ATP Rapid Diagnostic Test (RDT): Accelerating Failure to Maximize Reliability and Endurance

Coffee brewing is undoubtedly both an art and a science. Coffee enthusiasts go to great lengths to judge the perfect cup of coffee based on its taste, aroma and flavor. The quality of beans, where they were grown, how they were roasted, and even how they were ground all play important roles in making sure that a cup of coffee is up to par with a sommelier’s standards.

Interestingly, not all beans that go into each cup of coffee are of the same quality; yet, with the right processes and techniques, they can altogether make a satisfying drink. The same is true with integrated circuits (ICs) in a NAND flash storage device, such as a solid state drive (SSD), memory card or e.MMC.

Considering the quality variance, how can a manufacturer make sure that the device performs reliably throughout its guaranteed lifespan?

Beginning at the End

At ATP Electronics, it all starts with the end in mind. The reliability journey is a long and complex process, but for this article, we will try to simplify it with these steps.

1. Evaluate the application data usage workload.

Discussions with the customer will determine what the storage device will be used for, under what operating environments it will be used, what physical and electro-mechanical challenges it is expected to face, and other relevant factors. At this stage, endurance ratings based on drive rates per day (DWPD) and operational temperature range will be established.

2. Select a suitable NAND flash type.

ATP offers a complete line of NAND flash options that the customer can choose from to make sure that the building blocks of the storage device are right for the application. Depending on the desired endurance ratings, expected service life, capacity, and other considerations, ATP can help the customer select the most appropriate NAND flash. ATP’s portfolio includes both 2D (planar) or 3D NAND configured as single-level cell (SLC), multi-level cell (MLC), triple-level cell (TLC), or pseudo SLC (pSLC).、

3. Perform Rapid Diagnostic Test (RDT).

After the storage device is assembled with the selected NAND, it is then put through a stringent screening test. This step is similar to simulating a thunderstorm/heatwave within the device, to test whether it can meet the client's requirements. At ATP, we call this process Rapid Diagnostic Test or RDT, where 100% screening is done on every device and in every area of the drive with ATP’s self-built proprietary tester.

RDT: Ensuring Extra Robust Flash Storage

Some people like their coffee strong, robust, and concentrated like espresso. In industrial applications where supreme reliability and extended endurance are paramount, ATP RDT is the best way to deliver extra robust flash storage.

ATP RDT’s main goal is to accelerate the failure of weak NAND flash blocks so that only the most robust will remain on the device, thus maximizing reliable performance and endurance. RDT helps make sure that ATP products can endure extreme temperatures and harsh operating conditions.

At the outset, this appears to be an ironic process. To the untrained eye, this may not make sense. But the truth is, it is the key to delivering the highest-quality flash storage products for mission-critical applications.There are many parameters tested under RDT, but for simplicity's sake, this article will highlight the two most important elements — error correction code (ECC) & temperature.

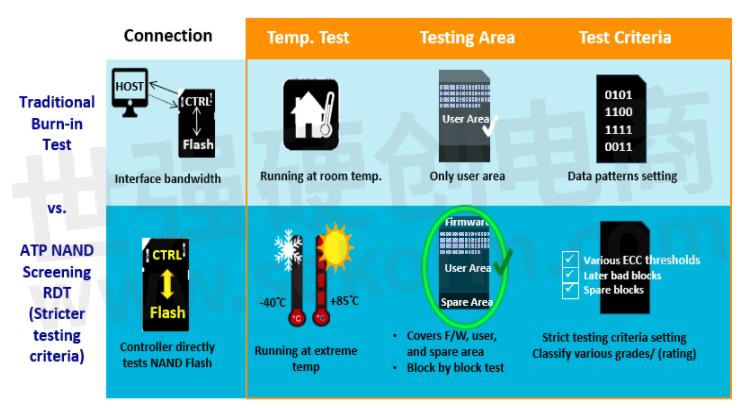

Figure 1. ATP-designed/built RDT process allows for direct and 100% NAND flash screening

Figure 2. ATP e.MMC devices are loaded into a specially designed RDT chamber for thermal cycling tests at both low (-40°C) and high (85°C) temperatures. ATP can perform high-volume testing according to customer request.

The ATP Advantages

1. RDT at Room and Extreme Temperatures: Challenging the Strength of the ECC

Other module houses only test at room temperature (25°C), which does not rigidly screen the NAND nor tests the true strength of the ECC. As a result of the relaxed criteria, fewer errors are identified because there’s not much ECC performance difference for strong and weak blocks. This causes the weaker blocks to be hidden behind the ECC.

