Bonding Pultrusion with a Plexus® Methacrylate Adhesive

It’s more than possible to expand your team’s design freedom when you work with an MMA adhesive (Methacrylate Adhesive) like those found in the Plexus brand. In addition to reducing print through, gaining gap control, and advanced design tips, bonding with Plexus has many benefits, especially when combined with pultrusion applications.

What is Pultrusion?

The word pultrusion is a combination of the words “pull” and “extrusion.” Pultrusion (or sometimes called pultruded FRP) is the combination of fibers and resin being pulled through a die to make a consistent cross-section. The final product has unique and tunable properties. The main attraction of pultruded parts is the high strength to weight ratio and corrosion resistance. The fibers are usually glass, but natural fibers, basalt, and carbon fibers can be used. The most common resin system is polyester, though polyurethane, epoxy, and vinyl esters are also used. Advancements such as using thermoplastic resins to enhance recyclability have started to gain traction.

Where is Pultrusion Used and Why?

Pultrusion has excellent strength-to-weight ratio, is non-corrosive, and usually non-conductive. Pultruded FRP has been used for ladders for many years due to those properties. Transportation OEMs (original equipment manufacturers) have started incorporating pultrusion into their manufacturing designs to help reduce vehicle weight, and infrastructure projects are including more pultrusion to reduce corrosion risks and increase the infrastructure’s expected life.

Bonding Pultruded Parts to Other Substrates

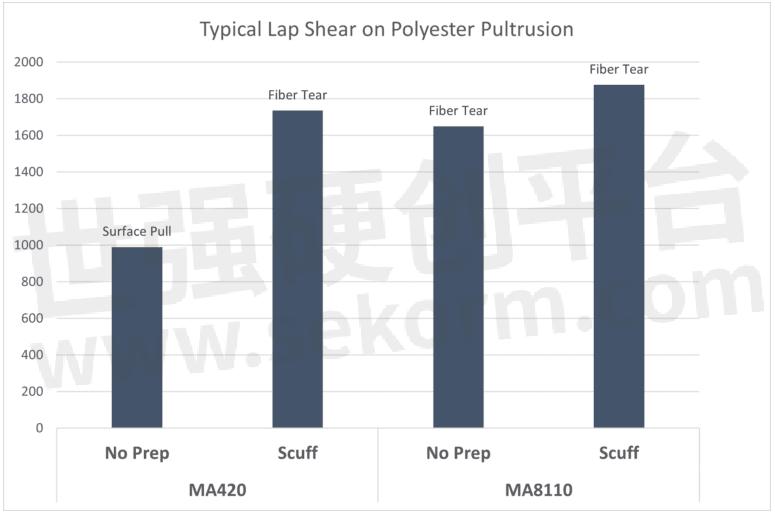

Plexus methacrylate adhesives have a long history of bonding pultruded parts. The ability of Plexus to cross bond pultrusion to other composites, metals, and thermoplastics has been a key criterion for selecting Plexus adhesives. Polyester pultrusion often requires abrasion to get the best adhesion, but Plexus MA8110 has instances where it bonds without abrasion (see below). Polyurethane based pultrusion can often be bonded as received.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由玄子转载自ITW markets,原文标题为:Bonding Pultrusion with a Plexus® Methacrylate Adhesive,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

ITW(依工聚合)粘合剂/密封剂/点胶设备/耐磨化合物/环氧树脂/聚氨酯 选型指南

描述- ITW Performance Polymers offers a wide range of products to the mining, coal-fired power, alternative energy (wind), transportation, marine,composites, engineered construction and general industrial markets.

