What is a Smart Ring Battery and The Manufacturing Process?

A smart ring battery (mostly also known as a curved lipo battery) is a small battery designed for smart rings, and they are an important part of wearable electronics. Smart ring batteries are usually made using lithium polymer battery technology because these batteries can be made in the desired shape and size to fit the compact design of the ring. Smart ring batteries are needed to provide smart rings with the necessary power to support functions like health and exercise monitoring, notification alerts, gesture control, and navigation and location tracking.

Fig.1

What are the features of the smart ring battery?

1. High energy density: despite their small size, polymer lithium-ion batteries can provide high energy density, which means they can store more power in a relatively small space.

2. Lightweight and compact: the design of the battery must be coordinated with the overall internal and external structural design of the ring, so they need to be as lightweight and compact as possible.

3. Sufficient battery life: Smart rings usually require batteries to support a longer usage time to avoid frequent charging.

4. Safety: Since batteries are close to the user's skin, they need to meet strict safety standards to prevent overheating, short-circuiting, or other potentially dangerous situations.

Which is better, the smart ring battery stacking process or the winding process?

Curved lipo battery is one of the important components of the smart ring, its performance quality can not only affect the service life and duration of the smart ring but also affect the appearance of the smart ring size and aesthetics. Since this is the case, then the following Grepow will do a comparison of the current electronic smart ring battery process.

The smart ring batteries used now belong to the high energy density lithium batteries, and there are two main production processes: stacking and winding. Let's briefly explore the differences between these two processes of batteries together.

The ring battery made by the stacking process can be more tightly sealed when the battery is molded into an arc, which will not affect the beauty of the battery edges and corners by edge wrinkles, and the battery pole coating will not be damaged due to severe extrusion, which will lead to capacity degradation, internal puncture short-circuiting, and shorter service life, and other consequences.

Fig.2

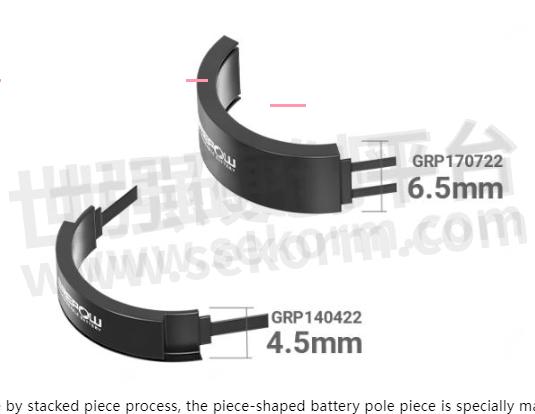

The ring battery is made by stacked piece process, and the piece-shaped battery pole piece is specially made for various shapes, when the battery is made into a curved mold, the sealing edge is tight, the edge wrinkles are close to zero, and the corners of the battery are smooth; what's more important is that the battery will not be damaged due to the extrusion of the pole piece coating, and it will avoid the problems such as capacity degradation, short circuit of the internal puncture and short service life.

Fig.3

Ring batteries using the winding process, as shown above, not only have an unsightly appearance after the bending arc is formed, but the internal structure of the battery is likely to be damaged because of the extrusion caused by the bending. Even if the battery is used normally at first, after some time, it is probable to be squeezed by the greater resistance of the place, resulting in easy heating or pole piece damage, the battery capacity will be greatly attenuated, and the service life is also greatly shortened.

The above is a brief introduction to the "smart ring battery and production process comparison". When selecting ring batteries, manufacturers need to consider the battery life, charge/discharge cycle stability, battery production process, and compatibility with other ring components. In addition, to meet the needs of different markets, battery suppliers need to offer a diverse range of products to suit different designs and technical specifications.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由三年不鸣转载自Grepow FAQS,原文标题为:What is a smart ring battery and the manufacturing process?,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

What Is a 6S LiPo Battery?

Lithium Polymer (LiPo) batteries are widely used in drones, RC vehicles, and various other applications due to their lightweight, high energy density, and power delivery. Among these, 6S LiPo batteries are particularly popular. This guide explores their specifications, types, and applications.

NMC Battery vs. LCO Battery: What’s the Difference?

When it comes to lithium-ion batteries, two of the most commonly discussed chemistries are NMC (Nickel Manganese Cobalt) and LCO (Lithium Cobalt Oxide). Both are widely used in a variety of applications, from electric vehicles to consumer electronics, but they differ significantly in terms of chemical composition, energy density, cycle life, and cost. Understanding the key differences between NMC and LCO batteries is essential for choosing the right battery for specific applications, whether you‘re powering a smartphone or an electric vehicle.

How Are Smart Rings Powered?

Smart rings are powered by efficient, rechargeable batteries and designed with energy-saving technologies, they provide a balance of performance and convenience. As a global leading lipo battery manufacturer, Grepow can provide extremely narrow smart ring batteries, as thin as 1.4mm and as narrow as 4.5mm, to meet the design requirements of various innovative smart rings.

