics

品类:High Power MELF Resistors

价格:¥0.5375

现货: 9,000

品牌:TT Electronics

品类:High Power MELF Resistors

价格:¥0.5375

现货: 9,000

现货市场

品牌:TT Electronics

品类:Low Resistance Metal Alloy Resistors

价格:¥0.7268

现货:160,000

品牌:TT Electronics

品类:Low Resistance Metal Alloy Resistors

价格:¥0.7268

现货:107,900

品牌:TT Electronics

品类:Wirewound Power Radial Terminal Resistors

价格:¥29.9250

现货:22,389

品牌:TT Electronics

品类:Wirewound Power Radial Terminal Resistors

价格:¥7.1649

现货:814

品牌:TT Electronics

品类:Wirewound Power Radial Terminal Resistors

价格:¥16.0569

现货:42

品牌:TT Electronics

品类:Wirewound Power Radial Terminal Resistors

价格:¥17.9550

现货:7

服务

可贴片PCB尺寸50*50mm-580*610mm;PCB厚度0.3-8mm;贴装精度CHIP元件+0.03,BGA Pitch 大于0.25mm;元件尺寸0201-74*74BGA;元件高度:30mm。

最小起订量: 1 提交需求>

可定制LAMP LED、 CHIP LED、 PLCC LED、 汽车用车规级LED、COB LED的尺寸/电压/电流等参数,电压1.5-37V,电流5-150mA,波长470-940nm。

最小起订量: 30000 提交需求>

登录 | 立即注册

提交评论