Keysight i7090 with PathWave Test Executive for Manufacturing

Manufacturing environments vary depending on the type of products you are building. While most industries do not require special consideration for their manufacturing space, the automotive industry and bio-medical sector require a higher level of control and cleanliness to their production floor. This is where no-touch manufacturing comes into play.

the author

No-touch manufacturing refers to a manufacturing setup whereby machines assemble and test products in a fully automated production line without operators and technicians. While you may think that having someone to watch over the production line helps, it may not be the case. The truth is that human beings are not consistent in decision-making. Each decision we make is a result of numerous factors and reasoning which includes personal experience and preference. The same problem can receive different solutions when managed by different people.

Physical contamination is another problem. The simple act of picking up a product off the production line and placing it back can introduce unwanted substances like oil and dirt onto the product or risk the misplacement of the product itself. One example is when the operator picks up a product for inspection and places it back on the conveyor line in the wrong orientation. This creates a line-stop scenario and can potentially damage equipment. Handling without proper grounding also results in electrostatic discharge damage to the product.

Minimizing human intervention during production enables the production to operate in a stable and predictable environment. Keysigt’s FlexiCore Parallel ICT system and i7090 Massively Parallel ICT system are automated inline handler systems designed specifically for high throughput automated inline test applications. Both models are supported by PathWave Test Executive for Manufacturing (PTEM) software which allows easy control of the handler’s operation. The automated inline handler operations are segmented into different operating stages with the relevant test steps built into the PTEM libraries. You can control how the handler operates without the need to manage the low-level details of the system’s sensors and drivers.

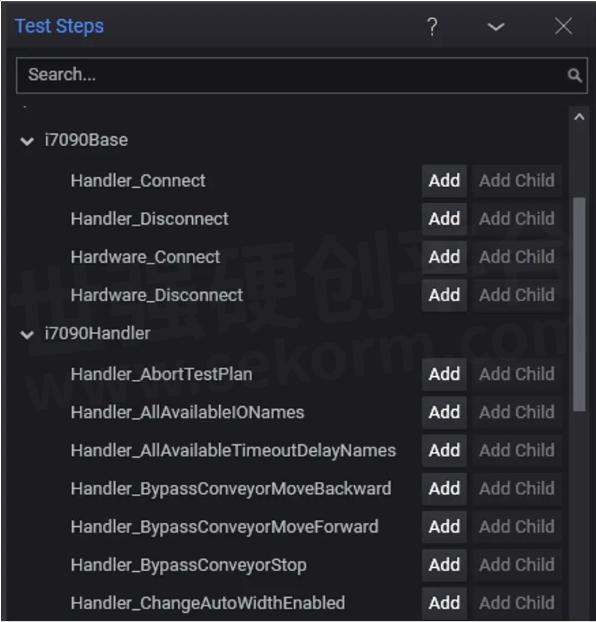

My earlier posts talk about the control of the FlexiCore Parallel ICT system using PTEM. This post discusses the control for the i7090 Massively parallel ICT system. In PTEM, test steps for the i7090 handler controls are listed under the i7090Base and i7090Handler sections. We just need a few of them to create the testplan for an automated test operation. The rest of the test steps allow you to control the movements of specific mechanisms in the handler manually or to query the states of various sensors.

Figure 1: i7090 inline handler control test steps built into PTEM.

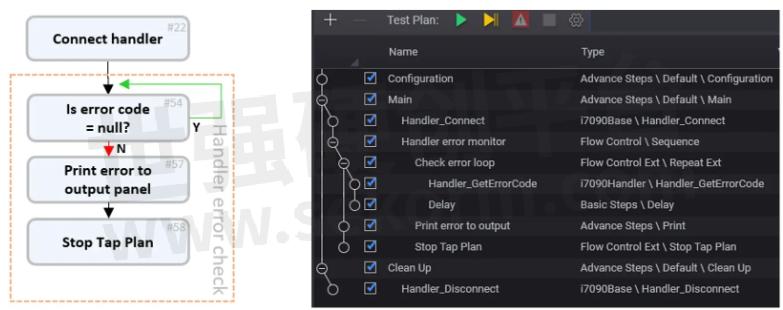

Let’s start by creating a sequence to monitor the error state of the handler. Figure 2 below shows a simple flowchart for the sequence. The flow starts with establishing a connection between the handler and PTEM. Once connected, we can query the error code of the handler and report the error state if detected.

Figure 2: Step sequence for handler error monitoring.

The step sequence in the PTEM testplan starts with the Handler_Connect step under the Main section. This step establishes the link between PTEM and the handler. The next step starts a conditional repeat loop to monitor the value of the error code from the handler.

Handler_GetErrorCode test step returns the value of the error code from the handler. A null value indicates normal operation whereas other values represent an error situation. Once an error is detected, the sequence exits the repeat loop and prints the error message before stopping the testplan execution with the Stop Tap Plan step. Upon stopping of the testplan, PTEM automatically executes the Clean-up section where the Handler_Disconnect step terminates the connection to the handler. This completes the handler error monitoring sequence in the testplan. When there is no error, the sequence continues to loop infinitely while the testplan executes other test operations in parallel.