型号- DEVCON® HP 250,MA8120 GB,MA300,MA420,SC VELR 4000,SC 7315,PLEXUS® MA2000 SERIES,PDR 9000,PLEXUS® MA420W,MA8105 GB,SC PDR 9000,SC 1050,SC 1500-LS,PC-120,PLEXUS® MA2030,PLEXUS® MA2045,MA1020,MA2230,PLEXUS® PU2105,MA310,MA1025,MA550,PLEXUS® MA832,SC 2000-OS LS,PLEXUS® MA830,GPE 30,PLEXUS® MA205HV,PLEXUS® MA320,TE 2400,SC PDR 6000,MA425,SC 4055,SC 1060,MA422,AO420,SC ALPHACOA® 1700,PU2105,PLEXUS® MA8105 GB,MA2245,PLEXUS® MA420FS,SC 900,PLEXUS® MA422,PLEXUS® MA300,PLEXUS® MA425,ALPHACOAT® 1710,MA560-1,PLEXUS® MA550,PLEXUS® MA8000 SERIES,PLEXUS® MA310,EPOXY PLUS™ 25,PLEXUS® MA2290,MA530,MA2015,F-2,SC 2000-CM,PDR 6000,PLEXUS® MA560-1,PLEXUS® MA420,GPE 100,SC 4000 HDT,ALPHACOAT 1700,MA920,PLEXUS® H4110,SC ALPHACOAT® 1700,SC 5000,PLEXUS® MA2230,PLEXUS® MA1020,GPE 3,PLEXUS® MA1025,PLEXUS® MA920,MA8110 GB,TE 1000,PLEXUS® MA530,DEVCON® FLEXANE® 80,ALPHACOAT 1710,MA590,PLEXUS® MA2000,PLEXUS® MA2245,MA420W,H4110,PLEXUS® MA8110 GB,SC 4600 HTT,2000-OS LS,ALPHACOAT® 1700,MA420FS,DEVCON® FLEXANE® 94,MA2030,MA2045,SC 4500,MA320,PLEXUS® MA2015,FLEXANE® FL-10,DEVCON® EPOXY COAT™ 7000 AR,SC 2000-HS,PLEXUS® MA590,DEVCON® CLEANER BLEND 300,DEVCON® EPOXY COAT™ 7000 NON-VOC,MA832,PLEXUS® MA8120 GB,MA830,DEVCON® WEAR GUARD™ 300RTC,DEVCON® EPOXY PLUS™ 25,SC 2045,SC 1070,SC 6000,SC1070,SC 1800-LS,DEVCON® EPOXY COAT™ 7000,GPE 15,WR-2,FLEXANE® FL-20,DEVCON® DEV-THANE™ 5,MA205HV,1800-LS,SC 2000-OS,MA2290,SC 4750,PLEXUS® MA8000

ITW 交通行业解决方案——汽车电子市场

描述- ITW公司作为一家全球化的工业品制造商,提供涵盖深海石油钻机、航天技术、桥梁、风力涡轮机、医疗保健、汽车和移动设备等领域的解决方案。公司业绩显著,2022年总收入达145亿美元。ITW专注于七大业务集团,包括汽车零部件、食品设备、测试测量、工业焊接、聚合和流体、工业和特殊产品。其产品广泛应用于交通运输、新能源汽车、汽车后市场、重工行业、流体行业、风能行业、船舶行业等多个领域。ITW提供多种高性能胶粘剂、密封剂、润滑和清洁等系列产品,满足不同行业和市场的需求。