As these weaker blocks have not been marked as “unsuitable,” data will be unknowingly written onto them. On the field, they will also be exposed to temperature challenges, ultimately compromising the reliability of the device and causing early life failure.

ATP’s RDT requires thermally stressing 100% of the drive at both room temperature (25°C) and at extreme ranges from -40°C up to 85°C, where more errors will appear. This challenges the strength of the ECC and pressures it to correct more errors.

As the ECC correction threshold is reached, more weak blocks can be marked as “unusable” or “uncorrectable.” In actual use, data will be written only on the robust blocks and the drive will be able to withstand harsh temperature ranges on the field. This minimizes early life failures, extends device endurance, and ensures the reliable operation of the device during its entire service life.

2. RDT Beyond the User Area: 100% Screening

Most module houses also typically test only the user area. ATP tests the entire drive, including user, meta/cache, spare and firmware areas.

3. RDT’s More Stringent Criteria: Thorough Screening and Accurate Ratings

This screening process does not only weed out defective components to prevent early life failures. It also detects later bad blocks, thus allowing ATP to accurately rate and classify various product grades for application-specific requirements. The process makes sure that all ATP products will deliver superior and reliable performance within their guaranteed lifespan.Moreover, ATP’s RDT is directly performed by the controller on the NAND flash. This speeds up the testing process by eliminating system bandwidth limitations.

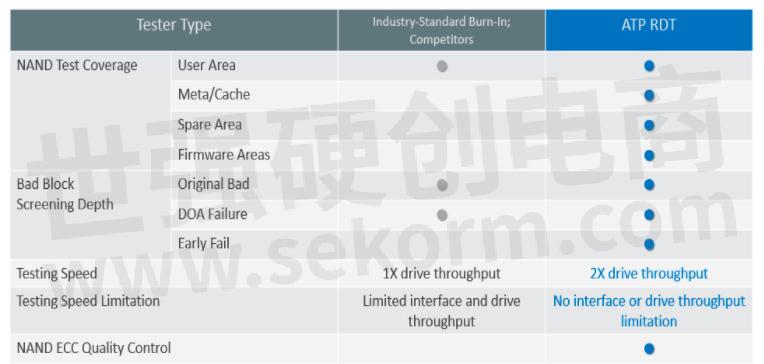

The figure and comparison table below summarize the advantages of ATP's RDT.

Figure 3. Advantages of ATP’s RDT over traditional burn-in tests.

Table 1. Comparison table between competitors’ standard burn-in tests and ATP’s RDT.

Conclusion

Like coffee beans, quality variance in NAND flash blocks comprising a storage device is a reality that we at ATP Electronics need to contend with. Industrial applications require storage to be robust, reliable and long-lasting so as not to compromise operations and to make sure that investments are worth the total cost of ownership (TCO).

By using stress accelerants such as temperature, RDT identifies qualified and unqualified blocks intended for specific applications, so customers can rest assured that the flash storage device will not fail before its specified end of life across the industrial temperature range and across various embedded/industrial usage cases.

Knowing that the ATP flash storage devices are reliable and enduring, customers can relax and enjoy their cup of coffee.

For more information on the RDT process and other testing capabilities, visit the ATP website or contact an ATP Representative.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由青莲居士转载自ATP,原文标题为:ATP Rapid Diagnostic Test (RDT): Accelerating Failure to Maximize Reliability and Endurance,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

【应用】ATP推出32G eMMC AF032GEC5X-SEK0511用于V2X系统,适用温度-40~85℃

V2X系统旨在通过允许车辆与几乎所有可检测的东西进行通讯来提高车辆的安全性,舒适性和便利性。在系统设计中需要用到eMMC进行数据存储,在此选用的ATP的32G Bytes的eMMC AF032GEC5X-SEK0511替换NAND FLASH。

ATP‘s PCB Assembly Solderability Validation Tests

ATP’s PCB assembly validation tests are part of the many reliability and endurance tests developed and performed by ATP to ensure strict compliance to the highest standards of quality. ATP is committed to delivering high-performance and high-endurance NAND flashes storage products to ensure the best value for the total cost of ownership (TCO).

SSD End-of-Life Validation Test: Ensuring Reliability, Endurance and Retention From 0% to 100% and Beyond EOL

ATP’s EOL Validation Test is just one of the many reliability and endurance tests developed and performed by ATP to ensure strict compliance to the highest standards of quality. ATP is committed to delivering high-performance and high-endurance NAND flashes storage products to ensure the best value for a total cost of ownership (TCO).

