WACKER Presents Silicone-Based Solutions for Electromobility and Medical Applications

At Silicone Expo Europe, which begins today, the WACKER Group is showcasing silicone-based product solutions for specific industrial sectors. The focus is on silicone gels for wound care, non-postcuring liquid silicone rubber for the food industry and medical technology, and self-adhesive liquid silicone rubber grades that adhere to polycarbonate and other high-performance plastics. Products for electromobility applications and resource-efficient silicones are also in the limelight. Silicone Expo Europe is taking place from February 28 to 29 in Amsterdam, the Netherlands.

SILPURAN® silicone adhesives have a proven track record over many years in the field of atraumatic wound dressings. As an adhesive layer, they enable secure and gentle fixation of wound dressings to the skin. SILPURAN® adhesive gels adhere so gently that pain-free removals of dressings are possible.

WACKER will be using Silicone Expo to showcase not only its tried-and-tested product range but also a silicone adhesive that adheres much more strongly than previous grades. SILPURAN® 2124 achieves an adhesive force of 6.0 newtons per 2.5 centimeters, determined in the 90° peel test on steel in accordance with EN 1639. This means that adhesion is so strong that the gel is suitable both for wound care and for fixing wearables, i.e. sensors, catheters, cannulas or other medical devices. SILPURAN® 2124 is biocompatible according to selected tests in accordance with ISO 10993 and USP, Chapter <88>, Class VI. It can be sterilized with ethylene oxide.

Scarcely visible, hardly noticeable: modern blood glucose monitors can be reliably and gently attached with SILPURAN® 2124 silicone adhesive from WACKER. The WACKER Group will be presenting the adhesive at this year’s Silicone Expo Europe.

ELASTOSIL® LR 3078 – Self-Adhesive on Polycarbonate and Other High-Performance Plastics

Another highlight is the ELASTOSIL® LR 3078 product line. This self-adhesive liquid silicone rubber cures rapidly and establishes a firm bond with the polycarbonate thermoplastic. This makes it easy to produce hard-soft combinations using two-component injection-mold-ing processes. The adhesion system developed by WACKER is free of bisphenol A structures. Cured rubber products of ELASTOSIL® LR 3078 have been successfully tested for biocompatibility.

The product also offers good adhesion properties as regards other high-performance plastics that are difficult to process using 2K methods, such as polyphenylene ether (PPE), polysulfone (PSU), polyether sulfone (PESU), polyphenyl sulfone (PPSU) and polyether imide (PEI). Thanks to its good adhesion, ELASTOSIL® LR 3078 paves the way to cost-effective large-scale production of respiratory and anesthesia masks, drug delivery systems or devices for minimally invasive examinations and operations.

WACKER is showcasing its ELASTOSIL® LR 5003 liquid silicone rubber line at Silicone Expo Europe. This is a non-postcuring grade that has a very low volatiles content and is therefore suitable for the large-scale manufacture of products in the food industry and other sensitive sectors.

Non-Postcuring Liquid Silicone Rubber

Silicone rubber frequently undergoes postcuring after processing. During this procedure, the cured silicone elastomer is heated in a well-ventilated oven for several hours to temperatures of up to 200℃. This eliminates volatile components while enhancing the strength of the silicone rubber. However, this is an expensive step in production that not only consumes a lot of time and energy, but also interrupts the flow of a highly automated production process.

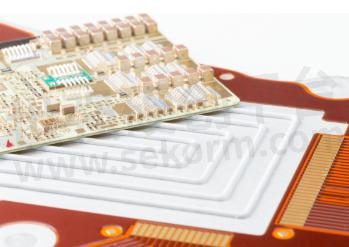

Thermally conductive silicone elastomers make ideal gap fillers. They take the waste heat produced by electronic components or batteries and dissi-pate it efficiently to a heat sink. WACKER will be presenting such products at Silicone Expo in Amsterdam.

WACKER has now developed a line of non-postcuring liquid silicone rubber grades under the name ELASTOSIL® LR 5003, which is parti-cularly suitable for the large-scale manufacture of products in the food industry and other sensitive areas. As far as their volatiles content is concerned, molded parts made from such silicones comply with the limits stipulated by the German Federal Institute for Risk Assessment (BfR) even without postcuring. They also meet the requirements of the U.S. Food and Drug Administration (FDA) for food contact products. This means that products such as reusable drinking straws, baking pans, dough scrapers, and other items can be produced very efficiently. ELASTOSIL® LR 5003 may be additionally postcured in order to achieve even greater strengths and an even lower volatiles content.

ELASTOSIL® LR 5003 complements ELASTOSIL® LR 5040, which is also a non-postcuring liquid silicone rubber. Even without postcuring, the latter exhibits a high degree of tear resistance, a property required, for example, for drinking and soothing teats, teething rings, and other babycare articles that have to withstand high mechanical stresses.