How to Custom Your Special-shape Battery?

In this passage, Grepow will look at some applications equipped with the curved lipo battery and a tool that especially helps you design the special-shape battery.

Grepow Battery will exhibit at 2022 Summer Asia Smart Wearable Exhibition

The bi-annual Asia Smart Wearable Exhibition (ASWE) will be held from July 18 to July 20 at Shenzhen International Convention and Exhibition Center. Grepow will bring its smart wear accessories shaped lithium-ion batteries and button batteries present, booth number: C24 in Hall 4.

Tips for maintenance and emergency disposal of agriculture drone battery

In this article, Grepow talks about how the agriculture drone battery is daily maintained, and how to dispose of it when there is an emergency.

GRP6530027-1C-1S1P-3.8V-430mAh 可充电聚合物锂离子电池产品规格书(Lithium-Polymer (LIP) rechargeable battery pack Specification Approval Sheet)

描述- 本资料为深圳市格瑞普电池有限公司生产的GRP6530027-1C-1S1P-3.8V-430mAh型可充电聚合物锂离子电池的产品规格说明书。内容包括产品规格、保护电路特性、喷码内容、组装示意图、包装方案、性能测试条件和操作指南等。

型号- GRP6530027-1C-1S1P-3.8V-430MAH

What are the Drone Smart Battery Protocols?

Smart drone batteries, equipped with advanced communication protocols, play a pivotal role in ensuring safety, reliability, and extended flight times. This article delves into the various protocols used in drone smart batteries, examining how they work, their specific use cases, and how they interact with other drone systems to enhance overall functionality.

GRP291428-1C-1S1P-3.7V-105mAh产品规格书(GRP291428-1C-1S1P-3.7V-105mAh Specification Approval Sheet)

描述- 本资料为深圳市格瑞普电池有限公司生产的GRP291428-1C-1S1P-3.7V-105mAh型可充电聚合物锂离子电池的产品规格说明书。内容包括产品规格、保护电路特性、喷码内容、组装示意图、包装方案、性能测试条件和操作指南等。

型号- GRP291428-1C-1S1P-3.7V-105MAH

Grepow covers a wide range of shaped batteries to maximize the use of product space, perfectly adapted to small portable electronic products

Grepow covers a wide range of shaped batteries: round lipo batteries, C-shaped batteries, curved lipo batteries, hexagonal batteries, fan-shaped batteries, triangular batteries, ultra-thin batteries, etc., to maximize the use of product space, perfectly adapted to small portable electronic products.

Smart Ring Battery Supplier and Manufacturer

A smart ring is one of the wearable devices. To meet multiple functions such as communication and body detection, it is particularly difficult to add smart accessories and batteries due to the small and flexible product volume. The miniature and arc-shaped shapes are just needed. In China, there are not many manufacturers that can make smart rings and micro-batteries, and Grepow is in a leading position in the industry.

Grepow Batteries Suit the Design of Various Smart Shoe Products,also ISO14000 Certified

Grepow battery has high pressure of 4.35 to 4.40V and a high energy density which can also work at low temperatures while having a longer cycle life. After 1,000 cycles, the original capacity remains 80%.

Grepow Custom Lipo Battery Pack Solutions for Consumer Electronics, Drones, UAVs, EVs and So on

Grepow‘s custom Lipo Battery Pack solutions offer unmatched flexibility, performance, and safety for a wide range of applications. By leveraging advanced technology and extensive customization options, Grepow ensures that each battery pack is tailored to meet the specific needs of its customers. Whether for consumer electronics, drones, electric vehicles, or industrial equipment, Grepow‘s LiPo battery packs provide reliable, high-performance power solutions.

How to Choose LiPo Battery for Drone?

In the world of drones, the right battery can make all the difference. Lithium Polymer (LiPo) batteries have become the go-to choice for drone enthusiasts and professionals alike, thanks to their high energy density, lightweight construction, and ability to deliver high discharge rates. If you‘re new to the drone scene or looking to upgrade your current setup, here‘s everything you need to know about LiPo batteries for drone.

Grepow 3.7V 40mAh LiPo Curve Shaped Battery 2508030

GREPOW is a high-technology lithium-polymer battery specialist who is capable of providing fully integrated battery solutions to power wide range of electronics equipment. When the dimension and weight of electronics is critical, GREPOW’s special shape batteries are proven to deliver good durability and reliability, outstanding performance and long cycle life for fast-growing smart, mobile and wearable electronics.

电子商城

服务

可自由定制电池形状,锂离子聚合物/磷酸铁锂成分,放电倍率Max. 50C (持续放电倍率) / 150C (脉冲放电倍率),充电倍率:Max. 5,厚度可达0.5mm。

最小起订量: 5000 提交需求>

使用FloTHERM和Smart CFD软件,提供前期热仿真模拟、结构设计调整建议、中期样品测试和后期生产供应的一站式服务,热仿真技术团队专业指导。

实验室地址: 深圳 提交需求>

登录 | 立即注册

提交评论