Coherent SmartWeld+ Processing Head Fills the Gaps in Production Welding

Production automation expert teamtechnik supplies everything from manual through fully automatic turnkey systems for manufacturing, assembly, and testing. Their expertise spans a huge range of technologies, including part handling, various testing methods, and joining processes, mainly for the e-mobility industry. In 2019, they were asked to develop a production welding system by a manufacturer of battery packs for handheld power tools.

In particular, teamtechnik was tasked with providing automated solutions for welding 11 different joints. These included joining a variety of materials together. Because they didn’t have extensive in-house expertise in laser welding, and so many processes had to be developed in short order, they reached out to COHERENT Labs to assist them.

A SMARTER WAY TO WELD

The Coherent team was supplied with material samples. A series of tests readily demonstrated that all these processes could be accomplished with the Coherent SmartWeld+ processing head, coupled with a 1kW, single-mode fiber laser (the HighLight FL1000CSM).

SmartWeld+ is a specialized welding tool that incorporates an advanced form of beam shaping, including a wide variety of oscillation patterns. It also enables precise control of delivered laser energy during the weld process. Together this allows the width, depth, and penetration profile of the weld seam to be carefully managed. It’s particularly useful for joining heat-sensitive materials and dissimilar material combinations, such as copper to aluminum or steel. Also, it can weld highly reflective or volatile materials with less spatter, porosity, and cracking.

DIFFICULT MATERIALS

SmartWeld+ even enables the processing of “difficult” materials – that is, those that aren’t traditionally compatible with laser welding. Some of the materials utilized in the battery pack construction fell into this category.

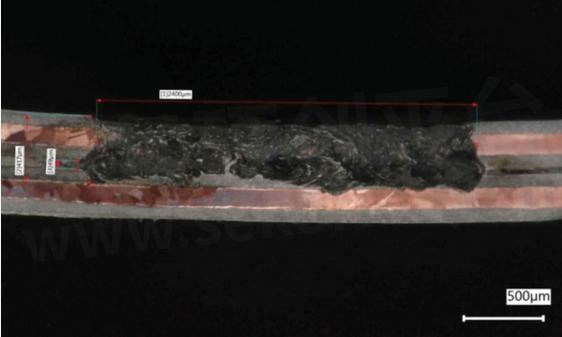

For example, one weld requires joining a 0.5 mm thick piece of zinc-coated copper to a 1.0 mm thickness of nickel-coated copper. The low melting point of zinc has presented problems for laser welding in the past. In particular, it bubbles chaotically when brought to the temperature necessary to melt copper. This results in voids and porosity in the finished weld seam, as well as a substantial amount of spatter.

This part required welds on both ends. One end was flat, and the other end had a 90° bend. These conditions were different enough that two separate sets of parameters had to be developed to optimize each weld. Plus, there is a plastic piece embedded in the part that must not be heated during welding.

The ability to adjust the exact shape of the weld using SmartWeld+ was very useful here. It allowed the creation of a joint that was large enough to provide the required level of electrical connection and mechanical strength without straying too close to the plastic part. While similar weld paths are used on each side of the part, the directions they are applied are different. The development teams in teamtechnik Poland and Coherent also found that for one of the welds, optimum weld results were obtained with a small gap between the parts.

For both welds, a key part of the solution was dynamic power modulation. This provides the ability to stabilize the melt pool during welding and eliminate porosity. It also substantially reduces spatter.

HANDLING PROCESS VARIABILITY

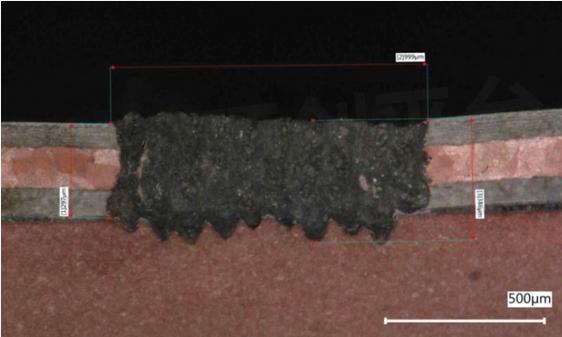

Another of the welds involved joining two 0.3 mm thick pieces of SIGMACLAD® together. SIGMACLAD

is a composite material specifically designed for making electrical

connections in Li-Ion batteries in packs. It’s a five-layer sandwich

consisting of Ni|stainless steel|Cu|stainless steel|Ni. This combination

delivers more desirable properties than any individual metal.

