3D Vapor Chambers: Revolutionary Heat Dissipation

As the field of AI continues to evolve, there is a growing need for more minor and more powerful semiconductor chips. However, upgrading semiconductor technology while keeping costs low has increased power consumption and heat generation in these chips. This has caused TDP rates to accelerate, making it increasingly challenging to manage heat in high-performance, compact electronics.

To address this issue, a 3D Vapor Chamber has been developed, which can handle over 500 watts of power. This technology is ideal for servers, base stations, repeater stations, and data centers. As a result, the global data center liquid cooling market is expected to grow from $1.82 billion in 2021 to $7.12 billion by 2028 at a compound annual rate of 21.5%.

Optimal Cooling Strategies and Cost Efficiency

Air cooling is typically enough for devices with a Thermal Design Power (TDP) of up to 350 watts, while liquid cooling is recommended for TDPs ranging from 350W to 1000W. For TDPs beyond 1000W, immersion liquid cooling is necessary.

However, recent corporate reports suggest that air cooling can effectively handle up to 1000W of heat energy. The optimal threshold for air cooling efficiency, though, lies around 500W. These evolving data on the scope of air cooling indicate ongoing technological advancements that meet customer demands.

The cost of 3D vapor chambers is approximately twice as high compared to traditional heat pipes or plates. This presents a favorable cost advantage over liquid cooling solutions, which can cost several times more than 3D VC. Therefore, 3D Vapor Chambers are an attractive choice in thermal management solutions.

3D Vapor Chambers: Efficient Thermal Management

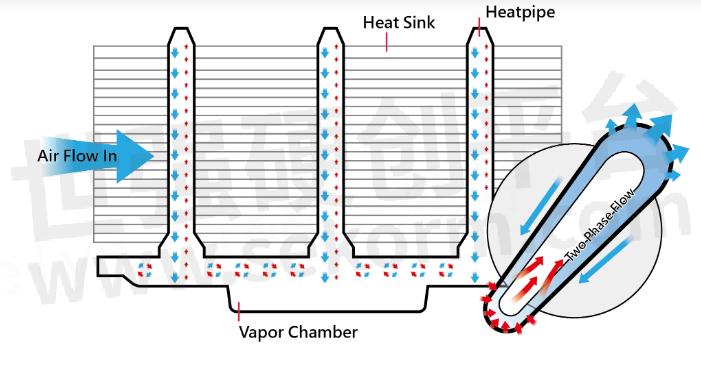

The 3D Vapor Chamber is a highly efficient thermal management solution for electronic devices. Unlike traditional heat plates that rely on heat pipes or plates, this chamber leverages the phase change properties of fluids to dissipate heat through a sealed chamber, surpassing the efficacy of conventional methods. The chamber's flexibility enables customization to cater to diverse client requirements. It offers a cleaner and more space-efficient solution, ensuring optimal thermal management.

Although the initial investment in a 3D Vapor Chamber may be higher than traditional heat dissipation methods, its superior thermal performance justifies the cost. This chamber outperforms conventional solutions, particularly in the medium to high power range, providing a cost-effective alternative to liquid cooling systems. Its adept heat dissipation capabilities ensure prolonged device functionality, making it a cost-efficient choice in the long run.

Enhancing Performance with Versatile Applications

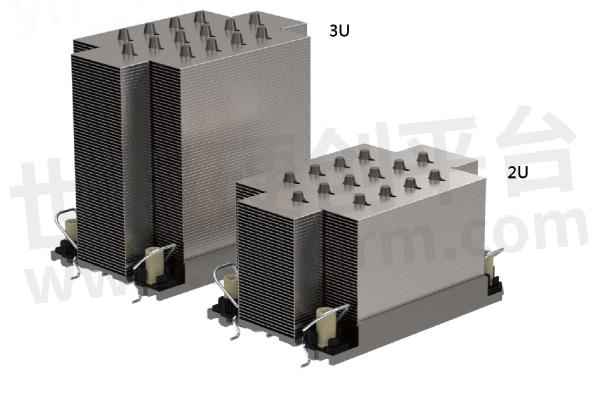

The 3D Vapor Chamber technology is helpful in high-end server networks such as base stations, repeater stations, and data centers. This technology disperses heat efficiently in compact and slim device designs, improving reliability and minimizing maintenance. This technology is versatile and can integrate into various electronic systems, enhancing their performance and longevity.