Now with the error monitoring sequence running, we can start initializing the handler and load the configuration settings. The i7090 system handler supports the import of pre-defined handler configuration files. This allows you to quickly configure the system to match different operation setups like conveyor widths and press heights.

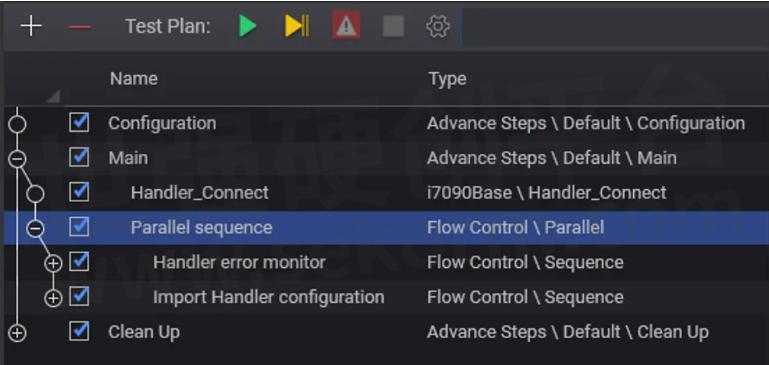

The use of Paralle l test step in PTEM allows multiple sequences to run at the same time. In our case, we keep the error monitoring sequence running in parallel with the other handler operation sequence. In Figure 3, the Parallel sequence group holds the Handler error monitor and Import Handler configuration groups as its child sequences. This creates two parallel running threads so that we continue to monitor for handler errors while importing handler configuration along with other tasks.

Figure 3: Error monitor and configuration import sequences run in parallel.

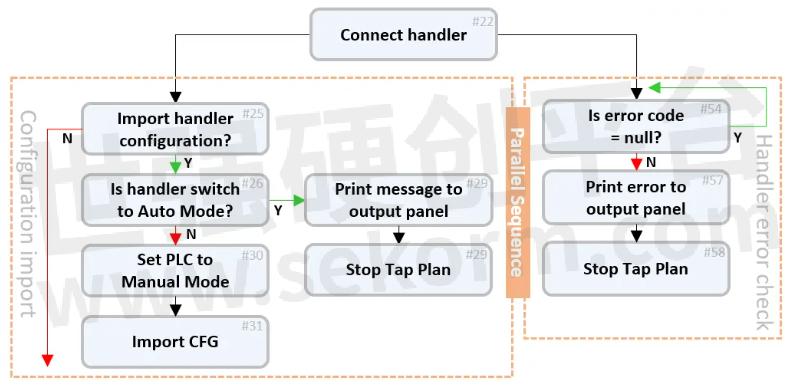

The flowchart in Figure 4 shows the sequence of importing handler configuration on the left and the parallel running handler error monitoring sequence on the right. Both sequences start after the connection to the handler is completed. While the error monitor sequence loops, the configuration import sequence loads the configuration file to the handler. Once the configuration is loaded, other sequences can follow while the error monitor sequence continues looping in parallel. We will talk about the other sequences in future posts.

Figure 4: Flowchart of error monitor and configuration import sequence.

Importing of configuration requires the handler to be switched into manual mode. In Figure 5, the beginning of the configuration import sequence checks the state of the handler using the Handler_IsSwitchInAutoMode step. If the return value is true, it indicates that the handler is not in manual mode and testplan prints an error message before terminating. If the return value is false, it means that the handler is correctly switched to manual mode. We then proceed to set the programmable logic controller (PLC) into manual mode with the Handler_SetManualMode step followed by the Handler_ImportSystemHandlerProfile step to import a 450mm single board configuration to the handler.

Figure 5: Testplan sequence to import handler configuration.

At this point, all necessary parameters required for the i7090 inline system have been loaded into the application. The handler is now ready to start the test operation.

Table 1 below provides the list of test steps that I discussed so far in this post. We will continue to add more to the list as we expand further into different test operations.

Table 1: Summary of handler control test steps described in this post.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由翊翊所思转载自Keysight Blogs,原文标题为:Keysight i7090 with PathWave Test Executive for Manufacturing,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

如何把KEYSIGHT示波器连接到matlab上?

怎么把KEYSIGHT示波器连接到matlab上呢?本文将讲解详细步骤。

Testing LED using PathWave Test Executive for Manufacturing

The standard in-circuit test measures each of the LEDs for their values and orientations. While this is sufficient to guarantee that each LED is good, more is needed to ensure the functionality of the product as a whole. With PathWave Test Executive for Manufacturing(PTEM), you can develop customized test sequences that test the actual functionality of the full assembly.

Boosting Your Manufacturing Analytics System with Keysight’s Pathwave Manufacturing Analytics (PMA)

With the recently launched feature that tracks all rework and scraps, PMA has helped manufacturers globally by working alongside their existing manufacturing systems to improve their cost of poor quality and leading towards lowering the defects of the test boards.

