A Test Socket Solution Overcomes The Challenges Posed by Traditional Vertical Spring Probes and Cantilever Scrubbing Contact Designs

Advances in semiconductor functionality, density, and chip-level integration are generating new challenges in testing. A Test socket solution overcomes the challenges posed by traditional vertical spring probes and cantilever scrubbing contact designs, providing a new level of performance and reliability.

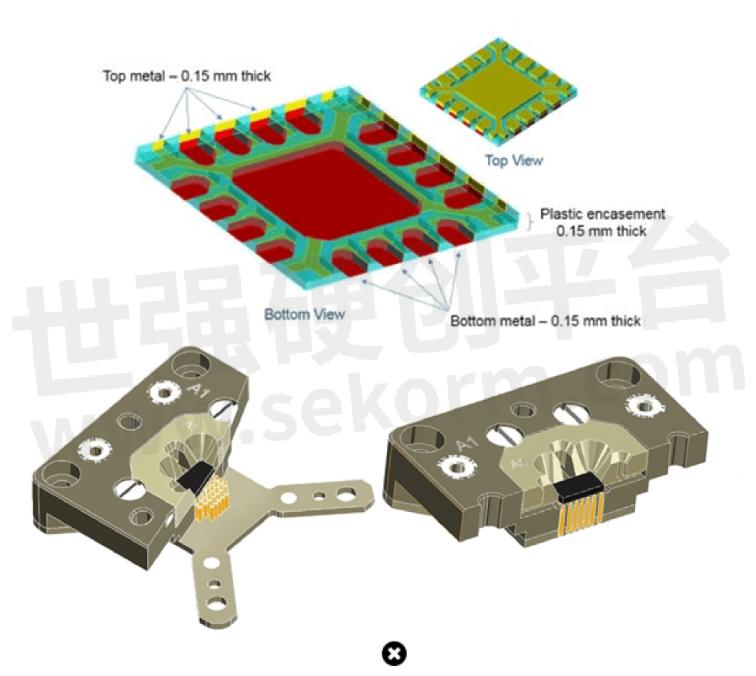

Integrated circuit (IC) designers are increasingly migrating to quad flat no-lead (QFN) packages to meet the needs of applications that have a small outline or low-profile footprint yet still require best-in-class electrical requirements and performance. QFN packages feature direct-attach peripheral pad structures, a large ground block for thermal and electrical performance, and a very thin stack height, making them ideal for many designs, but they also bring some challenges to the Test & Measurement process. To meet these testing challenges, a test socket solution that is robust, reliable, and electrically “clean” is needed.

As logic chips become more advanced, we are seeing a corresponding increase in pin counts, power consumption, and BGA package structures. However, for the majority of analog, mixed-signal, power, and RF devices, power and pin count take a back seat to electrical performance and reliability. Fabricated primarily on legacy (>16 nm) process nodes, these devices tend to have small numbers of 1/0 connections and ganged power connections. Device manufacturers make use of QFN packages to improve electrical performance while reducing the size, weight, and footprint of the equipment.

QFN packages use traditional wire bonding and molding encapsulation techniques to protect the silicon die. They also use near chip scale” pad layouts on the periphery, along with a large “ePad” or “exposed paddle“ With electrical pads fully contained inside the outline of the molded plastic package body, QFN eliminates many of the handling and reliability challenges of their QFP and SOIC predecessors. When a QFN is soldered onto a PCB, the connection is as short as possible, and - aside from certain coefficient of thermal expansion (CT) considerations - extremely robust. QFN features a very large ground pad in the center of the rectangular package body, which facilitates not only excellent electrical performance but greatly improves thermal dissipation. Instead of venting heat generated by the IC upward through the package body, the heat in a QFN ePad can be drawn downward into the PCB to thermal vias, greatly improving stability and performance.

To balance these needs, engineers look for a test socket solution with a short, highly controlled signal path and a robust mechanical structure. One key element of the mechanical structure that warrants special consideration is the wear rate on the surface pad of the PCB load board used to connect the socket to the automated test equipment (ATE). Load board costs routinely exceed $50,000 to $75,000, making it imperative that the socket actuation causes as little damage to the surface pads as possible. If the test socket causes pad damage, the test operations team may need to re-plate the PCB「s surface pads, or, worse, replace the entire PCB.

oxides with the same impact on PCB load board pads as a vertical spring probe, allowing for hundreds of thousands of cycles with little to zero maintenance. The Kepler is footprint-compatible with existing QFN offset socket solutions and can be implemented in short order for demanding high-volume IC applications.

