Keysight i7090 with PTEM – Auto Mode Operation

An automated inline handler system minimizes human involvement in the handling of the product through a manufacturing production line. This improves efficiency and guarantees consistency in the quality of the product as it removes the ambiguity of human judgments and prejudice. Balancing the beat rate of different systems in a production line decides how efficient the manufacturing process will be. The key is to distribute the workload among the different machines or testers along the production line such that all of them work at the same beat rate. With the KEYSIGHT i7090 automated inline test system and Pathwave Test Executive for Manufacturing (PTEM), you have the flexibility to tailor a test sequence specifically for a product to achieve the best performance.

This post is part of a series of blogs that I am publishing about test automation using Keysight i7090 inline handler with PTEM. The series aims to educate users on the operation of the i7090 handler system and the features of PTEM that support the test integration. If you would like more information on this, do check out the links to related posts at the end of this article.

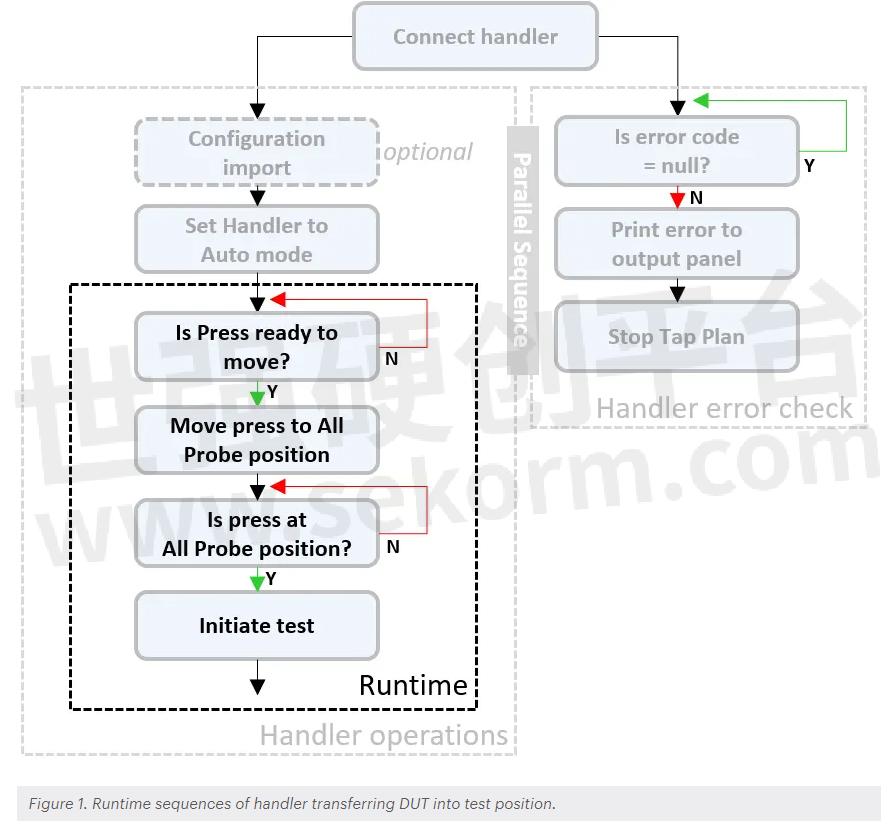

My earlier posts covered configuration import, system auto mode, and handler error monitoring sequences. Figure 1 shows an event flow chart on the transfer of a device under test (DUT) into the test position. Once the handler gets into auto mode operation, the programmable logic controller (PLC) takes over the transfer of the DUT and interacts with PTEM at certain intervals during the operation. Now let us look at the runtime section of the flowchart in Figure 1.

After the handler completes the initialization sequence, the PLC signals the upstream conveyor to transfer the DUT. The DUT travels on the conveyor until it arrives at the stopper position as shown in Figure 2. The figure shows an optional set of stoppers fitted into the i7090 handler allowing it to handle two DUTs at the same time for higher efficiency. Depending on the handler configuration settings, the PLC uses one or two of the stoppers accordingly during the transfer of the DUTs. Sensors along the conveyor rail detect the DUT position so that the PLC knows when to stop running the conveyor belts.

