WAYON Silicon Carbide Schottky Diodes with Lower Losses and Higher Switching Speeds

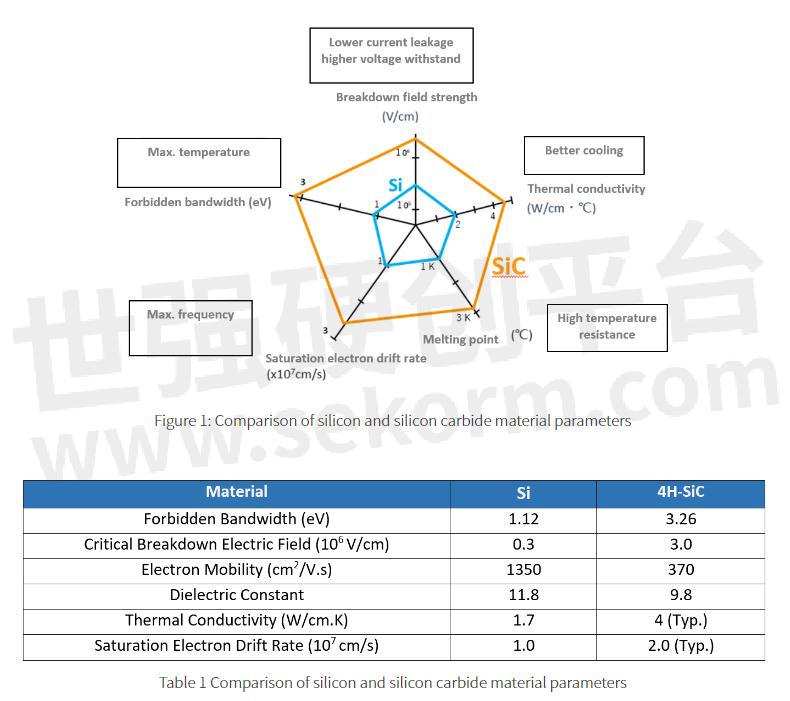

The third-generation semiconductor silicon carbide is currently the hottest topic in the semiconductor field. When it comes to silicon carbide (SiC), the first thing that comes up is its performance advantages, such as lower loss, higher voltage, higher frequency, smaller size, and higher junction temperature, making it ideal for manufacturing high-power electronic devices. In terms of applications, the relatively high cost of SiC makes customers hesitant to choose. In fact, in some applications with performance, efficiency, size, heat dissipation, and even system cost requirements, the cost gap between silicon carbide devices and silicon devices is narrowing. One typical example is the power supply industry.

Since silicon carbide materials have such obvious advantages, what benefits can silicon carbide Schottky devices actually bring?

1. Advantages of the device itself

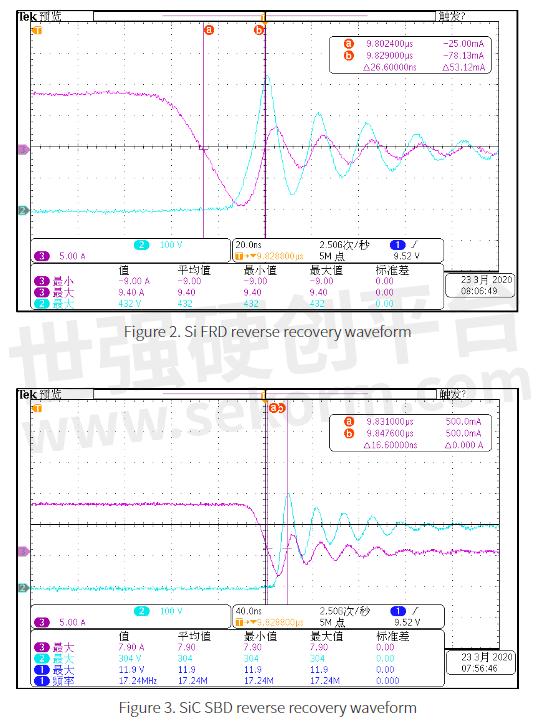

High breakdown voltage (commonly used voltage 650V/1200V), high reliability (junction temperature 175℃ ), small switching losses and conduction losses, device reverse recovery time is almost 0, and the recovery voltage stress is small (refer to the figure below), which helps to reduce system noise and improve EMI margin.

