【经验】导热垫片老化变硬问题怎么解决?

导热硅胶垫是目前常用的一种导热界面材料,应用在各种领域,像电子通信,消费电子,汽车电子等。然而在实际使用过程当中,会有不同的产品质量问题出现,其中比较常见的则是导热效果变差、硅油析出以及产品出现老化寿命下降硬度变大等问题,而在这些问题当中老化变硬的问题占据主要因素。

导热垫片的老化变硬是指:有机硅导热垫片在使用过程中,由于长期处于高温环境下,硬度会出现增长的现象,这将会使贴合度下降,增加热阻,同时导热垫片也容易开裂,甚至粉化,垫片寿命变短,严重情况还会出现导热垫片和被保护元器件分离,致使元器件直接裸露,严重影响垫片的使用效果和使用寿命,同时对电子电器设备也会造成损坏。

下面分析下导热垫片变硬的原因:

导热硅胶垫片是复合材料,由提供高弹性的加成型有机硅弹性体和提供导热性能的导热填料两部分混合制备而成。所以影响因素主要有以下几点:

1、交联剂过量太多(这个因数最大,也最容易出问题),一般来讲含氢硅油的添加时,含氢与乙烯基摩尔比需控制在(1.2-1.8): 1,这里的含氢包括侧氢和端氢硅油。很多人误认为端氢多加一点,强度会高一点,硬度会降低,所以会过量的加入端氢硅油,结果就是胶体回弹性下降,表面粘性下降,老化后硬度上升很快。

2、含氢硅油中的挥发分一般比较高,高的甚至会达到12%左右,这些挥发分中一部分是环硅氧烷单体(DMC),还有一部分是含氢小分子单体(直链或环状),这些含氢小分子的特性是中低温时活性不高,高温时会缓慢反应,从而引发的现象就是后期或老化后硬度变大。

3、乙烯基硅油和含氢硅油中挥发分偏高时,在老化过程中这些小分子会跑出,相当于体系油的量降低,这不仅会引起垫片变硬,同时还会使导热率下降。挥发后垫片接触界面还会变干,表面粘性下降。

4、粉料表面的包覆物不同,跟有机硅弹性体之间的相互作用力较弱,所以有些小分子物质会析出来,导致硬度变硬。

如何去解决这些问题呢:

1、控制好氢和乙烯基摩尔比,计算好氢和乙烯基摩尔比,控制在(1.2-1.8) : 1,端氢硅油添加量不宜过高,一般相对于乙烯基低于0.9。这样既能保证硬度稳定,还能保持产品回弹性。

2、控制原料的挥发分,有生产能力可将原料作预处理,或者直接使用挥发分低的厂家的乙烯基硅油和含氢硅油。

3、使用乙烯基含量低的乙烯基硅,一般来讲乙烯基含量低的硅油意味着分子量变大,粘度也会随之变大,这样会减少导热填料的填充量。而如果通过甲基硅油等增塑剂降低乙烯基含量,又会出现“冒油”的问题。

4、筛选合适厂家的导热填料,一定要跟有机体系相匹配上。

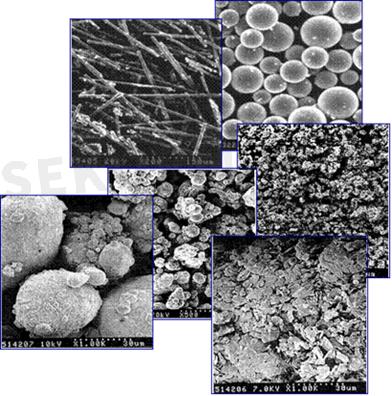

目前世强代理的固美丽导热垫片在老化变硬问题比其它厂家要好很多,其导热填料有自己独特的配方,其粒径,表面形貌及表面包覆物都是经过特殊设计和处理的,然后跟据其导热填料来设计有机体系,所以其可以精确控制好氢和乙烯基摩尔比,控制原料的挥发及乙烯基硅的含量,从而使整个体系的相容性达到最佳。所以固美丽的导热垫片非常柔软,热阻较小,挥发性和析油率都非常低,耐温性较好,而且使用寿命长,使用过程中基本不会出现导热效果变差现象,硬度也不会提高多少。固美丽常见的导热垫片有MCS30,TPS55和TPS60等。

