Unbreakable Bonds: Exploring the Chemical Resistance of MMA Adhesives

In an industry with a countless selection of adhesives categories and capabilities, finding the right glue for specific applications can be an overwhelming task. Whether you’re a hobbyist working on a ceramic project or an engineer searching for the best sealing adhesive for chemical-resistant applications, understanding the properties and competencies of an adhesive is critical. In this blog post, we will dive into the continual evolving adhesive class of MMA (methyl methacrylate) acrylic adhesives and their outstanding chemical resistance properties.

MMA Adhesives, also commonly known as acrylic adhesives, are sought out for their outstanding adhesion capabilities across various substrates, making them the go-to choice for many industries. These versatile adhesives are particularly renowned for their exceptional performance in challenging environments such as wide temperature ranges and applications where chemical resistance is a top priority.

Ceramics, with their fragile nature and porous surfaces, can be a challenge to bond. Ceramic glue is critical to many applications. Finding the best glue for ceramic applications is crucial to ensure longevity and durability. MMA adhesives, with their high tensile strength and resistance to chemicals, make them an ideal choice for bonding ceramics. Whether you’re fixing a broken vase or working on intricate ceramic art, MMA acrylic adhesives offer a reliable solution.

The strength and durability of MMA adhesives lie in their acrylic polymer and compound composition. This polymer family forms a durable bond with a wide range of materials, including metals, plastics, composites, coatings, and more. The unique structure of the acrylic polymer allows MMA adhesives to maintain their integrity even when subjected to various chemical exposures.

In applications where a tight, chemical-resistant seal is necessary, MMA adhesives stand out as sealing adhesives. As such, they can form a durable, impervious seal and structural joint that makes them an excellent choice for industries such as automotive, aerospace, and marine, where maintaining the integrity of joints and seams is crucial.

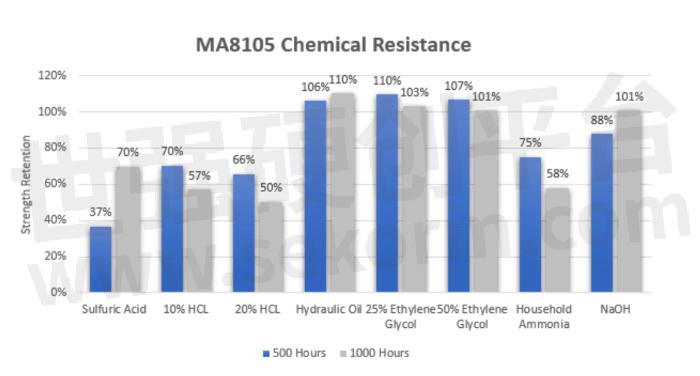

A chemical resistance chart is a valuable resource when choosing the right adhesive for a particular application. MMA adhesives are known for their compatibility with a wide range of plastics, including chemical-resistant plastics. This compatibility ensures that the adhesive will maintain its adhesion strength even in the presence of chemicals.

Acid-resistant MMA adhesives are strong leaders for such resistance, withstanding exposure to acids that many other adhesives would not. Corrosion inhibitors play an important role in chemical resistance in the adhesive industry. Whether you are working in a laboratory, chemical plant, or any other industrial environment where acid resistance is essential, MMA adhesives have a history of performance.

In applications where adhesives are subjected to wear and tear, MMA adhesives still hold their ground. Their exceptional long-term adhesion characteristics mean that they maintain their bond strength even under dynamic mechanical stress and environmental factors. This durability ensures that the bonded components remain intact, or structural for an extended period.

MMA acrylic adhesives are well-established performers in the adhesive world when it comes to chemical resistance and durability. MMA acrylic adhesives offer premium performance with their ability to form strong, long-lasting bonds even in challenging environments. Making this class of adhesives an invaluable choice for a diverse and wide range of applications. If you’re faced with a chemical bonding challenge, consider the durable properties of Plexus MMA acrylic adhesives to ensure your bonds will stand the test of time.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由玄子转载自ITW markets,原文标题为:Unbreakable Bonds: Exploring the Chemical Resistance of MMA Adhesives,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Metal to Metal Bonding with Structural Adhesives Facilitates More Effective Stress Distribution

Structural adhesives have become a popular choice for metal to metal bonding applications due to their ability to distribute stress evenly across a joint. This is especially important in applications where the bond is subjected to heavy loads or stress. This article explores the benefits of using structural adhesives in metal to metal bonding applications and how they can help to distribute stress more effectively.