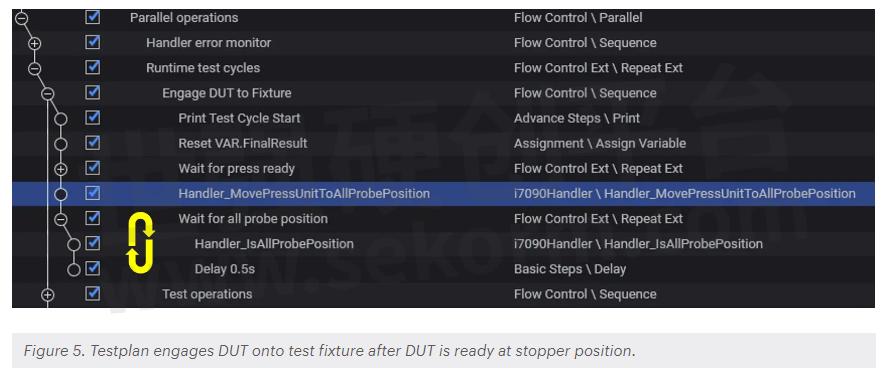

While the handler performs the transfer of the DUT, the PTEM test waits in a repeat loop for the DUT to get into position before sending the command to engage it into the test fixture as shown in Figure 3. Under the Parallel operations section of the test plan, there are two sets of sequences that run in parallel. The handler error monitor checks for any handler errors while Runtime test cycles wait for the DUT to get into position.

A repeat loop named “Wait for press ready” queries the PLC to check if the DUT is in position using the Handler_IsPressUnitReadyToReceiveMoveCommand step. The test step returns a Boolean value to a variable specified in the field Param1. The loop waits for this value to become True before exiting to the next step.

Within the repeat loop, test plan checks the state of the PLC every 0.5 seconds until it receives an active response from the PLC showing that the DUT is in position. It is important to add a small delay in the loop to prevent memory overflow while waiting for the DUT to arrive. The loop repeats itself until it fulfills the conditions for exit.

Software programming practices discourage the use of open-ended loops. These are loops that will keep going indefinitely if they do not receive the required conditions. Typical practice to prevent infinite looping is to have a predetermined timeout value included in the loop such that it exits the loop when the timeout expires regardless of the conditions.

Although you can set up the repeat loop with a timeout value in PTEM, I do not recommend doing this because it is difficult to estimate the arrival time of the next DUT in a production environment. Sometimes, the wait can range from an hour to the next day, or days.

For the testplan, it does not matter if the loop must wait for a long time for the upstream station to release the DUT, but when it does release the DUT, the testplan must be ready to receive the DUT. By adding a timeout to the loop, you limit the flexibility of the wait duration and the testplan may timeout and stop before the DUT is available. This creates unnecessary downtime to restart the testplan again. So how then can we overcome the infinite loop?

The answer is with the handler error monitoring sequences which runs in parallel with the repeat loop.

When the PLC starts the transfer of the DUT, it goes into an automated sequence to bring the DUT into the stopper position. When an unexpected event obstructs the transfer, PLC will generate an error, which in turn triggers the handler error monitor sequence in the testplan to stop and report the error. So, the infinite repeat loop will never be stuck if the DUT does not get to the stopper position.

With the DUT at the stopper position, testplan executes the next step to engage it onto the test fixture using the Handler_MovePressUnitToAllProbePosition test step.

Testplan now waits for the press to move to the All-Probe position. All Probe position is a parameter in the handler configuration that determines the position of the press when the DUT contacts all the test probes on the fixture.

The “Wait for all probe position” loop uses the Handler_IsAllProbePosition test step to check the engagement action at 0.5 second intervals. Again, there is no need to have a timeout loop for this as the PLC will trigger an error if the operation fails.

Now with the DUT engaged onto the test fixture, testing operations can start. Depending on the test requirements of the DUT, you can perform in-circuit or functional tests and device programming on the DUT.

Table 1 tabulates all the test steps that I have discussed so far in all my posts on automation control of the i7090 system. You can find more information in the related posts below. That is all for now. We will talk about the sequences to send the tested DUT out of the handler in my next post. Till then, feel free to drop me a message if you have any questions.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由雪飘梦飞转载自Keysight Blogs,原文标题为:Keysight i7090 with PTEM – Auto Mode operation,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

Keysight i7090 with PTEM – System Initialization

Automated inline handler systems for in-circuit testers rely on numerous sensors fitted around the system to detect and control mechanical operations. The programmable logic controller (PLC) runs a set of complex algorithms that supervise all handler operations and maintain control of safeguards. This ensures consistent and safe operation of the system. To prevent any external interruption to its operation, the PLC does not allow any user intervention to its process once it starts the automated operation.

Exclusive Preview: Eggplant Test Studio

In the ever-evolving software development landscape, the quest for efficiency, reliability, and quality reigns supreme. Test automation, a critical component of this journey, is constantly evolving to meet the demands of modern development practices. This is where Keysight Eggplant Test Studio emerges, providing a sneak peek into the future of test automation.