型号- LOCA,SL8130,HA系列,MA420,PSA系列,RTVS 8127 LV-C,PSA 2500,MA815,UB 45000,DC系列,SL6350,MA2060,EP6060,MA1020,MA3045,PLEXUS®DT1303,PLEXUS®DT2630,EP8080,MA310,MA1025,MA550,MA925 系列,T-BOND 25,PSA 11000,121FR,PSA 4500 FR,DC 1000,SA830,MA425,IC300,MA422,HA1510,AO420,UB 3000,PB 3500,RTVS 8127 LV,MA2003,PSA 4500,CFO,UB 20000,MA2805,SA830 系列,PLEXUS® DT2115,RTVS 27 HTC,PB 950,116FRFC,RTVS 3-95-1,121FR-DH,MA8101,RTVS 3-95-2,62010P,MA305HV,PSA 45000,LOCA系列,HP 250,PLEXUS®DT2530,10-104-06,HA1803,HA1804,68015P,PSA 21000 FR,MA805,MA925,SL6600,PSA 30000FR,KB65,HA1810,MA920,MA2090,HA1410,T-BOND E8,T-BOND E5,SL6200,SM2030,HA1820,MA216,IC510,PSA,PLEXUS®DT2435,SL系列,PLEXUS®DT2430,GB系列,PSA 750,NOVATTANE 2100,116FR,SM1330,68012P,PSA 11000 FR,SM2030 LV,SL6300,UB 15000,EP6250,MA920 系列,MA2045,PSA 21000,14167MA300,MA320,T-BOND EP7125,NOVATTANE 2130,HA2410,MA832,MA830,62030W,PB系列,SM1030,MA330,MA3940,PSA 30000,117FR,SM7530,PLEXUS® DT2325,HA1850,HP250Q,CIPG H1220,MA209,SL6,SL6400,SL6系列,UB系列,T-BOND E90

Plexus®MA425技术数据表

描述- Plexus® MA425是一种双组分甲基丙烯酸酯粘合剂,适用于热塑性塑料、金属和复合材料组装的结构粘合。该产品具有优异的疲劳耐久性、出色的冲击抵抗性和卓越的韧性,适用于交通运输和海洋工业的复合材料粘合应用。

型号- PLEXUS®,MA425,PLEXUS® MA425

Plexus(普莱克思)/Devcon(得复康)粘合剂选型指南

目录- Company Introduction MMA Structural Adhesives Polyurethane/Hybrid Structural Adhesives Epoxy Adhesives

型号- MA3940LH,MA8105,MA1020,PU2105,MA590,MA300,MA310,MA530,MA420,MA320,MA1025,MA550,MA3940,H4110,MA560-1,MA8120,MA425,MA832,MA920,MA830,MA422,HP250,MA8110

Plexus® HA1803 双组分,多元,弹性胶黏剂

描述- Plexus® HA1803是一种双组分、多元、弹性胶黏剂,具有中等模量和良好的断裂伸长率。该产品在高温、高湿等恶劣条件下表现出优异的抗老化性能,对多种材料具有良好的粘接力。Plexus® HA1803粘度适中,快速固化,不含溶剂,适用于电泳涂装。技术参数包括固化前后的密度、粘度、剪切强度等,以及耐化学和耐老化性能。产品适用于多种材料粘结,如金属、工程建筑型材、热塑性材料、玻璃等。

型号- PLEXUS® HA1803

粘合剂选择指南EMEA

描述- 本指南介绍了Plexus结构粘合剂产品线,适用于电动汽车电池、电子设备、电气设备的保护、绝缘、热管理和结构件粘接。产品具有全球可用性、符合行业规范和标准、优异的疲劳抗力等特点。指南涵盖了不同应用领域的解决方案,包括风力发电、船舶制造、通用工业和交通运输等,并提供了详细的性能参数和应用建议。此外,还强调了产品的技术支持和全球服务网络。

型号- MA3940LH,MA1020,PU2105,MA590,MA8120 GB,MA300,MA310,MA530,MA420,MA320,MA1025,MA550,MA3940,MA8110 GB,H4110,MA8105 GB,MA560-1,MA425,MA832,MA920,MA830,MA422,HP250

Metal to Metal Bonding with Structural Adhesives Facilitates More Effective Stress Distribution

Structural adhesives have become a popular choice for metal to metal bonding applications due to their ability to distribute stress evenly across a joint. This is especially important in applications where the bond is subjected to heavy loads or stress. This article explores the benefits of using structural adhesives in metal to metal bonding applications and how they can help to distribute stress more effectively.

Unbreakable Bonds: Exploring the Chemical Resistance of MMA Adhesives

This article dives into the continual evolving adhesive class of MMA (methyl methacrylate) acrylic adhesives and their outstanding chemical resistance properties.

