Metal to Metal Bonding with Structural Adhesives Facilitates More Effective Stress Distribution

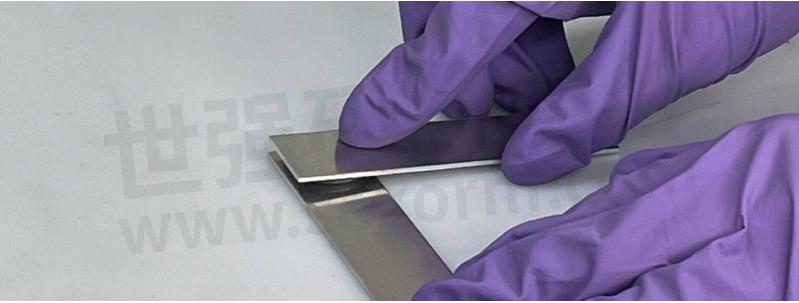

Bonding aluminum lap shear with Plexus Structural adhesives

Introduction

Structural adhesives have become a popular choice for metal to metal bonding applications due to their ability to distribute stress evenly across a joint. This is especially important in applications where the bond is subjected to heavy loads or stress. Let’s explore the benefits of using structural adhesives in metal to metal bonding applications and how they can help to distribute stress more effectively.

Structural Bonding

When metal bonding, it is important to consider the types of forces to which the joint will be subjected. These forces can include tensile, compressive, and shear forces, as well as thermal and dynamic loads. In traditional metal joining methods, such as welding and bolting, the joint is often weaker at the point of connection, which can cause stress concentration and lead to fatigue, and ultimately failure under heavy loads. Additionally, mechanical fasteners tend to loosen under dynamic loads or vibration. In contrast, structural adhesives can distribute stress evenly across the entire bonded surface, creating a strong and durable joint.

Adhesion Bond

Plexus® methacrylate structural adhesives are formulated to provide exceptional bonding strength and durability, and are extremely fatigue resistant, through the use of Plexus’ impact absorbing core-shell technology. In addition, Plexus MMAs can be used on bonded structures and to bond a wide range of metals, including aluminum, stainless steel, cold-rolled steel and others, making them a versatile solution for many different applications. The recently introduced Plexus 8100 series of 1:1 methyl methacrylate adhesives provide primerless bonding to aluminum and galvanized steel, reducing manufacturing steps and costs for surface preparation materials. There are many benefits to a good metal adhesive.

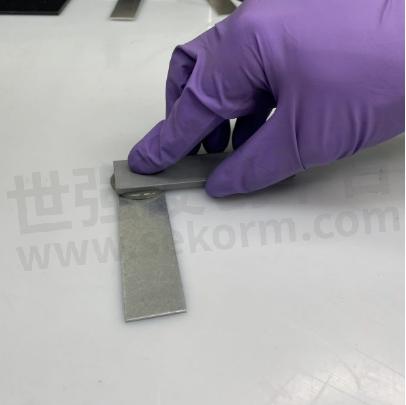

Bonding ECoated Steel to G90 Galvanized Steel with Plexus structural adhesive

Additional Benefits to Metal Bonding

Another benefit of using structural adhesives is that they can help to reduce weight and increase fuel efficiency in many different industries. For example, in the transportation and automotive industry, bonding metal parts with structural adhesives can help to reduce the weight of vehicles, leading to lower fuel consumption and operating costs. Electric vehicles take advantage of these properties as lower weight translates into greater vehicle range per charge. In addition, the use of structural adhesives in automotive applications can help to reduce the wear and tear on vehicle components, including composite structures, improving their lifespan and reliability.

Structural adhesives can also help to improve the aesthetics of metal to metal bonding applications. Unlike traditional joining methods such as welding and bolting, structural adhesives can create a clean and seamless bond that is free of visible fasteners or welds. This can improve the overall appearance of the finished product, which is especially important in applications where aesthetics are important, such as in the construction of high-end consumer products or architectural structures.

