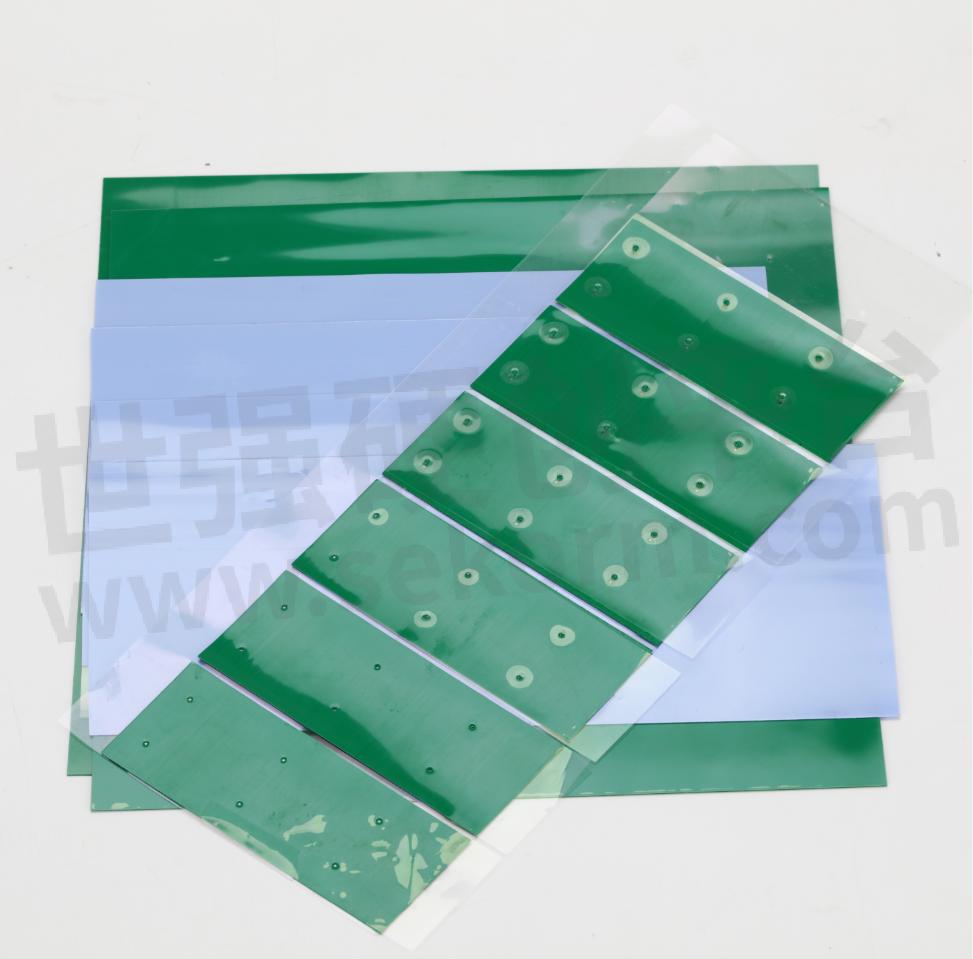

Thermal Phase Change Sheet: An Innovative Choice to Improve Heat Dissipation Efficiency

In conventional cooling systems, cooling modules are usually installed on or around the heat source surface of the device to actively guide heat. However, there is a common problem in this process: the contact between the heat source surface and the heat sink is not perfect, and a small gap is enough to affect the effective transfer of heat. This is because the heat will encounter air obstruction during the conduction from the heat source surface to the radiator, thereby reducing the heat conduction efficiency.

Among many thermally conductive materials, thermally conductive phase change sheets stand out for their unique properties. The characteristic of this material is that it can not only effectively reduce the contact thermal resistance between the heat source and the radiator, but also significantly improve the heat dissipation effect of the device. The key to the thermally conductive phase change sheet is its phase change capability: within a specific temperature range, it will soften but not lose, changing from a solid state to a thick semi-fluid paste. In this process, it can fill the gap between the heat source and the heat sink as much as possible, thereby effectively reducing the contact thermal resistance and improving heat conduction efficiency.

