UnitedSiC‘s Gen 4 SiC FET Boasts An On-resistance per Unit Area 2~3 Times Better than for The Other SiC MOSFETs

Through a combination of different attributes, Silicon Carbide (SiC) has established itself as the premier semiconductor technology for the electric vehicle (EV) sector – with devices outperforming those based on conventional Silicon (Si). Its advantages include elevated voltage ratings, superior power conversion efficiency levels, and the ability to deal with heightened temperatures.

On-board chargers (OBCs), DC-DC converters, and traction inverters all benefit from SiC, with the ongoing process and architectural enhancements certain to increase its already considerable appeal. Such enhancements will extend the reach of this wide bandgap material's operational parameters and further mitigate the power losses experienced. At the same time, the economies of scale that larger production volumes allow will mean that it can hit more attractive price points.

Use of SiC in an EV context

Covered very briefly, here are some of the dynamics now influencing the EV sector. Each should be given due consideration.

1. The need for more rapid charge cycles – Because of this, EV engineering teams are looking to deploy OBCs that can work at higher voltages. SiC devices have been introduced that can accommodate these voltages. The 650V voltage-rated devices that are generally available are not always sufficient, and higher voltage rating semiconductors are needed to accommodate higher battery voltages. At the same time, the cost premiums relating to the use of devices with 900V or 1200V ratings will be hard to justify. Solutions that offer a certain degree of voltage elevation, but without pushing up the expense involved too greatly would be the best fit here.

2. The need to support higher operating frequencies – To switch faster, switching losses must be minimized. Otherwise, efficiency levels will be reduced, and more space will be needed for thermal management mechanisms (which will add to the overall size, weight, and cost, and is, therefore, something that needs to be avoided).

3. Bringing about a significant reduction in the operating losses – By doing this, the range that can be covered by an EV before recharging is necessary will be extended. It is equally valid to use this for the downsizing of EV batteries. Both are interesting prospects for vehicle manufacturers.

4. Cost considerations – Another important factor that will accelerate the migration from internal combustion engine vehicles to EVs is the ability of manufacturers to reduce the investment that consumers must make when purchasing these vehicles. If this is to be done, then the costs relating to the various component parts must be curbed (the inverter element being a particularly large proportion of the overall expense).

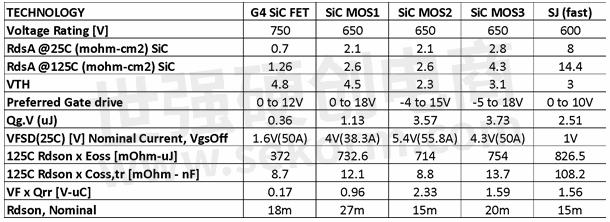

Recognizing the nature of these dynamics, and the urgency with which a viable solution needed to be found proved pivotal in driving UnitedSiC to develop its fourth generation (Gen 4) SiC technology. The specification improvements that have been made over the SiC technologies offered by other vendors are illustrated in Table 1. Here the new 750V-rated UJ4C075018K4S SiC FET is compared with three alternative 650V SiC MOSFETs, plus a Si-based super-junction FET device. Even though the Gen 4 SiC FET has a markedly higher voltage rating, the on-resistance per unit area of this technology is two to three times better than for the other SiC MOSFETs and more than an order of magnitude better than the Si FET option. This means that comparable performance can be achieved in much smaller format packages.

Table 1: UnitedSiC Gen 4 SiC FETs versus Si Superjunction and SiC competitive devices

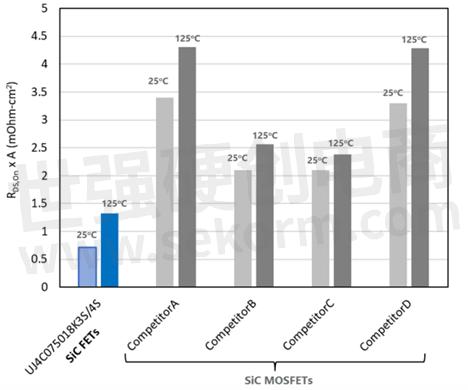

The reason for the ultra-low on-resistance per unit area is the high-density trench SiC JFET structure incorporated into the SiC FET. This is co-packaged with a low voltage Si MOSFET. The reduced area of the SiC JFET means that an extraordinarily low on-resistance will be exhibited for a given chip size (Figure 1). Conversely, a smaller FET with lower capacitance could be utilized while keeping down at an acceptable on-resistance.