To ensure that structural adhesives are applied correctly and effectively in metal to metal bonding applications, it is important to follow the manufacturer’s instructions and use the proper application techniques. This may include surface preparation, proper mixing and dispensing of the adhesive, and appropriate curing times and temperatures. In addition, it is important to select the right adhesive for the specific application, taking into consideration factors such as the type of metals being bonded, the load and stress requirements (prevent CTE mismatch), and the operating environment. If working in hot areas, select a high temperature adhesive to prevent application errors Sometimes glass beads are added to formulation, such as the Plexus MA8100 series of 1:1 MMA adhesives, as well as the MA800 series of 10:1 products.

Conclusion

By using structural adhesives, manufacturers can create strong, lightweight, and aesthetically pleasing products that are capable of withstanding extreme stress and loads. Whether bonding parts of an electric car or bonding trailer parts, Plexus structural adhesives have a lot to offer your team.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由玄子转载自ITW markets,原文标题为:Metal to Metal Bonding – Stress Distribution,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Unbreakable Bonds: Exploring the Chemical Resistance of MMA Adhesives

This article dives into the continual evolving adhesive class of MMA (methyl methacrylate) acrylic adhesives and their outstanding chemical resistance properties.

Why Plexus® Acrylic Adhesives are Great for ABS Bonding & Other Thermoplastics

Whether you need glue for plastic to metal or ABS to ABS, Plexus adhesives are designed to adhere to the ABS with no or little surface preparation. When wanting to bond ABS, all the grades within the Plexus portfolio are suitable offering high bond strengths with superior properties.

ITW(依工聚合)粘合剂/密封剂/点胶设备/耐磨化合物/环氧树脂/聚氨酯 选型指南

描述- ITW Performance Polymers offers a wide range of products to the mining, coal-fired power, alternative energy (wind), transportation, marine,composites, engineered construction and general industrial markets.

型号- DEVCON® HP 250,MA8120 GB,MA300,MA420,SC VELR 4000,SC 7315,PLEXUS® MA2000 SERIES,PDR 9000,PLEXUS® MA420W,MA8105 GB,SC PDR 9000,SC 1050,SC 1500-LS,PC-120,PLEXUS® MA2030,PLEXUS® MA2045,MA1020,MA2230,PLEXUS® PU2105,MA310,MA1025,MA550,PLEXUS® MA832,SC 2000-OS LS,PLEXUS® MA830,GPE 30,PLEXUS® MA205HV,PLEXUS® MA320,TE 2400,SC PDR 6000,MA425,SC 4055,SC 1060,MA422,AO420,SC ALPHACOA® 1700,PU2105,PLEXUS® MA8105 GB,MA2245,PLEXUS® MA420FS,SC 900,PLEXUS® MA422,PLEXUS® MA300,PLEXUS® MA425,ALPHACOAT® 1710,MA560-1,PLEXUS® MA550,PLEXUS® MA8000 SERIES,PLEXUS® MA310,EPOXY PLUS™ 25,PLEXUS® MA2290,MA530,MA2015,F-2,SC 2000-CM,PDR 6000,PLEXUS® MA560-1,PLEXUS® MA420,GPE 100,SC 4000 HDT,ALPHACOAT 1700,MA920,PLEXUS® H4110,SC ALPHACOAT® 1700,SC 5000,PLEXUS® MA2230,PLEXUS® MA1020,GPE 3,PLEXUS® MA1025,PLEXUS® MA920,MA8110 GB,TE 1000,PLEXUS® MA530,DEVCON® FLEXANE® 80,ALPHACOAT 1710,MA590,PLEXUS® MA2000,PLEXUS® MA2245,MA420W,H4110,PLEXUS® MA8110 GB,SC 4600 HTT,2000-OS LS,ALPHACOAT® 1700,MA420FS,DEVCON® FLEXANE® 94,MA2030,MA2045,SC 4500,MA320,PLEXUS® MA2015,FLEXANE® FL-10,DEVCON® EPOXY COAT™ 7000 AR,SC 2000-HS,PLEXUS® MA590,DEVCON® CLEANER BLEND 300,DEVCON® EPOXY COAT™ 7000 NON-VOC,MA832,PLEXUS® MA8120 GB,MA830,DEVCON® WEAR GUARD™ 300RTC,DEVCON® EPOXY PLUS™ 25,SC 2045,SC 1070,SC 6000,SC1070,SC 1800-LS,DEVCON® EPOXY COAT™ 7000,GPE 15,WR-2,FLEXANE® FL-20,DEVCON® DEV-THANE™ 5,MA205HV,1800-LS,SC 2000-OS,MA2290,SC 4750,PLEXUS® MA8000

