FPC Connectors: A Comprehensive Analysis of the Advantages and Disadvantages

FPC Connectors, also known as Flexible Printed Circuit connectors, are widely used in electronic devices as a connectivity solution. The main advantages of FPC connectors include their lightweight, flexibility, durability, and ease of maintenance, making them suitable for a wide range of industries. However, every product has its limitations, and FPC connectors are no exception. This article will delve into the advantages and disadvantages of FPC connectors.

Advantages

Lightweight and Flexible: FPC connectors have high flexibility and can be freely bent, making them ideal for applications with limited space. Their lightweight and flexible nature makes devices more portable and also facilitates maintenance and upgrades.

High Durability: FPC connectors are designed to have a long lifespan, often reaching millions of cycles. This is due to their excellent material selection and precise manufacturing processes. In environments where frequent usage is expected, FPC connectors maintain long-term stability and reliability.

Quick and Convenient Installation: Due to their flexible nature, FPC connectors can be quickly and easily installed onto circuit boards, significantly reducing installation and maintenance costs.

Diverse Interface Designs: FPC connectors come in various interface designs to meet different application requirements. Whether it's a miniaturized interface or a multifunctional one, FPC connectors offer corresponding solutions.

Disadvantages

Signal Transmission Quality: Although the transmission speed of FPC connectors is continuously improving, the signal transmission quality may be affected in high-frequency or high-data-rate applications.

Cost: The manufacturing cost of FPC connectors is relatively high, resulting in a higher price compared to some other connector options. This may limit their usage in price-sensitive fields.

Repair Difficulty: Due to the thin and flexible nature of FPC connectors, repairing them can be more challenging compared to other types of connectors. If damaged, replacing or repairing them may require more specialized equipment and skills.

Environmental Adaptability: While FPC connectors perform well in most environments, their performance may be affected in extreme conditions such as very high or low temperatures, strong magnetic environments, and so on.

Conclusion

In conclusion, FPC connectors have many significant advantages that make them an ideal choice in many applications. However, like any solution, FPC connectors also have limitations, such as cost, signal transmission quality, and repair difficulties. Therefore, when selecting FPC connectors, a comprehensive evaluation should be conducted based on the specific application requirements and environmental conditions.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由上山打老虎转载自Kinghelm News,原文标题为:FPC Connectors: A Comprehensive Analysis Of The Advantages And Disadvantages,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

What is the Difference Between FFC and FPC Connectors?

In order to improve your understanding of connectors, this paper will elaborate on two aspects: 1 A brief introduction of connectors, and 2 This paper introduces the differences between FFC connectors and FPC connectors, as well as their common types.

The Difference between FFC Connectors and FPC Connectors

In the electronics manufacturing industry, connectors are indispensable key components responsible for connecting circuits to ensure the stable transmission of current or signals. FFC connectors (Flexible Flat Cable Connector) and FPC connectors (Flexible Printed Circuit Connector) are two common types of connectors, each with unique characteristics and applications. This article will elaborate on the main differences between FFC connectors and FPC connectors.

Detailed Classification of FPC Connectors

With the rapid development of electronic technology, the application of Flexible Printed Circuit (FPC) boards in various electronic devices is becoming increasingly widespread. FPC connectors, serving as bridges between FPCs and other circuit boards, come in a wide variety, each with its characteristics. This article will provide a detailed overview of the classification of FPC connectors to help readers better understand and utilize these connectors.

The Visual Propaganda Matrix of “kinghelm Connects World“ Has Undergone An Iterative Upgrade, Accelerating The Implementation of Its Internationalization Strategy

“Kinghelm“ and “Slkor“ have developed into internationally renowned brands. These two companies have collaborated extensively in exploring and researching internet communication and promotion.

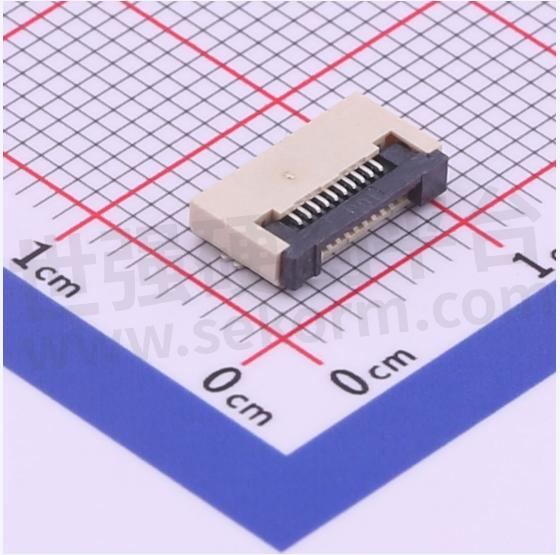

Kinghelm FPC Connector KH-FPC1.0-H2.0SMT-30P-QCHF: A Leader in Technological Innovation and Future Prospects

The Kinghelm KH-FPC1.0-H2.0SMT-30P-QCHF connector, with its fine pitch design, convenient SMT installation method, stable electrical connections, and wide application fields, will provide customers with higher quality connection solutions and promote innovation and development in the electronics industry.

