Why Thermal Gel Become More and More Popular?

The thermal gel is a kind silicone two-component paste-like thermal conductive filling material. It mainly meets the requirements of low pressure and high compressive modulus during use. It can realize automatic production. It has the properties of excellent contact with electronic products, low contact heat resistance, and excellent electrical insulation. This material has the advantages of thermal pad and thermal grease, while at the same time better compensating for the shortcomings of the above two materials.

The thermal gel has the advantages of good affinity, weather resistance, and good insulation performance. At the same time, it has strong plasticity, can meet the filling of uneven interfaces, and can meet the heat transfer requirements of various applications. It has the characteristics of high thermal properties, low compression force, high compression ratio, good electrical insulation performance, and excellent temperature resistance, which can be used automatically.

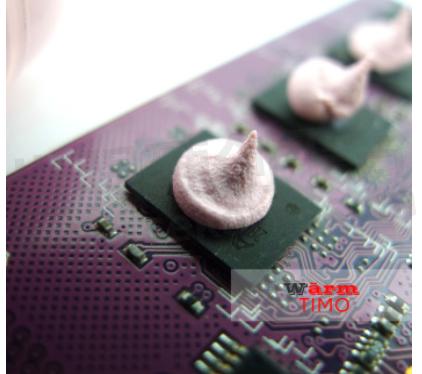

Fig.1

Thermally gel is typically packaged in syringes that are inherently solvent-free. It is currently the most advanced thermal conductive material, and suitable for robotic automated assembly lines.

1. Thermal gel has the advantages of high thermal conductivity, ultra-low thermal resistance, no need for heat treatment, convenient construction, etc.

2. It has the same plasticity as plasticine and is easy to match with product designs with large variations in thickness.

3. Will not deform when static usage after molding, excellent anti-aging performance.

4. Low-stress, low-modulus thermal conductivity products

5. Self-adhesive, no need to use additional adhesive products

6. Excellent high-temperature resistance, weather resistance, radiation resistance, and excellent dielectric properties

7. Superior chemical and mechanical stability

8. Store at room temperature and have low storage costs.

Fig.2

What else advantages does the thermal gel have?

1) Ultra-low thermal resistance of thermal gel to optimize heat dissipation of products

2) Convenient for R&D and design. Since the thermal gel is paste-like and permanently self-adhesive, there is no need to especially consider the product size and tolerance limits in the product design, and it can be flexibly used according to the best design effect.

3) Convenient procurement management, thermal gel is packed in the syringe, and one model specification can meet the needs of multi-machine and multi-products, greatly simplifying procurement management and warehouse management

4) The thermal gel process is automated, and the syringe package can be automatically dispensed, which greatly improves engineering efficiency, reduces labor cost and time costs, and optimizes the stability of the product.

Based on the advantages of high deformation, high thermal conductivity, and high insulation, the thermal gel is widely used in: Robotic automation assembly, automotive industry, communication industry, ABS system, LED chip, communication equipment, mobile phone CPU, memory module, power module such as IGBT, power semiconductor field, etc.

Waermtimo WT 5921 thermal gel is made of silicone, adding thermal conductive filler and bonding material in a certain proportion, and processed by a special process. It has excellent weather resistance, radiation resistance, and superior dielectric properties.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由三年不鸣转载自Waermtimo News,原文标题为:Why thermal gel become more and more popular?,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

What is Thermal Putty?

Thermal putty, also known as thermal gel, is a highly versatile thermal interface material (TIM) designed to efficiently transfer heat between electronic components and their cooling solutions.

How to Choose from Silicone Thermal Pad and Phase Change Thermal Pad?

In the fields of electronic product manufacturing and the automotive industry, thermal management solutions are crucial for the performance and longevity of devices. The choice of thermal conductive materials directly affects the efficiency of heat dissipation. This article compares two commonly used thermal conductive materials: silicone thermal pads and phase change thermal pads.