Figure 1: On-resistance per unit area comparison between 750V-rated UnitedSiC Gen 4 SiC FETs and rival 650V-rated FETs

To reduce the electrical and thermal resistance values (and keep the associated losses in check) the SiC substrate has been thinned considerably. To maintain structural integrity, the thinned substrate is attached to a Copper (Cu) lead-frame via a silver (Ag) sintering material (which has six times better thermal conductivity than standard soldering materials).

Other advantages that are derived by UnitedSiC's Gen 4 SiC technology include a dramatic lowering of the associated gate driving losses. This means that switching speeds can be as much as trebled without any risk of the gate drive ICs becoming overheated. There I no need for a negative gate drive. Thanks to the low forward voltage drop (VFSD) and minimal reverse recovery charge (QRR), a superior VF.QRR figure of merit (FoM) is exhibited. This cannot be matched by what any device currently on the market can deliver.

SiC is already making EV drivetrains and battery systems more efficient, allowing performance benchmarks to be attained that are way beyond the confines of Si semiconductor technology. The advent of next-generation SiC technology will further affirm its value in relation to the wider proliferation of EVs across the globe over the coming years.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由董慧转载自UnitedSiC,原文标题为:The True Realization of SiC’s Automotive Credentials,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

New Gate-drive Techniques Reduces the Cost and Complexity of Implementing Sic Fet Designs in Ev Systems

A sophisticated flyback converter coupled with the latest innovations in isolated gate drivers simplifies the task of driving SiC FETs in half-bridge configurations. It also reduces the cost and complexity of implementing SiC FET designs in the many EV systems using half bridges. As systems from onboard chargers to traction inverters adopt SiC FETs, electric vehicles gain higher efficiency, can work at higher voltages, and employ lighter-weight components, truly making them the automobiles of the future.

【技术】在与Si MOS/SiC MOS的比较中了解SiC FET导通电阻随温度产生的变化

使用UnitedSiC FET可以降低总传导损耗,并具有RDS(ON)的正常正温度系数,以确保单元和并联器件之间有效地共享电流。SiC MOSFET与之相比明显存在更高的潜在损耗和整体效率不足的问题。

【技术】UnitedSiC第四代SiC FET技术推进电动车设计提高功率密度并降低功耗

在牵引逆变器领域,第四代SiC FET技术将提供非常有吸引力的解决方案来应对成本效益挑战和基于SiC的高可靠牵引逆变器挑战。随着第四代750V SiC FET技术的推出,UnitedSiC为设计师们提供了可以让新设计提高功率密度、降低功耗并提升成本性能指标的器件。

【经验】SiC FET关断时VDS尖峰和振荡问题的解决方法

UnitedSiC的SiC FET能直接替代Si MOSFET,但其高开关速度也可能会使关断VDS电压产生尖峰和震荡,使系统的EMI变差。关断时的VDS尖峰和振荡产生的根本原因是高速开关过程中di/dt在杂散电感上产生了较高的感应电压。本文将给出并对比几种解决方案。

