How Is the Servo Controlled Through PWM?

DSPOWER servo motor is commonly controlled through Pulse Width Modulation (PWM). This control method allows you to precisely position the servo’s output shaft by varying the width of electrical pulses sent to the servo. In this article DSpower will show how it works.

Pulse Width Modulation (PWM): PWM is a technique that involves sending a series of electrical pulses at a specific frequency. The key parameter is the width or duration of each pulse, which is typically measured in microseconds (µs).

Center Position: In a typical servo, a pulse of around 1.5 milliseconds (ms) indicates the center position. This means the servo’s output shaft will be at its midpoint.

Direction Control: To control the direction in which the servo turns, you can adjust the pulse width. For instance:

A pulse less than 1.5 ms (e.g., 1.0 ms) would cause the servo to turn in one direction.

A pulse greater than 1.5 ms (e.g., 2.0 ms) would cause the servo to turn in the opposite direction.

Position Control: The specific pulse width directly correlates with the position of the servo. For example:

A 1.0 ms pulse might correspond to -90 degrees (or another specific angle, depending on the servo’s specifications).

A 2.0 ms pulse might correspond to +90 degrees.

Continuous Control: By continuously sending PWM signals at varying pulse widths, you can make the servo rotate to any desired angle within its specified range.

DSpower Servo Update Rate: The speed at which you send these PWM signals can affect how fast the servo responds and how smoothly it moves. Servos typically respond well to PWM signals with frequencies in the range of 50 to 60 Hertz (Hz).

Microcontroller or Servo Driver: To generate and send PWM signals to the servo, you can use a microcontroller (like an Arduino) or a dedicated servo driver module. These devices generate the necessary PWM signals based on the input you provide (e.g., the desired angle) and the servo’s specifications.

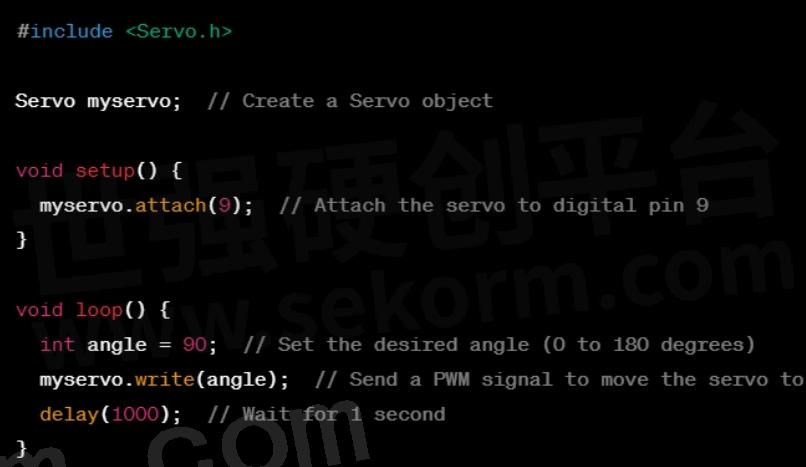

Here’s an example in Arduino code to illustrate how you might control a servo using PWM:

In this example, a servo object is created, attached to a specific pin, and then the write function is used to set the servo’s angle. The servo moves to that angle in response to the PWM signal generated by the Arduino.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由上山打老虎转载自DSPOWER News,原文标题为:How is the servo controlled through PWM?,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

What Kind of RC Servo Are Suitable for Remote-controlled Cars?

In this article, DSPOWER’ll take a closer look at remote control servos suitable for RC cars and what factors to consider when choosing one.

How to Select Suitable Remote Control Servos for Programming Robots?

Selecting the right remote control servo is crucial for programming a robot. Consider the precision, torque, communication protocols, compatibility, and brand when selecting a servo for your robot.

DSPOWER(德晟科技)微型集成伺服系统(舵机)选型指南

目录- Company Profile Brushless Servo & UAV Servo Mini Servo Series Digital Servo Series Robot Servo Wing Servo & Precition Gear Box Servo High Voltage Servo

型号- DS-S010A,DS-S022A,DS-H001,DS-S014M,DS-H006,DS-H009,DS-S006M,DS-H008,DS-S006L,DS-H003,DS-H002,DS-H004,DS-S003,DS-S004,DS-S001,DS-S002,DS-S002M,DS-S007A,DS-M005,DS-M004,DS-M003,DS-M002,DS-M001,DS-S020B-C,DS-S013M,DS-S016C,DS-R006,DS-F004,DS-S016,DS-S016M,DS-R004,DS-R005,DS-S017,DS-B002,DS-B003,DS-S008M,DS-F001,DS-F002,DS-B001,DS-F003,DS-U002,DS-U001,DS-Y003,DS-B008,DS-S009B,DS-S009A,DS-Y002,DS-Y001,DS-S011A,DS-S007,DS-S015M,DS-S005,DS-S006,DS-S007M,DS-S009,DS-S010,DS-S011,DS-S020A-C,DS-R002,DS-S011M,DS-R003,DS-S012,DS-S013,DS-R001

