KITAGAWA INDUSTRIES‘ Thermal Management Materials Meets Miniaturized and Faster Electronic Devices Needs

As electronic devices are becoming more miniaturized and faster, heat issues are put in the spotlight; the devices create high-temperature environments due to high-density design and continuous use. KITAGAWA Industries thermal management products help to lower temperature by conducting and insulating heat, resulting in better performance stability, and durability.

KITAGAWA Industries proposes suitable products with optimal materials, functions, and characteristics according to customers’ requirements and needs.

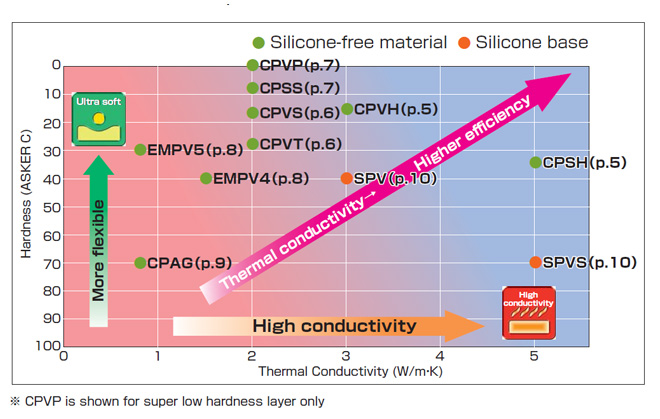

KITAGAWA Industries offers many kinds of Thermal management materials that have different features. Four Thermal pads are introduced here.

1. Non-Silicone Ultra-Low Hardness Type CPSS

<Features>

· Very soft thermal pad despite being non-silicone

· The pad has excellent adhesion due to good flexibility and stress relief, and therefore it can lower contact resistance.

· It uses non-silicone and creates no siloxane outgassing.

· Unlike silicone pads, the silicone-free pad bleeds hardly any oil and rarely causes problems to peripheral components.

<Applications>

In-vehicle, communication, and AV equipment

<Challenges>

Sometimes, a higher compression ratio of the thermal pad is required due to the components’ dimensional tolerances and gaps between units. However, if the pad has poor flexibility, loads on the heat-generating elements and printed circuit boards (PCBs) are large and may cause device malfunction. In addition, if object surfaces are not even, multiple thermal pads having different thicknesses may be necessary.

<Benefits>

KITAGAWA Industries products have excellent flexibility and stress relief and make the loads lower than the conventional thermal pads. (Since CPSS has high-stress relaxation, it is possible to increase the compression ratio, which allows high dimensional tolerances.)

<Non-silicone ultra-low hardness product>

· COOLPROVIDE (Both side tacky)/CPSS

· COOLPROVIDE (One side tacky)/CPSS-F

2. Non-silicone Highly Thermally Conductive Type CPVT, CPVH

<Features>

· Although it is a non-silicone high-thermal conductivity pad, the hardness is low.

· No siloxane gas is created and less likely to bleed oil compared with silicone type, and rarely causes problems to peripheral components.

<Applications>

In-vehicle, communication, AV and medical equipment, machine tools

<Challenges>

Conventional electrically insulating thermal pads usually have insufficient heat transfer.

High thermal conductivity pads have poor flexibility and stress release.

<Benefits>

KITAGAWA Industries products can lower contact thermal resistance since they possess both high thermal conductivity and low hardness.

<Non-silicone highly thermally conductive product>

· COOLPROVIDE/CPVT

· COOLPROVIDE (Both side tacky)/CPVH

· COOLPROVIDE (One side tacky)/CPVH-F

3. Non-silicone Composite Type EMPV

<Features>

· The thermal pad handles both thermal and EMC management. While having the same features as KITAGAWA Industries non-silicone thermal pads, it also suppresses electromagnetic (EM) waves with high magnetic permeability.

<Applications>

In-vehicle and communication equipment, LCD TV

<Benefits>

KITAGAWA Industries unique product helps to solve heat and EMC management issues. The pad can be utilized in limited internal spaces of equipment.

<Non-silicone composite product>

· COOLPROVIDE/EMPV4

4. Ceramic Heat Sink CECD

<Features>

· The heat sink is made of porous ceramic.

· Porous materials have large surface areas and excellent thermal emissivity even compared to metals, resulting in good heat dissipation.

· Around 30% lighter than aluminum

<Applications>

Communication equipment, electrical appliances

<Benefits>

Metal heat sinks may radiate EM waves, however, ceramics are insulators and radiate no EM waves.

<Ceramic heat sink product>

· CERACOLD/CECD

Thermal Solutions of KITAGAWA INDUSTRIES

More innovative, clean, and precise

As society and industrial structures change and develop at a dizzying pace, new technologies and functions bring the potential to drastically change KITAGAWA Industries way of life and values.