UnitedSiC SiC FET/SiC JFET/SiC肖特基二极管选型指南

目录- Product introduction SiC FETs SiC JFETs SiC Schottky Diodes

型号- UJ3D06506TS,UJ3D1220KSD,UF3C065040T3S,UF3C120080K3S,UF3C065040B3,UJ4C075023K3S,UJ3D1210KS,UF3N090350,UF3C SERIES,UJ3C065080B3,UJ3C120040K3S,UJ3N1701K2,UF3N SERIES,UJ3N065025K3S,UJ3N065080K3S,UF3SC120016K3S,UF3C065080K3S,UJ4SC,UF3N170400,UF3C065030K4S,UF3N120140,UF3N065600,UF3N170400B7S,UJ3D06510TS,UJ3D06560KSD,SC SERIES,UJ3C065030B3,UJ3D1210K2,UF3SC065007K4S,UF3C120400K3S,UJ4SC SERIES,UF4C120053K4S,UJ3C120150K3S,UJ4C075060K4S,UJ3D1202TS,UF3C065080B7S,UJ3D1220K2,SC,UF3C065080T3S,UF3C065040K3S,UJ3C120080K3S,UF3SC,UF4C120053K3S,UF3C120080K4S,UF3N090800,UJ4C075018K3S,UJ3D1210TS,UF3SC065030B7S,UJ4C075023K4S,UJ3D06530TS,UJ4C075060K3S,UJ3N SERIES,UJ3N120035,UF4C120070K3S,UF3SC120040B7S,UF3SC120016K4S,UJ4C SERIES,UJ4C075018K4S,UJ3C065080T3S,UF4SC120030K4S,UJ3N120035K3S,UJ3D06504TS,UJ3C065030K3S,UJ3D1205TS,UF3C065080B3,UJ3N065080,UJ4SC075009K4S,UJ3N120070K3S,UJ4C075033K3S,UF3SC SERIES,UF4C120070K4S,UF3C065030T3S,UJ3D06508TS,UJ3D1210KSD,UJ3D06516TS,UJ3D06512TS,UJ3D1250K2,UJ4SC075006K4S,UF3C120040K4S,UF3C065030B3,UF3C120150B7S,UJ3C SERIES,UF3C065040K4S,UJ4C075044K3S,UJ3C065030T3S,UJ4C,UJ3C120070K3S,UF3C065030K3S,UF4C,UJ3D1250K,UJ3D06520TS,UF3SC120009K4S,UF4C SERIES,UJ3N065025,UF3C120080B7S,UF3C120040K3S,UF3C120150K4S,UJ3C065080K3S,UJ3D1725K2,UJ3N120065K3S,UJ3D,UJ4C075044K4S,UJ3C,UJ3D06520KSD,UF3N065300,UF3C,UF3N,UJ3N120070,UJ4SC075011K4S,UJ4C075033K4S,UJ3N,UF3C170400K3S,UF4SC120023K4S,UJ3D SERIES,UF3SC065040B7S,UF3C065080K4S

1200V第4代SiC FET具有业界最佳性能,为高压市场提供最佳SiC电源解决方案

描述- **1200V Gen 4 SiC FETs性能卓越,助力高压市场发展** 本文介绍了UnitedSiC(现Qorvo)推出的1200V Gen 4碳化硅场效应晶体管(SiC FET),该产品家族扩展至更高电压应用。新推出的六款产品,包括23毫欧姆至70毫欧姆的UF4C/SC系列,提供TO247-4L(kelvin连接)封装的1200V/53毫欧姆和70毫欧姆SiC FET,以及TO247-3L封装的70毫欧姆SiC FET。这些SiC FET在性能上具有优势,适用于电动汽车市场向800V车载充电器(OBC)和DC/DC转换器的发展。新FET采用先进的垂直沟槽器件结构,提供行业最佳性能,包括最低的RDS(on) x Area、RDS(on) x Eoss、RDS(on) x Coss、(tr)和RDS(on) x Qg。此外,这些SiC FET还提供优异的热性能,有助于提高功率处理能力和降低开关损耗。

型号- UF4SC120030K4S,UF4C120053K3S,UF4C120030K4S,UF4SC SERIES,UF3C120040K4S,UF4C SERIES,UF4C120070K3S,UF4C,UF4C120070K4S,UF4C120053K4S,UF4SC120023K4S,UF4SC