It is worth noting that the thermal phase change sheet becomes soft under working conditions, but once it stops working and the temperature returns to the normal range, it will return to its original state. Compared with other thermal conductive materials, thermal phase change sheets show excellent performance in thermal conductivity efficiency, so they are widely used in scenarios with extremely high heat dissipation requirements, such as high-performance chips and large servers.

To sum up, thermally conductive phase change sheets play a vital role in the heat dissipation system of modern electrical equipment. With the continuous advancement of technology, it is expected that this material will play an important role in more demanding heat dissipation applications, providing strong support for the stable operation and long-term durability of electrical equipment.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由Vicky转载自SHEEN News,原文标题为:Thermal conductive phase change material: an innovative choice to improve heat dissipation efficiency,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Heat Dissipation Application of Thermal Interface Material in PCB board

There are many heat sources on the PCB board, so there are many thermal interface materials used, and the application range is very wide.

盛恩提供柔软的15.0W/m·K金刚石导热硅胶片,带有自粘性,在高功率电子设备导热具备良好优势

盛恩15年专注高可靠性导热材料研发生产,积极挑战新型导热材料的研发,具备生产具有低热膨胀率,超高导热率,及轻质量的金刚石导热硅胶片。除了其超高的导热率,在力学、光学、电学等也有着优异的表现。

盛恩专业从事高可靠性导热界面材料,具备多项国际认证,同时获得UL安全认证

在电子设备的热管理领域中,导热硅胶片的选择至关重要。面对市场上众多供应商,消费者常会问:“导热硅胶片哪家好?”这一问题的答案关系到产品的性能、可靠性及最终设备的操作效率。在这一领域中,盛恩凭借其出色的产品质量和服务,会是是您不错的选择。

Thermally Conductive Materials with Ultra-high Thermal Conductivity

The thermally conductive material is a general term for materials that are coated between the heating device and the cooling device of the equipment and reduce the contact thermal resistance between the two.

What Are the Characteristics of a Phase Change Thermal Pad?

The phase change thermal pad is a member of the thermally conductive material. , is also a very characteristic of a new type of thermal conductivity material. In this article, Sheen will introduce the characteristics of a phase change thermal pad.

Does the Thermal Pad Need to Have Glass Fiber?

In order to increase the tensile strength and stability of the thermal pad, it needs to be reinforced with glass fiber, so that the toughness of the thermal pad is improved.

Why Does Thermal Resistance Affect the Thermal Conductivity of Thermal Silicone Pad?

Thermal silicone pad is a kind of gap-filling thermal pad made of silicone resin as the base material and added with temperature-resistant and thermally conductive materials. It has the characteristics of high thermal conductivity, low thermal resistance, insulation, compression, etc.

Why Use Thermally Conductive Materials?

The purpose of using a thermal interface material is to fill the gap between the two and remove the air in the gap, thereby reducing the heat dissipation of the heating device and the cooling device. Indirect contact thermal resistance, thereby increasing the rate of heat transfer.

SP205A-30 导热相变片 Phase Change Thermal Interface Sheet

SP205A-30是一种相变材料,适用于电子设备的热管理。该产品能在45-55℃的温度范围内软化,以更好地填充接触界面缝隙,提高导热效率。它具有良好的导热率和低热阻特性,适合用于高频微处理器、电脑、服务器等领域。

盛恩 - 相变材料,PHASE CHANGE THERMAL INTERFACE SHEET,相变热界面片,导热相变片,SP205A-30,高频微处理器,台式电脑,手提电脑,LED照明产品,集成芯片,存储器,计算机服务器

SP205A-35 导热相变片

SP205A-35是一种适用于电子设备的热管理解决方案,采用相变材料技术,能够在特定温度范围内软化以填充接触面缝隙,提高散热效率。该产品具有高导热率、低热阻和自粘性等特点,适用于多种电子产品。

