Keysight i7090 with PTEM – System Initialization

Automated inline handler systems for in-circuit testers rely on numerous sensors fitted around the system to detect and control mechanical operations. The programmable logic controller (PLC) runs a set of complex algorithms that supervise all handler operations and maintain control of safeguards. This ensures consistent and safe operation of the system. To prevent any external interruption to its operation, the PLC does not allow any user intervention to its process once it starts the automated operation. As such, most of the automated inline systems have a closed-loop design that does not allow user customization of the handler operation.

However, it is possible to split the PLC’s algorithms into sections without degrading the robustness of the safeguards. In doing so, it opens little windows of opportunities into the PLC’s control of the handler and allows customization of the handler operations to suit user requirements.

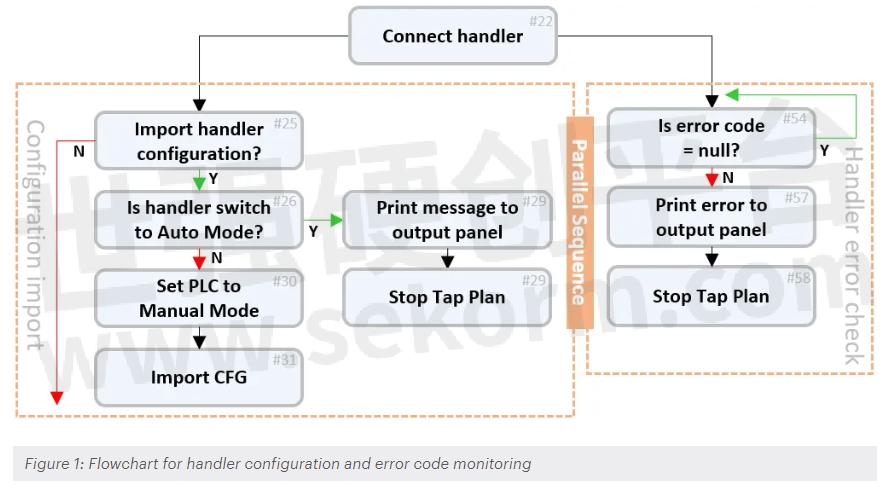

Figure 1 below recounts the flowchart that I discussed before.

From the flowchart in Figure 1, configuration import is an optional process as user can also set up the handler profile directly on the i7090 system handler application itself. You may choose to omit the configuration import and go directly to the next stage in the process.

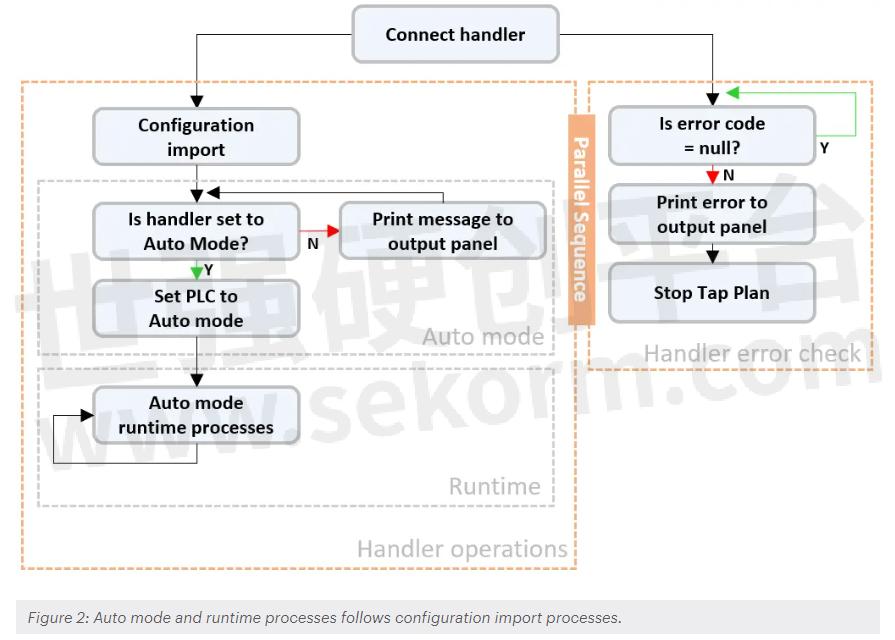

The next stage of the handler operation includes setting the handler into auto mode operation followed by the runtime processes. By combining the configuration import sequence into a single bubble and adding the auto mode and runtime processes, the updated flowchart is as shown in Figure 2. Since configuration import is optional, the flow can go directly into the Auto mode process after the handler control is connected to PTEM.