Specifically, copper provides excellent electrical and thermal

conductivity (for heat dissipation), while the stainless steel layers

make the material easier to weld and also increase weld joint strength.

The outer nickel layers facilitate soldering and lend good corrosion

resistance.

Because SIGMACLAD is specifically designed for

compatibility with laser welding, neither the teamtechnik nor Coherent

development teams expected that this join would represent much of a

challenge. But, in practice, they found that material thickness

variations, individual layer thickness variations, and low overall part

dimensional tolerances created process deviations and inconsistent fit-up. Testing determined that fixturing would be necessary to keep any gap

between the two parts to less than 0.05 mm to achieve a 100%

success rate for the welds.

The overall weld in this case is 1 mm x 2.5 mm. The focused laser

beam is much smaller than this, so the SmartWeld+ traces the beam back

and forth several times while stepping slightly in the perpendicular

direction between each scan to cover the entire area. Furthermore,

testing showed that it was necessary to modulate the laser while moving,

otherwise there was excessive spatter at the ends of the scan.

Some of the processes changed even after the equipment was installed and commissioned in the end user’s factory. The Coherent applications group continued to provide support to respond to this.

For example, in one weld 0.3 mm thick SIGMACLAD is joined to 1.0 mm thick nickel-coated copper. The problem here didn’t arise until after the equipment had been installed and operated successfully by the end user for two years. Then the materials supplier changed their formulation and also introduced issues with the cleanliness of the copper. This resulted in a substantial amount of spatter using the process recipe which they had originally employed without difficulties.

The flexibility of the SmartWeld+ proved particularly valuable in this case. In particular, the ability

to easily vary the weld parameters through software control without

making any changes to the hardware of fixturing. A new cycle of testing

at Coherent established that implementing laser power modulation in this

process would solve the problem.

PARTNERING FOR SUCCESS

Working with the Coherent development team allowed teamtechnik to concentrate on what they know best – namely automation. “We needed a partner to get all these laser welding processes developed within the time and cost constraints we had from our customer,” notes Maciej Zaborowski, Welding Technology Specialist, teamtechnik POLAND. “In particular we wanted to find someone who has the expertise and facilities to test the materials and determine if they could all be laser welded, and then develop specific process recipes that would work in production.”

“Coherent delivered on all these points. Plus, our cooperation with them didn’t end after this initial process development. They’ve continued supporting us as changes in materials created production variances in processes that had been working well up to then. There was no other laser vendor we could find who would take on this level of process responsibility.”

Figure 1. Cross section and top view of the 0.5 mm zinc-coated copper to 1.0 mm nickel-coated copper weld.

Figure 2. Cross section and top view of the 3mm SIGMACLAD to 3mm SIGMACLAD weld.

Figure 3. Cross section and top view of the 3mm SIGMACLAD to 1.0 mm nickel-coated copper welds.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由玄子转载自COHERENT News,原文标题为:SMARTWELD+ FILLS THE GAPS IN PRODUCTION WELDING,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Coherent SMARTWELD + 助力TEAMTECHNIK填补量产焊接空白

当teamtechnik签约开发一个量产焊接系统时,他们寻求Coherent的激光专业知识。通过使用Coherent的SmartWeld + 加工头和1 kW单模光纤激光器,成功完成了所有工艺。这种工具适合热敏材料和异种材料的焊接。此外,它还能处理传统上不适合激光焊接的材料。合作使teamtechnik能够专注于自动化领域,而Coherent持续提供支持以应对材料变化带来的挑战。

使用单模激光器进行医疗器械制造中的焊接应用

在探索下一代设备的设计时,通常都有一个共识,即,新设计要比上一代更小。因此,连接要求会变得更加严苛,特别是在减小焊缝尺寸和控制热输入方面。问题在于,从材料选择的角度来看,脉冲激光器有时会受到限制,因为高冷却速率会导致加工窗口变小或容易出现焊缝开裂情况。还有其他选择吗?