宇瞻(Apacer)工业用SSD选型指南

Company profile 3D NAND SSDs and Emergent Technologies Cloud/Defense Series SSD Featured Technologies Applications PCIe SSD SATA 2.5" SSD SATA M.2 SATA MO-276 / MO-297/ MO-300 SATA 7-pin Module Industrial CF/CFast/SD/microSD Card Industrial USB Drive Disk Module

宇瞻 - SATA 7-PIN MODULE,3D NAND SSDS,工业MICROSD卡,工业SSD,NGSFF(M.3) SSD,INDUSTRIAL MICROSD CARD,云SSD,工业U盘模块,工业CF卡,EDSFF SSDS,工业CFAST卡,工业USB驱动器,PATA SSD MODULE,PCIE BGA固态硬盘,SATA 7引脚模块,NGSFF SSDS,EDSFF SSD,工业SD卡,SATA 2.5" SSD,磁盘模块,3D NAND固态硬盘,PCIE SSD,PCIE固态硬盘,NGSFF(M.3)SSD,SSD,SSDS,CLOUD SSD,INDUSTRIAL USB DRIVE,SATA 2.5英寸SSD,3D NAND FLASH MEMORY,INDUSTRIAL SSD,NGSFF固态硬盘,PATA固态硬盘,PATA SSD,PATA DISK MODULE,NGSFF SSD,APACER SATA 2.5" SSD,EDSFF固态硬盘,PCIE BGA SSD,固态硬盘,INDUSTRIAL CF CARD,INDUSTRIAL SD CARD,国防SSD,DEFENSE SSD,DISK MODULE,INDUSTRIAL CFAST CARD,INDUSTRIAL USB DISK MODULE,UV110-UFM2,SDM7-M 7P 180D LP2H,UV110-UFM1,SM22P-CFAST,SDM5A 7P/180D LP2,US120-UFD5,SM21P-25,UV110-UFD5,SV25C-M242,INDUSTRIALSD R1,EH353-M,PT220-M280,UDM2A-M,SDM5A-M 7P/90D LP,SH250-M280,SV250-CFAST,SDM5A 7P/180D SLIM2,PV930-M280,SDM5A 7P/90D LP,SU210-25,CF6,CM710-CF,PV210-M280,SDM5A-M 7P/180D SLIM2,INDUSTRIAL MICROSD R1,SV25C-25,ST250-300,INDUSTRIAL SD H1-SL,SH24D-M280,SV250-25,SH250-25,SM230-M280,UH110-UFM1,SH24D-25,SU230-CFAST,SH250-300,SDM5A-M 7P/180D SLIM2H,ADM5S-M,SV170-ΜSSD,CS710-CF,SV250-M242,EH353,SDM5A 7P/90D LPH,PV220-M280,UDM 1U-M,PV140-25,ST250-M280,CF6A,PV910-M280,SH24D-300,ADM5S,INDUSTRIAL SD H1-M,SDM5A 7P/180D SLIM2H,ST250-25,PV920-M280,SV25C-M280,SDM7-M 7P/180D DP,SDM7-M 7P 180D LP2,SS210-300,SS220-M242,AH322,SH250-CFAST,EH163-M,AH321,UDM2A,SDM5A-M 7P/180D LP5,SH250-M242,INDUSTRIAL SD,SDM5A-M 7P/90D LPH,UH110-UFD4,SU220-CFAST,UM120-UFD5,SV240-297,INDUSTRIAL MICROSD H1-M,SDM5A-M 7P/180D LP5H,AFD257-M,CV110-MSD,CH110-MSD,SV250-7LP2/180D,SV25C-300,SM210-25,CH110-SD,SV250-300,ST250-M242,USZ20-UFD5,CV110-SD,SV240-M280,CH710-CF,AFD257,SV240-300,SS220-CFAST,PH920-M280,SV250-M280,SM230-CFAST,SS210-25,SLC-LITEX,SM230-M242,CH120-MSD,INDUSTRIAL MICROSD H1-SL,CF6-M,SM210-M280,PV22D-M280,CF6A-M,UV110-UFD1,UDM 1U,PV910-M242,PV910-CFX,INDUSTRIAL MICROSD,SV240-25,ST250-297,INDUSTRIES,伺服器,NETWORKING,SERVER,TRANSPORTATION,车联网,FACTORY AUTOMATION,INTERNET OF VEHICLE,ECOSYSTEM,REMOTE DEVICE MANAGEMENT,交通运输,游戏,MINIATURIZED SMART APPLICATIONS,物联网,INTELLIGENT TRANSPORTATION SYSTEM,行业,国防,IOT DEVICE,远程设备管理,保健,网络,智能交通系统,INTERNET OF THINGS,DEFENSE,5G,生态系统,工厂自动化,HEALTHCARE,GAMING,IOT 设备

