Keysights Scienlab Battery Test Solution Tests Batteries Economically and Efficiently

The modern alchemist’s quest for longer battery life is more challenging than ever. Good battery design for the e-mobility industry is akin to concocting a powerful potion, with the right balance of chemicals to handle different applications and challenging environments. The battery also needs to pack a punch to provide extra mileage on the road.

Battery makers face intense competition to get a slice of the pie in the electric vehicle (EV) battery market, which is poised to grow by $44.2 billion between 2020 and 20241. While technology has reduced the cost of an average Li-ion EV battery by 80% over the past decade, the battery remains the most expensive part of the electric car. Bringing down this cost component will help EVs win over more drivers.

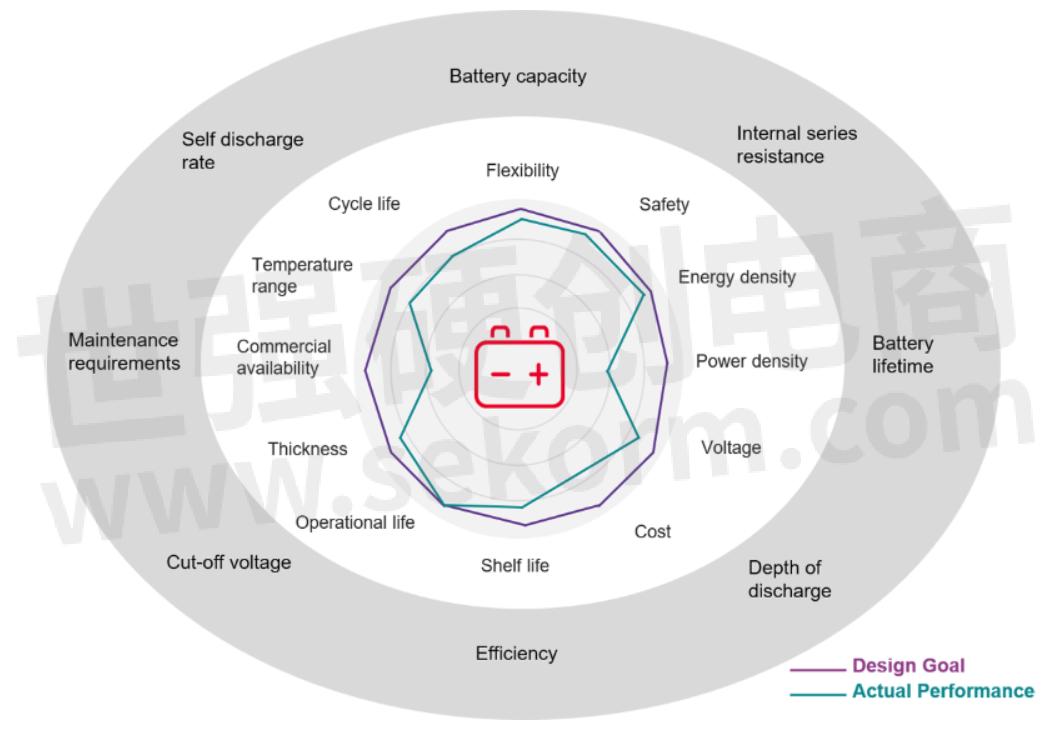

So just what does the modern alchemist have to balance, in formulating the ideal, and affordable battery? The answer lies in understanding what causes the gaps between design goals and real life performances (see example in Figure 1).

Creating the ideal cell chemistry requires an understanding of various parameters affecting battery performance, at the cell, module and pack levels, depending on the different aimed applications.

Figure 1. Different cell characteristics must be considered when developing a new cell, as cell characteristics depend on their applications.

To complicate matters, each battery cell exhibits different characteristics, depending on their applications. In designing and testing batteries, the battery cell design manager has to consider how to juggle various test parameters for multiple cell types under development, with available test resources.