2. Advantages of Application

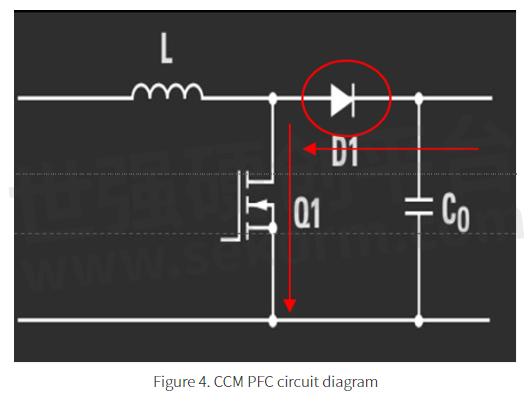

In CCM PFC circuits, the zero reverse recovery current of the silicon carbide Schottky reduces the current stress at the moment the main power MOSFET turns on, allowing it to convert power with less thermal loss. Silicon semiconductors must be much larger to achieve the same performance. This is reflected in the product, namely the silicon carbide Schottky in lower power supply temperature to improve conversion efficiency while also significantly reducing the size of the power supply, which will bring significant benefits to manufacturers.

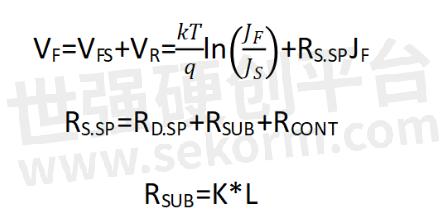

As an integral part of the power system, power semiconductors are one of the decisive factors in enhancing energy efficiency. In the history of Schottky's development, the pursuit of lower losses has been a common goal of the industry. Schottky device losses are mainly caused by conduction losses and switching losses, and useless power losses are released in the form of heat generation lines, causing an increase in power supply temperature.

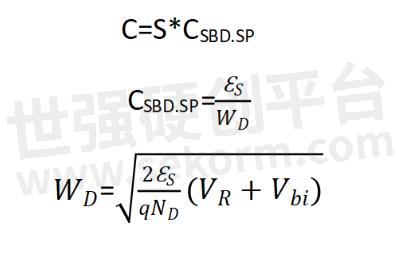

The conduction loss and forward voltage drop are positively correlated. Therefore, according to the VF forward voltage drop equation and the decomposition of the equation, we can conclude that reducing the chip thickness can effectively reduce VF. Thus, reducing the conduction loss.

Moreover, the switching loss is positively related to the capacitance value. According to the derived equation, reducing the junction area can effectively reduce the capacitance value and thus the switching loss.

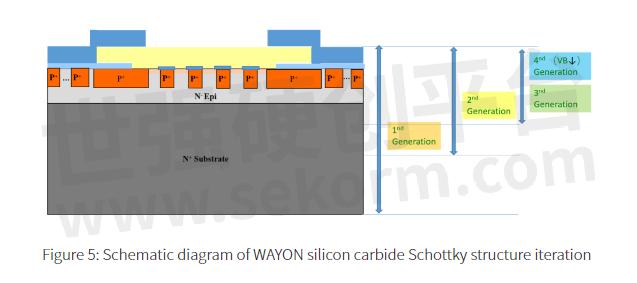

From a designer's perspective, the balance between forward voltage drops and capacitance is critical. The use of new processes can lead to better overall performance. The current process nodes for silicon carbide Schottky products can be broadly divided into the following four:

The first generation: chip thickness of 300μm or more for the process node, the common thickness is 300μm, 350μm, and 390μm. This process makes the chip thicker, which requires less scratching, metallization, and other processes in the processing. At the same time, the disadvantage is also obvious, due to the thicker chip, it is difficult to get a better comprehensive performance between the forward voltage drop and capacitance. Only a small number of domestic manufacturers are still using this process.