In 1984, KITAGAWA INDUSTRIES developed EMC components and early on proposed solutions to EM wave problems.

Since then KITAGAWA Industries have been providing advanced technologies and services in a wide range of fields, including new energy, engineering machinery, automobiles, biotechnology, IT, semiconductors, and medicine etc.

Together with KITAGAWA Industries clients, KITAGAWA Industries will continue to look ahead to accelerating technological innovation and aim for better products, more efficient production systems, and more innovative manufacturing.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由会飞的猪猪转载自KGS News,原文标题为:KITAGAWA INDUSTRIES’ Thermal management materials,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

High Thermal Conductivity Silicone Pad: An Innovative Choice for Heat Dissipation of Electronic Products

As the main raw material for high thermal conductivity silicone pads, silica gel plays an important role in the heat dissipation modules of electronic precision machinery products due to its excellent thermal conductivity and ductility. The soft texture of high thermal conductivity silicone gaskets makes them an ideal padding material, which can effectively fill the gaps between small parts, thereby improving the efficiency of heat conduction. Its convenience and economy during use make it the preferred heat dissipation material in various industries.

KGS 2023线上EMC技术研讨会&新产品发布会,超50个新品和解决方案等您解锁

KGS EMC技术研讨会&新产品发布会2023(线上会议)于2023年12月1日至2024年1月31日举行,新产品展示大约有50个新产品、开发企划产品和解决方案的介绍,还有EMC在线技术讲座将视频解说针对SiC半导体和车载装置的EMC对策验证技术。

派恩杰携自研功率器件产品出席CPEEC&CPSSC 2023,分享800V电压平台车规级器件技术与发展趋势

2023中国电力电子与能量转换大会暨中国电源学会第二十六届学术年会及展览会(CPEEC & CPSSC 2023)于2023年11月10-13日在广州召开。派恩杰应邀出席,半导体应用主任工程师雷洋博士在大会做专题工业报告——《面向800V电压平台的车规级碳化硅功率器件技术现状与发展趋势》。此外,派恩杰半导体也在现场展示最新技术及应用成果,展位号:三楼 3-015。

鸿富诚(HFC)热界面材料/屏蔽材料/吸波材料选型指南

目录- 公司介绍 Company Profile 热界面材料介绍 Thermal Interface Material Introduction 导热硅胶垫片 Thermal Pad 各向异性导热垫片 Anisotropic Thermal Pad 导热凝胶 Thermal Gel 导电泡棉 FOF Gasket 石墨泡棉 Graphite Foam 半包型导电泡棉 Half-wrapped Gasket SMT导电泡棉 SMT Gasket 全方位导电泡棉 XYZ Conductive Foam 导电PE Conductive PE 导电毛丝 Conductive FOA 导电布胶带 Conductive Fabric Tape 铜/铝箔胶带 Copper/Atuminum Foil Tape 吸波材料 Wave-absorbing Material 导热吸波材料 Thermal Conductive Absorbing Material

型号- H800-LY,HFS-15,HFS-18,H100,HFC-MC,H300,HFC-SMT,H500,H700,H350-SOFT,H100RS,H300-RB,HTG-150DK,HFC-MC系列,HTG-150D,HFC-GB系列,SMFB系列,H200RS,HFC-MFZ系列,HFC-AM,H1200,H250,HFC-GR系列,HTG-1000,HTG-100DK,H1000,HFS-20,H1000-SOFT,H150RS,HFC-A18000,SMFB,H250RS,HTG-600,HTG-500SF,HTG-800,SMFA,HTG-200,HFC-AM系列,HFC-MF,H300MAS,HFC-MT,SMT,H500-RB,HTG-200D,HFC-A系列,HFC-A25000,H150A15,H500-LY,HTG-800D,H100A15,HFS-30,HFC-AM5000,H200,H400,H600,H200-SOFT,H800,H300-SOFT,H100-SOFT,HFC-MF系列,HFC-AM1000,H200MAS,HFC-A5000,SMFA系列,H300-HC,HTG-300SF,HFC-MFZ,H150,HFC-GR,HTDG-250,H150-LY,H700-SOFT,H600-LY,H300-LY,HFC-A,H300-HR,H300-DR,SMT系列,HTG-300,HFC-GB,H200-LD,HTG-500,H150-LD

KGS(北弘科技、北川工业)导热材料选型表

可根据客户要求对硬度、厚度、使用温度等进行定制化设计;导热系数0.8~5;厚度0.15mm~3mm;防火等级V0;应用等级:工业级、汽车级、工业级;

|

产品型号

|

品类

|

导热系数(JIS R 2616)

|

硬度(ASKER C)

|

硬度(Shore 00)

|

厚度(mm)

|

体积电阻率(Ω·cm)

|

击穿电压(KV/mm)-JIS C2110-1

|

耐电压(KV/mm)-JIS C2110-1

|

防火等级(UL94)

|

使用温度(℃)

|

标准尺寸(mm)

|

应用等级

|

环保法规

|

|

CPVT-0.20F-200500S

|

非硅导热垫片

|

2

|

28

|

-

|

0.2

|

1.0*1013

|

11.1

|

5

|

-

|

-20~100

|

200*500

|

工业级

|

ROHS

|

选型表 - KGS 立即选型

A Brief Description of Thermally Conductive Materials - Carbon Fiber Thermal Pads