Why Plexus® Acrylic Adhesives are Great for ABS Bonding & Other Thermoplastics

Whether you need glue for plastic to metal or ABS to ABS, Plexus adhesives are designed to adhere to the ABS with no or little surface preparation. When wanting to bond ABS, all the grades within the Plexus portfolio are suitable offering high bond strengths with superior properties.

德聚(CollTech)胶粘剂产品选型指南(英文)

目录- Introduction of CollTech One/Two Part Epoxy Adhesives Acrylate UV Adhesives Underfill Materials/Hot Melt Adhesives/Coating Materials Thermal Conductive Adhesives/Conductive Adhesives/Thermal Greases Thermal Gels/Silicone Potting Materials Silicone Sealants/Polyurethane Sealants Adhesives for Structural Bonding/Instant Adhesives Product Applications

型号- N-SIL 8700,N-PU 5100,EW 6312,N-PU 5103,PW 1164,N-PU 5105,N-PU 5107,PW 1442,PW 2133,PW 1446,PW 1209,N-SIL 8275,PW 1206,PW 1448,N-SIL 8276,N-SIL 8552,EW 6609,EW 6608,N-SIL 8715,EW 6328,EW 6326,PW 1292,CT 7251H,EW 6320,PW 1451,N-SIL 8201,N-SIL 8206,N-SIL 8725,CT 7255B,EW 6658,EW 6657,N-SIL 8608,CT 7261,CT 7260,PW 2990,EW 6650,PW 1023,PW 1304,PW 1422,N-SIL 8210,N-SIL 8332,N-SIL 8215,N-SIL 8336,N-SIL 8337,EW 6615H,N-SIL 8735,N-SIL 8615,EW 6308,CT 7250,N-COAT 9368,CT 7251,CT 7258,N-COAT 9360,CT 7257,PW 1033,PW 1435,PW 1436,CT 7253,N-SIL 8580,CT 7256,CT 7255,N-SIL 8220,N-SIL 8740,HW 9905,N-SIL 8620,AW 2915,PW 1081,AW 2916,EW 6355,PW 1486,EW 6350,PW 2057,PW 1400,PW 1008,N-SIL 8112,N-SIL 8630,N-SIL 8113,AW 2920,N-COAT 9300,PW 1250,HW 9590,EW 6360,PW 2500,PW 2501,CT 5605,CT 5606,PW 1218,CT 5607,N-SIL 8640,EW 6619,CT 5608,EW 6615,EW 6339,SW 7037,CT 7250H,EW 6336,EW 6611,EW 6335,EW 6610,CT 7250L,PW 2550,PW 1465,PW 1066,SW 7022,N-SIL 8135,N-SIL 8533,CT 7258H,EW 6627,EW 6625,EW 6349,AW 2904,AW 2903,EW 6621,EW 6346,EW 6345,PW 1471,AW 2900,AW 2902,PW 1470,EW 6066,N-COAT 9560,AW 2901,PW 1475,EW 6064,EW 6061,EW 6060

ITW(依工聚合)粘合剂/密封剂/点胶设备/耐磨化合物/环氧树脂/聚氨酯 选型指南

描述- ITW Performance Polymers offers a wide range of products to the mining, coal-fired power, alternative energy (wind), transportation, marine,composites, engineered construction and general industrial markets.