The second generation: Products are represented by a chip thickness of 250μm. At present, most of the mass production products of domestic manufacturers use this process. WAYON's first-generation products are also developed based on this process (currently updated to the third generation). Yet, compared to the international first-tier manufacturers there are still some gaps in this technology.

The third generation: Products are represented by a chip thickness of 150μm. This process is a new technology platform launched by most domestic manufacturers at the end of 2021 to early 2022, most manufacturers are still in the research and development stage. At the same time, some of the international first-tier manufacturers have adopted 150μm process to mass produce, such as the CREE C6 series. Yet there is still a gap between this process and the international best level.

The fourth generation: Products are represented by 100μm thickness. This process level is the current best mass production level in the world. For example, Infineon C6 and other products are developed using this node process, obtaining the comprehensive advantages of VF and capacitance performance. This node is also used in WAYON's current mass production process, which is 1 to 1.5 generations ahead of the domestic mainstream.

After 3 years of research and development, coupled with continuous self-optimization and iteration during the development process, WAYON's silicon carbide Schottky products have been updated three times: 250μm, 150μm, and 100μm. At present, all mass production products adopt a 100μm node (WAYON's third generation) thin chip process, which reduces capacitance by reducing chip thickness, and conduction loss and using the method of reducing the effective junction area, so that the performance of device parameters such as device current density, conduction loss and switching loss is superior to the level of the industry.

Cell phones and other consumer power supplies, solar inverter power supplies, new energy electric vehicles and charging piles, industrial control special power supplies, etc. As an important and rapidly developing application area, the development of the power supply industry benefits from the technological progress of power devices, which in turn promotes the development and manufacture of power devices. The use of silicon carbide Schottky devices in power supply modules has the following advantages:

·Very low switching losses;

·Higher switching frequencies;

·High junction temperatures, resulting in reduced cooling requirements and heat dissipation requirements;

·Smaller packages for more compact solutions.

Government industrial encouragement policy is important, but the real market demand, better user experience, and product advantages are the keys to triggering the market.

WAYON Silicon Carbide Schottky presents the following series of products:

WAYON continues to work on the development of Silicon Carbide Schottky Diodes with lower losses and higher switching speeds. The products are still undergoing continuous self-optimization, and the fourth generation is under development.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由飞猫警长转载自WAYON News,原文标题为:WAYON Silicon Carbide Schottky,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

【产品】维安车规碳化硅肖特基产品具有高耐压、高浪涌、低漏电特性,成为新能源车载领域“得力干将”

维安车规SiC二极管从原材料指定、芯片设计以及封装要求进行了整体优化,器件的高耐压、高浪涌、低漏电特性决定了器件可以适应严苛的应用。产品涉及650V、1200V、1700V等多个电压档位;封装涉及TO247-3、TO247-2等封装形式。

【元件】维安推出采用100μm节点薄片工艺的第三代碳化硅肖特基产品,具有低开关损耗、高开关频率等特性

3年的潜心研发,加之在开发过程中不断自我优化迭代,维安碳化硅肖特基产品历经250μm、150μm、100μm三次更新,目前量产产品全部采用100μm节点(维安第三代)薄片工艺,通过降低芯片厚度降低导通损耗和使用缩小有效结面积的方法降低电容,使器件电流密度,导通损耗和开关损耗等器件参数性能优于同行业水平。

维安推出应用于光伏微型逆变器的全系列功率器件和完整的系统级解决方案

针对光伏市场应用,维安产品组合包括全系列的功率器件,具体包括高压SJ-MOSFET、中压SGT MOSFET和IGBT模组和第三代半导体碳化硅肖特基二极管SiC SBD,此外,维安还可以提供AC/DC、DC/DC、LDO、保护器件等产品来实现完整的系统级方案。

ROHM’s New EcoGaN™ Power Stage ICs BM3G0xxMUV-LB Series Contribute to Smaller Size and Lower Loss

ROHM has developed power stage ICs with built-in 650V GaN HEMTs and gate driver - the BM3G0xxMUV-LB series. The devices are ideal for primary power supplies inside industrial and consumer applications such as data servers and AC adapters.