- |

- +1 赞 0

- 收藏

- 评论 2

本文由刹那芳华提供,版权归世强硬创平台所有,非经授权,任何媒体、网站或个人不得转载,授权转载时须注明“来源:世强硬创平台”。

相关推荐

【经验】有机硅导热垫片渗油及挥发问题分析及解决方案

本文主要分析了导热垫片的渗油及挥发问题产生的原因,危害及解决方法,希望大家尽量选择国际大品牌,同时需要参考导热垫片数据手册里的Leachable silicone, %和Outgassing, % TML这两个参数。

【经验】光模块中各导热材料的应用及优缺点

光模块导热主要会用到空气,导热垫片,导热凝胶,U形金属块及高导热石墨等导热材料。其中空气没有成本但导热太差;导热垫片性价比高,但有一定压应力可能会造成光路偏离;导热凝胶可自动化生产且贴合度,任意成型,但前期准入门槛高;U形金属块导热效率高但增加重量,且需要开模;高导热石墨导热及均热效果突出但目前技术不够成熟且成本高。

【经验】陶瓷片VS导热垫片用于变频器中IGBT热处理的成本、性能优劣势对比分析

陶瓷垫片在变频器中IGBT上应用非常广泛,主要原因其具备25W/m-k的导热系数,感觉应用起来,导热性能应该非常优秀,另外很多很多应用还必须要求绝缘,陶瓷的绝缘强度约10~12KV/mm,参数上综合分析,陶瓷垫片是满足IGBT导热应用的绝佳选择。然而事实并非如此,陶瓷垫片硬和脆的特点带来了实际操作中的不便。本文通过综合对比导热垫片MCS30GL和陶瓷垫片在该应用的优劣,为你提供更多选择。

研讨会2024热设计服务&导热散热材料研讨会

12月5日直播,世强硬创平台将汇聚国内外顶尖品牌原厂,带来高导热热界面材料、新型散热器、隔热材料、散热风扇、TEC、氟化冷却液等新产品新技术。

【选型】Parker Chomerics(派克固美丽)热管理材料选型指南

目录- 产品简介 热传递基础 填缝材料 THERM-A-GAP™569,570,579,580,热垫片 THERM-A-GAP™974,G974,976,高性能热垫片 THERM-A-GAP™T63X系列,可涂布填缝材料 THERM-A-GAP™TP575NS,无硅热垫片 THERM-A-GAP™174,274,574,热垫片 THERMFLOW®相变垫片 HERMATTACH®热粘合带 THERM-A-FORM™可现场固化的灌注和底部填充材料 导热脂和导热胶 绝缘垫片 CHO-THERM®商用热绝缘垫片 CHO-THERM®高能热绝缘垫片 T-WING®和C-WING™薄型散热器 热管理词汇表 安全指南