Silicones in Electromobility

Frost, heat, moisture, vibrations, high electrical voltages, and charging currents – materials used in electric vehicles have to withstand a lot. Silicones from WACKER are capable of doing so. They prove their worth in many areas of application, whether in electrical systems, electronics, or the thermal management of batteries. Silicone Expo Europe allows WACKER to demonstrate how silicones are ensuring a sustainable transition to electromobility. Take the following two examples:

Charging currents and the resulting waste heat of battery-operated vehicles are constantly on the rise, with voltages of up to 800 V and charging currents of up to 350 A no longer uncomfortable. For this reason, the automotive industry needs extrudable materials that will reliably retain their electrical insulation properties over a very broad range of temperatures and long periods. Silicones such as ELASTOSIL® R plus 4305, a solid silicone rubber, are an ideal fit for applications such as these. When formulated with a corresponding heat stabilizer, the product can withstand temperatures of up to 200℃, without substantial changes in either its mechanical properties or its electrical characteristics.

Electric vehicles normally use lithium-ion batteries as their power source. These are usually installed below the passenger compartment, where they occupy most of the floor space. A thermally conductive gap filler is needed to provide thermal coupling between the battery modules and the heat-dissipation system. It must be aging-resistant to prevent premature battery failure and must lend itself to rapid application to large surfaces. For this, WACKER has developed flowable, silicone-based gap fillers that can be injected quickly and yield perfect results even in large areas, thereby facilitating high-speed large-scale production.

Resource-Efficient: ELASTOSIL® eco

ELASTOSIL® eco is another product that WACKER will be presenting at Silicone Expo. These silicones are produced in a resource-efficient manner and stem from plant-based methanol derived from non-fossil sources. ELASTOSIL® eco products are certified to the REDcert2 standard, thereby ensuring the traceability of renewable raw materials along the entire production process.

Presentation on Silicone Adhesives

WACKER will also be giving a technical presentation at Silicone Expo Europe. On February 29, Andrea Bogner, Senior Marketing Manager Industrial Solutions at WACKER SILICONES, and Peter Serrano, Global Segment Market Director for Performance Solutions at Loparex, a leading producer of paper and film release liners, will be talking about the combination possibilities of high-performance silicone adhesives and release films. The lecture starts at 1:10 p.m.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由玄子转载自WACKER Press-releases,原文标题为:WACKER Presents Silicone-Based Solutions for Electromobility and Medical Applications,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

瓦克展示面向电动汽车及医疗应用的有机硅解决方案

瓦克集团在2024年02月28日开幕的欧洲有机硅博览会(Silicone Expo Europe)上展示面向特定用户行业的有机硅产品解决方案,重点展示伤口护理用有机硅凝胶、食品工业及医疗技术用免恒温固化处理型液体硅橡胶,以及可粘附于聚碳酸酯和其它高性能合成材料的自粘型液体硅橡胶。

瓦克展示供固定电子组件使用的强力有机硅凝胶 SILPURAN® 2124

瓦克化学集团在本年度COMPAMED医疗技术专业展会上展示供医疗技术使用的有机硅产品,其中,具有强效附着力的SILPURAN® 2124有机硅凝胶首次亮相。ELASTOSIL® eco品牌的固体及液体硅橡胶也是展会的亮点产品,它们以生物甲醇为基础,用节约资源的方式生产而成。可自行粘附于聚碳酸酯和其它高效合成材料的ELASTOSIL® LR 3078液体硅橡胶,也在瓦克这家化学集团此次展示的产品之列

瓦克在2023年度国际塑料加工专业展会展示免恒温固化处理型液体硅橡胶及供有机硅激光打标使用的颜料膏

瓦克化学股份有限公司在2023年度国际塑料加工专业展会Fakuma上展示加工后无需二次硫化的硅橡胶新产品。ELASTOSIL®LR 5003液体硅橡胶适用于食品及其它敏感应用领域,无需热后加工,便可满足相关法律对极限值的规定。瓦克化学集团同时展示的,还包括一种新型有机硅弹性体打标解决方案:ELASTOSIL® Laser Marking颜料膏能够确保激光精准地对此类有机硅进行永久性标记。

德聚(CollTech)胶粘剂产品选型指南(英文)

目录- Introduction of CollTech One/Two Part Epoxy Adhesives Acrylate UV Adhesives Underfill Materials/Hot Melt Adhesives/Coating Materials Thermal Conductive Adhesives/Conductive Adhesives/Thermal Greases Thermal Gels/Silicone Potting Materials Silicone Sealants/Polyurethane Sealants Adhesives for Structural Bonding/Instant Adhesives Product Applications

型号- N-SIL 8700,N-PU 5100,EW 6312,N-PU 5103,PW 1164,N-PU 5105,N-PU 5107,PW 1442,PW 2133,PW 1446,PW 1209,N-SIL 8275,PW 1206,PW 1448,N-SIL 8276,N-SIL 8552,EW 6609,EW 6608,N-SIL 8715,EW 6328,EW 6326,PW 1292,CT 7251H,EW 6320,PW 1451,N-SIL 8201,N-SIL 8206,N-SIL 8725,CT 7255B,EW 6658,EW 6657,N-SIL 8608,CT 7261,CT 7260,PW 2990,EW 6650,PW 1023,PW 1304,PW 1422,N-SIL 8210,N-SIL 8332,N-SIL 8215,N-SIL 8336,N-SIL 8337,EW 6615H,N-SIL 8735,N-SIL 8615,EW 6308,CT 7250,N-COAT 9368,CT 7251,CT 7258,N-COAT 9360,CT 7257,PW 1033,PW 1435,PW 1436,CT 7253,N-SIL 8580,CT 7256,CT 7255,N-SIL 8220,N-SIL 8740,HW 9905,N-SIL 8620,AW 2915,PW 1081,AW 2916,EW 6355,PW 1486,EW 6350,PW 2057,PW 1400,PW 1008,N-SIL 8112,N-SIL 8630,N-SIL 8113,AW 2920,N-COAT 9300,PW 1250,HW 9590,EW 6360,PW 2500,PW 2501,CT 5605,CT 5606,PW 1218,CT 5607,N-SIL 8640,EW 6619,CT 5608,EW 6615,EW 6339,SW 7037,CT 7250H,EW 6336,EW 6611,EW 6335,EW 6610,CT 7250L,PW 2550,PW 1465,PW 1066,SW 7022,N-SIL 8135,N-SIL 8533,CT 7258H,EW 6627,EW 6625,EW 6349,AW 2904,AW 2903,EW 6621,EW 6346,EW 6345,PW 1471,AW 2900,AW 2902,PW 1470,EW 6066,N-COAT 9560,AW 2901,PW 1475,EW 6064,EW 6061,EW 6060