WAYON SILICON CARBIDE SCHOTTKY DIODE选型表

WAYON 提供SILICON CARBIDE SCHOTTKY DIODE(碳化硅肖特基二极管)选型:VRRM(V):650-1200,IF(A):2-40,IFSM(A):18-340,VF(V) Typ.:1.32-1.43。

|

产品型号

|

品类

|

VRRM(V)

|

IF(A)

|

IFSM(A)

|

VF(V) Typ.

|

IR(μA) Typ.

|

Package

|

|

WSRSIC006065NPC

|

SILICON CARBIDE SCHOTTKY DIODE

|

650

|

6

|

50

|

1.38

|

1

|

TO-220-2L

|

选型表 - WAYON 立即选型

WAYON(维安)电路保护产品选型指南

目录- OVER-VOLTAGE PROTECTION DEVICES MV & LV MOSFET POWER MOSFET IC PRODUCTS

型号- WE05DUCF,WMS140N06LG2,WMK043N10HGS,WEOS61089-17Q,WMM80R1K0S,WMB190DN10LG2,WMN26N65C4,WMQ30N04TS,WS4.5DPMF-BH,WMO35N06T1,WS6.3DFVH,WE05D5LC-B,SMF10CA,WS6.0P30SMC-B,SM4F36CA-AT,WMJ30N80M3,P8S24CA,WMN10N65C4,WS03D-B,WEOS4-100/300AS,WMN90R830S,WES806S,WMO048NV6LG4,WS18P6SMB,WMM12N80M3,WMM13N65EM,WECM5212Q,GDTN2RS3-470,WMK072N12LG2,WEOS4-150/270AS,WMLL025N10HGS,WMO80R480S,WMM90R360S,WMLL029NV8HGS,WMK05N70MM,WMK080N10LG2,WMN18N50C4,WS15D-B,WMR050N03LG4,5.0SMDJ20CAS,WMN15N60F2,WMN26N65F2,WMB120P06TS,WS64P6SMB-B,WEOS61089 SERIES,WS26P30SMC,WMLL020N10HG4,WMB108N03T1,SMF24A,WM03N58M2,WEOS61089-17F,WM03DN85A,WS05MDAC,GDTN2RS3B-150,WMLL020N10HGS,WML15N80M3,WMN10N65EM,WS08DF,WD3501,WS7.0P4S1,WS36D5-B-AT,WMO80R260S,WMB034N06HG4,WMF07N60C4,WMM07N90C2,WML06N80M3,WML80R260S,SMF58CA,WMO06N80M3,WS05-4R2P,WS2057KP,WS12M2TH,WS24P4S1-B,GDTA2RD8-800,WP8521,WMB60P02TS,WS12DFVXM,WS30P10SMB,WP8526,WMP03N80M3,WP8512,SMF3.3A,WMS13P04T1,WMP20N65EM,P6SMB120A,WMK30N70EM,WP250152S3-B,WMS05P06T1,GDTN2RS8-90,WP25P21F6-B,WMT04N15TS,WS05-2R2PL,WD2208,WE5112KF,WS6183EF,WEOS4-100/25AS2,WS12P4N3-AT,WS6.0P4SMA-B,WMM120N04TS,SM4F20CA-AT,WE5112KS,P6KE100A,WMK26N65C4,WS05D-B-AT,WMU25N06HG2,WML25N70EM,WM02P30M,WMS098N06LG2,WS3.3-4R1PH,WS3.3-2R1N,WS58P30SMC-B,WS12D-B-AT,GDTN3RD5-150,WMK14N65SR,WM02P56M3,WM02P56M2,WS12P4S1-B,WS48P6SMB-B,WE15DF,WMK28N65C4,WMO30P03TS,WMO26NV4T1,WML14N60C4,WP250152C5-B,WS4.5DPF-BH,WMK13N50C4,WMK049N12HG2,WMK072N12HG2,WS03D5-B,5.0SMDJ30CA,WML11N70SR,WS6112KF,WA3721,WS6.0P6SMB-B,WMM03N80M3,WA3722,WE05DLCF-B,WMM15N70C4,WMP06N70EM,WA3724,WS58P4SMA,WMK18N50C4,WMO10N105C2,WMA25N80M3,WMK08N60C4,5KP24CA,P6SMB16CA,WMP12N80M3,WS30DF,WS15D3HP,WS36P6SMB,WMK26N65F2,GDTN2RS5B-90,WJ1028,WMK90R830S,WML14N60F2,WJ1021,WML12N95C2,WMO55N03T1,SM4F15A-AT,WMJ90N65SR,WM06P17MR,WMA26N65C2,WP1506,WS6112KS,WMZ13N65EM,WS24P4S1H,WMK08N95C2,WS24M2T-BH-AT,WMO60P02TS,WMN10N65F2,WMK023N08HGS,WMM028N10HGS,WML90R1K1S,WMZ36N60C4,WMN14N70SR,WMK14N70C4,WS12DUC-B-AT,WMO690N15HG2,WM02DH08T,WMJ36N60C4,WMM26N70SR,WML20N70EM,WE05R,WE05D5BC-B-AT,WS4.5DPMF-BHM,WMP07N100C2,WM02DH08D,WS15P6SMB-B,WM02DH08M3,WS03DTUMS-BL,WE18DMS-B,WMM05N90C2,WMK25N80M3,WMJ90R360S,WP8111,12KP36CA,WMN15N95C2,WMS06P04T1,WM03P115R,WMK12N100C2,WMR14N03TB,WMP10N80M3,WMN05N105C2,5.0SMDJ43CA,WMP11N95C2,WEOS4-100/58AS,WMO16N65SR,WE03DUCF,WMO80R350S,WMO07N65C4,WMN15N60C4,WMK28N65F2,WE05DUCMS,WS4.5P4N3-BW,5KP33A,WS58P10SMB-B,WMB26N06TS,WMJ36N60F2,WM03P41M2,WE03DUCS,WEOS4-100/220AS,WMP13N65EM,WMJ12N80M3,WMT04P06TS,WMO10N50C4,WJ1043-AT,WM03P51A,WMB040N03LG2,WMM15N65F2,WEOS5-024GF,WMM08N70EM,WMJ26N65SR,WMN26N65SR,WMM040N08HGS,WML06N50C4,WS15P4S1-B,WMS13N03T1,WMO80N03T1,WMO26N60C4,WR1117A,WMQ119N10LG2,WM03N32M,WMN08N95C2,WS4.5DFVH,WMK26N60C4,WA3321,WML08N80M3,WMO16N70SR,WMM07N95C2,WMZ36N65C4,WA3324,WMM80P06TS,WML16N65SR,WMB060N08LG2,WP3302,WMT07N10TS,WP1118,WMK22N50C4,WML07N70C4,WML14N65F2,WE24D5,WMK07N105C2,WMM340N20HG2,WS03DLC-B,WP1113,WMO75N04T1,WP1112,WP1111,WM3DH60A,WP1117,WP1116,WP1115,SM8S24A,WP1114,WMO05N95C2,WP1108,WS40P30SMC-B,GDTN2RS3B-90,WMM08N70C4,WMN05N100C2,WS6112EF,WMS10DN04TS,WS15P30SMC-B,WS70RH,WS5.0P6SMB,WP1106,WMK048NV6HG4,WMO099N10LGS,WMM05N80M3,WEOS4XXGF,WP25021T5-B,WMK26N60F2,WMO10N100C2,WES806S2MC,WMJ35N80M3,WMO14N70C4,WMK80R720S,WA3331,WE05DMS-BH,WMP06N65EM,WMN06N90C2,WJ1044,WMP90R500S,WJ1043,WJ1042,WES506S2MC,WS712M,WJ1040,WA3339,WS15D,WMN53N65C4,WMO25P03TS,WMN10N60F2,WS6112ES,WMO20P04T1,WMR12N03T1,WMN13N50C4,WS64P4SMA-B,WECM5612Q,WS45P4SMA-B,WMK115N15HG4