ATP(华腾国际)DRAM存储模块和NAND闪存产品选型指南(英文)

Company Profile Segment Challenges and Solutions Thermal Solutions Endurance Solutions Security Solutions CFexpress & USB 3.0 Value Line SSDs DDR5 DRAM SOLUTIONS FLASH SOLUTIONS Flash Products Naming Rule Solutions & Technologies Flash Technology Overview table Complete Flash Spec Overview & Product Dimensions

ATP - ECC SO-DIMM,USB驱动器,MICROSD MEMORY CARDS,MICROSDHC CARD,DDR SO-DIMM,3D TLC SSDS,PCIE®GEN4高容量NVME M.2 2280固态硬盘,PCIE® GEN4 NVME U.2 SSD,SATA III 2.5" SSD,DDR2模块,PCIE® GEN 4 NVME M.2 2280 SSD,SD CARD,SATA III M.2 2280 SSD,PCIE®GEN4 NVME U.2固态硬盘,PCIE® GEN 3 NVME M.2 2280 SSD,NANODURA双通用闪存驱动器(UFD),PCIE®GEN 3 NVME M.2型1620 HSBGA固态硬盘,SD CARDS,CFEXPRESS TYPE B MEMORY CARDS,DRAM,非ECC UDIMM,NVME固态硬盘,SECURSTOR MICROSD CARD,DDR2 MODULES,DDR4 RDIMMS,SATA III MSATA SSD,SSDS,PCIE® GEN 3 NVME M.2 2242 SSD,SD卡,LEGACY (SDR/DDR) DRAM MODULES,ECC UDIMM,NON-ECC UDIMM,PCIE® GEN4 NVME CFEXPRESS CARD,NANODURA双UFD,PCIE® GEN 3,PCIE® GEN 3 NVME M.2 TYPE 1620 HSBGA SSD,SDHC CARD,E.MMC,HIGH-SPEED TYPE B CFEXPRESS CARDS,高速B型CFEXPRESS卡,PCIE® GEN4 HIGH-CAPACITY NVME M.2 2280 SSD,DDR3模块,DDR5 DIMM,MICROSD卡,PCIE®GEN3 NVME U.2固态硬盘,SOLID STATE DRIVES,SDXC卡,DRAM MODULES,SATA III M.2 2242 SSD,PCIE® GEN3 NVME M.2 2242 SSD,NON-ECC SO-DIMM,DUAL-INLINE MEMORY MODULES (DIMMS),CFAST卡,NVME散热器球栅阵列(HSBGA)固态硬盘,PCIE®GEN 3 NVME M.2 2242固态硬盘,SD MEMORY CARDS,MICROSD CARDS,非ECC SO-DIMM,PCIE®GEN 3 NVME M.2 2280固态硬盘,SDHC卡,DDR3 UDIMM,DDR3 MODULES,PCIE® GEN3 NVME M.2 2280 SSD,存储卡,固态硬盘,DDR3 MODULES,SECURSTOR MICROSD卡,MICROSDXC CARD,DDR3 SO-DIMM,NAND FLASH MEMORY,PCIE® GEN3 NVME M.2 2230 SSD,DDR4模块,DDR5 MEMORY,DDR5 DIMMS,WIDE TEMPERATURE RDIMM,HSBGA SSDS,NVME HEAT SINK BALL GRID ARRAY (HSBGA) SSDS,DDR4-3200模块,SDXC CARD,NANODURA DUAL UNIVERSAL FLASH DRIVES (UFDS),SATA III 2.5英寸固态硬盘,DDR4-3200 MODULE,RDIMM,MICROSDHC卡,PCIE® GEN 3 NVME M.2 2230 SSD,DDR4 MODULES,DRAM模块,DDR4宽温度RDIMM,MICROSDXC卡,NVME SSDS,DDR5内存,MEMORY CARDS,NVME M.2 TYPE 1620 HSBGA SSD,SDRAM,DDR5模块,CFEXPRESS