型号- DEVCON® HP 250,MA8120 GB,MA300,MA420,SC VELR 4000,SC 7315,PLEXUS® MA2000 SERIES,PDR 9000,PLEXUS® MA420W,MA8105 GB,SC PDR 9000,SC 1050,SC 1500-LS,PC-120,PLEXUS® MA2030,PLEXUS® MA2045,MA1020,MA2230,PLEXUS® PU2105,MA310,MA1025,MA550,PLEXUS® MA832,SC 2000-OS LS,PLEXUS® MA830,GPE 30,PLEXUS® MA205HV,PLEXUS® MA320,TE 2400,SC PDR 6000,MA425,SC 4055,SC 1060,MA422,AO420,SC ALPHACOA® 1700,PU2105,PLEXUS® MA8105 GB,MA2245,PLEXUS® MA420FS,SC 900,PLEXUS® MA422,PLEXUS® MA300,PLEXUS® MA425,ALPHACOAT® 1710,MA560-1,PLEXUS® MA550,PLEXUS® MA8000 SERIES,PLEXUS® MA310,EPOXY PLUS™ 25,PLEXUS® MA2290,MA530,MA2015,F-2,SC 2000-CM,PDR 6000,PLEXUS® MA560-1,PLEXUS® MA420,GPE 100,SC 4000 HDT,ALPHACOAT 1700,MA920,PLEXUS® H4110,SC ALPHACOAT® 1700,SC 5000,PLEXUS® MA2230,PLEXUS® MA1020,GPE 3,PLEXUS® MA1025,PLEXUS® MA920,MA8110 GB,TE 1000,PLEXUS® MA530,DEVCON® FLEXANE® 80,ALPHACOAT 1710,MA590,PLEXUS® MA2000,PLEXUS® MA2245,MA420W,H4110,PLEXUS® MA8110 GB,SC 4600 HTT,2000-OS LS,ALPHACOAT® 1700,MA420FS,DEVCON® FLEXANE® 94,MA2030,MA2045,SC 4500,MA320,PLEXUS® MA2015,FLEXANE® FL-10,DEVCON® EPOXY COAT™ 7000 AR,SC 2000-HS,PLEXUS® MA590,DEVCON® CLEANER BLEND 300,DEVCON® EPOXY COAT™ 7000 NON-VOC,MA832,PLEXUS® MA8120 GB,MA830,DEVCON® WEAR GUARD™ 300RTC,DEVCON® EPOXY PLUS™ 25,SC 2045,SC 1070,SC 6000,SC1070,SC 1800-LS,DEVCON® EPOXY COAT™ 7000,GPE 15,WR-2,FLEXANE® FL-20,DEVCON® DEV-THANE™ 5,MA205HV,1800-LS,SC 2000-OS,MA2290,SC 4750,PLEXUS® MA8000

以硅树脂为动力的汽车显示器的创新

描述- WACKER公司针对汽车显示屏开发了一系列硅酮产品,以应对大尺寸、曲面显示屏在亮度、耐久性、安全性等方面的挑战。这些产品包括光学粘合剂、密封胶、散热材料和阻尼元件等,旨在提高显示屏的清晰度、耐用性和可靠性。WACKER的硅酮产品如LUMISIL®、ELASTOSIL®和SEMICOSIL®等,在汽车显示屏领域具有显著优势。

型号- LUMISIL ® 345 UV DAM,LUMISIL ® 205 UV,ELASTOSIL ® RT 725 LV,WACKER SILGEL ®,LUMISIL ® 203 UV,LUMISIL ®,SEMICOSIL ® 821 UV,LUMISIL ® 102,LUMISIL ® 202 UV,LUMISIL ® 100,SEMICOSIL ®,LUMISIL ® 245 UV,LUMISIL ® 105,ELASTOSIL ®,WACKER SILGEL ® 612 PT,ELASTOSIL ® RT 724,LUMISIL ® 307 UV DAM,SEMICOSIL ® 822 UV,LUMISIL ® 102 FC,SEMICOSIL ® 823 UV,SEMICOSIL ® 811

Parker Chomerics(派克固美丽)导电特种材料选型指南

目录- Electrically Conductive Paints and Coatings Electrically Conductive Sealants/Gap Fillers Electrically Conductive Adhesives/Grease Electrically Conductive Specialty Materials Ordering Information