Keysight将在NEPCON China 2024展示创新PCBA测试与汽车技术解决方案

NEPCON China 2024,即将为您呈现一场全新的电子制造行业盛宴!作为PCBA组装和测试领域的技术创新巅峰展会,Keysight将呈现前沿解决方案,助力PCBA测试稳步前行。还将展示汽车行业中最新的功能测试方案及半导体线键解决方案

是德科技ICT在线测试及板级功能测试用户交流会邀您相约

是德科技ICT在线测试及板级功能测试用户交流会,是德科技将推出专门为汽车行业PCBA测试设计的系列颠覆性解决方案,有新产品从高达5760点的两模组3070 inline S7i,到各种功能测试方案;从揭露数据背后秘密的PathWave,到科技前沿的分段边界扫描方案;从运用在超多联板超高产能的i7090,到半导体封装中的隐藏缺陷;是德科技无处不在,时刻关心着您的产品制造测试。

是德科技与您相约NEPCON Asia深圳,将带来涵盖SMT产线的系统化电子制造测试解决方案,推动工业4.0

Keysight的系统化电子制造测试解决方案涵盖SMT产线,包括ICT、功能测试和开创性的PathWave制造数据分析(PMA)软件-旨在推动您的工厂步入工业4.0时代,是推动运营改进的重要力量。PMA从设计到制造在各个层面提供全面支持,实现问题的主动检测和优化。

Testing LED using PathWave Test Executive for Manufacturing

The standard in-circuit test measures each of the LEDs for their values and orientations. While this is sufficient to guarantee that each LED is good, more is needed to ensure the functionality of the product as a whole. With PathWave Test Executive for Manufacturing(PTEM), you can develop customized test sequences that test the actual functionality of the full assembly.

Keysight i7090 with PathWave Test Executive for Manufacturing

Keysigt’s FlexiCore Parallel ICT system and i7090 Massively Parallel ICT system are automated inline handler systems designed specifically for high throughput automated inline test applications.

是德科技大规模并行测试系统i7090荣获第十六届远见奖,可以测试多达2560个测试点

2023年3月9日,是德科技(Keysight Technologies,Inc.)i7090大规模并行测试系统荣获第十六届《SMT China表面组装技术》远见奖(Vision Awards)中的“VA优秀卓越大奖”和“VA编辑推荐奖”两项殊荣。

Keysight Massively Parallel Board Test System Selected by LACROIX in Automotive Printed Circuit Board Manufacturing

Keysight Technologies, Inc. delivers advanced design and validation solutions to help accelerate innovation to connect and secure the world, announced that LACROIX Electronics has deployed the company‘s i7090 Massively Parallel Board Test System in their automotive printed circuit board manufacturing facility to reduce labor costs and improve throughput.

Keysight Lidar Target Simulator is A Benchtop Solution to Test Lidar Devices in The Design Verification and Manufacturing Stages

The solution is designed to reduce the test cost by significantly reducing the floor space as it can simulate target distances from 3 to 300 meters and surface reflectivity from 10% to 94% while supporting volume production and accelerating the testing with full automation and analytics software.

Keysight Introduces i7090 Massively Parallel Board Test System Supporting up to 20 Cores

Keysight Technologies, Inc. , a leading technology company that helps enterprises, service providers and governments accelerate innovation to connect and secure the world, has introduced the new i7090 massively parallel board test system. This is a new category of automated test equipment designed to perform tests in parallel, on multiple printed circuit board assemblies (PCBA), to achieve high volume throughput which speeds time-to-market and reduces cost-of-test.

Datalogging for Functional Test Using PathWave Test Executive for Manufacturing

PTEM uses a flexible approach to allow you to customize your data log. Instead of a standard “log everything” feature, PTEM lets you choose the necessary information to include in the data log. This reduces the overall file size of the data log as it does not have unnecessary data.

是德科技宣布为Autotalks安全连接车辆芯片组的射频校准和验证提供测试支持,加快产品上市

2023年6月19日,是德科技日前宣布,其 PathWave Test Executive for Manufacturing Developer 版本开始支持 Autotalks 蜂窝车联网(LTE V2X)芯片组和专用短程通信(DSRC)芯片组的自动射频校准和验证测试。这些芯片组通常用于远程信息处理控制单元(TCU)。

【经验】如何利用PTEM开发FlexiCore在线并行的ICT系统测试计划

本文为读者介绍PTEM,这是一种开源的解决方案,它有着对用户友好的接口和内置的测试步骤。文章介绍了PTEM的一些优势,同时在一个初次使用者的视角介绍如何利用PTEM开发一个FlexiCore在线并行的ICT系统测试计划。

Use FlexiCore to Automate The Functional Test

The automation trend is pushing more functional tests(FCT) systems into automated inline platforms. We have the FlexiCore Keysight has the FlexiCore Automated Inline Parallel In-circuit Test(ICT) system that house a standard instrument rack at the back of the system to provide the flexibility for installing different types of instruments according to user‘s functional test needs.

现货市场

登录 | 立即注册

提交评论