CARDS,DDR UDIMM,SATA III M.2 2280固态硬盘,UNIVERSAL FLASH DRIVES,PCIE® GEN3 NVME U.2 SSD,NANODURA DUAL UFDS,DDR1模块,DDR1 MODULES,U.2 SSD,MICROSD CARD,PCIE® GEN3 NVME,USB DRIVES,SOLID STATE DRIVES,SSD,DDR5 MODULES,NAND型闪存,DDR4 RDIMM,COMPACTFLASH CARD,DDR4 WIDE-TEMP RDIMMS,3D TLC固态硬盘,COMPACTFLASH卡,PCIE®GEN4 NVME CFEXPRESS卡,CFEXPRESS B型存储卡,CFAST CARD,PCIE®GEN 3 NVME M.2 2230固态硬盘,SDRAM SO-DIMM,PCIE®GEN 4 NVME M.2 2280固态硬盘,PCIE® GEN4 NVME M.2 2280 SSD,HSBGA固态硬盘,SATA III M.2 2242固态硬盘,A750PI,E650SC SERIES,S600SC,B800PI,S750 SERIES,S600SI,S600SCA,E750PC SERIES,B600SC,N700PC,S700SC,E650SC,A750 SERIES,E600VC,S800PI,A750PI SERIES,I800PI,A600VC,A650SI,A650SC,N700 SERIES,S650SI,N750,N750PI,A800PI,A700PI,N700SI,N650 SERIES,E600SAA,N700SC,A750,N600SC,A600VC SERIES,E600SA,E650SI,E650SI SERIES,N750 SERIES,E700PIA,TR-03153,N600SI,S650,S650SC,E700PAA,N650SIA,E600SI,B600SC SERIES,S750SC,S600SIA,I700SC,N650SI,N600VI,E600SIA,E750PI,N650SC,N750PI SERIES,N600VC,I600SC,E750PC,S700PI,A650 SERIES,N650,N600 SERIES,N600VC SERIES,S650 SERIES,A650,AES-256,E700PI,A600SI,E750PI SERIES,N700PI,E700PA,S750,S750PI,E700PC,A600SC,EDUCATION,汽车,TRANSPORTATION INFRASTRUCTURE,NETWORKING,AUTONOMOUS DRIVING,IN-VEHICLE,DIGITAL VIDEO RECORDERS (DVRS),AUTOMATION,TEST,驱动器记录器,DRIVE RECORDER,数据记录器,EDGE COMPUTING,AUTONOMOUS VEHICLES,能源,TRANSPORTATION SYSTEMS,网络,TEST & MEASUREMENT,工业4.0,无人机,CYBERSECURITY,MEC,自动化,汽车应用,网络安全,WEB SERVER,数据中心,AUTOMOTIVE APPLICATIONS,5G,AUTOMOTIVE,IVI,SD-WAN,EV INFRASTRUCTURE,MEASUREMENT,RAILWAY,电信,MEASURING SYSTEMS,NETWORKING,INDUSTRIAL,无风扇电脑,TRANSPORTATION,IIOT,航空航天,测量系统,车队管理,DATA CENTER,车内,FANLESS PC,TELECOMMUNICATIONS INDUSTRY,IOT,POINT-OF-SALE SYSTEMS(POS),电动汽车基础设施,物联网(IOT),工业物联网,AUTOMOTIVE STORAGE,ENERGY,DEFENSE,FLEET MANAGEMENT,SURVEILLANCE SYSTEMS,交通运输,游戏,铁路,INDUSTRIAL 4.0,工业,国防,自动驾驶,AUTOMATION,INTERNET OF THINGS (IOT),BOX PC,测试,边际运算,测量,INTERNET OF THINGS,DATA LOGGER,NGFW,O-RAN,汽车存储,交通基础设施,TELECOM,INDUSTRIAL,TEST AND MEASUREMENT,教育,AEROSPACE,KIOSK,GAMING,DRONES