FFC FPC Connector: The Key to Seamless Electrical Connections

Introduction:FFC (Flexible Flat Cable) and FPC (Flexible Printed Circuit) connectors are crucial components in the field of electrical engineering. These connectors play a significant role in ensuring seamless and efficient electrical connections in a wide range of electronic devices and equipment. In this article, we will explore the importance and applications of FFC FPC connectors and how they contribute to the advancement of the electrical industry.

FFC vs. FPC Connectors: Choosing the Right Connector for Your Application

When it comes to connecting electronic components, FFC (Flat Flexible Cable) and FPC (Flexible Printed Circuit) connectors are two popular options. Understanding the differences between them can help you choose the right solution for your application. This article will explore the key features, advantages, and typical use cases of FFC and FPC connectors to guide your decision-making process.

FFC FPC Connector: Everything You Need to Know

FFC FPC connectors are essential components in the electrical and electronic industry. Their flexibility, compact design, excellent electrical performance, ease of installation, and cost-effectiveness make them a preferred choice for connecting various electronic devices.

Kinghelm FFC/FPC Connector KH-CL1.0-H2.5-28PS Solves the Problem of Flexible Flat Cable Connection

Because of the progress of the times, the rapid development of science and technology, and the development of the electronics and electrical industry in recent years in all aspects makes the application of FPC connectors more and more widespread.

金航标FPC连接器选型表

金航标FPC连接器选型:每排PIN数:2-60,间距(mm):0.5-2.5mm,塑胶厚度(mm):2.5-3.8mm,多种安装方式:翻盖/直插/弯插/立贴/卧贴/掀盖等。

|

产品型号

|

品类

|

间距(mm)

|

类别

|

安装方式

|

PIN

|

高度(mm)

|

|

KH-0.5-H3.25-6PIN

|

FPC连接器

|

0.5mm

|

翻盖下接

|

卧贴

|

6P

|

3.25mm

|

选型表 - 金航标 立即选型

金航标天线选型表

金航标提供汽车定位天线,陶瓷天线,北斗天线,胶棒天线,蓝牙天线,吸盘天线,GPS天线,PCB天线,WIFI蓝牙FPC天线,玻璃钢天线,WiFi天线,4G通讯天线,吸盘弹簧天线,定位天线,通讯天线,羊角天线,一字天线,WIFI胶棒天线选型:信号2.4-6G,阻抗(Ω):50Ω,驻波比:≤1.5: 1/≦1.3/≤2.0/≤2.5等,最大功率(W):3-50W,极化方式:垂直/线性/水平极化/右旋圆极化等。

|

产品型号

|

品类

|

频率

|

信号

|

线材

|

阻抗(Ω)

|

驻波比

|

增益(dBi)

|

最大功率(W)

|

尺寸

|

规格

|

极化方式

|

方位波束宽度

|

|

YL46-4G-SMA-174-3M

|

汽车定位天线

|

698-960/1710-2700MHz

|

4G

|

RG174线

|

50Ω

|

≤2.0

|

2.15dBi

|

40W

|

46*16mm

|

SMA镀金内螺内针

|

垂直

|

全向

|

选型表 - 金航标 立即选型

金航标RJ45连接器选型表

金航标提供RJ45连接器选型:额定电压(V):125 VAC RMS,额定电流:1.5A,LED:不带LED/带LED,类别:RJ插座,规格:弯插/直插/全包全塑等。

|

产品型号

|

品类

|

种类

|

LED

|

规格

|

颜色

|

额定电流

|

额定电压

|

使用寿命

|

接触电阻

|

|

KH-RJ45-56-8P8C-D-T

|

RJ45网络连接器

|

RJ45网络连接

|

带LED

|

带弹

|

黑色

|

1.5A

|

125 VAC RMS

|

至少750次循环

|

最大35mΩ

|

选型表 - 金航标 立即选型

金航标转接线选型表

金航标提供转接线选型,由套管、接头、端子、公针、公头同轴线/射频线等组成的射频连接线套件,线长(mm):20-14000,种类:TNC转IPEX/IPEX转SMA/SMA转IPEX/MMCX转SMA/MMCX转IPEX/MMCX转BNC等,颜色:黑色/白色/灰色/棕色/蓝色,套数:两件套/四件套/五件套/六件套。

|

产品型号

|

品类

|

种类

|

线长(mm)

|

线材

|

颜色

|

规格

|

|

KH-TNC-113IPEX-65

|

连接线转接线

|

TNC转IPEX

|

65

|

RG113线

|

黑色

|

TNC母头母针直头镀镍转I-PEX

|

选型表 - 金航标 立即选型

电子商城

服务

可加工2-32层PCB/1-5阶HDI/FPC柔性线路板/Rigid-Flex Board软硬结合板,最小线宽线距:2mil;最小孔:3mil;铜厚:1-10OZ。

最小起订量: 1 提交需求>

可加工PCB层数:1-30层;板材类型:FR4板/铝基板/铜基板/刚扰结合板/FPC板/高精密板/Rogers高频板;成品尺寸:5*5mm~53*84cm;板厚:0.1~5.0mm。

最小起订量: 1 提交需求>

登录 | 立即注册

提交评论