Reliability and Lifetime Considerations for High Stability Gold Terminated NTC Chip Thermistor

Reliability data and lifetime modelling of TE connectivity NTC chip THERMISTORs (leadless, gold-terminated chips) for applications in telecommunications and optoelectronics, based on general principles of telcordia sr-332.

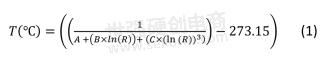

As the global demand for telecommunications connectivity and systems continues to grow there is an expectation that the overall performance of those systems will be enhanced. Consideration of performance includes factors such as network speed, bandwidth, storage capacity and reliability. System reliability can be defined as the ability of a system to perform specified functions for specified time intervals under specified operating conditions, without failure. System reliability depends on the reliability of the modules and components that comprise the system. Reliability can be defined and quantified so that it is an important design factor to be considered in system development. This paper discusses some reliability and lifetime considerations for particular types of electronic components: Negative Temperature Coefficient (NTC) Thermistors. NTC Thermistor components are formed from ceramic materials that have semiconductor properties. This means that the number of charge carriers available for electrical conduction increases as temperature increases so that electrical resistance decreases as temperature increases. This effect is described by a Negative Temperature Coefficient of Resistance, and the components are classified as “NTC Thermistors” or Thermally Sensitive Resistors. The use of NTC Thermistors as Temperature Sensors is based on a defined relationship between Resistance and Temperature, the R/T characteristics. This is defined by the Steinhart-Hart Equation which is a relationship of the form:

Where T is the Temperature in degrees Centigrade, R the Resistance in Ohms, and A, B and C are constants derived from Resistance/Temperature calibrations. NTC Thermistors are used extensively for Temperature Sensing in various applications in telecommunications and optoelectronics modules. The typical physical form of the NTC sensors used in such applications is a chip, with dimensions of the order of 0.35 to 1mm in length and width and thickness of the order of 0.20 to 0.75mm.

There is conductive metallisation on opposing faces so that conduction is through the chip. Gold is typically used as a conductor material to optimise thermal and electrical conduction and to be compatible with wire-bonding and die-attach technology. A typical mounting arrangement for Gold Chip thermistors is as shown below:

The essential reliability consideration for NTC Thermistors is that the R/T characteristics conform to defined tolerance limits. NTC thermistors rarely fail in a catastrophic manner. Rather than failing through open-circuit or short circuit behaviour they show a change or drift in resistance. A value of ± 1.0% change in resistance value at 25°C is used as a typical limit for practical situations, but different limits may be applied depending on the application.

Reliability Definitions and Parameters:

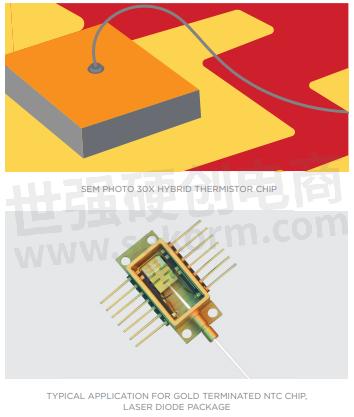

The failure rate for components is usually designated as λ and is generally expressed as “failures per unit time”, typically failures per hour, λhours. An associated value used to describe reliability of components is Mean Time to Failure, referred to as MTTF and usually designated as θ. MTTF is the reciprocal of the failure rate so that:

Because the number of failures per hour is generally very low, the electronics component and semiconductor industries also describe failure rate in terms of “Failures in Time” or FIT which is defined as the failure rate per billion hours so that:

![]()

Reliability modelling and predictions are based on components operating in normal lifetime conditions where the failure rate is approximately constant. In this situation the distribution of failures as a function of time is of the form:

![]()

It is usually not practical to make extensive measurements of failure rates in actual applications under normal operating conditions. Instead, the principle of Highly Accelerated Stress Testing (HAST), is used to measure failure rates at elevated stress levels. Extrapolation calculations are then performed to predict failure rates at normal operating conditions. For NTC Thermistor components the relevant failure mode is a change in resistance at a reference Temperature, relative to defined limits. This failure mode is due to various failure mechanisms, such as propagation of micro-cracks in the ceramic material and changes at the interface between the metallization and the ceramic material. The main stress that influences the development of failure modes is the temperature to which components are exposed so temperature stress testing is considered here. The rate at which the observed failure mode progresses can be modelled mathematically by the Arrhenius Rate Equation which states:

![]()

Where R is the rate of progression of the failure mode, e = 2.7183, (base of Natural Logarithms) k is Boltzmann’s Constant: 8.6x10-5 eV/K (electron-Volt per Kelvin). T is the Temperature in Kelvin, Ea is the Activation Energy, expressed in electron-Volt which is estimated from evaluations and proprietary data for NTC Thermistors. For most practical situations, for NTC Thermistor components at temperatures in the approximate range -40°C to +200°C, the value of Ea is approximately constant so the relative rate of progression of the failure mode is dependent on temperature. It is useful to define an acceleration factor, designated as Af , which is the ratio of the rates of failure mode progression for a component at two different temperatures. When the normal operating temperature is designated as Tuse and the elevated temperature used for stress testing is designated as Ttest, and the associated rates as Ruse and Rtest, then the Ratio and the Acceleration Factor are given by:

![]()

The acceleration factor is used to develop a High Temperature Operating Life (HTOL) model. In this model the failure rate, λ, for a sample of components is defined as the ratio of the total number of failures and the cumulative time of operation which is defined as Equivalent Device Hours (EDH), with

![]()

where: D = Number of devices tested H = Test hours per device Af = Acceleration Factor derived from the Arrhenius equation The failure rate per hour, λhours is then given by:

![]()

Where r is the number of failures observed in the sample for which the EDH value was defined. In practice, the term r, is defined by applying a probability function (χ2, Chi-squared) to the observed number of failures to model their statistical distribution in the relevant time interval.

Evaluations and Results:

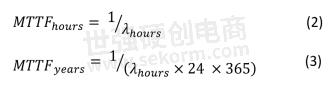

These principles were used in evaluations at TE Connectivity to derive values for failure rates and Mean Times To Failure (MTTF) for variants of electro-ceramic material systems used to produce Gold Chip NTC Thermistor Components. Samples of each variant were mounted in 20-pin CerDIP packages, using silver filled epoxy to form a mechanical, thermal and electrical bond to the substrate and with a gold wire bond to the top electrode as shown:

The components were subjected to Accelerated Stress Testing and evaluations were performed based on principles outlined in Telcordia SR-332. After an initial screening of the components, calibrations were performed on a test fixture in an oil bath at +25°C ±0.05°C at zero-power conditions. The thermistors in the CerDIP packages were subjected to un-powered temperature stress, in air, at “stress test” temperatures of +50°C, +75°C, +100°C, +125°C, +150°C. For each electro-ceramic material type, statistically significant numbers of samples were used for evaluations at these temperatures with calibrations at +25°C performed at 0 hours as reference and after stress test intervals of 336 hours, 1008 hours, 2016 hours, 7560 hours and 10080 hours. These calibration intervals and values were used to calculate values for cumulative Equivalent Device Hours (EDH) and failure rates relative to various resistance drift limits based on the initial resistance values at 25°C.