WACKER(瓦克)固体和液体硅橡胶产品选型指南

描述- 瓦克是一家全球运营的特种化学品公司,产品的技术含量高且发展成熟,被广泛应用于人类日常生活的各个领域,上至太阳能电池,下至瓷砖胶粘剂,一应俱全。瓦克为100 多个国家和地区供应3000多种产品。

型号- R 701/80,R PLUS 4370/50,ELASTOSIL® R PUS 4001/40,R PLUS 4001/90,LR 3023/60,R PLUS 4020/50,LR 3271/45,R PLUS 4305/70,LR 3071/30,LR 3070/60,R 780/80 OH,LR 3093/65,LR 5040/30,R PLUS 4020/60,R 701/70,R 861/60 S,R 402/75 S,R PLUS 4066/60,R PLUS 4370/40,R PLUS 4001/80,LR 3844/30,6700/60,ELASTOSIL® LR 6320 F,R 401/10 OH,LR 3005/70,R PLUS 4305/80,LR 3003/20 TR,R 401/55 S,ELASTOSIL® LR 3003/30,R 420/70 S,R 755/60 OH,LR 5040/20,LR 3071/40,R 401/70 S,ELASTOSIL® LR 6250 F,LR 3092/65,R PLUS 4020/70,R PLUS 4050/55 MH,R 701/60,R 861/70 S,R PLUS 4001/70,ELASTOSIL ® RD 6620 F,LR 3842/60,LR 3843/30,R 756/60 OH,LR 3005/60,R PLUS 4806/20,R PLUS 4305/90,R PLUS 4060/50,LR 3070/40,R 401/60 S,R 701/50,R 752/70 OH,LR 3065/30,LR 3016/65,R 700/80,R 401/60 KX S,R 760/70 MH,R 781/80,LR 3842/70,LR 3005/50,LR 3022/60,R PLUS 4001/60,LR 34004/50,R PLUS 4060/60,LR 3070/50,R 701/40,LR 3040/40,LR 3834/50 ULTRA,ELASTOSIL ® 47007,R PLUS 4305/30,LR 3025/40,LR 3074/60,ELASTOSIL ® E50 N,LR 5040/70,6610/60,6760/50,R 402/65 OH,ELASTOSIL ® RD 3151 F,R 401/20 OH,R 401/80 S,LR 3003/25,LR 3070/20,R 510/70 S,LR 3040/50,ELASTOSIL® LR 6360 F,R 401/30 S,R PLUS 4305/40,R PLUS 573/70,6610/50,R 752/50 OH,LR 5040/60,LR 3070/30,LR 3011/50 FR,ELASTOSIL® LR 6200 A/B,ELASTOSIL® LR 6260 A/B,R 510/60 S,LR 3844/40,LR 3040/60,6000/05,R 865/40 S,R PLUS 4846/30,6610/40,R 101/25 OH,R PLUS 4305/50,LR 3003/03,LR 3003/05,AUX 8251 RO,LR 3856/20,LR 5040/50,R PLUS 4070/60,WACKER ® FINISH CT 51 L,R 570/70 OH,LR 3844/50,R PLUS 573/50,6400/40,LR 3040/70,R PLUS 4020/40,R 756/70 OH,LR 5040/45,LR 3856/30,LR 5040/40,R PLUS 4070/30,LR 3066/70,6000/20,LR 3043/70,6400/50,R 401/30 OH,R PLUS 4000/40,ELASTOSIL ® RD 6600 F,LR 3003/60,LR 3004/30,R 750/50 0H,LR 3675/30,LR 3078/60,R 101/65 OH,6600/60,R PLUS 4361/60,R PLUS 4070/20,R 401/40 S,LR 3852/50,6000/10,R PLUS 4366/60,R PLUS 4350/55,R 512/70 OH,LR 3066/60,LR 3020/60,6400/60,LR 3003/50,R 865/50 S,R PLUS 4303/60,LR 3078/70,6600/50,ELASTOSIL® R 401/40,R 750/40 OH,LR 3851/50,6000/40,LR 3170/40,LR 3675/50,LR 3846/20,LR 3003/40,R PLUS 4303/70,LR 3078/40,LR 7601/60,R 420/40 S,6600/40,R 101/35 OH,LR 3040/30,LR 7601/50,6000/30,ELASTOSIL ® E91,LR 3066/80,LR 3846/30,R 770/75 OH,R 770/50 OH,LR 3003/30,LR 3078/50,R PLUS 4360/60,R PLUS 4303/80,R 570/60 OH,AUX 8250 RO,LR 3066/30,ELASTOSIL® LR 3003/20 TR,LR 3004/70,LR 3005/40,ELASTOSIL ® E43 N,ELASTOSIL ® E92 N,LR 3842/40,R PLUS 4001/50,6740/40,LR 3078/20,R 865/60 S,LR 3671/30,R 420/60 S,LR 3072/40,LR 7601/80,6000/60,R 756/40 OH,LR 3065/50,R 501/75 OH,6000/50,R 420/30 OH,LR 3003/10 TR,ELASTOSIL® LR 3001/55 FR A/B,LR 3043/40,LR 3003/90,LR 3842/50,R PLUS 4001/40,R PLUS 4000/70,LR 3004/60,LR 3001/55 FR,LR 3841/50,LR 3005/30,LR 3078/30,LR 3671/40,R 401/90 OH,LR 3094/60,ELASTOSIL® NT 76,LR 7601/70,ELASTOSIL® LR 6240 A/B,LR 3072/50,LR 3015/70,LR 3066/50,R 502/75 OH,LR 3003/80,R PLUS 4001/30,6700/50,LR 3043/50,LR 3004/50,R 416/70 MH,R PLUS 4000/60,LR 3003/85,LR 3671/50,R 570/50 OH,LR 3162,R PLUS 4061/60,LR 3071/50,R 756/50 OH,R 700/40,R 770/60 OH,R PLUS 4050/55,LR 3066/40,R PLUS 4001/20,LR 3043/60,R PLUS 4000/50,LR 3003/70,6700/40,LR 3004/40,R 865/70 S,R 101/45 OH,LR 3076/70,LR 3153,R 420/50 S,LR 3072/30,6000/70,LR 3071/60,R 490/55 OH,R 401/50 S,R PLUS 4305/60 S,LR 3015/50