型号- 65-00-T6XX-0030,WW-XX-5442-ZZZZ,WW-XX-D426-ZZZZ,T500,69-XX-20684-ZZZZ,WW-XX-D387-ZZZZ,69-12-XXXXX-A274,WW-XX-D390-ZZZZ,WW-XX-4659-ZZZZ,61 - 07 - 0909 - G570,69-XX-20698-ZZZZ,6WWXXYYYYZZZZ,T630,WW-XX-D409-ZZZZ,WW-XX-YYYY-ZZZZ,WW-XX-D6875-ZZZZ,WW-XX-D375-ZZZZ,WW-XX-D410-ZZZZ,69-XX-20686-ZZZZ,WW-XX-D424-ZZZZ,THERM-A-FORM™ T64X,69-11-25177-T630,65-00-T6XX - 0030,65-00-T670-3790,WW-XX-D399-ZZZZ,T63X,T404,T647,60-12-20264-TW10,69-11-24419-T630,T405,T646,T766,T644,T642,WW-XX-D385-ZZZZ,62-20-23116-T274,69-11-27155-575NS,69-12-22745-CW10,69 - 12 - XXXXX - A569,WW-XX-D414-ZZZZ,65-00-YYYY-ZZZZ,T650,T636,T635,WW-XX-D389-ZZZZ,65-00-T6XX - 0010,575-NS,WW-XX-D407-ZZZZ,62-16-23115-A274,WW-XX-8531-ZZZZ,WW-XX-D392-ZZZZ,WW-XX-D373-ZZZZ,69-11-27156-575NS,65-00-1642-0000,60-12-20267-TW10,T64X,69-11-27157-575NS,WW-XX-D379-ZZZZ,62-13-23114-T274,WW-XX-D396-ZZZZ,WW-XX-D382-ZZZZ,WW-XX-D418-ZZZZ,WW-XX-D403-ZZZZ,60-XX-YYYY-ZZZZ,274,WW-XX-4306-ZZZZ,62-04-23111-A274,65-00-1641-0000,65-00-T644-0045,WW-XX-402-ZZZZ,62-16-23115-T274,69-XX-20675-ZZZZ,WW-XX-4353-ZZZZ,WW-XX-D397-ZZZZ,T670,WW-XX-D417-ZZZZ,WW-XX-D378-ZZZZ,T405-R,T418,WW-XX-D419-ZZZZ,T777,T413,T414,WW-XX-D380-ZZZZ,T411,T412,69-12-22849-CW10,60-12-20269-TW10,65-00-T6XX-0180,WW-XX-D421-ZZZZ,WW-XX-4997-ZZZZ,WW-XX-D377-ZZZZ,T660,WW-XX-4305-ZZZZ,69-XX-27083-ZZZZ,69-12-23802-CW10,67-XX-YYYY-ZZZZ,69-11-27159-575NS,T444,65-01-1641-0000,WW-XX-4511-ZZZZ,174,TP575NS,65-00-T646-0200,WW-XX-D428-ZZZZ,WW-XX-5791-ZZZZ,WW-XX-8302-ZZZZ,WW-XX-D371-ZZZZ,WW-XX-D422-ZZZZ,974,976,65-00-T647-0200,WW-XX-6956-ZZZZ,T558,T557,WW-XX-4996-ZZZZ,61-07-0909-G174,62 - 20 - 0909 - A579,69-XX-20685-ZZZZ,60-12-20268-TW10,T441,62 - 20 - 0909 - A574,WW-XX-D381-ZZZZ,WW-XX-D412-ZZZZ,G974,65-00-T6XX - 0300,WW-XX-D411-ZZZZ,WW-XX-D374-ZZZZ,61 - 07 - 0909 - G174,WW-XX-4661-ZZZZ,WW-XX-D391-ZZZZ,PC07DS-7,WW-XX-D425-ZZZZ,WW-XX-D386-ZZZZ,6W-XX-YYYY-ZZZZ,WW-XX-D372-ZZZZ,WW-XX-D430-ZZZZ,65-00-T6XX-0300,WW-XX-D427-ZZZZ,WW-XX-D408-ZZZZ,WW-XX-D413-ZZZZ,69-11-27158-575NS,THERM-A-FORM™ 164X,WW-XX-D388-ZZZZ,69-XX-27072-ZZZZ,WW-XX-D423-ZZZZ,WW-XX-D376-ZZZZ,WW-XX-5792-ZZZZ,69-XX-20687-ZZZZ,WW-XX-D429-ZZZZ,WW-XX-D398-ZZZZ,T630G,6-6W-XX-YYYY-ZZZZ,69-XX-27070-ZZZZ,62-07-23112-A274,WW-XX-5527-ZZZZ,69-XX-27082-ZZZZ,62-10-23113-A274,WW-XX-D395-ZZZZ,1642,1641,WW-XX-4969-ZZZZ,65-00-T650-0003,WW-XX-4374-ZZZZ,WW-XX-D370-ZZZZ,WW-XX-D401-ZZZZ,62-20-23116-A274,WW-XX-D404-ZZZZ,WW-XX-D420-ZZZZ,C-WING,62-13-23114-A274,62-04-23111-T274,69-11-27154-575NS,65-00-T6XX - 0180,62-10-23113-T274,65-00-T644-0200,65-00-T642-0035,WW-XX-D383-ZZZZ,WW-XX-D405-ZZZZ,1671,60-12-20266-TW10,69 - 12 - XXXXX - A274,WW-XX-D416-ZZZZ,62-07-23112-T274,569,WW-XX-D065-ZZZZ,164X,T725,69-XX-YYYY-ZZZZ,65-00-T6XX-0010,65-00-T642-0250,65-00-T646-0045,WW-XX-D393-ZZZZ,THERM-A-GAP™ T63X,T609,570,WW-XX-D400-ZZZZ,69-XX-21259-ZZZZ,1678,574,1674,579,WW-XX-D406-ZZZZ,69-XX-20672-ZZZZ,65-00-T647-0045,WW-XX-D394-ZZZZ,69-XX-20991-ZZZZ,T710,580,WW-XX-D384-ZZZZ,WW-XX-D415-ZZZZ,60-12-20265-TW10,T-WING