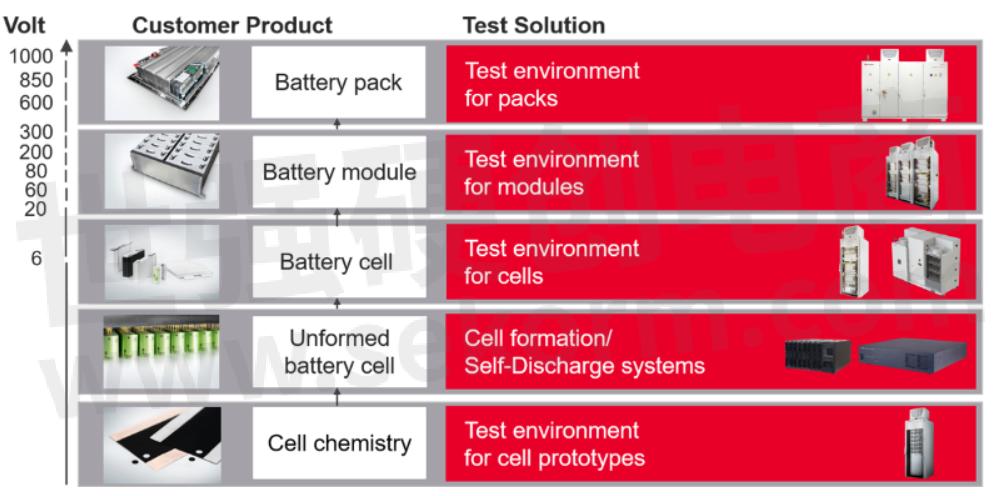

For instance, in EVs and hybrid EVs, fast charging and extended range are important, hence the battery design must prioritize tests to achieve higher capacity, efficiency, and energy density goals among others. To manage and meet these requirements efficiently, battery cell manufacturers need to anticipate the types of tests that must be carried out throughout the entire battery development chain (see Figure 2). Furthermore, the rapidly evolving EV battery market also means manufacturers have to adopt future-proof design-for-test solutions to ensure attractive return on investments in their design and test solutions.

Figure 2. Each stage of the battery development cycle, from cell, to module and pack, requires rigorous testing to meet design criteria.

Recently, ElringKlinger AG, a global leading developer of automotive drive systems and volume manufacturer for battery components, decided to collaborate with KEYSIGHT2 to further accelerate the development of batteries. Their aim is to deliver highly efficient and reliable battery systems to their customers in a fast, consistent, and cost-efficient way.

ElringKlinger will test their cells to identify the most effective combination of cells for their targeted end-customer applications, using Keysight's Scienlab Battery Test Solution.

Battery modules consisting of several of those cells are used to develop battery systems including a battery management system (BMS), thermal management and necessary mechanical components.

ElringKlinger established a highly customized turn-key laboratory that includes the full range of Keysight's Scienlab Battery Test Systems, including safety environment for testing battery cells, modules and packs.

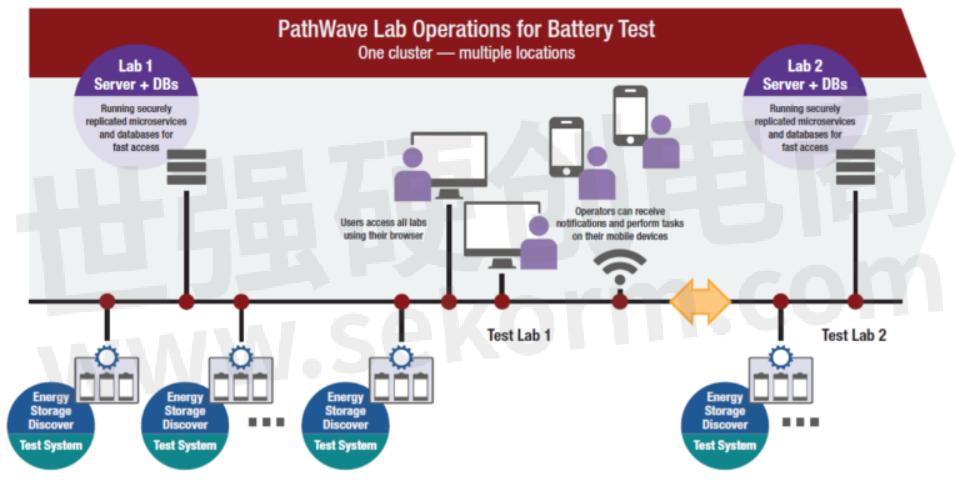

In addition to the test and control software Energy Storage Discover, Keysight provided a cloud-based software PathWave Lab Operations for Battery Test (see Figure 3) which enables ElringKlinger to optimize and efficiently manage the end-to-end workflow for the entire lab including resources, hardware and devices under test.

Figure 3. Computing and communications architecture for PathWave Lab Operations for Battery Test.

Essentially, PathWave Lab Operations for Battery Test provides a scalable platform, from smaller test labs with one or two test systems up to large laboratories consisting of multiple test systems of different types. This enables multiple labs in different locations to share test plans and data, improve productivity, and allow common analysis of test data.

Commenting on the collaboration with Keysight, Dr. Freundt, Head of Battery Testing and Validation at ElringKlinger AG, said, "The intensive exchange with Keysight on a very professional level and their deep understanding of our needs make Keysight the perfect partner to jointly drive this project to success."