Switching the handler into auto mode lets the PLC take over command of the handler operations and execute the handler initialization algorithm. During the initialization process, you can continue to monitor the handler error codes and terminate the operation if required. However, you cannot alter the initialization steps that the PLC dictates. In this post, I will share details of the events during the initialization process when you set the handler to auto mode. We will leave the runtime processes to the next post.

Getting into the auto mode operation is a two-step process.

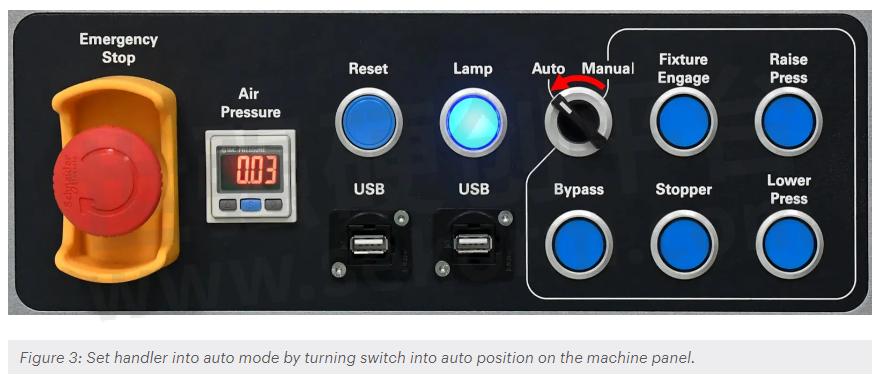

First, switch the handler into auto operation by turning the selector switch on the machine panel from Manual to Auto as shown in Figure 3.