Product Environmental Quality Certification

型号- CHO-SHIELD 571,THERM-A-GAP 569PT,CHO-SEAL 1285,SOFT-SHIELD 3500,SOFT-SHIELD 5000,CHO-SEAL 1401-S,CHO-SEAL V6433,CHO-SEAL 0862,THERMFLOW T725,CEL-XX-5103-XXXX,CHO-SEAL 1278,CHO-SEAL 0860,THERM-A-GAP T652,CHO-SEAL 1291,CHO-SEAL 1290,CHO-FORM 5575,CHO-THERM 1641,CHO-THERM 1646,THERM-A-GAP GEL 40,THERM-A-GAP T654,THERMATTACH T491,CHO-BOND 320,CHO-SEAL 1287,THERM-A-GAP 579KT,CHO-FORM 5560,CHO-SHIELD 596,CHO-MUTE 9000,THERM-A-GAP PAD70TP,SOFT-SHIELD 4850,FPCV-14244,THERM-A-GAP PAD30PN,CHO-FOILCCD,FPCV-13701,THERM-A-GAP F174,CHO-SHIELD 4076,THERMFLOW PC07DM-7,THERM-A-GAP GEL 40NS,CHO-SEAL 1298,CHO-SEAL 6503,CHO-SEAL 6502,CHO-MASK II CMT,CHO-THERM T609,THERM-A-GAP T630,CHO-FORM 5550,THERM-A-GAP T636,CHO-SEAL S6304,THERM-A-GAP G580,THERM-A-GAP T635,CHO-SEAL S6305,CHO-THERM T290,THERM-A-FORM 1641,THERM-A-FORM 1642,THERM-A-GAP G574,CHO-BOND 584,THERM-A-GAP 569PB,THERM-A-GAP G579,CHO-SEAL 1501,THERM-A-GAP PAD30G,THERMFLOW T710,THERM-A-GAP PAD30A,THERMAL GREASE T660,CHO-MUTE 9025,CHO-MUTE 9020,CHO-FORM 5541,CHO-FORM 5542,CHO-SEAL 6372,CHO-SEAL 6371,CHO-SEAL 6370,CHO-LUBE E117,THERM-A-GAP A580,SOFT-SHIELD 1000,THERM-A-GAP G570,THERM-A-GAP PAD60,CHO-FAB CFT,CHO-SEAL 1358,CHO-SEAL 1236,CHO-SEAL 1239,CHO-SEAL L6303,CHO-THERM T500,CHO-SEAL 1250,THERMAL GREASE T650,CHO-FOIL CCD,CHO-FOIL CCE,THERM-A-GAP T174,THERM-A-GAP A574,CHO-FOIL CCH,CHO-FOIL CCJ,CHO-FOIL CCK,THERM-A-GAP A570,THERM-A-GAP A515 RFA,CHO-FORM 5538,THERM-A-PAD-579PN,CHO-MUTE 9005,CHO-SHIELD 1091,THERM-A-GAP PAD60A,THERM-A-GAP A569,CHO-SEAL 1260,CHO-FORM 5526,CHO-FORM 5528,THERM-A-GAP GEL 8010,CHO-BOND 1099,CHO-FORM 5519,THERM-A-GAP 6579,THERM-A-GAP F574,THERM-A-GAP TPS60,THERM-A-GAP 579PN,FPCV-14832,THERM-A-GAP GEL 8017,CHO-BOND 1091,CHO-SIL 1485,CHO-JAC CJ-022-26,THERM-A-GAP 579PB,THERM-A-GAP 579,CHO-SEAL 1273,THERM-A-GAP PAD30,THERMAL GREASE T670,CHO-SIL 1356,CHO-FOIL CAD,THERM-A-GAP T274,CHO-SEAL 1270,CHO-FORM 5513,SOFT-SHIELD 2000,THERM-A-GAP 579PT,CHO-FORM 5515,CHO-SORB,THERM-A-GAP 6569,CHO-BOND 1088,TECKNIT 72-0008,THERM-A-GAP G174,CHO-LUBE4220,CHO-BOND 584-29,CHO-BOND 1083,CHO-SEAL 1265,THERM-A-GAP PAD80,CHO-BOND 1085,CHO-BOND 1086,THERMATTACH