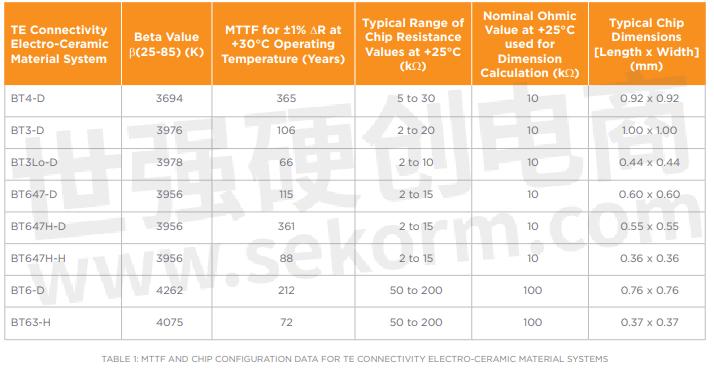

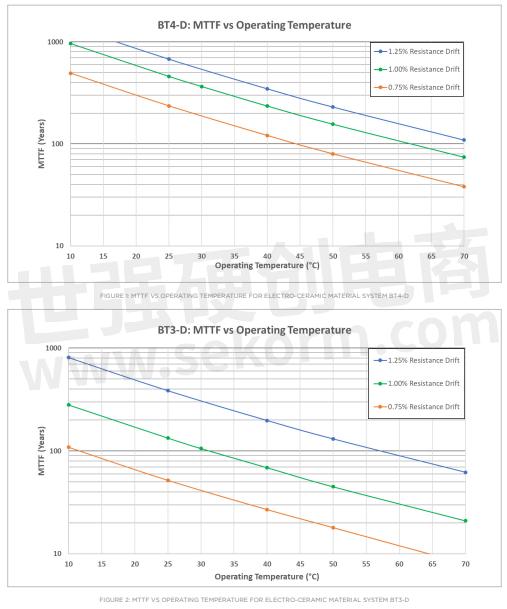

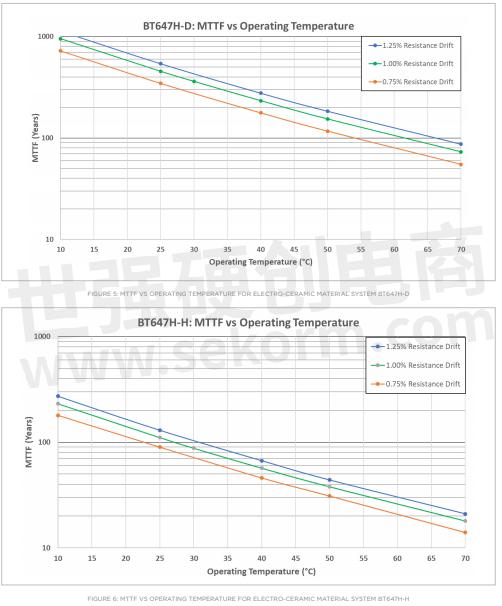

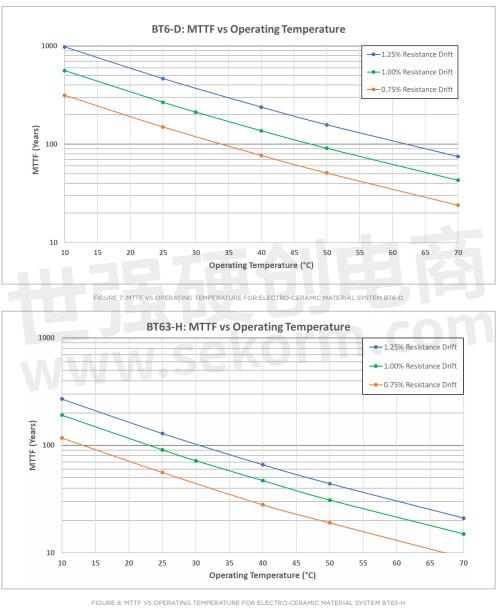

The results of the evaluations can be summarised as follows:

Conclusions: This paper has outlined some of the principles and considerations for generating extended reliability data for Gold Chip NTC thermistor materials using Accelerated Stress Testing based on the Arrhenius Equation and a High Temperature Operating Life Model (HTOL). The presented data and analysis provide estimated values of Mean Time To Failure for Gold Chip NTC Thermistors using various electro-ceramic material systems. The information is intended to provide design engineers with an overview of some of the critical factors in physical form, Resistance/Temperature characteristics, and reliability considerations for optoelectronic system design. The data provides confidence in the use of TE Connectivity Gold Chip Thermistor products in systems where the expected operating lifetime exceeds 20 years. As the range of applications for Gold Chip Thermistors continues to develop it is advisable to perform reliability evaluations based on configurations that reflect actual operating conditions. TE Connectivity can provide technical support to optimise the performance of NTC Gold Chip sensors in systems which depend on accurate and reliable Temperature Measurement.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由微笑向前转载自TE Connectivity,原文标题为:RELIABILITY AND LIFETIME CONSIDERATIONS FOR HIGH STABILITY GOLD TERMINATED NTC CHIP THERMISTOR,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

44032型精密环氧树脂NTC热敏电阻器

该资料介绍了TE Connectivity公司生产的型号为44032的高精度环氧NTC热敏电阻。该产品具有30,000欧姆在25°C下的阻值,互换性好,长期稳定性高,灵敏度强,采用导热环氧涂层,符合RoHS标准。适用于各种高温范围应用、精密仪器测量、需要稳定性的通用应用以及检测微小温度变化的应用。