SiC FET用户指南

描述- 本指南提供了使用RC阻尼器与快速切换SiC器件的实用解决方案和指导。通过实验双脉冲测试(DPT)验证了该解决方案。阻尼器损耗被精确测量,以帮助用户计算阻尼电阻的功率等级。分析了阻尼器在硬切换和软切换应用中的有益影响。指南还包括SiC FET的使用表格,提供了不同型号器件的栅极驱动电压和应用类型信息。

型号- UJ3C065080T3S,UJ4C075018K4S,UF4SC120030K4S,UF3C065040T3S,UF3C120080K3S,UJ3C065030K3S,UF3C065040B3,UF3C065080B3,UJ4C075023K3S,UF4SC120053K4S,UJ4SC075009K4S,UJ4C075033K3S,UJ3C065080B3,UJ3C120040K3S,UF3C065030T3S,UF4SC,UF3SC120016K3S,UF3C065080K3S,UJ4SC,UF3C065030K4S,UJ3C065030B3,UF3CXXXYYYK3S,UJ4SC075006K4S,UF3SC065007K4S,UF3C120040K4S,UF3C065030B3,UF3C120400K3S,UJ4CXXXK3S,UF3C120150B7S,UF3C065040K4S,UJ4C075044K3S,UJ3C065030T3S,UJ4C,UJ3C120070K3S,UF3C065030K3S,UF4C,UJ3C120150K3S,UJ4C075060K4S,UF3C065080B7S,UF3C170400B7S,UF4SC120070K4S,UF3CXXXYYYK4S,UF3SC120009K4S,UF3C120080B7S,UF3C065080T3S,UF3C120040K3S,UF3C120150K4S,UF3C065040K3S,UJ3C120080K3S,UJ3C065080K3S,UF3SC,UF3C120080K4S,UJ4C075044K4S,UJ3C,UJ4C075018K3S,UF3C,UF3SC065030B7S,UJ4C075023K4S,UJ4C075060K3S,UJ3CXXXYYYK3S,UF4SC120053K3S,UF4SC120070K3S,UF SERIES,UJ4SC075011K4S,UJ4C075033K4S,UF3C120150K3S,UF3C170400K3S,UF4SC120023K4S,UF3SC120040B7S,UF3SC065040B7S,UF3SC120016K4S,UF3C065080K4S

UnitedSiC FET用户指南

描述- 本指南提供了使用RC阻尼器与快速切换SiC器件的实用解决方案和指导。通过实验双脉冲测试(DPT)验证了该解决方案。阻尼器损耗被精确测量,以帮助用户计算阻尼电阻的功率等级。分析了阻尼器在硬切换和软切换应用中的有益影响。指南还包括SiC FET的使用表格,提供了不同型号器件的栅极驱动电压和应用类型信息。

型号- UJ3C065080T3S,UJ4C075018K4S,UF3C065040T3S,UF3C120080K3S,UF3SC065040D8S,UJ3C065030K3S,UF3SC065030D8S,C1808C681JGGAC7800,UF3C065040B3,UF3C065080B3,UJ4C075023K3S,UJ4SC075009K4S,CRCW201010R0JNEFHP,UJ4C075033K3S,UJ3C065080B3,UJ3C120040K3S,UF3C065030T3S,UF3SC120016K3S,UF3C065080K3S,UJ4SC,UF3C065030K4S,CRCW25124R70JNEGHP,UJ3C065030B3,UF3CXXXYYYK3S,UJ4SC075006K4S,C1206C680JGGAC7800,UF3SC065007K4S,UF3C120040K4S,UF3C065030B3,UF3C120400K3S,UJ4CXXXK3S,UF3C120150B7S,UF3C065040K4S,UJ4C075044K3S,C1206C151JGGAC7800,UJ3C065030T3S,UJ4C,UF3C065030K3S,UJ3C120150K3S,UF3C120400B7S,UJ4C075060K4S,CRCW20104R70JNEFHP,UF3C065080B7S,UF3C170400B7S,UF3CXXXYYYK4S,202R18N101JV4E,SR1206FR-7W4R7L,UF3SC120009K4S,UF3C120080B7S,KTR18EZPF10R0,UF3C065080T3S,UF3C120040K3S,UF3C120150K4S,UF3C065040K3S,UJ3C120080K3S,UJ3C065080K3S,UF3SC,KTR18EZPF4R70,UF3C120080K4S,UJ4C075044K4S,CRCW251210R0JNEGHP,UJ3C,UJ4C075018K3S,UF3C,UF3SC065030B7S,C1206C221JGGAC7800,C1210C331JGGACTU,SR1206FR-7W10RL,UJ4C075023K4S,UJ4C075060K3S,UJ3CXXXYYYK3S,UJ4C075033K4S,UJ4SC075011K4S,UF3C120150K3S,UF3C170400K3S,UF3SC120040B7S,UF3SC065040B7S,UF3SC120016K4S,UF3C065080K4S,202R18N470JV4E