Robot Servo: Key Elements Analysis and Selection Guide

In today‘s rapidly evolving world of robotics, servo play a crucial role as one of the core components of robots. This article will provide a detailed analysis on key factors we should consider when choosing and using a robot servo.

DSPOWER Lanuched DS-E025A 3KG Clutch L-type Serial Building Block Steering Servo Motor

DSPOWER DS-E025A 3KG clutch L-type serial building block steering servo/motor Detailed introduction.

DSPOWER Launched the 2g Hollow Cup Micro Servo Ds-m005 with Small Body and Large Force Torque ≥0.35kgf·cm

The 2g hollow cup micro steering gear launched by Deseng Intelligent provides ≥0.35kgf.cm in small volume by carrying high-performance hollow cup motor; cm‘s high torque while still maintaining excellent response speed. In addition, it can also add electronic protection function to effectively prevent the phenomenon of blocking and burning and sweeping teeth.

Application of DSpower Servo in Unmanned Aerial Vehicles (UAV)

The application of servos in the field of drones has significant advantages, such as small size, light weight, simple structure, and easy installation. The application is not limited to basic functions such as flight control and attitude adjustment, but also involves multiple aspects such as executing complex actions and providing high-precision control.

What is a Servo? Analysis of the Internal Structure of the Servo

What is a servo motor? First, the name “servo motor“ is actually a colloquial term coined by those who play with model aircrafts and boats, as this type of motor is often used for rudder control. A servo motor is essentially a simple servo system, and it is also the most common type of servo system.

Overview of the Application of Servos in Different Types of Robots

Servos are widely used in the field of robotics, covering various aspects such as humanoid robots, quadruped robots, cleaning robots, service robots, special robots, as well as educational and scientific research robots.

DSpower Sweeping Robot Servo with High Torque Enables Precise Movement Control and Efficient Cleaning Operations in Sweeping Robots

DSpower‘s sweeping robot servo is a specialized motor that enables precise movement control and efficient cleaning operations in sweeping robots. Its features, such as precise positioning, high torque, durability, and power efficiency, contribute to the effectiveness and reliability of modern autonomous cleaning devices.

What Is a Brushless Servo?

A brushless servo, also known as a brushless DC motor (BLDC), is a type of electric motor commonly used in industrial automation applications. Unlike traditional brushed DC motors, brushless servo do not have brushes that wear out over time, which makes them more reliable and durable.

Designed for Smart Logistics, The Lever Servo DS-R018 50KG Pull Loop Control Multiple Feedback

DS-R018 logistics steering gear, integrated modular design; Steel transmission structure, effectively reduce the impact of the feed box, while with high performance brushless motor and magnetic encoder, to increase the load life of the steering gear to 2 million times; RS485 communication protocol with multi-angle position calibration system, closed-loop control, real-time feedback, but also one-click setting of the median, to ensure installation consistency.

DSPOWER Durable 20KG Class Semi-aluminum Frame Metal Tooth Servo DS-S020B Has a Maximum Torque of 28kgf.cm

The DS-S020B released by desheng Intelligence is a 20KG high performance standard servo. The servo adopts a radium-carved semi-aluminum frame shell design, which improves the overall strength while also optimizing the heat dissipation performance and maintaining a beautiful appearance. At 7.4V, the maximum output torque can reach 28kgf.cm. The design of copper teeth and aluminum teeth is used in the servo, which can effectively prevent the phenomenon of the servo sweeping teeth.

电子商城

品牌:TE connectivity

品类:Rotary Displacement Sensors

价格:¥2,789.4858

现货: 0

服务

使用FloTHERM和Smart CFD软件,提供前期热仿真模拟、结构设计调整建议、中期样品测试和后期生产供应的一站式服务,热仿真技术团队专业指导。

实验室地址: 深圳 提交需求>

可定制风扇尺寸范围:17mm*17mm*05mm~172mm*172mm*51mm。支持轴流风扇、离心风扇、涡流风扇、横流风扇等等产品的个性化定制。

最小起订量: 50000 提交需求>

登录 | 立即注册

提交评论