The popularization and research of 5G communication technology enables people to feel the experience of high-speed surfing in the network world, and also promotes the development of some 5G-related industries, such as unmanned driving, VR/AR, cloud computing, etc., 5G communication technology In addition to bringing people a pleasant network experience, it also has the problem of heat dissipation that needs to be solved.

Coolprovive™/CPSS

描述- 本资料介绍了COOLPROVIDETM / CPSS热导非硅型材料,其具有超软的特性,适用于降低热阻和提高散热效率。该产品采用无硅酮配方,减少油泄漏,并具有良好的压缩应力松弛性能。

型号- CPSS,CPSS-F

Coolprovive™/CPVH

描述- 本资料介绍了COOLPROVIDETM / CPVH热导非硅型材料,适用于高温应用。该产品具有超软、高导电性的特点,采用ASKER C 15材料,减少热阻并降低对加热元件和PCB的负载。它不含硅胶,无硅烷挥发,与基于硅胶的热材料相比油渗出较少。

型号- CPVH,CPVH-F

Waermtimo Provides Professional Thermal Conductivity Solutions to 5G Device Heat Dissipation

How to do a good job of heat dissipation of high power and high heat consumption products in the 5G era has become the trickiest problem that engineers need to face. Waermtimo provides customers with professional thermal conductivity solutions, including WT5912 and WT5902 series thermal pads and WT5921 series thermal gel.

Reusable Waermtimo Thermal Pads and Thermal Gel without Solvents Are Excellent Solutions to SmartWatch Heat Dissipation

As the load on the chip or processor of the Apple Watch is getting larger, the heat generation increase accordingly, placing higher requirements on heat-conducting and heat-dissipating materials. Recommended solutions include Waermtimo WT5912 and WT5902 series thermal pads and WT5921 series thermal gel.

北川工业的热管理材料,实现更好的性能稳定性和耐用性

随着电子设备变得越来越小型化、速度越来越快,散热问题成为人们关注的焦点。根据客户的要求和需求,北川工业提供多种具有不同特性的热管理材料。

Waermtimo’s High-Strength Thermal Pads Help LED Projectors Dissipate Heat More Effectively

This does not maximize the LED projectors‘ heat dissipation effect, because the heat sink and the chip cannot be perfectly bonded, and the air in the gap between the two is a poor conductor of heat. Therefore, a thermally conductive silicon film is required to achieve heat conduction.

热管理解决方案

描述- 本文主要介绍了低分子量硅氧烷、热导率、热阻、体积电阻率等热管理相关术语,并详细阐述了不同类型的热管理材料,如COOLPROVIDETM系列热界面材料、热扩散片、热阻尼材料等。文章还涉及了这些材料在电子设备中的应用,包括EMI吸收、热传导、振动阻尼等功能。

型号- CPVH,CECD-3.0-040040T,CPVT-F,CPAG-T,EMPV5-F,CPVP-F,CPVS-F,CPAG,CPSS,HSD,SPV,CPSH-F,HSD-0.30,CECD,CPSH,CECD-1.5-020020T,CPSS-F,HSD-0.22,HSD SERIES,CPVT,HSD-0.07,CPVT,CPVS,EMPV4,EMPV5,CPVP,CECD-3.0-020020T,SPVS,CPVH-F,EMPV4-F

Coolprovive™/CPVT

描述- 本资料介绍了COOLPROVIDETM / CPVT™热导非硅型散热材料。该材料适用于移动应用等有限间隙空间,具有超薄设计,厚度在0.1mm至0.25mm之间,具有良好的工作性和低热阻特性。

型号- CPVT-F,CPVT

电子商城

服务

可定制均温板VC最薄0.4mm,有效导热系数超5,000 W / m·K(纯铜(401 W/m·K ,石墨烯1,200 W/m·K)。工作温度范围同时满足低于-250℃和高于2000℃的应用,定制最低要求,项目年采购额大于10万人民币,或采购台套数大于2000套。

提交需求>

可来图定制均温板VC尺寸50*50mm~600*600 mm,厚度1mm~10mm,最薄0.3mm。当量导热系数可达10000W/M·K,散热量可达10KW, 功率密度可达50W/cm²。项目单次采购额需满足1万元以上,或年需求5万元以上。

提交需求>

登录 | 立即注册

提交评论