M-WP008工业和国防应用中可靠闪存存储产品的关键设计注意事项白皮书

本文探讨了在工业和防御应用中设计可靠闪存产品的关键考虑因素。文章强调了在恶劣环境中保持可靠性的重要性,并详细讨论了固态硬盘(SSD)的设计考虑因素,包括NAND闪存的选择、控制器设计、错误纠正码(ECC)和低密度奇偶校验(LDPC)技术。此外,文章还提到了其他潜在故障机制,如读干扰和数据保留,以及如何通过优化固件算法和背景扫描来提高可靠性。最后,文章强调了应用设计在提高闪存SSD可靠性方面的重要性。

SMART - 固态驱动器,SOLID-STATE DRIVES,安防,INDUSTRIAL,DEFENSE,工业

ATP(华腾国际)DRAM存储模块和NAND闪存产品选型指南(中文)

公司简介 细分市场挑战和解决方案 热管理解决方案 TSE闪存解决方案 DRAM解决方案 闪存解决方案 闪存解决方案-固态驱动器和模块 闪存解决方案-存储卡 闪存解决方案-托管NAND 闪存产品命名规则 闪存规范概述和产品尺寸

ATP - CFAST 卡,USB驱动器,DIMM,MICROSDHC CARD,工业MICROSD卡,SD CARD,SDXC CARD,固态驱动器,SD,CFEXPRESS卡,MICROSD卡,高速B型CFEXPRESS卡,SDXC卡,工业SD卡,紧凑型闪存卡,MICROSD CARD,SDHC卡,SSD,DRAM模块,通用闪存驱动器,CFEXPRESS 卡,COMPACTFLASH CARD,SECURSTOR MICROSD卡直插式内存模块,MICROSD存储卡,存储卡,双列直插式内存模块,NAND闪存,CFAST CARD,固态硬盘,工业SD,3D NAND闪存,存储器,MICROSDXC CARD,SDHC CARD,E.MMC,A750PI,S600SC,N750PI系列,B800PI,S750 SERIES,S600SI,S600SCA,B600SC,N700PC,S700SC,N600,E650SC,E750,E750PC系列,E600VC,S800PI,I800PI,E750 SERIES,A600VC,A650SI,N600系列,A650SC,N700 SERIES,S650SI,N750,N750PI,A800PI,A700PI,N700SI,E600SAA,N700SC,A750,N600SC,A600VC SERIES,E600SA,E650SI,E700PIA,N600SI,S650,S650SC,E700PAA,N600VC系列,N650系列,N650SIA,N750系列,E600SI,S750系列,E650,N700,S750SC,S600SIA,I700SC,N650SI,N600VI,E650SI系列,E600SIA,E650SC系列,E750PI,N650SC,S650系列,N600VC,I600SC,E750PC,A600VC系列,A650系列,S700PI,N700系列,N650,N600 SERIES,N600VC SERIES,A750PI系列,S650 SERIES,A650,E700PI,E750PI系列,A600SI,N700PI,A750系列,E700PA,E650 SERIES,S750,S750PI,E700PC,A600SC,DVR,数据记录,机器人,汽车,监视系统,自动化系统,成像系统,无镜摄像机,边缘计算,物联网,WAN边缘基础设施,数据记录器,手持计算,网络,工业4.0,无人机,自动化,MEC,数字通信,汽车黑匣子,网络安全,数据中心,EV 基础设施,企业,EV,5G,监控系统,POS,WEB服务器,IVI,SD-WAN,电信,自助服务亭,IIOT,航空航天,测量系统,车队管理,运输系统,无风扇PC,IOT,盒式电脑,运输,销售点系统,工业物联网,车内管理,电动汽车,游戏,铁路,工业,国防,云计算,高端数字摄像机,自动驾驶,能量,测试,测量,销售点交易,NGFW,交通基础设施,O-RAN,销售点,工控机,教育,自动驾驶汽车,行车记录仪,监控,数字录像机,IPC,嵌入式

【产品】ATP发布采用3D TLC NAND flash设计的A1性能等级SD/microSD卡产品系列S600Sia

2019年10月,专注于工业应用的存储解决方案领导厂商ATP Electronics(华腾国际科技)日前发布了其最新产品线 S600Sia, 这是ATP首个采用3D TLC NAND flash设计的A1 性能等级SD卡和microSD卡产品系列,是高可靠存储产品,可进行定制化设计,面向汽车电子及工业领域应用。

ATP(华腾国际)固态硬盘选型指南

Since 1991, we have consistently distinguished ourselves as one of the world’s leading original equipment manufacturers (OEM) of high-performance, high-quality and high-endurance NAND flash products and DRAM modules.