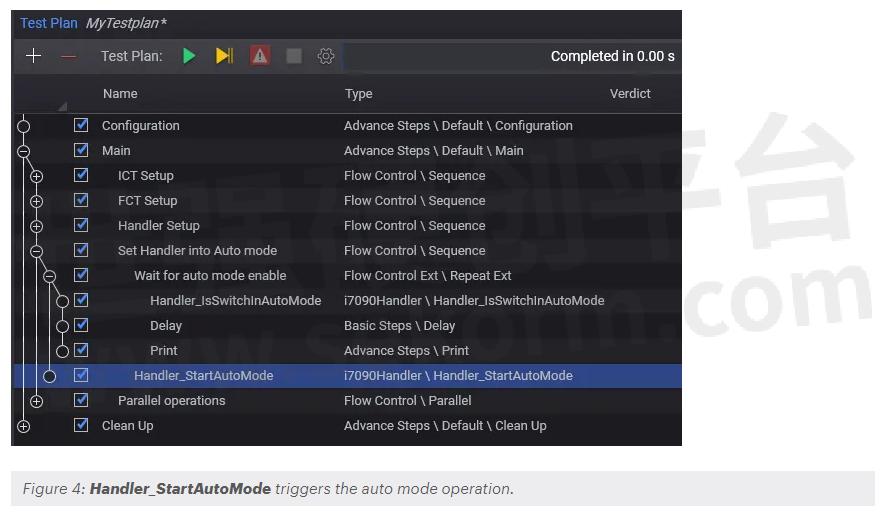

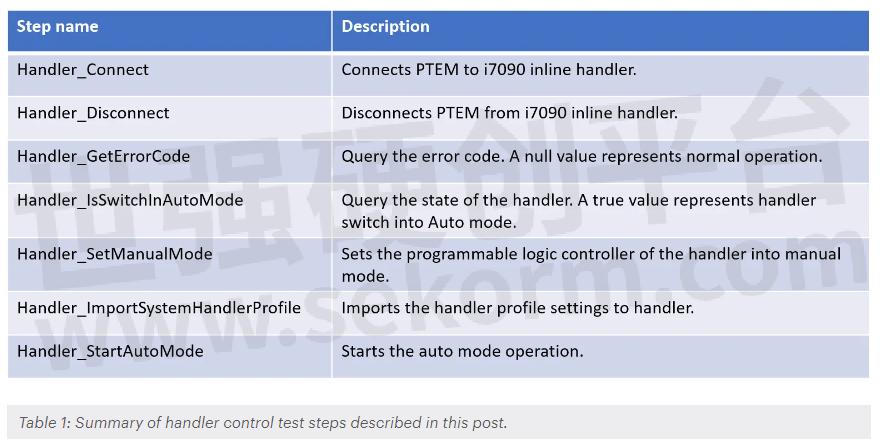

The next step is to start the auto mode operation in the PLC. In the PTEM testplan shown in Figure 4, I created a repeat loop to monitor the selector switch using the Handler_IsSwitchInAutoMode test step and waited for it to enter the auto position. Within the loop, I included a print step to display a text message and prompt the operator to make the switch. Once the selector switch is in auto, the repeat loop exits and calls the Handler_StartAutoMode test step to start auto mode operation at the PLC.

In auto mode operation, the handler starts with the initialization of the hardware before going into the board transfer stage to bring in the device under test (DUT). For initialization to happen, the handler must not be in any error state, and the fixture must be correctly locked down, with all doors closed. No foreign items, including any DUT, should be in the test bay area or on the fixture. Make sure to remove any tools or equipment from the test bay before triggering auto mode operation. Monitor the initialization sequences as the testplan executes, to confirm that the handler receives the correct commands before leaving it to run on its own.

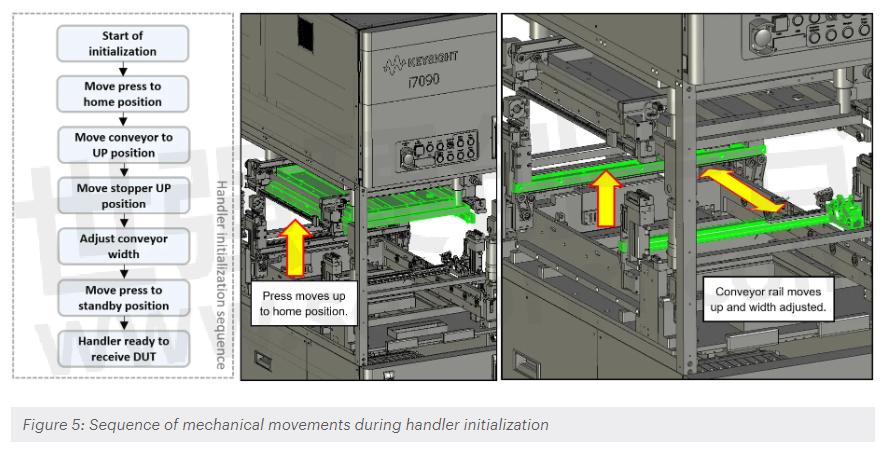

Initialization starts with the press, conveyor, and stopper returned to their home positions. The first action to expect after going into auto mode is that the press should start to move upwards, followed by the conveyor rail and stopper. During the process, the PLC monitors all the position sensors in the handler and reports errors if any one of them fails to respond correctly. The completion of these movements is confirmation that the mechanical hardware is functioning well.

Next, the handler configures the width of the conveyor to the targeted setting in the system handler application. You will notice the handler moves the rear conveyor outwards to its home position, and then inwards until it reaches the targeted width. If adjustment is successful, the adjusted width matches that of the DUT, else it is an indication that you may have set the parameters wrong, or the adjustment motors are defective.

The final phase of the initialization process is getting the press ready at the standby height position. From its home position at the top, the press moves downwards and halts at the standby height position. Standby height is the position of the press where it is slightly above the DUT. This gives sufficient clearance for the DUT to pass under it and move to the stopper position. Moving the press downwards from the standby height is more efficient than having the press to travel from the home position at the top. This reduces the time it takes to engage the DUT into the fixture. Once the press reaches standby height, the handler is now ready to receive DUT. Once the upstream conveyor presents a DUT to the handler, the transfer will begin automatically.