TE CONNECTIVITY - PRECISION EPOXY NTC THERMISTOR,精密环氧NTC热敏电阻器,701032,MODEL 44032,44032RC-BP,44032,44032RC,701132,GENERAL APPLICATIONS REQUIRING STABILITY,APPLICATIONS REQUIRING SENSING SMALL CHANGES IN TEMPERATURE,需要稳定性的一般应用,非冷凝潮湿环境,需要感测温度微小变化的应用,高温应用,HIGH-RANGE TEMPERATURE APPLICATIONS,NON-CONDENSING MOISTURE ENVIRONMENTS,精密公差仪表,TIGHT TOLERANCE INSTRUMENTATION

GA10K3A1 SERIES I THERMISTORS

本资料介绍了GA10K3A1系列热敏电阻的特性、尺寸规格和应用。该系列产品采用环氧涂层和锡镀引线,提供多种精度温度容差分类,适用于温度测量、指示、控制和补偿等多种应用。

TE CONNECTIVITY - 电热调节器,THERMISTORS,GA10K3A1C,GA10K3A1D,GA10K3A1A,GA10K3A1B,GA10K3A1,GENERAL INSTRUMENTATION APPLICATIONS,一般仪器应用,TEMPERATURE SENSING, CONTROL AND COMPENSATION,TIGHT TOLERANCE INSTRUMENTATION,精密公差仪表,温度传感、控制和补偿

微型轴向玻璃NTC热敏电阻器

本资料介绍了TE Connectivity公司生产的微型轴向玻璃封装NTC热敏电阻。这些热敏电阻具有2至500千欧姆的阻值范围,适用于焊接,温度范围为-40°C至+250°C,符合RoHS标准。它们广泛应用于空气流量检测系统、血液分析、液体液位感应、平板温度传感、医疗导管设备、空调单元和流体流量传感等领域。

TE CONNECTIVITY - NTC CHIP,MINIATURE AXIAL GLASS NTC THERMISTORS,微型轴向玻璃NTC热敏电阻器,NTC芯片,GA5KM3348J15,GA150KM3976J15,GA2KM3187J15,GA100KM3499J15,GA500KM4261J15,GA10KM3499J15,血液分析,液位传感,LIQUID LEVEL SENSING,PLATEN TEMPERATURE SENSING,AIR CONDITIONING UNITS,AIR-FLOW DETECTION SYSTEMS,流体流量传感,压板温度传感,BLOOD ANALYSIS,空调机组,医用导管装置,MEDICAL CATHETER DEVICES,FLUID FLOW SENSING,气流检测系统

SERIES II THERMISTORS

BetaCURVE系列II热敏电阻是一种小型环氧涂层设备,具有实心镀锡引线。该系列产品提供绝缘引线和PTFE绝缘层,以增强在环氧树脂或粘合剂安装或灌封热敏电阻时的连接强度。它还提供了多种精密度温度公差分类,适用于各种应用。

TE CONNECTIVITY - 电热调节器,THERMISTORS,GA30K5A1IB,GA3K3A1ID,GA30K5A1IC,GA30K5A1IA,GA3K3A1IA,GA3K3A1IC,GA30K5A1ID,GA3K3A1IB,GA100K6A1IA,GA100K6A1IB,GA100K6A1IC,GA100K6A1ID,GA50K6A1IC,GA50K6A1ID,GA5K3A1IA,GA30K6A1IA,GA50K6A1IA,GA30K6A1IB,GA50K6A1IB,GA5K3A1IC,GA30K6A1IC,GA5K3A1IB,GA30K6A1ID,GA5K3A1ID,GA3K3AI,GA10K3A1IC,GA10K3A1IB,GA10K3A1IA,GA10K3A1ID,GA2.2K3A1ID,GA2.2K3A1IC,GA2.2K3A1IB,GA2.2K3A1IA,GA10K4A1IB,GA10K4A1IA,GA10K4A1ID,GA3K3AI1B,GA10K4A1IC,GENERAL INSTRUMENTATION APPLICATIONS,一般仪器应用,TEMPERATURE SENSING, CONTROL AND COMPENSATION,TIGHT TOLERANCE INSTRUMENTATION,精密公差仪表,温度传感、控制和补偿

10220685-00金片热敏电阻器

TE Connectivity提供了一系列金端接无引线NTC芯片热敏电阻,适用于现代混合微电子需求。这些热敏电阻具有顶部和底部金属化,可使用行业标准芯片粘合和线焊技术附着到混合、IC或PC电路。芯片可以焊接或用导电环氧树脂粘接到板上,适用于空间受限的终止点。典型方形芯片尺寸从0.35毫米到1.2毫米不等,具体取决于首选的陶瓷系统和标称欧姆电阻。提供金芯片产品的MTTF可靠性信息,供客户选择和设计。