型号- CHO-SHIELD 571,52-01-2001-0000,50-30-0584-0029,CHO-LUBE 4220,52-01-0571-0000,50-10-1086-0000,52-03-2056-0000,CHO-BOND 2165,CHO-SHIELD 608,CHO-BOND 1077,596,52-00-2002-0000,52-00-2003-0000,51-02-4669-0000,50-33-1038-0000,50-01-0584-0208,50-00-1091-0000,CHO-SHIELD 604,72-00002,72-00005,CHO-BOND 1075,52-03-2044-0000,50-05-0580-0208,50-02-1030-1000,4220,50-01-1030-0000,2044,2040,52-01-2002-0000,50-00-0584-0208,52-00-2001-0000,54-01-4220-0000,CHO-SHIELD 4994,CHO-SHIELD 2056,CHO-SHIELD 596,50-01-2165-0000,2056,52-01-0579-0000,50-01-1085-0000,52-01-0604-0000,50-04-2165-0000,52-01-0596-0000,52-04-4994-1000,52-03-0610-0000,CHO-SHIELD 2044,50-01-1075-0000,50-10-0584-0029,52-00-2002-1000,50-02-1038-0000,CHO-SHIELD 4900,50-02-1075-1000,50-00-1029-0000,50-01-1091-0000,CHO-SHIELD 2040,CHO-SHIELD 579,4994,50-00-0584-0029,CHO-SHIELD 610,CHO-SHIELD 576,72-08116,CHO-BOND 584-208,52-04-2002-0000,CHO-BOND 580-208,CHO-BOND 360-20,CHO-BOND 1029,52-01-0576-0000,CHO-LUBE E117,50-02-1038-1000,50-01-0580-0208,CHO-BOND 1035,52-04-0608-0000,51-05-4669-0000,TECKNIT 8116,50-03-0584-0029,50-02-1077-0000,CHO-BOND 4669,CHO-BOND 1038,52-04-2001-0000,50-02-1016-0000,CHO-BOND 1030,52-00-2001-1000,CHO-BOND 4660,51-00-1035-0000,2001,CHO-BOND 1019,50-00-0360-0020,50-02-0584-0029,52-03-4994-1000,50-01-1121-0000,52-00-2003-1000,604,CHO-SHIELD 1091,608,50-02-1075-0000,50-31-1038-0000,TECKNIT 0005,51-01-1035-000,TECKNIT 0002,50-04-1086-0000,50-01-1077-0000,50-01-1029-0000,51-02-4660-0000,50-02-1030-0000,571,51-05-4660-0000,576,610,CHO-BOND 1016,2003,50-01-1038-0000,54-01-E117-0200,2002,51-00-1035-1000,50-01-0584-0029,50-02-2165-0000,CHO-SHIELD 2002,52-00-0596-0000,CHO-SHIELD 2003,54-02-4220-0000,CHO-SHIELD 2001,50-01-1019-0000,52-01-2003-0000,50-01-1016-0000,CHO-BOND 1121,50-01-0360-0020,52-03-2040-0000,52-04-2003-0000,50-01-1086-0000,52-02-4900-0000,CHO-BOND 584-29,CHO-BOND 1085,CHO-BOND 1086

Plexus(普莱克思)/Devcon(得复康)粘合剂选型指南

目录- Company Introduction MMA Structural Adhesives Polyurethane/Hybrid Structural Adhesives Epoxy Adhesives

型号- MA3940LH,MA8105,MA1020,PU2105,MA590,MA300,MA310,MA530,MA420,MA320,MA1025,MA550,MA3940,H4110,MA560-1,MA8120,MA425,MA832,MA920,MA830,MA422,HP250,MA8110

适用于汽车行业的粘合剂产品组合

描述- Jowat公司提供针对汽车行业的粘合剂解决方案,涵盖内饰、行李箱、发动机舱、过滤器、外饰和电动汽车高压电池等多个领域。产品包括热熔胶、聚氨酯分散胶、溶剂胶等,适用于汽车内饰的粘合、行李箱和发动机舱的粘合、过滤器的制造、外饰件的安装以及电动汽车电池组件的粘合。Jowat粘合剂具有高耐热性、高粘接强度、良好的加工性能等特点,能够满足汽车行业对粘合剂的高要求。

型号- 263.45,JOWAT-TOPTHERM® 230.20,613.10,JOWATHERM-REAKTANT ® 628.97,263.05,JOWAT-TOPTHERM ® 264.50,642.90,238.88,JOWATHERM-REAKTANT ® 612.61,628.32,JOWAT-TOPTHERM ® 230.70,JOWAT-TOPTHERM ® 263.05,238.80,491.00,493.25,JOWATHERM-REAKTANT ® 642.30,JOWAT-TOPTHERM ® 263.45,JOWATHERM-REAKTANT ® 629.72,JOWAT-TOPTHERM® 265.00,JOWAT-TOPTHERM ® 221.00,158.97,610.61,613.90,JOWATHERM-REAKTANT ® 613.79,614.50,157.27,613.40,JOWAT® 493.60,JOWAT® 491.00,JOWAT® 493.25,614.18,JOWAPUR® 157.27,JOWAT-TOPTHERM® 230.90,493.60,238.75,230.70,JOWATHERM-REAKTANT ® 610.70,761.10,JOWAT-TOPTHERM ® 263.15,JOWATHERM-REAKTANT ® 642.00,221.00,JOWATHERM-REAKTANT ® MR 614.50,630.80,264.50,JOWATHERM-REAKTANT ® 612.11,JOWAT-TOPTHERM ® 263.17,JOWAT-TOPTHERM ® 238.80,263.85,JOWATHERM-REAKTANT ® MR 642.90,JOWATHERM-REAKTANT® 613.79,JOWAT-TOPTHERM® 238.88,JOWATHERM-REAKTANT ® 628.32,613.79,230.20,238.60,JOWAT-TOPTHERM ® 262.95,642.30,238.20,628.97,JOWATHERM-REAKTANT ® 613.10,JOWAT-TOPTHERM® 221.00,JOWATHERM-REAKTANT ® 610.61,JOWAT-TOPTHERM ® 238.97,491.20,JOWAT-TOPTHERM® 263.85,612.61,263.30,245.85,157.07,263.15,230.90,612.90,JOWAT® 491.20,642.00,263.17,JOWAT-TOPTHERM ® 230.20,JOWACOLL® 761.10,JOWATHERM-REAKTANT ® 613.90,JOWAT-TOPTHERM® 238.75,JOWAT-TOPTHERM ® 263.30,629.72,238.97,JOWAPUR® 157.07,JOWATHERM-REAKTANT ® 613.40,JOWAT-TOPTHERM ® 238.20,JOWATHERM-REAKTANT ® 630.80,JOWAPUR® 158.97,JOWATHERM ® 245.85,JOWAT-TOPTHERM ® 238.60,612.11,265.00,JOWATHERM-REAKTANT ® MR 612.90,JOWATHERM-REAKTANT ® 614.18,610.70,262.95