硅胶模具真空铸造

描述- 真空铸造技术,特别是使用硅橡胶模具,是快速原型制作的关键技术。它具有低成本、快速生产、高功能性、多种表面处理选项等特点,适用于生产原型和小批量产品。与3D打印相比,真空铸造在几何自由度、功能性和外观质量方面具有显著优势。ELASTOSIL® M硅橡胶因其优异的流动性和耐久性,成为真空铸造的理想材料。

型号- ELASTOSIL® M 4644 A/B,ELASTOSIL® M 4645 A/B,ELASTOSIL® M 4670 A/B,M 4645,ELASTOSIL® M 4641 A/B,ELASTOSIL®,ELASTOSIL® M,M 4670

Parker Chomerics(派克固美丽)Tecknit EMI 屏蔽材料选型指南

目录- Company Profile and Products introduction Electromagnetic Compatibility Overview EMI SHIELDING DESIGN Special Applications Knitted Wire Mesh Metal Fibers and Screens Oriented Wires Conductive Elastomer EMI Shielding Windows Air Vent Panels Conductive Systems Products Shielding Components Beryllium Copper Gaskets Fabric-over-Foam Gaskets EMI Shielding Products Glossary and Appendix

型号- 82-12916,21-13910,82-12911,21-13911,21-13912,60-02010,21-13913,60-02011,21-13914,60-02012,21-13915,60-02013,21-13916,60-02014,21-13917,60-02015,21-13918,60-02005,88-12342,60-02006,60-02007,60-02008,60-02009,48-00476,43-46210,88-12347,21-13900,82-12921,21-13901,XX-X1500,21-13902,60-02002,60-02003,60-02004,21-13907,XX-X1506,21-13908,XX-X1505,21-13909,XX-X1508,XX-X1507,XX-X1502,XX-X1501,XX-X1504,XX-X1503,48-00481,88-12337,73-00081,XX-X1509,60-02030,21-13933,60-02031,21-13934,60-02032,21-13935,60-02033,43-13794,60-02027,60-71043,60-02028,60-71044,60-02029,88-12362,60-71042,60-71047,60-71048,60-71045,60-71046,86-10094,89-50010,43-43162,86-10093,89-50012,86-10090,89-50014,86-10092,89-50016,86-10091,86-10076,84-70079,86-10075,89-7XXXX,21-13920,86-10077,84-70076,84-70075,60-02020,84-70078,60-02021,84-70077,60-02022,84-70072,60-02023,84-70071,60-02024,84-70074,60-02025,84-70073,60-02026,88-12352,60-02016,43-46208,60-02017,60-02018,43-46206,60-02019,88-12357,89-50020,89-50021,86-10082,89-50022,43-00003,89-50023,43-43175,89-50024,43-43178,72-08116,89-50025,43-00000,89-50026,89-50027,86-10080,73-00025,60-02052,60-02053,43-13335,60-02054,43-13334,60-02055,88-12392,60-02056,60-02057,60-02058,60-02059,84-70070,89-50070,89-50072,89-50074,CS 9,CS 8,89-50076,89-50078,CS 3,CS 2,CS 1,43-00030,88-12372,600,601,602,603,604,605,606,607,43-00021,608,43-00020,609,43-00041,43-00040,60-02070,73-00008,60-02071,60-02072,60-02073,60-02074,60-02075,60-02076,XX-X1511,60-02077,XX-X1510,60-02078,60-02079,83-30184,XX-X1517,XX-X1516,83-30182,XX-X1519,83-30183,XX-X1518,83-30180,XX-X1513,83-30181,XX-X1512,610,XX-X1515,611,XX-X1514,612,613,614,615,616,617,618,619,60-02060,60-02061,60-02062,60-02063,XX-X1520,60-02064,60-02065,XX-X1522,60-02066,XX-X1521,60-02067,60-02068,60-02069,88-12397,620,XX-X1523,621,622,83-30190,623,624,625,626,627,628,629,43-00042,62250,62252,84-70025,86-10021,FS2,84-70024,FS1,84-70027,84-70026,86-10022,5X-72100,84-70021,FS6,84-70020,FS5,84-70023,84-70022,20-X0107,20-X0104,20-X0105,20-X0102,630,631,20-X0101,632,633,82-12086,634,635,636,79-10138,637,79-10139,638,79-10136,639,79-10137,43-46610,79-10135,84-70017,86-10016,86-10015,60-02080,84-70014,60-02081,84-70013,60-02082,84-70016,86-10012,60-02083,84-70015,86-10011,84-70010,84-70012,84-70011,20-X0119,20-X0117,20-X0118,20-X0116,20-X0113,640,20-X0114,641,20-X0111,82-12096,642,20-X0112,643,644,20-X0110,645,646,82-12091,647,648,649,84-70007,86-10003,84-70006,86-10002,86-10005,86-10004,84-70003,84-70002,84-70005,86-10001,84-70004,86-10000,5X52000,84-70001,84-70000,86-10007,86-10006,86-10008,650,651,652,653,654,655,656,657,82-12061,43-13707,79-10143,79-10144,661,662,79-10142,5X-64500,663,664,43-46608,79-10140,43-46606,79-10147,79-10148,79-10146,86-10069,86-10068,XX-X1136,82-12046,82-12041,88-12302,43-43142,89-5XXXX,88-12307,XX-X1140,5X-71200,43-43161,XX-X1148,XX-X1144,82-12056,201,202,82-12051,203,204,205,86-10061,206,207,208,86-10062,209,86-10042,XX-X1114,XX-X1110,210,211,212,79-10194,XX-X1116,213,214,82-12021,79-10192,XX-X1118,215,88-12322,79-10193,216,217,218,219,43-43123,5X-53800,86-10032,42252,86-10031,43-13746,XX-X1124,82-12026,XX-X1120,220,221,222,223,224,XX-X1128,225,226,227,228,88-12317,229,86-10041,42250,230,231,43-43984,232,43-43987,233,43-43986,234,235,236,237,238,239,43-43981,5X-55600,43-43980,43-43983,56-74000,5X-52100,82-12126,240,69-10001CSP,56-74016,82-12131,69-10031A,82-12101,69-10030A,5052,82-12106,43-43974,43-43975,43-43978,43-43977,43-43972,43-43971,89-70122,89-70123,42-X1700,89-70124,89-70120,89-70121,42-X1709,5X-61000,42-X1706,42-X1705,42-X1708,42-X1707,42-X1702,42-X1701,42-X1704,42-X1703,89-70111,89-70112,89-70113,89-70114,89-70110,5X-66700,89-0111B,89-70100,89-70101,89-70102,89-70103,5X-53400,89-70104,83-30153,83-30154,43-13262,43-13261,43-16764,60-70211,60-70212,60-70210,60-70215,5X-55200,60-70216,5X-65000,60-70213,60-70214,60-70219,60-70217,60-70218,89-70152,89-70153,89-70154,43-13245,88-12297,83-30173,83-30174,83-30171,83-30172,60-70222,83-30170,60-70223,60-70220,60-70221,89-70144,89-70141,89-70142,89-70143,5X-61900,82-12973,83-30133,43-16792,82-12972,83-30134,83-30131,43-16310,82-12974,83-30132,83-30141,43-16304,43-16306,43-16308,89-70133,89-70134,89-70130,89-70131,43-13268,83-30144,83-30142,83-30143,83-30152,72-00236,82-55604,82-55603,21-13950,21-13951,21-13953,83-30113,82-55609,82-12956,83-30114,83-30111,83-30112,82-55606,83-30110,45-09810,45-09811,45-09812,45-09813,89-50110,89-50111,89-50112,89-50113,89-50114,82-55615,82-55612,21-13940,21-13941,21-13942,21-13943,82-12966,21-13944,21-13945,83-30124,21-13946,21-13947,83-30122,21-13948,82-55618,82-12961,83-30123,21-13949,83-30120,83-30121,43-16795,43-16796,83-30130,43-16797,43-16799,89-50120,89-50121,89-50122,89-50123,89-50124,82-55625,89-70184,82-12936,89-70181,89-70182,89-70183,89-70173,89-70174,83-30104,82-12946,83-30102,89-70171,83-30103,89-70172,83-30100,83-30101,82-12941,60-70200,60-70201,60-70204,60-70205,89-50100,60-70202,89-50101,60-70203,89-50102,60-70208,89-50103,60-70209,89-50104,60-70206,