具有业界出众性能的1200V第四代SiC FET为高压市场提供优秀SiC功率解决方案

UnitedSiC扩充了1200V产品系列,将突破性的第四代SiC FET技术推广到电压更高的应用中。新UF4C/SC系列中的六款新产品的规格从23毫欧到70毫欧,现以TO247-4L(开尔文连接)封装提供,而1200V的53毫欧和70毫欧SiC FET还以TO247-3L封装提供。

SiC FET的起源和发展—与SiC MOS及其他替代技术的性能比较

使用宽带隙半导体作为高频开关为实现更高的功率转换效率提供了有力支持。一个示例是,碳化硅开关可以实施为SiC MOSFET或以共源共栅结构实施为SiC FET。本文追溯了SiC FET的起源和发展,直至最新一代产品,并将其性能与替代技术进行了比较。

【经验】适用于SiC FET的简单RC缓冲电路,可解决电压过冲和振铃等问题

随着我们的产品接近边沿速率超快的理想半导体开关,电压过冲和振铃开始成为问题。适用于SiC FET的简单RC缓冲电路可以解决这些问题,并带来更高的效率增益。UnitedSiC将在本文中进行详细的分析。

【产品】UnitedSiC推出新的UF4C/SC系列1200V第四代SiC FET 非常适合主流的800V总线结构

UnitedSiC宣布推出新一代1200V碳化硅(SiC)场效应晶体管(FET)系列,这些产品在导通电阻方面具备业界出众的性能表征。新的UF4C/SC系列1200V第四代SiC FET非常适合主流的800V总线结构,这种结构常见于电动车车载充电器、工业电池充电器、工业电源、直流太阳能逆变器、焊机、不间断电源等应用。

【产品】1200V/80mΩ的SiC FET UF3C120080K3S,最高工作温度175℃

UnitedSiC的SiC FET(碳化硅场效应晶体管)采用了独特的共源共栅(cascode)电路配置,将常开型SiC JFET与Si MOSFET共同封装在一起,从而构建出常关型SiC FET器件。UF3C120080K3S是一款1200V的SiC FET。

可直接替换IGBT和Si MOS的第三代SiC FET,提供革命性的功率转换性能

现在已经出现了第三代SiC FET,这是一种Si-MOSFET和SiC JFET的共源共栅布置,处于宽带隙技术的前沿。作为IGBT和Si-MOSFET的直接替代品,SiC FET用于升级电动机驱动、UPS逆变器、焊机、大功率交直流和直流转换器等。

UJ3C065030B 3650V-27MW SiC FET规格书

描述- 本资料介绍了650V-27mW碳化硅场效应晶体管(SiC FET)的详细规格和应用信息。该器件采用独特的“级联”电路配置,结合了SiC JFET和Si MOSFET,实现低导通电阻、低栅极电荷和优异的反向恢复特性,适用于开关电感负载和标准栅极驱动应用。

型号- UJ3C065030B3

现货市场

登录 | 立即注册

提交评论