T405,CHO-SEAL 6452,CHO-SEAL 6330,THERMATTACH T404,CHO-SHRINK TUBES,CHO-LUBE 4220,CHO-BOND 360-208,CHO-SEAL 2561Y,CHO-FAB CRS,CHO-FORM 5506,THERM-A-GAP GEL 45,CHO-BOND 1076,CHO-BOND 2165,FPCV-13444,CHO-BOND 1077,CHO-SHIELD 608,THERM-A-GAP GELAB,CHO-BOND 1072,CHO-SEAL 1310,CHO-BOND 1073,CHO-SHIELD 604,CHO-BOND 1075,THERMATTACH T418,THERMATTACH T412,THERMATTACH T413,THERMATTACH T414,CHO-SEAL 6460,THERM-A-GAP 575NS,CHO-SEAL S6600,THERM-A-GAP G515 RFA,CHO-STRAP,CHO-BOND 1067,CHO-BOND 1069,THERM-A-GAP PAD70TPF,THERM-A-GAP TC60,THERMATTACH T410,THERMATTACH T411,THERMATTACH T428,CHO-SHIELD 2056,CHO-SHIELD 4916,CHO-SHIELD 4914,CHO-BOND 1055,CHO-BOND 1056,CHO-THERM T444,CHO-THERM T441,THERM-A-GAP TC50,THERM-A-FORM CIP35,CHO-SEAL 1215,CHO-SHIELD 2052,CHO-SEAL 1217,CHO-BOND 1053,CHO-SEAL 1212,CHO-SEAL 1350,THERM-A-FORM T644,THERM-A-FORM T646,THERM-A-GAP GEL 30,CHO-SHIELD 2044,THERM-A-FORM T647,CHO-SHIELD 4900,CHO-SHRINK BOOT,THERMFLOW T310,THERM-A-GAP G974,CHO-SHIELD 2040,CHO-SHIELD 610,CHO-SEAL 2557,THERMFLOW T557,CHO-SEAL 1221,CHO-SEAL 1224,THERM-A-FORM T642,THERMFLOW T558,CHO-BOND 360-20,SOFT-SHIELD 3700,CHO-SEAL 2542,THERM-A-FORM T644G,THERM-A-GAP T580,CHO-BOND 1029,THERM-A-GAP GEL20,THERM-A-GAP T630G,CHO-BOND 1035,CHO-BOND 1038,CHO-BOND 4669,CHO-BOND 592,THERMFLOW T766,CHO-BOND 1030,CHO-BOND 4660,THERM-A-GAP GEL 4517,THERM-A-GAP T574,CHO-JAC,CHO-THERM 1680,THERM-A-GAP T570,SOFT-SHIELD 4008,SOFT-SHIELD 4800,CHO-BOND 1018,CHO-BOND 1019,CHO-THERM 1684,THERM-A-GAP A174,SOFT-SHIELD 4004,SOFT-SHIELD 4002,THERM-A-GAP T579,SOFT-SHIELD 4000,SOFT-SHIELD I,TECKNIT 72-08116,CHO-BOND 1024,CHO-BOND 1027,CHO-SEAL 1401,THERM-A-GAP A579,THERMFLOW T777,THERM-A-GAP TPS60G,CHO-SEAL 6313,TECKNIT 0005,CHO-THERM 1671,TECKNIT 0002,CHO-SIL 1401,THERM-A-GAP GEL60HF,CH0-SEAL 0860,CHO-THERM 1674,CHO-THERM 1679,THERM-A-GAP T569,CHO-THERM 1677,THERM-A-GAP G274,CHO-THERM 1678,CHO-BOND 1016,THERM-A-GAP GEL37,CHO-SEAL 6308,THERM-A-GAP 976,THERM-A-GAP PAD30KT,CHO-SEAL 6307,CHO-SEAL 1651,CHO-SHIELD 2002,THERM-A-GAP GEL 75,CHO-SHIELD 2003,THERM-A-GAP 974,CHO-SHIELD 2001,CHO-THERM 1661,THERM-A-GAP A274,THERM-A--FORM CIP35,CHO-BOND 1121,THERM-A-GAP HCS,CHO-SEAL1285,CHO-SEAL 6435