Parker Chomerics(派克固美丽)热界面材料(用于电子产品散热)选型指南

目录- Company Profile Heat Transfer Fundamentals Thermal Gels Gap Filler Pads Phase Change Materials Thermal Tapes Potting and Underfill Materials Dielectric Pads Heat Spreaders Thermal Greases Glossary

型号- PAD30G,60-XX-D065-ZZZZ,60-XX-4353-ZZZZ,60-XX-D379-ZZZZ,60-XX-D417-ZZZZ,G570,PAD30A,GEL 75,T500,60-XX-6875-ZZZZ,60-XX-D420-ZZZZ,G974,60-XX-D381-ZZZZ,60-XX-4305-ZZZZ,60-XX-D382-ZZZZ,G579,579PN,A580,60-XX-D396-ZZZZ,T630,60-XX-4997-ZZZZ,60-XX-4306-ZZZZ,PAD 30,60-XX-D416-ZZZZ,6W-XX-YYYY-ZZZZ,60-XX-4996-ZZZZ,60-XX-D421-ZZZZ,60-XX-D402-ZZZZ,60-XX-6956-ZZZZ,60-XX-D404-ZZZZ,G569,60-XX-D415-ZZZZ,60-XX-D418-ZZZZ,60-XX-D429-ZZZZ,65-00-T670-3790,65-1P-CIP35-5600,60-XX-D395-ZZZZ,60-XX-D398-ZZZZ,60-XX-5792-ZZZZ,69-1X-YYYYY-ZZZZZZ,65-00-CIP35-0400,60-XX-D406-ZZZZ,T404,T647,60-12-20264-TW10,PAD60A,T405,T646,60-XX-D400-ZZZZ,T766,T644,T642,60-XX-4511-ZZZZ,60-XX-D384-ZZZZ,60-XX-D428-ZZZZ,60-XX-5791-ZZZZ,65-00-YYYY-ZZZZ,60-XX-D419-ZZZZ,T650,60-XX-D385-ZZZZ,60-XX-D391-ZZZZ,T636,T635,60-XX-D394-ZZZZ,G580,TC50,60-XX-D397-ZZZZ,60-XX-D378-ZZZZ,60-XX-D375-ZZZZ,60-XX-D425-ZZZZ,1641,65-5P-CIP35-10452,60-XX-D422-ZZZZ,60-XX-D372-ZZZZ,60-XX-D403-ZZZZ,60-12-20267-TW10,GEL 37,6W-XX-1015-ZZZZZZ,60-XX-D373-ZZZZ,60-XX-D409-ZZZZ,PC07DM-7,60-XX-4661-ZZZZ,579KT,60-XX-D387-ZZZZ,60-XX-YYYY-ZZZZ,60-XX-D412-ZZZZ,65-00-1641-0000,60-XX-D388-ZZZZ,65-00-T644-0045,65-00-T644-0200,GEL 30,64-XX-YYYY-ZZZZ,60-XX-D374-ZZZZ,60-XX-D390-ZZZZ,60-XX-4659-ZZZZ,60-XX-D408-ZZZZ,T670,65-00-T642-0035,T405-R,60-XX-4374-ZZZZ,T418,60-XX-D424-ZZZZ,60-XX-D410-ZZZZ,GEL 45,T777,1642 65-00-1642-0000,60-XX-D413-ZZZZ,T414,T411,T412,1671,60-12-20266-TW10,60-XX-8531-ZZZZ,60-12-20269-TW10,60-XX-D407-ZZZZ,PAD 60,569PN,60-XX-5527-ZZZZ,65-XX-YYYYY-ZZZZ,60-XX-5442-ZZZZ,60-XX-D426-ZZZZ,569,65-00-CIP35-0200,65-00-CIP35-0045,T660,PAD30PN,HCS10,T725,60-XX-D370-ZZZZ,60-XX-D376-ZZZZ,67-XX-YYYY-ZZZZ,65-00-T642-0250,60-XX-8302-ZZZZ,T444,GEL 8010,T766-06,65-00-T646-0045,A569,65-01-1641-0000,60-XX-D423-ZZZZ,PAD30KT,60-XX-D392-ZZZZ,60-XX-4969-ZZZZ,T609,570,65-00-T646-0200,1678,1674,60-XX-D371-ZZZZ,974,60-XX-D399-ZZZZ,60-XX-D405-ZZZZ,579,60-XX-D401-ZZZZ,976,60-XX-D377-ZZZZ,65-00-CIP35-1200,65-00-T647-0200,65-00-T647-0045,60-XX-D393-ZZZZ,60-XX-D427-ZZZZ,65-00-T650-0160,T558,HCS10G,6W-XX-0909-ZZZZZZ,T710,T557,CIP 35,60-XX-D383-ZZZZ,A579,PAD60,60-XX-D386-ZZZZ,580,60-XX-D389-ZZZZ,A570,60-XX-D430-ZZZZ,GEL 25NS,60-XX-D411-ZZZZ,HCS10A,60-XX-D414-ZZZZ,60-12-20268-TW10,T441,60-XX-D380-ZZZZ,60-12-20265-TW10