As chip updates become faster and more complex, evaluation and qualification processes are evolving to provide higher test reliability in less test time. To realize these goals, a new generation of Test & Measurement components feature optimized design and superior mechanical performance. Today's test processes are an essential step in the goal to help designers successfully engineer new products and get them to market quickly.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由JWM转载自Smiths Interconnect getattachment,原文标题为:HOME PRODUCTS MARKETS NEWS TECHNOLOGY SUPPLIERS BUYERS GUIDEARCHIVE SEARCH,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

一文解析晶圆级测试插座:半导体测试的关键工具

在半导体制造过程中,测试是确保芯片质量和性能的重要环节。晶圆级测试插座(Wafer-Level Test Socket)是用于在晶圆阶段对芯片进行电气测试的关键工具。本文欣同达将详细介绍晶圆级测试插座的工作原理、设计特点、应用场景以及其在半导体测试中的重要性。

IC测试座在电子制造中的应用及其作用

在现代电子制造过程中,IC测试座扮演着不可或缺的角色。无论是消费电子、汽车电子、工业控制,还是通信设备,IC测试座的应用无处不在。本文,我们将从多个方面深入探讨IC测试座在电子制造中的应用及其作用,希望能为您提供一些有价值的视角。

5G时代芯片测试工程师面临的巨大挑战!

5G网络速度远超4G,毫米波技术是5G时代关键一环。5G芯片测试面临五大挑战:波形更复杂、仪器需宽带线性且经济高效、组件测试量更大、MIMO和波束形成系统测试空间依赖高、批量生产测试需快速高效扩展。为解决这些问题,需快速、准确且经济高效的测试解决方案,ANDK测试座将推出支持5G芯片测试的IC test socket产品。

Melexis(迈来芯) PTC04芯片编程器 数据手册

描述- PTC04是一款用于Melexis可编程IC的高效、精确校准程序器。它支持快速开发,具有通用编程工具、快速插件软件应用、Atmega128核心、可通过RS232和USB更新固件等特点。该程序器适用于实验室原型制作和生产设备,可用于串行编程和特性化。

型号- MAGNET-T04,PTC04-DB-HALL01,MAGNET-T03,PTC-TESTBENCH-4SIP-0X,PTC04,MAGNET-T02,MAGNET-T01,PTC-04,PTC04-DB-91209,PTC04-DB-PRESSURE01,PTC04-DB-90316,PTC04-19-X,PTC04-DB-SPI,PTC04-19-3,PTC04-19-4,PTC04-19-1,PTC04-19-2,PTC04-DB-PRESSURE01,PTC04-DB-XXXXX,PTC04-DB-DEBUG,PTC04 SENSOR MULTI CALIBRATION BOARD,SOFTWARE ENVIRONMENT MPT (WINDOWS),PTC04-DB-HALL02,PTC04-DB-HALL03,PTC04-TESTBENCH-MAGNETIC,PTC04-DB-FASTLOADER,PTC-TESTBENCH-TSSOP-SO8-0X,PTC04-DB-CALIB,PTC04-DB-HALL04,PTC04-DB-HALL05,PTC04-DB-FL,PTC04-DB-HALL03,PTC04-DB-80104,PTC04-DB-ACT

德普福专业射频连接解决方案

描述- 德普福电子科技有限公司提供专业的射频连接解决方案,涵盖毫米波信号传输领域的技术与项目。公司具备从仿真、零件设计到组装、调试、测试、服务的全产业链能力。主要服务包括毫米波系统集成、半导体测试、高频连接器与线缆定制等。德普福拥有丰富的产品线,包括射频探针、射频IC Socket、毫米波系统、射频调试与测试等,并提供定制化服务。公司致力于成为中国最顶尖的射频组件及测试测量系统集成服务商。

型号- RJ系列,QDD800-MCB-16,RJHS-S08E-H4-N,QSFP,RCM7-SD08-XXXS-6YE,RT系列,SFP28,SLC70,RC系列,RJHS-S16E-M4-N,RCHD-SD16-XXXS-4NC,Q-DD,QSFP28,RCHS-HS16-XXXS-4NC,RCHD-SD08-XXXS-4NX,RCHS-D216-XXXS-4NE2,RJHD-S08E-H4-N,RCM7-SD08-050S-6NA,RCM7-SD16-050S-6YA,RJKL-S08E-M4-Y,J599,SLC70系列,RCM7-SD16-050S-6NA,DSFP,QSFP-DD,RCM7-SD08-050S-6YA,RCM7-SD16-XXXS-6YE

Smiths Interconnect’s DaVinci 112 High-Speed Test Socket Wins Best Test Measurement Award at the 2024 Global Electronics Achievement Awards

Shenzhen, November 5, 2024 – Smiths Interconnect is thrilled to announce that its DaVinci 112 high-speed test socket received the prestigious Best Test Measurement Award of the Year at the Global Electronics Achievement Awards (GEAA) ceremony held at the Four Seasons Hotel in Shenzhen. This annual event honors industry leaders and companies making significant contributions to global electronics innovation.