ITW 交通行业解决方案——汽车电子市场

描述- ITW公司作为一家全球化的工业品制造商,提供涵盖深海石油钻机、航天技术、桥梁、风力涡轮机、医疗保健、汽车和移动设备等领域的解决方案。公司业绩显著,2022年总收入达145亿美元。ITW专注于七大业务集团,包括汽车零部件、食品设备、测试测量、工业焊接、聚合和流体、工业和特殊产品。其产品广泛应用于交通运输、新能源汽车、汽车后市场、重工行业、流体行业、风能行业、船舶行业等多个领域。ITW提供多种高性能胶粘剂、密封剂、润滑和清洁等系列产品,满足不同行业和市场的需求。

型号- LOCA,SL8130,HA系列,MA420,PSA系列,RTVS 8127 LV-C,PSA 2500,MA815,UB 45000,DC系列,SL6350,MA2060,EP6060,MA1020,MA3045,PLEXUS®DT1303,PLEXUS®DT2630,EP8080,MA310,MA1025,MA550,MA925 系列,T-BOND 25,PSA 11000,121FR,PSA 4500 FR,DC 1000,SA830,MA425,IC300,MA422,HA1510,AO420,UB 3000,PB 3500,RTVS 8127 LV,MA2003,PSA 4500,CFO,UB 20000,MA2805,SA830 系列,PLEXUS® DT2115,RTVS 27 HTC,PB 950,116FRFC,RTVS 3-95-1,121FR-DH,MA8101,RTVS 3-95-2,62010P,MA305HV,PSA 45000,LOCA系列,HP 250,PLEXUS®DT2530,10-104-06,HA1803,HA1804,68015P,PSA 21000 FR,MA805,MA925,SL6600,PSA 30000FR,KB65,HA1810,MA920,MA2090,HA1410,T-BOND E8,T-BOND E5,SL6200,SM2030,HA1820,MA216,IC510,PSA,PLEXUS®DT2435,SL系列,PLEXUS®DT2430,GB系列,PSA 750,NOVATTANE 2100,116FR,SM1330,68012P,PSA 11000 FR,SM2030 LV,SL6300,UB 15000,EP6250,MA920 系列,MA2045,PSA 21000,14167MA300,MA320,T-BOND EP7125,NOVATTANE 2130,HA2410,MA832,MA830,62030W,PB系列,SM1030,MA330,MA3940,PSA 30000,117FR,SM7530,PLEXUS® DT2325,HA1850,HP250Q,CIPG H1220,MA209,SL6,SL6400,SL6系列,UB系列,T-BOND E90

Plexus®MA425技术数据表

描述- Plexus® MA425是一种双组分甲基丙烯酸酯粘合剂,适用于热塑性塑料、金属和复合材料组装的结构粘合。该产品具有优异的疲劳耐久性、出色的冲击抵抗性和卓越的韧性,适用于交通运输和海洋工业的复合材料粘合应用。