WACKER Presents Silicone-Based Solutions for Electromobility and Medical Applications

At Silicone Expo Europe, the WACKER Group is showcasing silicone-based product solutions for specific industrial sectors. The focus is on silicone gels for wound care, non-postcuring liquid silicone rubber for the food industry and medical technology, and self-adhesive liquid silicone rubber grades that adhere to polycarbonate and other high-performance plastics.

面向标牌制造商的Plexus®结构粘接解决方案

描述- 本资料主要介绍了针对标识制造商的结构粘合解决方案。资料对比了竞争对手的粘合剂和Plexus®粘合剂的特点,包括粘合速度、表面处理、耐候性等。详细列出了Plexus®系列粘合剂的产品信息,包括颜色、描述、UL认证、开放时间、混合比例、拉伸强度和延伸率。此外,还提供了与竞争对手产品的相对劳动成本比较,以及Plexus®粘合剂的优势。资料最后提醒用户,提供的技术信息和推荐仅供参考,不作为客户测试的替代。

型号- MA205HV,MA685,MA320,MA8120,MA832,MA830,MA8110

Plexus®MA425技术数据表

描述- Plexus® MA425是一种双组分甲基丙烯酸酯粘合剂,适用于热塑性塑料、金属和复合材料组装的结构粘合。该产品具有优异的疲劳耐久性、出色的冲击抵抗性和卓越的韧性,适用于交通运输和海洋工业的复合材料粘合应用。

型号- PLEXUS®,MA425,PLEXUS® MA425

Plexus(普莱克思)粘合剂选型指南

目录- Brand Introduction Structural Adhesives

型号- MA8105,PU2105,MA2045,MA685,MA300,MA420,MA2245,MA320,MA560-1,MA832,MA8120,MA830,MA1020,MA2230,MA590,MA310,MA530,MA2015,H4110,MA205HV,MA420FS,MA425,MA422,MA2030,MA8110

Jowat(胶王)过滤行业用粘合剂选型指南

目录- Filter Industry Powerful Adhesives Overview Filter Manufacturing Filter Media

型号- 614.40,262.90,614.60

粘合剂选择指南EMEA

描述- 本指南介绍了Plexus结构粘合剂产品线,适用于电动汽车电池、电子设备、电气设备的保护、绝缘、热管理和结构件粘接。产品具有全球可用性、符合行业规范和标准、优异的疲劳抗力等特点。指南涵盖了不同应用领域的解决方案,包括风力发电、船舶制造、通用工业和交通运输等,并提供了详细的性能参数和应用建议。此外,还强调了产品的技术支持和全球服务网络。

型号- MA3940LH,MA1020,PU2105,MA590,MA8120 GB,MA300,MA310,MA530,MA420,MA320,MA1025,MA550,MA3940,MA8110 GB,H4110,MA8105 GB,MA560-1,MA425,MA832,MA920,MA830,MA422,HP250

TE Connectivity(泰科TE)胶粘剂/密封剂选型指南

目录- Adhesives-THERMOSETS Adhesives-THERMOPLASTICS Adhesives-SEALANTS Adhesive/Sealant Product Characteristics Tables Adhesive/Sealant Selection Table Adhesives Substrate Preparation Procedures and Installation Guide

型号- S1260,S1184,S1030,S1006,S1017,S1009,S1255-04,S1264,S1297,S1278-02,S1124,S1278,S1125,S1048,S1278-01

电子商城

登录 | 立即注册

提交评论