Keysight i7090 with PTEM – System Initialization

Automated inline handler systems for in-circuit testers rely on numerous sensors fitted around the system to detect and control mechanical operations. The programmable logic controller (PLC) runs a set of complex algorithms that supervise all handler operations and maintain control of safeguards. This ensures consistent and safe operation of the system. To prevent any external interruption to its operation, the PLC does not allow any user intervention to its process once it starts the automated operation.

Keysight将在NEPCON China 2024展示创新PCBA测试与汽车技术解决方案

NEPCON China 2024,即将为您呈现一场全新的电子制造行业盛宴!作为PCBA组装和测试领域的技术创新巅峰展会,Keysight将呈现前沿解决方案,助力PCBA测试稳步前行。还将展示汽车行业中最新的功能测试方案及半导体线键解决方案

Keysight i7090 with PTEM – Auto Mode Operation

An automated inline handler system minimizes human involvement in the handling of the product through a manufacturing production line. This improves efficiency and guarantees consistency in the quality of the product as it removes the ambiguity of human judgments and prejudice. Balancing the beat rate of different systems in a production line decides how efficient the manufacturing process will be. The key is to distribute the workload among the different machines or testers along the production line such that all of them work at the same beat rate.

是德科技与您相约NEPCON Asia深圳,将带来涵盖SMT产线的系统化电子制造测试解决方案,推动工业4.0

Keysight的系统化电子制造测试解决方案涵盖SMT产线,包括ICT、功能测试和开创性的PathWave制造数据分析(PMA)软件-旨在推动您的工厂步入工业4.0时代,是推动运营改进的重要力量。PMA从设计到制造在各个层面提供全面支持,实现问题的主动检测和优化。

是德科技大规模并行测试系统i7090荣获第十六届远见奖,可以测试多达2560个测试点

2023年3月9日,是德科技(Keysight Technologies,Inc.)i7090大规模并行测试系统荣获第十六届《SMT China表面组装技术》远见奖(Vision Awards)中的“VA优秀卓越大奖”和“VA编辑推荐奖”两项殊荣。

是德科技ICT在线测试及板级功能测试用户交流会邀您相约

是德科技ICT在线测试及板级功能测试用户交流会,是德科技将推出专门为汽车行业PCBA测试设计的系列颠覆性解决方案,有新产品从高达5760点的两模组3070 inline S7i,到各种功能测试方案;从揭露数据背后秘密的PathWave,到科技前沿的分段边界扫描方案;从运用在超多联板超高产能的i7090,到半导体封装中的隐藏缺陷;是德科技无处不在,时刻关心着您的产品制造测试。

Keysight Massively Parallel Board Test System Selected by LACROIX in Automotive Printed Circuit Board Manufacturing

Keysight Technologies, Inc. delivers advanced design and validation solutions to help accelerate innovation to connect and secure the world, announced that LACROIX Electronics has deployed the company‘s i7090 Massively Parallel Board Test System in their automotive printed circuit board manufacturing facility to reduce labor costs and improve throughput.

Keysight Introduces i7090 Massively Parallel Board Test System Supporting up to 20 Cores

Keysight Technologies, Inc. , a leading technology company that helps enterprises, service providers and governments accelerate innovation to connect and secure the world, has introduced the new i7090 massively parallel board test system. This is a new category of automated test equipment designed to perform tests in parallel, on multiple printed circuit board assemblies (PCBA), to achieve high volume throughput which speeds time-to-market and reduces cost-of-test.

是德科技即将亮相NEPCON China 2023,提供系统化电子制造测试解决方案

NEPCON China 2023将于7月19日-21日在上海世博展览馆隆重开幕。Keysight的系统化电子制造测试解决方案涵盖SMT产线,包括ICT、功能测试和开创性的PathWave制造数据分析(PMA)软件-旨在推动您的工厂步入工业4.0时代,是推动运营改进的重要力量。

Use FlexiCore to Automate The Functional Test

The automation trend is pushing more functional tests(FCT) systems into automated inline platforms. We have the FlexiCore Keysight has the FlexiCore Automated Inline Parallel In-circuit Test(ICT) system that house a standard instrument rack at the back of the system to provide the flexibility for installing different types of instruments according to user‘s functional test needs.

是德科技ICT在线测试及板级功能测试用户交流会邀您相约,分享最新的颠覆性解决方案和汽车行业电动汽车新兴技术测试方案

加入是德科技的交流会,与是德科技分享最新的颠覆性解决方案和汽车行业电动汽车新兴技术测试方案,为您的制造业发展之旅注入动力!携手共进,开创美好未来!

现货市场

服务

提供是德(Keysight),罗德(R&S)测试测量仪器租赁服务,包括网络分析仪、无线通讯综测仪、信号发生器、频谱分析仪、信号分析仪、电源等仪器租赁服务;租赁费用按月计算,租赁价格按仪器配置而定。

提交需求>

朗能泛亚提供是德(Keysight),罗德(R&S)等品牌的测试测量仪器维修服务,包括网络分析仪、无线通讯综测仪、信号发生器、频谱分析仪、信号分析仪、电源等仪器维修,支持一台仪器即可维修。

提交需求>

登录 | 立即注册

提交评论