盛恩 - PHASE CHANGE THERMAL INTERFACE SHEET,相变热界面片,导热相变片,SP205A-35,高频微处理器,集成芯片,存储器,手提电,脑台式电脑,计算机服务器,LED 照明产品

SP205A-L-80 导热相变片

SP205A-L-80是一种导热相变片,适用于电子器件散热。该材料在45-55℃范围内发生相变,具有良好的导热率和低热阻特性,能有效填充散热器与电子器件间的空隙,提高散热效率。

盛恩 - PHASE CHANGE THERMAL INTERFACE SHEET,相变热界面片,导热相变材料,导热填充材料,导热相变片,SP205A-L-80,高频微处理器,台式电脑,手提电脑,集成芯片,存储器,计算机服务器,LED 照明产品

SP-350P 导热相变片

SP-350P是一种相变温度介于50℃至65℃的热传导相变材料,室温下为固态,超过相变温度后变为液态,具有良好的润滑和压缩性。该产品适用于填充散热器和功率消耗型电子器件之间的间隙,以降低热阻,提高散热效率。

盛恩 - PHASE CHANGE THERMAL INTERFACE SHEET,相变热界面片,导热相变片,SP-350P,高频微处理器,台式电脑,开关电源,HIGH FREQUENCY MICROPROCESSORS,POWER MODULES,计算机服务,SWITCHING MODE POWER SUPPLIES,电脑服务,笔记本,手提电脑,MEMORY MODULES,电源模块,NOTEBOOK,开关模式电源,存储模块,LED照明,LED LIGHTING,AUDIO AMPS,COMPUTER SERVES,LED 照明,DESKTOP PCS,缓存芯片,CACHE CHIPS,内存模块,音频放大器

SP205A-60 导热相变片

SP205A-60是一种相变材料,适用于电子设备的热管理。该产品在45-55℃开始软化,能更有效地填充接触界面缝隙,提高导热效率。它具有自粘性、低热阻和高导热率等特点,广泛应用于高频微处理器、电脑、服务器等领域。

盛恩 - 相变材料,PHASE CHANGE THERMAL INTERFACE SHEET,相变热界面片,导热相变片,SP205A-60,高频微处理器,台式电脑,手提电脑,集成芯片,存储器,计算机服务器,LED 照明产品

SP205A-30 导热相变片

SP205A-30是一种适用于电子设备的热管理解决方案,它利用相变材料的特性来提高导热效率。该产品在特定温度范围内从固态变为液态,能更好地填充接触面间的缝隙,降低热阻。

盛恩 - 相变材料,PHASE CHANGE THERMAL INTERFACE SHEET,相变热界面片,导热相变片,SP205A-30,高频微处理器,台式电脑,手提电脑,集成芯片,存储器,计算机服务器,LED 照明产品

SP205A-50 导热相变片

SP205A-50是一种相变材料,适用于电子设备的热管理。该产品在特定温度范围内软化以填充接触面缝隙,提高导热效率,同时在室温下保持固态以便于操作。

盛恩 - 相变材料,PHASE CHANGE THERMAL INTERFACE SHEET,相变热界面片,导热相变片,SP205A-50,高频微处理器,台式电脑,手提电脑,集成芯片,存储器,计算机服务器,LED 照明产品

电子商城

服务

使用FloTHERM和Smart CFD软件,提供前期热仿真模拟、结构设计调整建议、中期样品测试和后期生产供应的一站式服务,热仿真技术团队专业指导。

实验室地址: 深圳 提交需求>

提供稳态、瞬态、热传导、对流散热、热辐射、热接触、和液冷等热仿真分析,通过FloTHERM软件帮助工程师在产品设计初期创建虚拟模型,对多种系统设计方案进行评估,识别潜在散热风险。

实验室地址: 深圳 提交需求>

登录 | 立即注册

提交评论