笔记本cpu用导热硅脂还是导热硅胶片导热效果好?

常规笔记本电脑CPU会选用导热硅脂来进行散热,长时间使用会存在老化掉粉的风险。导热垫片就不会。可推荐Parker Chomerics 导热垫片MCS30,导热系数3.5W/mk,性价比高,数据手册可见:THERM-A-GAP™ GEL 8010 & GEL30 High Performance Fully Cured Dispensable GELS 数据手册

【选型】如何选择一款合适的导热垫片?

导热垫片占了导热界面材料一半的市场份额,应用非常广泛,所以导热垫片选择成为很多工程师的难点,导热垫片有几个非常重要的参数:导热系数,厚度,硬度,基体等,本文从这几个方面分析了导热垫片如何选择。

EU REACH ARTICLE SVHC DECLARATION OSHA ARTICLE SAFETY DATA SHEET

型号- CHO-BOND 1024,THERM-A-GAP T274,CHO-BOND 1027,CHO-MUTE 9020,THERMFLOW T766,CHO-MUTE 9025,CIP 210,CHO-BOND 1019,SOFT-SHIELD 2000,CEL-XX-5103-XXXX,THERM-A-GAP 976,THERM-A-GAP 974,THERM-A-GAP A569,CON-SIL A,THERMFLOW T777,THERM-A-GAP F574,CHO-SHIELD 596,CHO-THERM T500,CHO-BOND 360,THERM-A-GAP HCS,THERM-A-GAP A579,THERM-A-GAP A574,THERM-A-GAP T174,THERM-A-GAP A570,PREMIER AB140FR,FPCV-14244,FPCV-13701,CHO-BOND 592,THERM-A-GAP 579PT,CHO-BOND 1035,THERM-A-GAP TPS60,CHO-SEAL V6433,CHO-SEAL 1290,THERM-A-GAP 579PB,CHO-BOND 1030,THERM-A-GAP G570,THERM-A-GAP A580,THERM-A-GAP T579,CL-130,THERM-A-GAP G569,CHO-BOND 584,SOFT-SHIELD 1000,CHO-BOND 1029,72-08116,THERM-A-GAP T630,CHO-BOND 1067,CHO-BOND 1069,CHO-THERM 1661,CHO-SEAL L6303,THERM-A-GAP T636,THERM-A-GAP T635,THERM-A-GAP G580,THERMATTACH T491,CHO-SEAL 1285,CONSIL NC,CHO-SEAL 0860,THERM-A-GAP G574,CHO-SEAL 0862,THERM-A-GAP G579,THERM-A-FORM 1642,THERM-A-FORM 1641,THERM-A FORM T644,CIP 250,THERM-A-GAP GEL30,CHO-THERM 1679,CHO-BOND 1056,THERMAL GREASE T650,CHO-BOND 1055,CHO-THERM 1677,CHO-THERM 1678,CHO-THERM 1674,CHO-THERM 1671,CHO-BOND 1053,THERM-A-GAP 569PT,CHO-FAB CFT,CHO-LUBE 4220,CHO-FORM 5513,SOFT-SHIELD 4850,CHO-FORM 6600,CHO-FORM 5515,THERM-A-GAP T652,CHO-THERM T290,THERM-A-GAP 569PB,CHO-THERM 1684,THERM-A-GAP TPS60G,CHO-MUTE 9000,CHO-THERM 1680,CHO-SHIELD 610,CHO-BOND 1086,CHO-THERM T609,THERM-A-GAP T654,CIP 110,CHO-SHIELD 4076,THERM-A-GAP T630G,CJ-022-26,CHO-SHIELD 608,THERMFLOW T310,PREMIER