Form Has No Limits-ELASTOSIL®FX硅橡胶,用于特殊效果成型

描述- Elastosil® FX铂金固化硅橡胶用于电影、电视和剧院中的逼真皮肤效果制作。产品包括多种基础橡胶、凝胶和添加剂,适用于FX化妆/生命铸造、面具、身体部位/假体效果、伤口和疤痕等。产品特点包括:安全用于皮肤、非常柔软、优异的延伸性、出色的再现细节。产品系列包括ELASTOSIL® FX 30凝胶、FX 10、FX 20和FX 28,可根据需求调整硬度。此外,还提供Elastosil® FX软化和添加剂,以适应不同的加工需求。

型号- ELASTOSIL ® FX 10,ELASTOSIL ® FX 20,ELASTOSIL ® FX,ELASTOSIL ® FX 30 GEL,ELASTOSIL ® FX 28

瓦克SILPURAN®系列有机硅凝胶满足从医用到家用的需求,具有易储存,安全性高等特点

瓦克SILPURAN®系列硅凝胶不仅可以同时满足皮肤、患者和医护人员的需求,还能在生产方面降低成本,提高效能。

WACKER Presents Silicone Resins SILRES® H60 A/B and SILRES® H62 C for the Impregnation of Electric Motors

At CWIEME, the international trade fair for coil winding, insulation and electrical manufacturing, WACKER is presenting silicone-based specialty resins for impregnating electric motors. Highlights at CWIEME also include the room-temperaturecuring silicone rubber ELASTOSIL® N 2076.

为您的硅树脂增添一抹色彩

描述- 本资料介绍了WACKER公司生产的ELASTOSIL®彩色硅橡胶浆料,包括FL和PT两种类型。这些浆料适用于多种硅橡胶产品,提供丰富的颜色选择。资料详细列出了各种颜色的RAL编号、适用标准和认证信息,并强调了产品在食品接触和生物相容性方面的合规性。此外,资料还提到了特殊颜色浆料和透明浆料的可用性,以及如何定制特殊颜色配方。