Smiths Interconnect Expands into Burn-In Test Market with Acquisition of Plastronics

Smiths Interconnect, a division of Smiths Group plc, announces that it has completed the acquisition of Plastronics, a leading supplier of burn-in test sockets and patented spring probe contacts for the semiconductor test market segment, as well as custom connectors for industrial applications.

REFPDT007-EVK-001B零件清单

型号- PS2501L-1,C-S1608,NJM78L05UA,MCR03EZPJ332,MCR03EZPJ334,GRM188B11H102KA01,PC089-01-00-50P,RK73B1JTTD104J,NJM2732M,TR10P,RK73B1JTTD472J,STR-A6079M,GRM188B31H104KA92,PH-1X10RG2,GRM1851X1H222JA44,B5B-PH-K-S,RK73B1JTTD103J,PH-2X09SG,MOSX1C334J,REFPDT007-EVK-001B,UDZS5.1B,GRM188B11H103KA01,ECQE6104KF,ELXZ350ELL101MF15D,HOT-2608B,ELXZ100ELL681MF15D,S3B-EH,RK73B1JTTD271J,2SC3325,SBR1U150A-13,TC4069UBF,PH-1X04SG,RK73B1JTTD102J,MCR03EZPJ152,GRM188R71E105KA12,S4B-EH,MOSX1C1R0J,NJM431U,GRM185B31E105MA12,DE1E3KX102MA4BN01,GRM188R71E104KA01,FHU-2×4SG,PH-2X04SG,MCR10EZPJ105,PH-2X08SG,MCR03EZPJ101,RK73B1JTTD101J,MCR03EZPJ102,TA48M05F,MCR03EZPJ103,24LC64SN,EG01C,MCR03ERTJ302,CT-6E-P5KΩ,ECQE6103KF

Smiths Interconnect Offers Quick-Delivery Galileo Test Socket for Rapid Device Bring Up, Characterization and Failure Analysis

Smiths Interconnect announces its new Galileo test socket for Area Array and Peripheral Package Test.Galileo is an innovative, low-profile test socket engineered to support today’s high performance Digital and RF applications.

Semiconductor Test Sockets: Key to Shipping Quality ICs

Smiths Interconnect is a leading provider of technically differentiated electronic components, subsystems, microwave and RF products that connect, protect and control critical applications in the commercial aviation, defense, space, medical, rail, semiconductor test, wireless telecommunications and industrial markets. The company has 25 sales, R&D and manufacturing locations in 12 countries in the Americas, EMEA and Asia-Pacific.

简单介绍芯片测试座及其作用

本文中欣同达将为大家简单介绍芯片测试座及其作用,希望对各位工程师朋友有所帮助。芯片测试座(chip test socket)是一种可用来测试ic,内存颗粒与pcb板焊接是否良好的测试工具。

Smiths Interconnect DaVinci 112 Test Socket: A Game-Changer in High-Speed Chip Testing

The Davinci 112 test socket is designed to tackle some of the most complex challenges in testing Application Specific Integrated Circuits (ASICs). By offering a full range of high-speed testing solutions for 0.35mm pitch and above, the DaVinci 112 ensures precise, reliable results.

Smiths Interconnect Participated in SEMICON Taiwan September 4-6, 2024

In 2024, with the recovery of demand in the consumer electronics market and customer inventory reduction, coupled with the increasing testing demand for new AI-driven models with large packages, high pin counts, and high-power consumption GPUs, CPUs, HPCs, and AI products, we believe Smith Interconnect will see even greater opportunities in the semiconductor testing market.

FAQs at Smiths Interconnect: Test Sockets, Capabilities, and Support

At Smiths Interconnect, we receive some of the same questions repeatedly, so we’d like to offer up those answers early on for our existing and potential customers. Here are some of our most frequently asked questions, and if you still have thoughts, questions, or concerns, we’re here to help!

史密斯英特康千瓦级散热技术亮相2024年印度半导体展会

史密斯英特康以突破性产品Area Array Test Socket为主,包括DaVinci 112和 DaVinci Micro,具备高速效能和高载流能力,适用于GPU测试中的有源串扰隔离,CPU、ASIC和其他高速数位应用测试。

电子商城

登录 | 立即注册

提交评论