The 3D Vapor Chamber technology is a suitable solution for the cooling challenges that modern electronic systems face, especially those with high-performance standards and compact designs. Integrating this technology into network infrastructures like base stations and repeater stations can improve their performance and longevity. Similarly, incorporating this technology into high-end servers and data centers can increase cooling efficiency, reduce maintenance costs, and enhance reliability.

Nextron's Role in Advancing 3DVC Technology

Nextron stands at the forefront of innovation, seamlessly integrating 3DVC technology into high-speed transmission systems. Nextron's expertise lies in crafting tailored solutions that meet specific application demands, ensuring optimal thermal management and performance. With advanced manufacturing techniques and a commitment to excellence, Nextron is poised to drive the future of thermal management solutions, unlocking limitless possibilities in the realm of electronics.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由walkonair转载自Nextron News,原文标题为:3D Vapor Chambers: Revolutionary Heat Dissipation,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Why is ACDC Module Power Supply the Preferred Choice for Electronic Devices?

The ACDC module power supply has become the preferred choice for electronic equipment mainly due to its efficient and stable DC output, integrated design and reliability, wide input voltage range, multiple protection functions, and easy maintenance and upgrade. These features make the ACDC power supply module have a wide range of application prospects and important value in electronic equipment.

Power Module: The Heart of Electronic Devices

As an indispensable key component in modern electronic devices, the power module plays an important role in converting electrical energy into the specific voltage and current required by the device. It is not only the basis for the stable operation of electronic equipment, but also a key factor in ensuring the performance of the equipment to the extreme. This article will take a closer look at the working principle, classification, and importance of power modules, and show how this technology plays an important role in various electronic devices.

AC-DC Power Supply: Efficient and Reliable Solution for Your Electronic Devices

In today’s world of modern technology, electronic devices have become an integral part of our daily lives. From smartphones to computers, from home appliances to automobiles, all of these devices require a constant and reliable source of power to operate. This is where an AC-DC power supply comes in handy. In this article, we will discuss what an AC-DC power supply is, how it works, and why it is an efficient and reliable solution for your electronic devices.

认识AI硬体的开放架构-OAI&OAM,正凌为为OAM设计者提供高速I/O与OAM相关产品,共同迎接AI发展新挑战

开放加速器模块(OAM)为AI服务器开发商提供了一种高效且可扩展的解决方案,使他们能够更容易地整合新的AI加速器。OAM具有高效能与效率、可扩展性和支持多样的应用场景等优点,但同时也面临着技术和设计复杂性、高功耗管理和标准化和兼容性等挑战。正凌作为一家拥有高速传输、机构设计与散热模组的方案商,为OAM设计者提供了配合散热的结构设计和加工工艺上的挑战解决方案。

UU9.8 Common Mode Inductor: Safeguarding Electronic Devices

In the world of electronic devices, the purity and stability of signals are as crucial as a lifeline. The UU9.8 common mode inductor stands as a loyal guardian of this lifeline.

【产品】正凌提供400G高速连接与散热解决方案QSFP112,每条通道皆可支援112Gb/s

大型数据中心对资料传输速度的要求不断提升,正凌推出QSFP模组QSFP112,每条通道皆可支援112Gb/s并可向后兼容QSFP56及QSFP28;在不重建网路结构的前提下,该产品是升级频宽最具成本效益的方式,也是迈向800G通讯的垫脚石。

正凌多种板对线、板对板连接器可用于汽车安全系统,最高工作温度达+125 ℃

汽车安全系统根据是否为预防性质,分为“主动安全“与“被动防护“两种。“被动防护“发展较早,主要在碰撞发生时,减缓驾驶人与乘客所受到的伤害,例如安全气囊,安全带,鞭打保护系统等是车辆中常用的被动安全系统。本文主要介绍正凌可用于汽车安全系统的板对线、板对板连接器。