型号- ELASTOSIL® COLOR PASTE FL OCHRE BROWN,ELASTOSIL ® COLOR PASTE FL LIGHT GREEN,ELASTOSIL® COLOR PASTE FL ZINC YELLOW,ELASTOSIL ®,ELASTOSIL® COLOR PASTE PT DARK BROWN,ELASTOSIL® COLOR PASTE FL RED BROWN,ELASTOSIL® COLOR PASTE FL UV FLUORESCENT,ELASTOSIL® COLOR PASTE FL BLACK,ELASTOSIL® COLOR PASTE FL TRAFFIC GREEN,ELASTOSIL® COLOR PASTE PT TRAFFIC RED,ELASTOSIL® COLOR PASTE FL SILVER,ELASTOSIL® COLOR PASTE PT BASIC BLACK,ELASTOSIL® COLOR PASTE PT DARK BLUE,ELASTOSIL ® COLOR PASTE FL YELLOW GREEN,ELASTOSIL® COLOR PASTE PT LASER MARKING BLACK,ELASTOSIL® COLOR PASTE FL WHITE,ELASTOSIL® COLOR PASTE FL PAPYRUS WHITE,ELASTOSIL ® COLOR PASTE FL SIGNAL VIOLET,ELASTOSIL® COLOR PASTE FL GERBERA RED,ELASTOSIL® COLOR PASTE PT PURE ORANGE,ELASTOSIL® COLOR PASTE PT RASPBERRY RED,ELASTOSIL® COLOR PASTE PT HELIOGREEN,ELASTOSIL® COLOR PASTE FL RED IRON OXIDE,ELASTOSIL® COLOR PASTE PT ULTRAMARINE BLUE,ELASTOSIL® COLOR PASTE FL L7\SER MARKING WHITE,ELASTOSIL ® COLOR PASTE FL BLOOD ORANGE,ELASTOSIL ® COLOR PASTE FL LIGHT BLUE,ELASTOSIL® COLOR PASTE FL GRAY,ELASTOSIL® COLOR PASTE PT ULTRAMARINE BLUE ELASTOSIL® COLOR,ELASTOSIL® COLOR PASTE FL BEIGE RED PANTONE 7514 C,ELASTOSIL® COLOR PASTE FL AZORES BLUE,ELASTOSIL® COLOR PASTE FL ULTRAMARINE BLUE,ELASTOSIL® COLOR PASTE FL PURPLE VIOLET,ELASTOSIL® COLOR PASTE FL BLUE 5002 TRANSLUCENT,ELASTOSIL® COLOR PASTE FL DEEP BLACK,ELASTOSIL® COLOR PASTE PT SILVER,ELASTOSIL® COLOR PASTE FL RED,ELASTOSIL® COLOR PASTE PT GREEN,ELASTOSIL® COLOR PASTE FL PARLOUR RED,ELASTOSIL® COLOR PASTE PT LASER MARKING WHITE,ELASTOSIL® COLOR PASTE FL ORANGE,ELASTOSIL® COLOR PASTE PT BLUE,ELASTOSIL® COLOR PASTE PT TRAFFIC WHITE,ELASTOSIL® COLOR PASTE FL IVORY,ELASTOSIL® COLOR PASTE FL MAIZE YELLOW,ELASTOSIL® COLOR PASTE PT WHITE,ELASTOSIL® COLOR PASTE FL SQUIRREL GRAY,ELASTOSIL® COLOR PASTE PT TRAFFIC GREEN,ELASTOSIL® COLOR PASTE FL GFW,ELASTOSIL® COLOR PASTE FL PEARL ORANGE,ELASTOSIL® COLOR PASTE FL RED VIOLET,ELASTOSIL® COLOR PASTE FL RASPBERRY RED,ELASTOSIL® COLOR PASTE FL IRON GRAY,ELASTOSIL® COLOR PASTE FL BLUE LILAC,ELASTOSIL® COLOR PASTE PT VIOLET,ELASTOSIL® COLOR PASTE FL ICEBLUE 34070,ELASTOSIL® COLOR PASTE FL YELLOW GREEN,ELASTOSIL® COLOR PASTE FL LIGHT