Structural Adhesive Bonding in Composite Recreational Boat Building: The Methacrylate Advantage

Structural adhesive bonding, particularly with methacrylate adhesives, has transformed the composite recreational boat building industry. The combination of superior bond strength, durability, flexibility, and ease of application makes methacrylates an ideal choice for boat builders aiming for high performance and longevity.

The Suitability of Plexus® Adhesives for Bonding Low Surface Energy Plastics

This blog post explores the effectiveness of Plexus adhesives for bonding low surface energy substrates. The Plexus team has introduced two new adhesives, as promising solutions to overcome the difficulties of bonding low energy surface plastics: Plexus PU2105 and Plexus H4110. When bonding low surface energy substrates, in conjunction of a surface pre-treatment, these two Plexus adhesives exhibit excellent adhesion properties, allowing them to form strong bonds with various materials specifically plastics like TPOs.

Plexus® Methacrylate Adhesive with Patented Core-Shell Technology: A Revolution in Bonding Solutions

This article explores the unique features and benefits of Plexus methacrylic adhesives and how core-shell technology enhances Plexus’ bonding solutions every day.

用于电动汽车的粘合剂和灌封解决方案

型号- RTVS 27FC,PLEXUS MA320,INSULCAST 3-95-2,PLEXUS PU2105,PLEXUS PU2325,PLEXUS PU2435,DEVCON PSA 4500,INSULCAST 140FR,PLEXUS MA3940LH,PLEXUS MA8110,PLEXUS H4110

KD1003甲基丙烯酸酯胶粘剂技术数据表

描述- KD1003是一种先进的非导电双组分甲基丙烯酸酯粘合剂,适用于各种电子组件的结构粘接。它能够在无底漆的情况下将金属与工程热塑性塑料和复合材料组装牢固地粘接在一起。该产品混合比例为体积比10:1,工作时间为5-6分钟,具有高强度、优异的疲劳耐久性、卓越的抗冲击性和良好的韧性。

型号- KD1003

用于OEM结构和装配应用的粘合剂解决方案

描述- ITW Performance Polymers提供多种先进的结构性粘合剂,用于简化组装过程,降低生产成本并提高制造效率。产品包括Plexus甲基丙烯酸甲酯粘合剂、Devcon环氧树脂粘合剂和Permatex氰基丙烯酸酯粘合剂,适用于多种复合材料、热塑性塑料、金属和不同基材的粘合。资料详细介绍了产品特性、应用领域、化学指南和订购信息。

型号- GPE 3,MA300,MA420,5 MINUTE® EPOXY,TE 1000,MA8120,MA2000 WHITE,MA8000,MA8000 SERIES,MA1020,MA2230,MA590,MA310,MA1025,MA550,MA2015 WHITE,A0420,5 MINUTE® EPOXY GEL,GPE 30,MA420FS,TE 2400,MA425,MA422,DEV-THANE™ 5,MA2030,MA2045,MA685,MA2245,MA2000 WHITE SERIES,MA320,2-TON EPOXY,EPOXY PLUS 25,MA560-1,1 MINUTE EPOXY GEL,MA832,PLASTIC-WELDER WHITE,MA830,FOOD GRADE POT & SEAL,MA530,HP 250,DEV-THANE 5,MA2045 WHITE,GPE 15,MA205HV,GPE 100,MA920,MA2090,AO/MA420,MA2290,10 MINUTE EPOXY,MA8110

钢门用MA8105 GB

描述- Plexus MA8105 GB 是一种高性能MMA粘合剂,具有快速固化特性。该产品适用于钢制门装配,可减少焊接需求并提高生产效率。它包含玻璃珠以保持一致的粘接线厚度,并提供多种包装选项。

型号- MA8105,81057,81058,81059,81053,81054,81055

电子商城

服务

使用FloTHERM和Smart CFD软件,提供前期热仿真模拟、结构设计调整建议、中期样品测试和后期生产供应的一站式服务,热仿真技术团队专业指导。

实验室地址: 深圳 提交需求>

登录 | 立即注册

提交评论