,WS05D-BH,WM02N50M,WJ1051,WJ1050,WML10N80M3,WMM90N08TS,WMN22N50C4,WMN08N60C4,WMB35P06TS,WMB46N03T1,WMO03N90C2,WS30DFVXMA,WA3358,WMO053NV8HGS,WM03N115A,WMO030N06HG4,WML14N65C4,WS36P30SMC-B-AT,WS4.5DPVL-AT,WS24P30SMC-AT,WML40N50C4,WMJ90N65C4,WMB50P03TS,WS1139ES,WML10N105C2,WMP08N70EM,WE3.3-8R2P,WML10N50C4,WS1219PT,WS24P4S1-BH,WS12M2T-AT,GDTA2RD5B-350,WMK25N50C4,WP3883CL,WS6414KC,WM03P91A,WML28N60C4,WMK05N105C2,WS05M2T-B,WS12M2T-BA,WS12P4SMA-B,WA3358A,WMT04N10TS,WS43P4SMA-B-AT,WE03DRF-B-AT,WS15P6SMB-BEM,WP6422,WMK80N08TS,WMQ30DP03TS,WP6420,WML03N90C2,WMN90R260S,WML20N65EM,GDTA2RD8-90,WMB037N10HGS,WML80R350S,WMQ55N04T1,WS48P6SMB,WMM36N60F2,WS03DTUF-B,WS05-4R5S,WMO14N65C4,WS15DUCMF,WMK10N60F2,WE03DUCF-AT,WS6173KS,WJ1051-AT,WMO11N80M3,WMO07N70C4,WMO08N80M3,WM02P60M2,WMN05N70MM,WML30N65EM,WML80R480S,WMB60P03TA,WML13N70EM,WMM18N65EM,WMJ95N60F2,GDTN2RS6-1200,WMO14N65F2,WA3393,WMN80R720S,WS12P6SMB-B,WMO90R1K5S,WS05-4R3P,WS12M2T-B,WMN07N80M3,WS15M2T-B,WM04P56M2,WMP05N90C2,WMS08DH04T1,WMF06N80M3,WMQ37N03T1,WP25P21T6-B,WMQ040N03LG2,WMQ40N03T1,WMB034N06LG4,WMM36N60C4,WS6.0P10SMB,GDTA2RD5B-90,WMM060N10HGS,WMK14N70SR,WS3.3-4R2P-AT,WS12DF-B,WEOS61089-17HN,GDTR3RD6-90,WMK25N10T1,WML06N90C2,WMK10N60C4,WS4.5DPF-B,WMO100N07T1,WMN09N90C2,WS07P4N3,WS18P4N3U,WMQ060N08LG2,WMK05N65MM,WML05N95C2,WMJ90N65F2,WS300P6SMB-B,WMK220N20HG3,WMB119N10LG2,WMK80N04T1,WS12D5-B,WMS690N15HG2,WMP07N95C2,WML07N65C4,WMM15N65C4,WE05MUC,WMP15N70C4,5.0SMDJ70CA,WES506S,WEOS4-80/25AS,WML12N105C2,WMQ30N03T2,WP2006,WMP07N60C4,WMJ26N70SR,WMM28N50C4,WA34310A,GDTA2RD5B-75,WMO90R1

Powering New Infrastructure, WAYON Launched the Domestic “coolest” MOSFET WMJ120N60CM with High-voltage of 600V

WAYON has developed an ultra-low on-resistance product WMJ120N60CM. The 600V high-voltage SJ-MOS in a conventional TO-247 package has a low on-resistance Rdson of 16.5mΩ, which can effectively improve the power density of power supply, solving the application pain point.

电子商城

现货市场

登录 | 立即注册

提交评论