What Are the Common Types of FPC Flexible Circuit Boards?

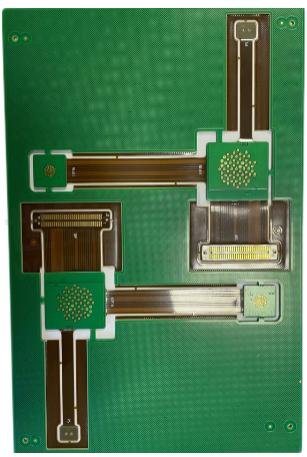

According to BLF, at present, FPC flexible circuit boards are single-sided, double-sided, Multi-layer flexible circuit boards, and rigid-flexible combined circuit boards of four kinds.

Single-side flexible circuit board is the lowest cost when the electrical performance requirements are not high printed board. In single-side wiring, a single-side flexible circuit board should be selected. It has a chemically etched conductive pattern layer, and the conductive pattern layer on the flexible insulating substrate is calendered copper foil. The insulating substrate may be polyimide, polyethylene terephthalate, arylamide fiber ester, and polyvinyl chloride.

A Double-sided flexible circuit board is a conductive graph etched on both sides of the insulating substrate film. The metallization hole connects the two sides of the insulating material to form a conductive path to meet the flexural design and use function. The covering film can protect the single and double-sided wire and indicate the position of the element.

The multi-layer flexible circuit board is a single or double-sided FPC flexible circuit board of 3 or more layers laminated together, through drilling and electroplating to form a metalized hole, forming a conductive path between different layers. In this way, there is no need to use a complex welding process. Multilayer circuits have great functional differences in terms of higher reliability, better thermal conductivity, and more convenient assembly performance. The interaction of assembly size, number of layers, and flexibility should be taken into account when designing the layout.

The traditional rigid-flexible circuit board is composed of rigid and flexible substrates pressed together. The structure is tight and metalized to form a conductive connection. If a printed board has both front and back components, the rigid flexible circuit board is a good choice. But if all the components are on one side, it is more economical to use a double-sided flexible circuit board and layer FR4 reinforcement on the back.

FPC flexible circuit board with mixed structure is a kind of multi-layer board, the conductive layer is composed of different metals. An 8-layer board uses FR-4 as the medium for the inner layer and polyimide as the medium for the outer layer, with leads extending from three different directions of the motherboard, each of which is made of a different metal. Copper alloy, copper, and gold are used as independent leads. This kind of hybrid structure is the only feasible solution when the relationship between electric signal conversion heat conversion and electrical properties is harsh. It can be evaluated by the convenience of the interconnecting design and the total cost to achieve the best performance-price ratio.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由上山打老虎转载自BLF,原文标题为:What are the common types of FPC flexible circuit boards?,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

解析四种FPC柔性线路板的常见类型:单面、双面、多层和刚柔结合

本文中宝利峰将为大家介绍四种常见的FPC柔性电路板类型。目前FPC柔性电路板有:单面、双面、多层柔性电路板和刚柔结合电路板四种。

技术探讨 发布时间 : 2023-11-18

FPC成型方式及环境介绍

在FPC出产制造中,成型,是在品检包装前的工序,也是制造过程中的最终一道工序。为了让每片产品的外形一致、漂亮、标准、符合规划要求,FPC成型方法一般挑选模冲成型以及切开成型、手艺成型。本文中宝利峰将为大家介绍FPC成型方式及环境。

技术探讨 发布时间 : 2023-11-19

一文详解柔性线路板优势与特性

在电子产品加工行业中。柔性线路板是由柔性绝缘基板制成的印刷电路,主要用于手机、笔记本电脑、数码相机、PDA、液晶显示器等产品。从性能上说,它拥有硬音刷电路板所不具备的优点,本文简单分享柔性线路板FPC的优点。

技术探讨 发布时间 : 2023-12-04

新添柔性线路板厂商,宝利峰与世强硬创达成战略合作

宝利峰的柔性线路板有单面柔性线路板、双面柔性线路板、多层柔性线路板和刚柔结合线路板共四种。

签约新闻 发布时间 : 2023-12-13

通过FPC软板遇上电磁屏蔽膜后的阻抗变化研究,为设计提供修正阻抗计算方式参考

随着电子器件朝着小型化、便携化方向发展,电子器件的组装也越来越集约化。挠性线路板,由于其具有体积小、重量轻、线路密度高等优点,逐渐地取代了传统导线在电子器件组装的作用。从近几年来,挠性线路板(FPC)占印制线路板(PCB)市场份额从不足10 %提高至20 %以上,也证明了FPC软板柔性线路板市场需求的发展。

设计经验 发布时间 : 2024-02-09

一文详解双面柔性线路板

本文介绍了双面柔性线路板LED火焰灯柔性板特点,结构,工作原理及其他特性。

原厂动态 发布时间 : 2024-01-04

双面柔性线路板制造工艺全解过程

柔性线路板除部分材料以外, 柔性线路板所用的材料基本都是卷状的。由于并不是所有的工序都一定要用卷带工艺进行加工,有些工序必须裁成片状才能加工,如双面 柔性线路板的金属化孔的钻孔,目前只能以片状形式进行钻孔,所以双面柔性线路板第一道工序就是开料。

设计经验 发布时间 : 2023-11-24

服务

可加工PCB层数:1-30层;板材类型:FR4板/铝基板/铜基板/刚扰结合板/FPC板/高精密板/Rogers高频板;成品尺寸:5*5mm~53*84cm;板厚:0.1~5.0mm。

最小起订量: 1 提交需求>

可加工2-32层PCB/1-5阶HDI/FPC柔性线路板/Rigid-Flex Board软硬结合板,最小线宽线距:2mil;最小孔:3mil;铜厚:1-10OZ。

最小起订量: 1 提交需求>

登录 | 立即注册

提交评论