BUJE,ELASTOSIL® COLOR PASTE FL HYGIENE GREEN,ELASTOSIL® COLOR PASTE PT YELLOW,ELASTOSIL® COLOR PASTE PT RED VIOLET,ELASTOSIL® COLOR PASTE PT RED,ELASTOSIL® COLOR PASTE FL GREEN,ELASTOSIL® COLOR PASTE PT LIGHT BLUE,ELASTOSIL® COLOR PASTE PT GRAY,ELASTOSIL® COLOR PASTE FL LIGHT GREEN,ELASTOSIL® COLOR PASTE PT ORANGE,ELASTOSIL ® COLOR PASTE FL ZINC YELLOW,ELASTOSIL® COLOR PASTE FL TRAFFIC WHITE,ELASTOSIL® COLOR PASTE FL PURE ORANGE,ELASTOSIL® COLOR PASTE PT DEEP BLACK,ELASTOSIL® COLOR PASTE PT LIGHT BROWN,ELASTOSIL ® COLOR PASTE FL PURPLE VIOLET,ELASTOSIL® COLOR PASTE PT RED BROWN,ELASTOSIL® COLOR PASTE FL L7\SER MARKING BLACK,ELASTOSIL® COLOR PASTE FL MOUNTAIN BLUE,ELASTOSIL ® COLOR PASTE FL TRAFFIC GREEN,ELASTOSIL® COLOR PASTE FL SIGNAL VIOLET,ELASTOSIL® COLOR PASTE FL MAY GREEN,ELASTOSIL® COLOR PASTE FL DARK BLUE -,ELASTOSIL® COLOR PASTE FL PASTEL ORANGE,ELASTOSIL ® COLOR PASTE FL MAIZE YELLOW,ELASTOSIL ® COLOR PASTE FL BLUE LILAC,ELASTOSIL® COLOR PASTE FL BUJE,ELASTOSIL® COLOR PASTE FL L7\SER MARKING BLACK TRL,ELASTOSIL® COLOR PASTE PT BLACK,ELASTOSIL® COLOR PASTE FL HELIOGREEN,ELASTOSIL® COLOR PASTE FL YELLOW,ELASTOSIL® COLOR PASTE FL BLOOD ORANGE,ELASTOSIL ® COLOR PASTE FL MAY GREEN,ELASTOSIL ® COLOR PASTE FL PEARL ORANGE,ELASTOSIL® COLOR PASTE FL WINDOW GRAY,ELASTOSIL® COLOR PASTE FL PINE GREEN,ELASTOSIL® COLOR PASTE FL BLUE 5026 D,ELASTOSIL® COLOR PASTE FL SIGNAL GREEN,ELASTOSIL® COLOR PASTE PT LASER MARKING BLACK TRL,ELASTOSIL® COLOR PASTE FL LIGHT GRAY,ELASTOSIL® COLOR PASTE FL DUST GRAY,ELASTOSIL ® COLOR PASTES,ELASTOSIL® COLOR PASTE FL LIGHT BLUE,ELASTOSIL ® COLOR PASTE FL RED BROWN

瓦克的有机硅凝胶SILPURAN® 2114和SILPURAN® 2124能够保证可穿戴设备牢固附着,并且对皮肤温和

为不断提高产品的附着性能和佩戴舒适度,瓦克坚持拓展高性能硅凝胶产品系列,SILPURAN® 2114和SILPURAN® 2124便是相应成果。这两种有机硅胶粘剂新产品能够满足皮肤佩戴中短时长的严苛要求,并具备极佳的整体性能.

Semcosil®9711 TC CN

描述- SEMCOSIL® 9711 TC CN是一种预固化、剪切稀化、易于施用的单组分硅橡胶,具有优异的热导率。该产品在应用中不会进一步固化,对接口具有良好的粘附性,无需额外的粘合促进剂。所有表面必须仔细清洁,无任何会分解SEMCOSIL® 9711 TC CN的污染物。产品适用于电子行业和ICT行业的散热器接口应用。

型号- SEMCOSIL® 9711 TC CN

瓦克ELASTOSIL® LR 3078液体硅橡胶牢固粘合——不预处理亦无妨

在需要使用有机硅软硬复合材料时,聚碳酸酯至今是一个尤其令人发愁的问题——直到瓦克推出ELASTOSIL® LR 3078,界面剂和等离子预处理等从此变得多余:这种液体硅橡胶能够出色地附着于聚碳酸酯,亦可毫无困难地用双组分注射成型工艺进行加工。由硬质材料和弹性软质材料组合而成的塑料部件应用广泛。

电子商城

登录 | 立即注册

提交评论