Why Thermal Silica Pads Are Leading Materials for Electronic Product Cooling?

The application of a thermal pad not only solves the problem of heat dissipation but also has the effect of insulation and shock absorption between components. It is the best choice for the design and development of ultra-thin electronic products.

德聚(CollTech)丙烯酸/环氧/硅系/聚氨酯产品选型指南

描述- CollTech has business operations spaning across Asia, Americas and Europe and support customers on an array of applications used in the automotive, consumer electronics, semiconductor, medical device, renewable energy and general industry market. CollTech has been committed to providing exemplary customer service by offering solutions for applications requiring high-performance materials.

型号- PW 1506F,PW 1401D,N-SIL 8112TC,PW 1518M,PW 1516HF,EW 6710,N-PU 5612B,N-SIL 8113B,EW 6300M4B,PW 1518MB,N-SIL 8557C,PW 1442,EW 6300M,AW 2922M,N-SIL 8391,NOBELPLA 3090F,N-SIL 8522BL,NOBELPLA 3090C,N-SIL 8532W,N-SIL 8551,N-SIL 8552,N-SIL 8553,N-SIL 8556,N-SIL 8115B-L,N-SIL 8138B,N-SIL 8522BLHQ,N-SIL 8522LD,PW 1504H-2,EW 6300M4,PW 1451,EW 6300M2,PW 2440NRHQ,N-SIL 8118XY,N-SIL 8523WL-2,CT 6020H,N-SIL 8138T,PW 2440NR,EW 6652,PW 1485LD,NOBELPLA 3090LV,PW 1422,CT 6020HV,AW 2928MT,PW 1516NF-2,N-SIL 8610,N-SIL 8115BXY,EW 6684-3,N-SIL 8539HB,PW 1008M,N-PU 5667HQ,EW 6300,N-SIL 8551W,PW 1488 KT,N-SIL 8523W,N-SIL 8462,NOBELPLA 3036HV,N-PU 5103M,PW 2440LR,PW 1485B,PW 1490MC,PW 1485L,EW 6640HB,PW 1081,PW 1485M,EW 6078,N-SIL 8522WL,N-PU 5667,PW 1485N,PW 1081M,PW 1488,N-SIL 8352,N-SIL 8113,N-SIL 8630,N-SIL 8356,PW 2466R,N-SIL 8358,N-SIL 8118,N-SIL 8537P,N-SIL 8511HB,PW 1446M,PW 1486MH,PW 1490C,AW 2928,CT 6020,PW 1490D,AW 2922,PW 1490E-2,PW 1516NF,EW 6300M4-HV,N-SIL 8512BT,N-SIL 8523WL-2HQ,PW 2466E,PW 1486ML,N-SIL 8539BH,EW 6660HV,PW 2440NRPO,N-SIL 8530L,PW 1504F,N-SIL 8523,N-PU 5801B-DD,N-SIL 8522HB,CH 9000,NOBELPLA 3086,N-SIL 8552HB,CT 2290,N-SIL 8539E,N-SIL 8522WLHQ,N-SIL 8539G,CT 2295,N-SIL 8608D,PW 1462,N-SIL 8539B,CT 6010,EW 6300F,N-SIL 8530,N-SIL 8135,N-SIL 8551NT,N-SIL 8539W,N-SIL 8522WLPO,PW 2460N,N-SIL 8539S,N-SIL 8539M,N-SIL 8539N,AW 2903,N-SIL 8113XY,PW 1488M,N-SIL 8556F,PW 2440HRHQ,PW 2440HR,AW 2902,AW 2901,NOBELPLA 3090

Bornsun Offers Thermally Conductive Interface Materials to Meet WiFi Router‘s heat dissipation

As a medium for wireless Internet access, routers need to provide users with faster network transmission efficiency, which brings about a greater need for heat dissipation. In addition, the public‘s demand for lighter and lighter everyday products has led to the development of smaller routers, which makes the internal thermal management of the product more difficult.