型号- PLEXUS®,MA425,PLEXUS® MA425

Plexus(普莱克思)/Devcon(得复康)粘合剂选型指南

目录- Company Introduction MMA Structural Adhesives Polyurethane/Hybrid Structural Adhesives Epoxy Adhesives

型号- MA3940LH,MA8105,MA1020,PU2105,MA590,MA300,MA310,MA530,MA420,MA320,MA1025,MA550,MA3940,H4110,MA560-1,MA8120,MA425,MA832,MA920,MA830,MA422,HP250,MA8110

面向标牌制造商的Plexus®结构粘接解决方案

描述- 本资料主要介绍了针对标识制造商的结构粘合解决方案。资料对比了竞争对手的粘合剂和Plexus®粘合剂的特点,包括粘合速度、表面处理、耐候性等。详细列出了Plexus®系列粘合剂的产品信息,包括颜色、描述、UL认证、开放时间、混合比例、拉伸强度和延伸率。此外,还提供了与竞争对手产品的相对劳动成本比较,以及Plexus®粘合剂的优势。资料最后提醒用户,提供的技术信息和推荐仅供参考,不作为客户测试的替代。

型号- MA205HV,MA685,MA320,MA8120,MA832,MA830,MA8110

粘合剂选择指南EMEA

描述- 本指南介绍了Plexus结构粘合剂产品线,适用于电动汽车电池、电子设备、电气设备的保护、绝缘、热管理和结构件粘接。产品具有全球可用性、符合行业规范和标准、优异的疲劳抗力等特点。指南涵盖了不同应用领域的解决方案,包括风力发电、船舶制造、通用工业和交通运输等,并提供了详细的性能参数和应用建议。此外,还强调了产品的技术支持和全球服务网络。

型号- MA3940LH,MA1020,PU2105,MA590,MA8120 GB,MA300,MA310,MA530,MA420,MA320,MA1025,MA550,MA3940,MA8110 GB,H4110,MA8105 GB,MA560-1,MA425,MA832,MA920,MA830,MA422,HP250

Plexus(普莱克思)粘合剂选型指南

目录- Brand Introduction Structural Adhesives

型号- MA8105,PU2105,MA2045,MA685,MA300,MA420,MA2245,MA320,MA560-1,MA832,MA8120,MA830,MA1020,MA2230,MA590,MA310,MA530,MA2015,H4110,MA205HV,MA420FS,MA425,MA422,MA2030,MA8110

Devcon(得复康)/Permatex(泰扬)MRO & OEM胶粘剂选型指南

目录- Maintenance and Repair Products MRO Applications Product Selector Guide Surface Preparation Metal Repair Putties Metal Repair Liquids Abrasion Resistant Wearing Compounds Urethane Casting Compounds Urethane Repair Compounds Flooring Repair & Resurfacing And Product Selector Guide Emergency Repair Products Assembly and Repair Threadlockers Liquid and Gel Threadlockers Retaining Compounds Thread Sealants Gasket Makers Permatex Anti-Seize Lubricants Gasket Sealants Specialty Adhesives OEM Adhesives Epoxy Adhesives Instant Adhesives Urethane Adhesives Dispensing Systems Mix Nozzle Selector Guide Agency Approvals and Reference Charts Item Numbers