TE CONNECTIVITY - 金片热敏电阻,GOLD CHIP THERMISTOR,金端接无引脚NTC片式热敏电阻,GOLD TERMINATED LEADLESS NTC CHIP THERMISTORS,10220685-00,LOCALIZED TEMPERATURE SENSING,LASER DIODE MODULES,THERMAL PROTECTION OF SENSITIVE CIRCUITS,COMMUNICATIONS SYSTEMS,热辐射识别,局部温度传感,WIRELESS APPLICATIONS,红外线传感,THERMAL RADIATION RECOGNITION,混合电路温度补偿,INFRARED SENSING,HYBRID CIRCUIT TEMPERATURE COMPENSATION,通信系统,热电堆传感器,敏感电路的热保护,无线应用程序,激光二极管模块,THERMOPILE SENSORS

GA10K3MCD1 MICRO BetaCHIP (MCD) THERMISTOR PROBES

该资料介绍了TE Connectivity公司生产的GA10K3MCD1型号微型BetaCHIP(MCD)热敏电阻探头。这些探头适用于需要快速温度响应且空间受限的应用。它们具有±0.2℃的温度容差,采用聚酰亚胺管封装,并涂有导热环氧树脂。

TE CONNECTIVITY - MICRO BETACHIP (MCD) THERMISTOR PROBES,微型BETACHIP(MCD)热敏电阻探头,GA10K3MCD1,TEMPERATURE CONTROL FOR BATH SHOWERS,淋浴器的温度控制,PELTIER TEMPERATURE TRACKING SENSORS,珀耳帖温度跟踪传感器,实验动物研究,MEDICAL CATHETERS,LABORATORY ANIMAL RESEARCH,医用导管,LOW VOLUME FLOW SENSORS (LIQUIDS OR GASES),DNA RESEARCH SENSORS,低体积流量传感器(液体或气体),DNA研究传感器

10K3D732热敏电阻探头

本资料介绍了TE Connectivity公司生产的10K3D732型NTC热敏电阻探头。该产品具有10,000欧姆的标称阻值,适用于温度传感、控制和补偿。其主要特点是快速响应时间、高稳定性和可靠性,工作温度范围为-40℃至+105℃,精度为±0.2℃。此外,还提供了详细的性能规格和订购信息。

TE CONNECTIVITY - THERMISTOR PROBE,热敏电阻探头,10K3D732,GA10K3D732,温度补偿,TEMPERATURE SENSING,TEMPERATURE CONTROL,TEMPERATURE COMPENSATION,GENERAL INSTRUMENTATION,温度传感,通用仪器,温度控制

医疗方面,用来检测颅内压,需要选用一款NTC搭配使用测量温度,由于开孔面积不能过大,要求直径尽可能小,对精度要求在±0.5℃以内就可以,请问有无合适推荐?

您好,推荐给您TE的MICRO BetaCHIP (MCD) THERMISTOR PROBES系列,精度可达±0.2℃,直径最大0.5mm 参考数据手册:https://www.sekorm.com/doc/2322767.html

55004型精密玻璃NTC热敏电阻器

本资料介绍了TE Connectivity公司生产的型号为55004的高精度玻璃NTC热敏电阻。该产品具有高温度性能、长期稳定性和高灵敏度,适用于高温环境下的湿度应用和低至中等范围的温度测量。

TE CONNECTIVITY - PRECISION GLASS NTC THERMISTOR,精密玻璃NTC热敏电阻器,55004,MODEL 55004,055301,55004-BP,055101,HIGH MOISTURE APPLICATIONS,高湿度应用,44000系列环氧树脂的直接更换,中低温应用,USE UP TO 200°C,TIGHT TOLERANCE INSTRUMENTATION,APPLICATIONS REQUIRING SENSING SMALL CHANGES IN TEMPERATURE,使用温度高达200°C,APPLICATIONS REQUIRING IMPROVED STABILITY,需要提高稳定性的应用程序,LOW TO MID RANGE TEMPERATURE APPLICATIONS,需要感测温度微小变化的应用,DROP IN REPLACEMENT FOR 44000 SERIES EPOXY,精密公差仪表