Waermtimo, a New Composite Cooling Material Supplier, Anounced a Distribution with Sekorm to Enrich Carbon Fiber Thermal Conductive Materials and More

Waermtimo focuses on developing various new composite heat dissipation materials. It has more than 10 kinds of patented technologies, including two-component thermal conductive silicon sheet, PET film with spherical graphite layer, high-density graphene radiators, heat dissipation materials, and their preparation methods, to provide customers with heat conduction materials with high thermal conductivity and low thermal resistance.

Waermtimo WT5902 and WT5921 Series High Thermal Conductive Materials Suitable for VR Glasses Heat Conduction

Important components are densely distributed on the motherboards of the somatosensory devices, like VR glasses or VR headsets. High thermal conductive materials suitable for heat conduction and evacuation of VR glasses include Waermtimo WT5902 series thermal pad and WT5921 series thermal gel.

55 Top Electronic Materials Brands Authorized Sekorm as Main Distributor

In order to enrich the choice of electronic materials for Hard & Core Technology enterprises, Sekorm has continuously expanded its electronic material brand. At present, Sekorm is an authorized distributor of 40 electronic material brands.

【应用】WT5921-86导热凝胶用于10G combo pon光模块,渗油率<0.01,导热系数8.6W/mK

10G combo pon光模块采用带制冷器封装的激光器,所以发热量比较大,需要用高导热的导热材料将激光器上的热量传导到外壳上散热。针对其散热,推荐沃尔提莫导热系数高达8.6W/mK的WT 5921-86导热凝胶。

Colltech半导体元件材料解决方案

型号- N-SIL 8340,N-SIL 8341,N-SIL 8636,EW 6728,N-SIL 8170,N-SIL 8172,N-SIL 8051,EW 6505CL

Waermtimo Offers High-strength Thermal Conductive Pad and Thermal Pad for High-speed Optical Module Heat Dissipation

To solve the heat dissipation problem of the optical module, the heat dissipation panel must meet the two conditions of heat conduction and heat dissipation. The heat dissipation of chip components mainly uses high thermal conductive materials with a certain degree of flexibility.

Thermal Pad on LED Lights-Small Size, Great Effect!

LED lights have many advantages such as energy saving, environmental protection, safety, long life, high brightness, easy maintenance, etc., not only general lighting, but also used in various fields such as indication, display, decoration, backlight, etc. It’s called four generations of light sources.

沃尔提莫新材料技术股份有限公司简介

描述- 沃尔提莫新材料技术股份有限公司(WaermTimo)是一家专注于导热、散热高新材料生产制造的国家高新技术企业。公司提供导热效能优异、性价比高的导热材料产品,具备自主研发能力、敏捷的生产能力、严格的品控管理和快速灵活的交付能力。产品应用领域广泛,包括电子产品的发热器件散热解决方案。公司拥有德国斯图加特、日本大阪、天津、深圳和东莞等研发和制造中心,并与西门子、捷普电子、富士康等知名企业建立战略合作关系。主要产品包括高端导热灌封胶、碳纤导热垫片、导热界面材料、高导热矽垫片和导热凝胶等。

型号- WT5921-30,WT5921-20,WT5921-35,WT5902,WT5921,WT5932,WT5932-30P,WT 5921-86,WT5932系列,WT5932-30D,WT5921-15AB,WT5902系列,WT5921-25AB,WT5935C

【产品】以硅树脂为基材的导热凝胶WT 5921-86,耐温范围宽至-50~200℃,导热系数8.6W/(m·K)

WT 5921-86是一款由沃尔提莫推出的以硅树脂为基材,添加导热填料及粘结材料按一定比例配置而成,并通过特殊工艺加工而成的泥状物,又叫导热胶泥。耐温范围宽至-50~200℃,导热系数8.6W/(m·K),具有极好的耐气候性、耐辐射及优越的介电性能。

电子商城

登录 | 立即注册

提交评论