正凌连接器选型表

正凌连接器以下参数选型,工作温度:-55℃~+125℃;湿气敏感性等级:2a;安规/环境规范(Certification/Environmental specifications):ROHS;应用等级(Application Level):E级

|

产品型号

|

品类

|

工作温度范围(°C)

|

湿气敏感性等级

|

安规/环境规范(Certification/Environmental specifications)

|

应用等级(Application Level)

|

|

NX5ABBB70X01AA

|

连接器

|

-55°C to 125°C

|

2a

|

ROHS

|

E级

|

选型表 - 正凌 立即选型

【选型】正凌(Nextron)应用于新能源汽车的连接器选型指南

目录- 核心技术/应用/案例 板对线系列 板对线&板对板系列&非防水系列 板对线防水系列 & Power Element系列

型号- Z-C02C018510020,Z-C02FH0010****,Z-C09B501110361,Z-C10BA01110061,C11系列,Z-C08B001110091,Z-C10BE01110101,Z-C08B401110251,Z-C08B001110041,SBC系列,C08系列,Z-C12BC01110161,Z-C12B001110091,Z-C11B201110081,Z-C10B401110101,Z-C08B201110161,Z-C09B001110091,Z-C10BB01110081,Z-C09B201110091,Z-C08B501110361,Z-C09B401110251,Z-C08B301110161,Z-C02FC0*0**001,Z-C03M****00***,SIC系列,C11 SERIES,Z-C10B201110081,C08 SERIES,Z-C11B401110101,Z-C12B101110161,STC系列,Z-C02M0***00***,Z-C09B101110161,Z-C10B*0**1***1,Z-C11BA01110061,Z-C12BA01110091,Z-C12B401110251,Z-C11B501110121,Z-C11BB01110081,807系列,2.2MM,Z-C09B201110161,Z-C04M0********,C10系列,Z-C06FH00*00***,Z-C10B301110101,Z-C10BD01110101,Z-C12B*0**1***1,Z-C07FT0*0**001,Z-C08B*0**1***1,Z-C12BD01110251,Z-C02C009030020,Z-C11BF01110121,Z-C11B101110081,Z-C11BE01110101,Z-C12BB01110161,Z-C07M0********,Z-C09B601110361,Z-C06M0***00***,Z-C03FC0*0**001,Z-C09B101110091,Z-C08B101110161,C09系列,Z-C10BC01110081,Z-C11B001110061,Z-C07FH00*00***,Z-C04F0********,Z-C12B501110361,C12 SERIES,Z-C11B*0**1***1,Z-C11BD01110101,807 SERIES,Z-C02C013520020,C10 SERIES,Z-C12B201110161,Z-C09B301110251,Z-807B*0**0****,Z-C03FH00*00***,Z-C11BC01110081,C09 SERIES,C12系列,Z-C11B301110101,Z-C12B301110251,Z-C09B*0**1***1,Z-C10B001110061,Z-C10B101110081

正凌SPE连接器更快的资料传输速度,更具效率,改善工业物联网效能

正凌完整的SPE连接器系列除了标准的2 way SPE产品,也提供模组化和客制SPE组合解决方案。若有超过1.36A(50V)的高功率传输需求,4 way SPE会是您的最佳选择。正凌所有SPE产品都依据IEEE802.3bp(1000BASE-T1)标准开发设计,互配后符合IP67防尘防水等级,并有多种锁固方式(卡扣式、推拉式和螺纹…等)。

正凌携高速连接器、液体冷却解决方案探索高效能运算的未来

作为高速运算技术的伙伴企业,正凌了解 I/O 和高速运算的要求,能够提供灵活的解决方案,以适应不同的机箱设计。 可以说,正凌正在引领这场革命,利用液体冷却和 3D Vapor Chamber(3D VC)等技术的进步,满足高效能运算应用不断发展的需求。

【产品】正凌QSFP56高速连接器可向下兼容QSFP28及QSFP+,提供200Gbps的聚合解决方案

为提供次世代5G传输更可靠的讯号链接,正凌拥有包含SFP、OSFP及QSFP等完整的高速连接器产品系列。QFSP56连接器可向下兼容QSFP28及QSFP+,4组速率达50Gbps PAM4之电气通道提供高达200Gbps的聚合解决方案。

电子商城

服务

可定制VC的常规厚度范围1.5mm至15mm,最薄可至0.2mm,最大可达400x400mm,功率范围3~2000w。3D VC较常规2D-VC功率提升30~40%。

最小起订量: 1000套 提交需求>

可定制变压器电压最高4.5KV,高频30MHz;支持平面变压器、平板变压器、OBC变压器、DCDC变压器、PLC信号变压器、3D电源、电流变压器、反激变压器、直流直流变压器、车载充电器变压器、门极驱动变压器等产品定制。

最小起订量: 100000 提交需求>

登录 | 立即注册

提交评论