Coherent Offers Complete Laser Micro Welding Solutions for Line builders and Integrators, Accelerating Time to Market

With the PowerLine FL, Coherent delivers a precision welding subsystem package with the knowhow and support to ensure success. Precision laser welding and cutting are with a ready to integrate package with laser, processing head, vision and/or process monitoring. All is from one supplier.

日本电产集团综合产品目录(Nidec Group Products Catalog)

描述- 日本电产集团发布第10版产品目录,涵盖从精密小型马达到超大型电机的全系列产品。产品应用于信息技术、办公自动化、汽车、机器人、家电、物流、农业等多个领域。公司致力于成为全球领先的驱动技术企业,并积极应对汽车电动化、机器人应用扩展等五大技术创新浪潮。

型号- PM4系列,H300,D SERIES,NRFEIS-5060,DFS,GATS-2000 SERIES,TPI SERIES,GATS-7800 SERIES,R-6100,TVX,GATS-6300,GATS-8600,SX-20,RWI SERIES,ZI20A,GATS-7500系列,LSR-3230,BP100,RSH,GATS-7700 SERIES,K-MC1000,P2H系列,E300,GATS-2000系列,GATS-6300系列,NVM-6060GCP,VL-H系列,GATS-7500,MH3NCV,VL SERIES,GATS-7800系列,SS-SV,DEWE3-A4,TPI,TVX SERIES,RGA20,NRTES-1000 SERIES,FCPL,ΜV1,RSH系列,ZG SERIES,ID300,FMD,TPI系列,GATS-8600系列,S-CART,GATS-6300 SERIES,KS,CM,R-580,SS-SV SERIES,ANEX SERIES,LD SERIES,VP600GC,GE15FR PLUS,MD2,ANEX系列,NRTES-1000,P2H SERIES,FFB,VL系列,LS,RSH SERIES,RVL,VL-H SERIES,RVP,F600,SS-SV系列,S-FLAG,GATS-7500 SERIES,REC-92FT,DEWE3-PA8,ECO-KA,KCV1000-5AX,S-CART-V1000-LFT,RVL SERIES,RVP SERIES,R-700 SERIES,P2H,ZE16C,CPLS,S-CART-V500,HM500S,VM53RⅡ,GATS-7700,ANEX,NRTES-1000系列,HM-X6100,RWI,TVX系列,KA SERIES,S-CART-MINI,GATS-2000,PM4,VL-H,GATS-7700系列,CBZ,GH,GATS-8600 SERIES,R-700,R-5920系列,NRFEIS-3570,DFS SERIES,MVR-HX,MAF130EⅡ,BL-V20,ECO-KA SERIES,SERIES S-FLAG,RWI系列,HE,GATS-7800,R-5920

Coherent Introduces New Laser Welding Head With Tactile Seam-Tracking Technology for Electric Vehicle Manufacturing

Coherent Corp., a leader in advanced laser processing solutions, today introduced HIGHtactile, a new laser welding head with tactile seam-tracking technology ideal for electric vehicle (EV) manufacturing applications.

精密焊接与切割:Coherent高性价比PowerLine FL系列光纤激光器子系统

工业激光器的领导者Coherent高意近日推出PowerLine FL系列光纤激光器子系统。该新产品系列易于集成与安装、操作简单,是精密焊接与切割的理想选择。PowerLine FL系列现提供200W、400W和600 W的连续输出功率。该系列还有脉冲配置,可提供均值150W、峰值1.5kW以及均值300W、峰值3kW的输出功率。

亮点FL紧凑型高功率单模和多模光纤激光器

描述- HighLight FL Compact系列工业光纤激光器提供了一种经济高效的焊接解决方案。该系列激光器具有Coherent独特的多级背反射免疫系统,提高了可靠性和使用寿命,并能够安全地处理高反射材料,如黄铜、铜和铝。该系列激光器提供单模或多模选项,功率范围从1kW到10kW,适用于焊接、切割和表面处理等应用。

型号- HIGHLIGHT FL5000C,HIGHLIGHT FL1000CSM,HIGHLIGHT FL1500CSM,HIGHLIGHT FL6000C,HIGHLIGHT FL2500CSM,HIGHLIGHT FL7500C,HIGHLIGHT FL8000C,HIGHLIGHT FL1000C,HIGHLIGHT FL10000C,HIGHLIGHT FL4000C,HIGHLIGHT FL2000CSM,HIGHLIGHT FL2000C

Coherent Introduces New HIGHmotion 2D Laser Processing Head Optimized for Deep Copper Welds Over Wide Working Areas in EV Applications

Coherent, a leader in advanced laser processing solutions, today introduced its new HIGHmotion 2D laser processing head that is rated for 8 kW beam delivery and which has been optimized for deep copper welds over wide working areas in electric vehicle (EV) manufacturing applications.