APEI-140,CHO-BOND 1076,CHO-BOND 2165,THERMAL GREASE T670,SOFT-SHIELD 5000,CHO-SHIELD 604,THERMFLOW T557,CHO-BOND 1073,CHO-BOND 1072,THERMFLOW T558,PREMIER A240-FRHF,CHO-MUTE 9005,THERM-A-GAP 579KT,CHO-SEAL S6600,SOFT-SHIELD 3500,CHO-SEAL 6370,THERM-A-GAP A274,CHO-SEAL 6372,THERM-A-GAP F174,FPCV-13444,CHO-SEAL 1356,CHO-SEAL 1236,CHO-FORM 5541,THERM-A-GAP 579,CHO-SHIELD 2002,CHO-FAB CRS,CHO-BOND 1091,THERM-A-GAP TS15,THERM-A-GAP T569,THERM-A-GAP G274,CHO-SEAL 1221,PRIMER 1083,CHO-FORM 5550,PRIMER 1088,PRIMER 1085,CHO-THERM 1646,CHO BOND 4660,CHO-FORM 5506 FIP-C,CHO-FORM 5519,THERM-A-GAP T574,THERM-A-GAP GEL45,THERM-A-GAP T570,XTS8010,THERM-A-GAP A174,THERM-A-GAP T579,TC60,CHO-SEAL 1212,SOFT-SHIELD 4008,SOFT-SHIELD 4800,THERMFLOW PC07DM-7,CHO-SEAL 1217,SOFT-SHIELD 4002,SABIC C6200,SOFT-SHIELD 4000,CHO-FORM 5528,CHO-FORM 5526,SOFT-SHIELD 4004,THERM-A-FORM CIP35,THERM-A-GAP T580,THERM-A-GAP G515 RFA,CHO-SEAL 6460,TC50,THERM-A-GAP G174,PREMIER A220,SOFT-SHIELD 3700,PREMIER A225,R4013-24-C,THERMATTACH T410,THERMATTACH T411,CHO-SEAL 6452,THERM-A-FORM T646,CHO-SEAL 6330,THERMFLOW T725,XTS8030,CHO-MASK II CMT,THERM-A-FORM T647,PREMIER A230,THERM-A-FORM T642,PREMIER A235,CHO-BOND 4669,THERM-A-GAP G974,THERMATTACH T414,THERM-A-GAP 575NS,THERMATTACH T412,THERMATTACH T413,THERMATTACH T418,THERM-A-FORM T644G,CHO-FOIL CCK,CHO-FOIL CCJ,CHO-JAC,PARPHORM 1945,THERM-A-GAP GELAB,CHO-SHIELD 2044,CHO-FOIL CCD,CHO-SHIELD 4900,CHO-FOIL CCH,CHO-FOIL CCE,CHO-SEAL 6435,PREMIER A240,CIP 300,THERMATTACH T404,CHO-SEAL S6304,THERMATTACH T405,CHO-BOND 1121,TW10,CHO-SHIELD 2056,CHO-SHIELD 4914,CHO-SHIELD 4916,CHO-SEAL 6313,CHO-FORM 5560,CHO-SEAL 6307,PRIMER 1099,CHO-SHIELD 2052,THERM-A-GAP A515 RFA,PARPHORM 1800,THERMFLOW T710,CHO-FOIL CAD,CHO-SHIELD 571,PREMIER A240EC,TPS60G,CHO-SEAL 1401,CHO-THERM T441,CHO-THERM T444,THERMATTACH T428,CHO-SHIELD 1091