ATP - PCIE®GEN4 X4 M.2 2280,U.2 SSD,PCIE® GEN3 NVME M.2 2230 SSD,DDR5 MEMORY,PCIE®GEN3 NVME M.2 2230固态硬盘,MICROSDHC CARD,PCIE® GEN4 NVME U.2 SSD,SATA III 2.5" SSD,USB DRIVE,SD CARD,SATA III M.2 2280 SSD,SDXC CARD,PCIE®GEN3 NVME M.2 2280固态硬盘,SATA III 2.5英寸固态硬盘,PCIE®GEN4 NVME U.2固态硬盘,USB 2.0 EUSB,CFEXPRESS TYPE B MEMORY CARDS,M.2 TYPE 1620 HSBGA SSD,M.2 2242 SSD,NVME固态硬盘,MICROSDHC卡,PCIE® GEN4 X4 M.2 2280, U.2 SSDS,SECURSTOR MICROSD CARD,MSATA固态硬盘,PCIE® GEN4 NVME E1.S SSD,SATA III MSATA SSD,DRAM模块,PCIE®GEN4 NVME M.2 2280固态硬盘,MICROSDXC卡,NVME SSDS,DDR5内存,PCIE ® GEN4 NVME CFEXPRESS CARD,EMMC,SD卡,PCIE®GEN4 NVME E1.S固态硬盘,DRAM MODULES,M.2 2280固态硬盘,PCIE®GEN3 NVME M.2 2242固态硬盘,PCIE® GEN4 NVME CFEXPRESS CARD,NANODURA双UFD,E1.S PCIE GEN4 X4 SSD,SDHC CARD,袖珍闪存卡,E.MMC,PCIE® GEN3 NVME M.2 TYPE 1620 HSBGA SSD,MICROSD,M.2 2280 SSD,M.2 2230 SSD,SATA III M.2 2280固态硬盘,PCIE® GEN3 NVME U.2 SSD,NANODURA DUAL UFDS,MICROSD卡,CFEXPRESS卡,PCIE®GEN3 NVME U.2固态硬盘,SDXC卡,SATA III M.2 2242 SSD,PCIE® GEN3 NVME M.2 2242 SSD,MICROSD CARD,CFAST卡,1.ES PCIE GEN4 X4固态硬盘,SDHC卡,PCIE®GEN3 NVME M.2型1620 HSBGA固态硬盘,随身碟,CFEXPRESS CARD,COMPACTFLASH CARD,COMPACTFLASH卡,PCIE®GEN4 NVME CFEXPRESS卡,PCIE® GEN3 NVME M.2 2280 SSD,PCIE ® GEN3 NVME M.2 TYPE 1620 HSBGA SSD,EUSB,VALUE LINE SSDS,M.2型1620 HSBGA SSD,CFEXPRESS B型存储卡,CFAST CARD,M.2 2230固态硬盘,价值线固态硬盘,MSATA SSD,SECURSTOR MICROSD卡,PCIE® GEN4 NVME M.2 2280 SSD,MICROSDXC CARD,COMPACT FLASH CARD,M.2 2242固态硬盘,PCIE ® GEN3 NVME U.2 SSD,SATA III M.2 2242固态硬盘,A750PI,S600SC,B800PI,S750 SERIES,S600SI,B600SC,N700PC,A750 SERIES,E650SC,N601,N651SI,A600VI,S800PI,E600VC,I800PI,A600VC,A650SI,A650SC,N651SC,N750,S650SI,A600VI SERIES,N750PI,N651SIE,A800PI,N601 SERIES,A700PI,N651SIA,N650 SERIES,E600SAA,A750,A600VC SERIES,N600SC,E600SA,E650SI,N750 SERIES,E700PIA,N600SI,S650,S650SC,N651SI SERIES,E700PAA,B600SC SERIES,E600SI,N600VI SERIES,I700SC,N600VI,N650SI,E600SIA,N650SC,E750PI,N600VC,I600SC,E750PC,N651,S700PI,A650 SERIES,N650,N751PI,S700PC,N600VC SERIES,N651 SERIES,S650 SERIES,A650,N601SC,S750PC,E700PI,A600SI,N700PI,E700PA,S750,S750PI,E700PC,N651SCE,A600SC,数据记录,伺服器,汽车,AI SURVEILLANCE INFRASTRUCTURES,NETWORKING,ARTIFICIAL INTELLIGENCE (AI)-ENABLED SURVEILLANCE,HANDHELD COMPUTING,工业企业,物联网,手持计算,WEB SERVERS,网络,DATA LOGGING,POINT-OF-SALE (POS) TRANSACTIONS,自动化,IMAGING,企业,5G,STORAGE,成像,POS,销售点(POS)交易,BOX PCS,AUTOMOTIVE,SERVER,电信,ENTERPRISE,TRANSPORTATION,ROBOTICS,IOT,交通运输,SURVEILLANCE,人工智能(AI)监控,盒装PCS,边缘计算系统,工业,机器人学,AUTOMATION,EDGE COMPUTING,MISSION-CRITICAL APPLICATIONS,边际运算,INTERNET OF THINGS,EDGE COMPUTING SYSTEMS,TELECOM,INDUSTRIAL,INDUSTRIAL ENTERPRISE,关键任务应用程序,监控,存储器,人工智能监控基础设施,网络服务器

ATP e.MMC v5.1嵌入式闪存存储解决方案

该资料介绍了ATP e.MMC v5.1嵌入式闪存解决方案,强调其在工业级性能、极端耐用性和可靠性方面的特点。它符合AEC-Q100 Grade 2和Grade 3标准,具有高耐久性,支持JEDEC e.MMC v5.1标准,并采用153球FBGA封装。ATP e.MMC集成了NAND闪存、复杂的闪存控制器和快速的多媒体卡(MMC)接口,适用于空间受限但需在恶劣环境中保持可靠性的嵌入式系统。