Coherent‘s New Compact CNC-Controlled Micro-Welder ExactWeld 410 Increases Productivity for Medical Devices Manufacturers

The ExactWeld 410 is a compact, high-precision automated welding system that provides ease-of-use and operational flexibility. It increases productivity for manufacturers of medical devices and other high-precision components.

Coherent ARM Fiber Laser and SmartWeld+ Surpass Traditional Remote Welding Systems is Reinventing Laser Processing for EVs

Meeting the challenge of EV manufacturing often requires novel and innovative solutions. Traditional tools which have performed well in the past for other uses sometimes don’t possess the capabilities needed for these highly exacting processes.

Coherent高意2023年锐意创新:发布收发器、泵浦激光器模块等众多新品

本文主要是Coherent高意对2023年的回顾,包含30+的新品发布、企业合作、荣誉奖项和社会责任方面。Coherent 高意利用从材料到系统的各种突破性技术为市场创新者赋能,支持他们定义未来。它面向工业、通信、电子和仪器四大市场,在多样化的各种应用中提供能引起客户共鸣的创新。

PH20 SmartWeld+高功率、高精度激光加工头

描述- PH20 SmartWeld+是一款高性能、高精度的激光加工头,适用于薄厚材料的高难度焊接过程,包括铜铝及异种材料的焊接。它通过精确控制焊接截面和质量同时产生最小热输入来实现高效焊接。该设备结合了固定光束传输光学系统和动态扫描模块,并可通过软件实现多种预编程扫描模式。

型号- PH20

Coherent Releases New Specialty Optical Fiber for Lidar and Quantum Computing Applications

Coherent Corp. (NYSE: COHR), a leader in high-performance optical networking and laser solutions, announced today a first-to-market single-mode (SM), polarization-maintaining (PM) erbium-ytterbium co-doped optical fiber for high-power 1550nm narrow linewidth and single-frequency amplifiers.

振镜扫描仪PHF系列半导体激光加工头紧凑型系列

描述- 该资料介绍了Coherent公司的Galvo Scanner PHF系列激光扫描器,这是一种用于二极管激光器的紧凑型处理头。它适用于塑料焊接、选择性焊锡和热处理等应用,具有多种焦斑尺寸和工作场域选择,配备光纤连接器、准直单元和F-Theta透镜。

型号- PHF SERIES,PHF

Coherent Introduces 30 kW Laser Cutting Heads, Enabling Faster Cutting of Thick Sheet Metal

Coherent Corp. , a leader in advanced laser processing solutions, today announced that it introduced its next-generation flat sheet cutting laser head series with ultrahigh-power ratings reaching 30 kW.

电子商城

品牌:COHERENT

品类:Single-Stage Thermoelectric Module

价格:¥138.0250

现货: 1,250

品牌:COHERENT

品类:Single-Stage Thermoelectric Module

价格:¥745.0191

现货: 600

品牌:COHERENT

品类:Single‐Stage Thermoelectric Module

价格:¥192.4021

现货: 524

品牌:COHERENT

品类:Single‐Stage Thermoelectric Module

价格:¥252.6552

现货: 518

品牌:COHERENT

品类:Single-Stage Thermoelectric Cooler

价格:¥1,971.8640

现货: 508

品牌:COHERENT

品类:Single-Stage Thermoelectric Module

价格:¥488.7889

现货: 500

品牌:COHERENT

品类:Single-Stage Thermoelectric Module

价格:¥107.1444

现货: 486

品牌:COHERENT

品类:Single-Stage Thermoelectric Module

价格:¥432.0068

现货: 475

品牌:COHERENT

品类:Single-Stage Thermoelectric Module

价格:¥485.0000

现货: 460

现货市场

登录 | 立即注册

提交评论