10K3A1系列1热敏电阻

本资料介绍了TE Connectivity公司生产的10K3A1系列热敏电阻(NTC)的性能规格和应用。该系列产品具有耐高温、快速响应时间等特点,适用于温度传感、控制和补偿等领域。

TE CONNECTIVITY - THERMISTOR,热敏电阻,10K3A1B,10K3A1A,10K3A1 SERIES,10K3A1D,10K3A1C,ASSEMBLY INTO PROBES FOR A WIDE VARIETY OF APPLICATIONS,GENERAL INSTRUMENTATION APPLICATIONS,温度补偿,TEMPERATURE SENSING,一般仪器应用,TEMPERATURE CONTROL,将探针组装成多种应用,TEMPERATURE COMPENSATION,精密公差仪表,温度传感,TIGHT TOLERANCE INSTRUMENTATION,温度控制

【技术】高稳定性金芯片NTC热敏电阻的可靠性和寿命建模分析

本文基于TELCORDIASR-332的一般原则,TE Connectivity介绍用于电信和光电子领域的金芯片NTC热敏电阻(无铅、金端接芯片)的可靠性数据和寿命建模。

3K3A1系列1热敏电阻

本资料介绍了TE Connectivity公司生产的3K3A1系列热敏电阻的性能规格和应用。该系列产品具有耐高温、快速响应时间等特点,适用于温度传感、控制和补偿等领域。

TE CONNECTIVITY - BETACURVE NTC THERMISTOR CHIP,SERIES 1 THERMISTOR,系列1热敏电阻,BETACURVE NTC热敏电阻芯片,3K3A1A,3K3A1B,3K3A1 SERIES,3K3A1C,3K3A1D,3K3A1,GENERAL INSTRUMENTATION APPLICATIONS,温度补偿,组装成探针,TEMPERATURE SENSING,ASSEMBLY INTO PROBES,一般仪器应用,TEMPERATURE CONTROL,TEMPERATURE COMPENSATION,精密公差仪表,温度传感,TIGHT TOLERANCE INSTRUMENTATION,温度控制

100K6MBD1微型BetaCurve热敏电阻探头(MBD)

本资料介绍了TE Connectivity公司生产的Mini BetaCurve热敏电阻探头(MBD)的技术规格和应用。该产品具有快速响应时间、小直径尖端和多种引线长度可供选择,适用于医疗探针和小流量传感等领域。

TE CONNECTIVITY - NTC THERMISTOR,NTC TEMPERATURE SENSOR,微型BETACURVE热敏电阻探头(MBD),NTC热敏电阻,NTC温度传感器,MINI BETACURVE THERMISTOR PROBE (MBD),100K6MBD1,小型医用探针,SMALL MEDICAL PROBES,TEMPERATURE SENSING,MICRO-FLOW SENSING,温度传感,微流量传感

30K6A1系列1热敏电阻

本资料介绍了TE Connectivity公司生产的30K6A1系列热敏电阻的性能规格和应用。该系列产品具有耐高温、快速响应时间、良好的互换性和稳定性等特点,适用于温度传感、控制和补偿等领域。

TE CONNECTIVITY - THERMISTOR,热敏电阻,30K6A1 SERIES,30K6A1,30K6A1A,30K6A1B,30K6A1C,30K6A1D,ASSEMBLY INTO PROBES FOR A WIDE VARIETY OF APPLICATIONS,GENERAL INSTRUMENTATION APPLICATIONS,温度补偿,TEMPERATURE SENSING,一般仪器应用,TEMPERATURE CONTROL,将探针组装成多种应用,TEMPERATURE COMPENSATION,精密公差仪表,温度传感,TIGHT TOLERANCE INSTRUMENTATION,温度控制

电子商城

现货市场

服务

提供稳态、瞬态、热传导、对流散热、热辐射、热接触、和液冷等热仿真分析,通过FloTHERM软件帮助工程师在产品设计初期创建虚拟模型,对多种系统设计方案进行评估,识别潜在散热风险。

实验室地址: 深圳 提交需求>

使用FloTHERM和Smart CFD软件,提供前期热仿真模拟、结构设计调整建议、中期样品测试和后期生产供应的一站式服务,热仿真技术团队专业指导。

实验室地址: 深圳 提交需求>

登录 | 立即注册

提交评论