ATP - MANAGED NAND,管理NAND,E.MMC,E600SI,E650SC,E600SAA,E700PI,E600SA,E650SI,E600VC,E700PIA,E600SIA,E700PA,E750PI,E700PAA,E750PC,E700PC

DuraFlash™XL+|SD 3.01|SD卡

SMART的XL+ SD卡是一款高性能、工业级的SD卡,适用于网络、电信、数据通信、嵌入式计算、医疗、汽车和工业应用等OEM市场。这些SD卡采用SLC NAND闪存,容量从1GB到32GB不等,符合SD v3.01标准,具备错误检测和纠正算法,以及静态和动态磨损平衡技术,确保长期可靠运行。

SMART - SD卡,SD CARD,SH9SD032GSNIDSI02,SP9SD001GPBI8SI01,SP9SD002GPBI9SC01,SH9SD016GSNICSC02,SP9SD002GPBI9SE01,SH9SD008GSNICSI02,SP9SD002GPBI9SI01,SH9SD032GSNIDSC02,SP9SD001GPBI8SC01,SP9SD001GPBI8SE01,SH9SD004GSMIBSI02,SH9SD004GSMIBSC02,XL+,SH9SD016GSNICSI02,SH9SD008GSNICSC02,医学,MEDICAL,电信,安防,嵌入式计算,NETWORKING,汽车,无线通讯,工业仪表,EMBEDDED COMPUTING,TELECOMMUNICATIONS,通信,游戏,数字商用摄像机,汽车远程信息处理,DATA COMMUNICATIONS,DIGITAL COMMERCIAL CAMCORDERS,航空娱乐系统,NAVIGATION,网络,导航,数据通信,COMMUNICATIONS,工控,信息娱乐,AUTOMOTIVE TELEMATICS,DEFENSE,INFOTAINMENT,INDUSTRIAL METERS,TELECOM,AIRLINE ENTERTAINMENT SYSTEMS,工业应用,INDUSTRIAL APPLICATIONS,INDUSTRIAL CONTROL,AUTOMOTIVE,GAMING

ATP Launches Customizable SecurStor microSD Cards with Secure Boot and HW AES-256 XTS Encryption

ATP Electronics, the global leader in specialized storage and memory solutions, has launched the SecurStor microSD cards – the latest in its line of secure NAND flash storage products for the Internet of Things (IoT), education, automotive, defense, aerospace and other applications requiring confidentiality and reliability.

ATP Exhibits at Embedded World 2024

Participants should not miss a visit to ATP’s Booth in Hall 1-210, where ATP once again demonstrates its commitment to redefine memory and data storage reliability, scalability, and efficiency. Attendees to Embedded World 2024 can expect to see a new breed of flash storage solutions with ATP’s 176-layer NAND flash innovation, industrial enterprise-readiness for Edge computing and artificial intelligence, and latest DDR5-5600 memory offerings.

Bringing 3D TLC NAND Flash Endurance and Reliability Closer to SLC/MLC

The advent of 3D NAND technology allowed for more relaxed lithography and broke planar NAND limitations. By stacking cells vertically, 3D NAND flash increased drive reliability and endurance. ATP breaks new ground with its new 3D TLC-based SATA SSDs.

ATP Showcases “Industrial Only“ Memory and Storage Solutions for Connecting Embedded Intelligence at EW2020

ATP Electronics, the leading manufacturer of “Industrial Only” memory and storage solutions, showcases its latest robust and high-performance products for the era of connected embedded intelligence at Embedded World 2020.

电子商城

现货市场

服务

拥有IC烧录机20余款,100余台设备,可以烧录各种封装的IC;可烧录MCU、FLASH、EMMC、NAND FLASH、EPROM等各类型芯片,支持WIFI/BT模组PCBA烧录、测试。

最小起订量: 1 提交需求>

可烧录MCU/MPU,EPROM,EEPROM,FLASH,Nand Flash, PLD/CPLD,SD Card,TF Card, CF Card,eMMC Card,eMMC,MoviNand, OneNand等各类型IC,IC封装:DIP/SDIP/SOP/MSOP/QSOP/SSOP/TSOP/TSSOP/PLCC/QFP/QFN/MLP/MLF/BGA/CSP/SOT/DFN.

最小起订量: 1 提交需求>

登录 | 立即注册

提交评论