The testplan is now in the parallel operation process where it is constantly monitoring for errors and waiting for the DUT to get into position. Once a DUT is in position, the testplan continues into the runtime operation, which we will discuss in the next post.

Table 1 tabulates all the test steps that I have discussed so far in all my posts on automation control of the i7090 system. You can also check out my previous post on KEYSIGHT i7090 with PTEM where I shared how the error monitoring sequences can be created easily with PTEM. Meanwhile, if you have questions or comments regarding what you have just read, feel free to send me a message.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由雪飘梦飞转载自Keysight News,原文标题为:Keysight i7090 with PTEM – System initialization,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

Keysight i7090 with PTEM – Auto Mode Operation

An automated inline handler system minimizes human involvement in the handling of the product through a manufacturing production line. This improves efficiency and guarantees consistency in the quality of the product as it removes the ambiguity of human judgments and prejudice. Balancing the beat rate of different systems in a production line decides how efficient the manufacturing process will be. The key is to distribute the workload among the different machines or testers along the production line such that all of them work at the same beat rate.

Keysight将在NEPCON China 2024展示创新PCBA测试与汽车技术解决方案

NEPCON China 2024,即将为您呈现一场全新的电子制造行业盛宴!作为PCBA组装和测试领域的技术创新巅峰展会,Keysight将呈现前沿解决方案,助力PCBA测试稳步前行。还将展示汽车行业中最新的功能测试方案及半导体线键解决方案

是德科技与您相约NEPCON Asia深圳,将带来涵盖SMT产线的系统化电子制造测试解决方案,推动工业4.0

Keysight的系统化电子制造测试解决方案涵盖SMT产线,包括ICT、功能测试和开创性的PathWave制造数据分析(PMA)软件-旨在推动您的工厂步入工业4.0时代,是推动运营改进的重要力量。PMA从设计到制造在各个层面提供全面支持,实现问题的主动检测和优化。

是德科技大规模并行测试系统i7090荣获第十六届远见奖,可以测试多达2560个测试点

2023年3月9日,是德科技(Keysight Technologies,Inc.)i7090大规模并行测试系统荣获第十六届《SMT China表面组装技术》远见奖(Vision Awards)中的“VA优秀卓越大奖”和“VA编辑推荐奖”两项殊荣。

是德科技ICT在线测试及板级功能测试用户交流会邀您相约

是德科技ICT在线测试及板级功能测试用户交流会,是德科技将推出专门为汽车行业PCBA测试设计的系列颠覆性解决方案,有新产品从高达5760点的两模组3070 inline S7i,到各种功能测试方案;从揭露数据背后秘密的PathWave,到科技前沿的分段边界扫描方案;从运用在超多联板超高产能的i7090,到半导体封装中的隐藏缺陷;是德科技无处不在,时刻关心着您的产品制造测试。

Keysight i7090 with PathWave Test Executive for Manufacturing

Keysigt’s FlexiCore Parallel ICT system and i7090 Massively Parallel ICT system are automated inline handler systems designed specifically for high throughput automated inline test applications.

Keysight Massively Parallel Board Test System Selected by LACROIX in Automotive Printed Circuit Board Manufacturing

Keysight Technologies, Inc. delivers advanced design and validation solutions to help accelerate innovation to connect and secure the world, announced that LACROIX Electronics has deployed the company‘s i7090 Massively Parallel Board Test System in their automotive printed circuit board manufacturing facility to reduce labor costs and improve throughput.

Keysight Introduces i7090 Massively Parallel Board Test System Supporting up to 20 Cores

Keysight Technologies, Inc. , a leading technology company that helps enterprises, service providers and governments accelerate innovation to connect and secure the world, has introduced the new i7090 massively parallel board test system. This is a new category of automated test equipment designed to perform tests in parallel, on multiple printed circuit board assemblies (PCBA), to achieve high volume throughput which speeds time-to-market and reduces cost-of-test.