Parker Chomerics 产品概述

型号- CHO-TOUCH™,CHO-STRAP®,CHO-SEAL®,STREAMSHIELD OMNI-CELL® SHIELD-CELL,T-WING®,CHO-MUTE®,CHO-MASK®,SPRING-LINE®,DURALAN™,CHO-BOND®,CHO-FAB®,THERM-A-GAP™,WIN-SHIELD®,CHO-SORB®,THERM-A-FORM™,CHO-THERM®,THERMFLOW®,CHO-SHRINK®,THERMATTACH®,METALASTIC®,PREMIER™,CHO-FOIL®,CHO-LUBE,SOFT-SHIELD®,CHO-FORM®,POLA®,TECKFILM™,CHO-SHIELD®

THERM-A-GAP™ PAD 80 8.3 W/m-K Thermally Conductive High Performance Gap Filler Pad

型号- PAD 80,6W-XX-1015-ZZZZZZZ,THERM-A-GAP™ PAD 80

【选型】用于汽车真空泵主芯片与壳体间散热的绝缘导热垫片61-04-0404-MCS30GL

为改善汽车真空泵主芯片与壳体间的散热能力,更大程度上降低芯片表面的温度,一般需要在主芯片IC背面的PCB板上通过导热界面材料与外壳的铝板(散热器)接触散热,推荐Parker Chomerics(派克固美丽)MCS30系列导热垫片61-04-0404-MCS30GL,可满足设计需求,该导热垫片颜色为粉色,导热系数为3.0W/mK,双面带胶(硅胶自然粘性)。

电子商城

服务

可定制均温板VC最薄0.4mm,有效导热系数超5,000 W / m·K(纯铜(401 W/m·K ,石墨烯1,200 W/m·K)。工作温度范围同时满足低于-250℃和高于2000℃的应用,定制最低要求,项目年采购额大于10万人民币,或采购台套数大于2000套。

提交需求>

可来图定制均温板VC尺寸50*50mm~600*600 mm,厚度1mm~10mm,最薄0.3mm。当量导热系数可达10000W/M·K,散热量可达10KW, 功率密度可达50W/cm²。项目单次采购额需满足1万元以上,或年需求5万元以上。

提交需求>

登录 | 立即注册

提交评论