- |

- +1 赞 0

- 收藏

- 评论 0

本文由ChangeArmy转载自Keysight,原文标题为:Building Better Batteries,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

Keysight and Proventia Collaborate to Optimize Electric Vehicle Battery Test Solutions

Keysight Technologies and Proventia Oy have collaborated to improve electric vehicle (EV) battery test solutions.

Keysight Enables Microamp Solutions to Accelerate Development of mmWave Radio Units for Private 5G Networks

Keysight Technologies announced that Microamp Solutions has selected Keysight Open Radio Architect (KORA) solutions to meet increasing demand for mmWave radio units in private 5G networks.

Keysight Cyber Training Simulator Provides Universities a Realistic Turnkey Cyber Range

Keysight Technologies has introduced Keysight Cyber Training Simulator (KCTS), a comprehensive, turnkey cyber range that simulates real-world traffic using the company‘s BreakingPoint solution.

电动汽车电池系统中电隔离和热传递的交叉:OBC、DC-DC和逆变器

描述- 本文探讨了电动汽车(EV)电池系统中电气隔离和热管理的挑战。文章强调了在电池管理系统(BMS)、充电器(OBC)、DC-DC转换器和逆变器等关键组件中,电气隔离和热管理的重要性。文章讨论了电池化学、电池组设计、热管理策略和电气隔离技术,以及它们如何影响电动汽车的性能、安全性和成本效益。此外,文章还提到了相关标准和法规,以及如何通过先进材料和制造工艺来优化电气隔离和热管理解决方案。

The Necessary Sensors for an Ev Battery Pack & Cell Connection System

In a typical Electric Vehicle, the battery pack may experience thousands of charge and discharge cycles throughout its life. The pack Battery Management System monitors voltage, current, and temperature of cells.

【元件】高能量密度动力电池EV battery适用于两轮电动车,具有较轻的重量以及良好的散热性能

朗升新推出EV battery电动两轮车的高能量密度动力电池,具有高能量密度、高倍率放电能力、超长的循环寿命以及良好的散热性能;体积小、重量轻、支持CAN及RS485通讯,能够为小动力产品提供最优的解决方案。

Electric Vehicle Malfunctions Due to Lack of Fuses or Diodes

With the development of life, electric vehicles have also become popular. In order to facilitate people‘s travel, many families have started to use electric vehicles, which are convenient and affordable. However, there are still many unknown problems that arise during use. Today, the editor will briefly talk about the structural issues of electric vehicles.

EV Battery Pack Water Detection Sensor from Amphenol Sensors

With the sharp growth of electric vehicles, many OEMs are using a water cooling system for the EV battery system. When water escapes the system and leaks into the battery pack, dangerous conditions are created. Amphenol Advanced Sensors‘ Water Detection Sensor monitors for water leakage by constantly checking resistance values. If a leak is detected in the EV battery pack, this sensor technology provides immediate notification.

Use of Adhesives in an EV Battery

Adhesive technology is an important component of EV battery pack manufacturing. ITW Performance Polymers offers a full range of globally available adhesives to meet all critical battery requirements.

eVTOL Battery vs EV Battery: What’s the Difference?

While both eVTOL and EV batteries share similarities in their reliance on lithium-ion technology and the need for safety, durability, and performance, the operational demands of eVTOLs push the boundaries of battery technology further. eVTOL batteries must meet more stringent requirements, including higher discharge rates, rapid charging capabilities, and exceptional safety standards to ensure reliable performance in flight.

How Does The Power Battery Packs of Electric Vehicle Survive The Summer?

Electric vehicles are becoming more and more popular among the public, and their core power batteries need to be resistant to high temperature, water, and frost. If the electric car does not work, the first time we should consider is the “core“ (battery) problem, so in the hot summer, how to deal with the high temperature?

电子商城

现货市场

服务

提供是德(Keysight),罗德(R&S)测试测量仪器租赁服务,包括网络分析仪、无线通讯综测仪、信号发生器、频谱分析仪、信号分析仪、电源等仪器租赁服务;租赁费用按月计算,租赁价格按仪器配置而定。

提交需求>

支持GSM / GPRS 等多种制式产品的射频测试,覆盖所有上行和下行的各项射频指标,包括频差、相差、调制、功率、功控、包络、邻道泄漏比、频谱、杂散、灵敏度、同道干扰、邻道干扰、互调、阻塞等等。满足CE / FCC / IC / TELEC等主流认证的射频测试需求。

实验室地址: 深圳 提交需求>

登录 | 立即注册

提交评论