型号- 15260,14210,10130,11340,11460,13120,25224,DF039,25228,81724,81725,80003,24250,27125,24010,29025,10770,81173,15820,15940,13800,11500,12710,19510,10260,11470,12560,13130,85080,11350,30095,85519,85915,13090,80628,27010,09128,27250,80078,80633,80632,51531,14500,10780,80071,81160,51813,14503,14270,19600,13100,14277,70213,17140,70450,26250,80022,24350,10110,11320,FL-20,10230,14278,14279,15800,10080,15250,13110,14200,10240,11450,14285,17150,14280,27110,57535,77124,80011,81860,31163,80017,80016,25210,80015,15810,15656,10120,11330,14289,10760,FL-10,11730,56725,14250,14251,82180,10050,14255,11780,15980,81409,70350,72250,27725,54550,80045,60950,24210,33694,11781,15985,11420,10210,12750,51845,10610,81095,DA999,15350,17130,14265,15990,81915,24225,24105,81878,72261,81913,10220,10620,15043,14350,82080,15047,10270,11480,17100,80855,51580,85913,11767,11800,26210,59225,56750,3333,11760,11762,15049,68050,14630,10710,11765,14240,11490,15850,13550,19770,70144,15330,26225,80208,15050,DA052,24325,77164,72161,56525,DA051,27036,31120,59235,27037,56521,80050,11770,11495,11410,85224,27150,82194,10720,14404,29050,82195

Structural Adhesive Bonding in Composite Recreational Boat Building: The Methacrylate Advantage

Structural adhesive bonding, particularly with methacrylate adhesives, has transformed the composite recreational boat building industry. The combination of superior bond strength, durability, flexibility, and ease of application makes methacrylates an ideal choice for boat builders aiming for high performance and longevity.

Plexus® HA1803 双组分,多元,弹性胶黏剂

描述- Plexus® HA1803是一种双组分、多元、弹性胶黏剂,具有中等模量和良好的断裂伸长率。该产品在高温、高湿等恶劣条件下表现出优异的抗老化性能,对多种材料具有良好的粘接力。Plexus® HA1803粘度适中,快速固化,不含溶剂,适用于电泳涂装。技术参数包括固化前后的密度、粘度、剪切强度等,以及耐化学和耐老化性能。产品适用于多种材料粘结,如金属、工程建筑型材、热塑性材料、玻璃等。

型号- PLEXUS® HA1803

用于运输的粘合解决方案

描述- Plexus粘合剂解决方案在交通运输行业中的应用广泛,适用于多种材料,如热塑性塑料、金属和复合材料。其产品能够提供耐用连接,减少装配成本,并提高最终组件的质量。Plexus粘合剂在卡车、公交车和火车制造中的应用包括减少车辆重量、提高美学效果、增强耐腐蚀性和耐疲劳性。此外,Plexus提供全面的客户支持和技术援助,确保产品质量和可靠性。

型号- 300,MA300,400,MA310,MA420,800 SERIES,400 SERIES,MA832,800,MA515,300 SERIES

北美地区粘合剂选择指南

描述- 本资料介绍了Plexus系列高级结构粘合剂和绝缘铸封产品的应用范围和技术特点。产品适用于电动汽车电池、电子产品、交通运输、风力发电、船舶制造和通用工业等领域。资料详细说明了Plexus粘合剂的化学成分、混合比例、固化时间、拉伸强度、耐疲劳性能等参数,并提供了全球销售和服务网络信息。

型号- MA1020,MA2230,PU2105,MA590,MA8120 GB,MA2045,MA300,MA420,MA2245,MA310,MA530,MA320,MA2015,MA8110 GB,H4110,MA8105 GB,MA560-1,MA205HV,MA420FS,MA425,MA832,MA830,MA422,MA2030

The Suitability of Plexus® Adhesives for Bonding Low Surface Energy Plastics

This blog post explores the effectiveness of Plexus adhesives for bonding low surface energy substrates. The Plexus team has introduced two new adhesives, as promising solutions to overcome the difficulties of bonding low energy surface plastics: Plexus PU2105 and Plexus H4110. When bonding low surface energy substrates, in conjunction of a surface pre-treatment, these two Plexus adhesives exhibit excellent adhesion properties, allowing them to form strong bonds with various materials specifically plastics like TPOs.

电子商城

服务

使用FloTHERM和Smart CFD软件,提供前期热仿真模拟、结构设计调整建议、中期样品测试和后期生产供应的一站式服务,热仿真技术团队专业指导。

实验室地址: 深圳 提交需求>

登录 | 立即注册

提交评论