是德科技即将亮相NEPCON China 2023,提供系统化电子制造测试解决方案

NEPCON China 2023将于7月19日-21日在上海世博展览馆隆重开幕。Keysight的系统化电子制造测试解决方案涵盖SMT产线,包括ICT、功能测试和开创性的PathWave制造数据分析(PMA)软件-旨在推动您的工厂步入工业4.0时代,是推动运营改进的重要力量。

在线测试仪的值

描述- 本文探讨了在电路测试仪(ICT)在印刷电路板(PCB)制造中的价值。ICT通过电气探针测试PCB上的所有组件,隔离并逐个检查组件,即使在组件相互连接的情况下也能进行。ICT能够快速、经济地检测制造过程中的常见缺陷和组件故障,通过内置的自动测试程序生成器简化编程过程。ICT内置电源为PCB供电,许多型号可升级进行在线编程和高级功能测试。它提高了测试的可移植性和可重复性,有助于缩短上市时间和降低测试成本。此外,ICT能够识别大多数问题,包括开路、短路或不良组件,从而更容易诊断缺陷的根本原因,并减少返工和废品成本。

在线测试仪-N5747A高功率电源

描述- 本文探讨了Keysight Technologies公司N5747A高功率电源在客户产品——一个网络板项目中的首次成功应用。该网络板项目原本在Keysight *Medalist* i3070 Series 5在线测试仪上进行批量生产,需要+12V @ 18A的输入电源。通过使用两个N5747A模块替换原有的6624和6642电源模块,实现了对现有测试程序和夹具的轻微修改,成功测试了500块板,并实现了电源模块成本节约、夹具布线工作量减少和电源模块效率提升。

型号- N5747A

是德科技ICT在线测试及板级功能测试用户交流会邀您相约,分享最新的颠覆性解决方案和汽车行业电动汽车新兴技术测试方案

加入是德科技的交流会,与是德科技分享最新的颠覆性解决方案和汽车行业电动汽车新兴技术测试方案,为您的制造业发展之旅注入动力!携手共进,开创美好未来!

集成电路过功率保护的关键技术应用说明

描述- 本文介绍了Keysight Technologies的Medalist i3070 Series 5在线测试系统中的新安全功能——电源监控电路(PMC)。PMC能够实时监控集成电路的电源节点,防止因电源意外关闭而导致IC引脚过载电流。当电源低于用户定义的阈值时,测试将停止并显示故障信息。该功能可在调试和量产过程中使用,以防止因电压故障或过压而损坏IC,从而节省成本。

型号- 213176,213177,213178,213173,213174,111177,213175,111178,123175,123174,123177,123176,123173,201176,201175,201178,201177,123178,201174,201173,111175,111176,111173,111174

Keysight Technologies(是德科技) Mini In-Circuit Tester Application Note

描述- Keysight Mini In-Circuit Tester (ICT) 是一款模块化电路测试仪,支持标准通信协议(SCPI)命令。它能够集成到不同应用中,提供电路测试覆盖,并具备器件或引脚级别的缺陷信息。文章讨论了SCPI命令和潜在的使用模型,包括独立模型、集成模型和并行/集成并行模型。Keysight Mini ICT支持简单测试生成和自动化测试生成,并通过SCPI接口与其他仪器进行通信。该测试仪旨在提供高质量测试覆盖,同时降低成本,并作为模块化设计补充现有测试,提供完整的板级测试策略。

现货市场

服务

提供是德(Keysight),罗德(R&S)测试测量仪器租赁服务,包括网络分析仪、无线通讯综测仪、信号发生器、频谱分析仪、信号分析仪、电源等仪器租赁服务;租赁费用按月计算,租赁价格按仪器配置而定。

提交需求>

朗能泛亚提供是德(Keysight),罗德(R&S)等品牌的测试测量仪器维修服务,包括网络分析仪、无线通讯综测仪、信号发生器、频谱分析仪、信号分析仪、电源等仪器维修,支持一台仪器即可维修。

提交需求>

登录 | 立即注册

提交评论