LEAP Technology Has Developed A Kind of Sensor – Based on WACKER ELASTOSIL® Silicone Films

Smart Materials

Integrated sensors turn articles of clothing into truly high-tech garments that can monitor your breathing or map your movements on a computer screen. With support from WACKER, Danish start-up LEAP Technology has developed just this kind of sensor – based on ultrathin silicone films and conductive silicone elastomers.

The sports shirt hugs her torso like a second skin, registering the pilates student’s every movement without her noticing a thing. The highly accurate sensors constantly transmit data over a Bluetooth connection to a smartphone, whose software detects incorrect movements, protecting the athlete from muscle tears or inflammations – even when she is working out in her living room, where there is no instructor to monitor whether she is doing the exercises correctly.

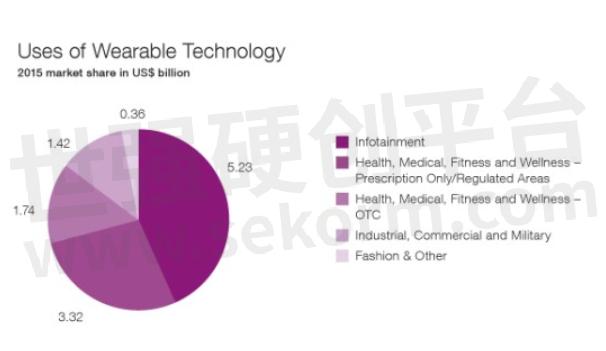

Smart textiles – textiles with integrated sensors intended to make the clothing of the future more intelligent – are opening up new growth opportunities in the athletic apparel, consumer electronics, and medical technology industries. Market researchers at IDTechEx estimate that total global sales of wearable technologies – of which smart textiles account for an ever-increasing share – will reach approximately €12 billion this year and roughly €70 billion by 2025.

Benefits for Rehab Patients

There is virtually no limit to the potential applications of this technology. For gamers, sensors on the body can transmit movements onto a screen, allowing players to compete in a sword fight with a virtual opponent. Like yoga or pilates instructors, physical therapists can also use integrated sensors, in this case, to determine whether rehab patients are performing their therapy exercises exactly as prescribed.

“This kind of wearable technology offers a number of advantages, especially in rehabilitation or for long-term patients,” says Renate Glowacki, an applications chemist for silicone films at WACKER. “The materials work around the clock, imperceptibly monitoring processes like swelling or respiratory movement, and warning the wearer or the treating physician if the patient’s health is threatened.”

Electroactive elastomers made by LEAP Technology undergo a test: a power source is attached to the coated silicone film.

Highly sensitive mini sensors are at the heart of smart clothing. “Textiles are the interface between the individual and their environment,” explains Dr. Rahimullah Sarban, founder of LEAP Technology, a Danish company currently producing sensor components and parts for manufacturers of smart textiles and for other industries. “That makes integrating sensor elements into clothing pretty much the perfect way of detecting the wearer’s movements and bodily functions – his biomechanics.”

Production of electroactive elastomers: the silicone film is coated with a layer containing a silicone filled with carbon black so that it is conductive and functions as an electrode.

Sandwiched Between Electrodes

These kinds of elastic sensors are made possible through the use of innovative materials such as electroactive polymers (EAPs), which are based on silicone rubber films. ELASTOSIL Film is the brand name under which WACKER markets these ultrathin films, which are only 20 to 200 microns thick (the diameter of a human hair, by comparison, is roughly 70 microns). The film is sandwiched between two electrodes – electrodes that can be made of WACKER silicone elastomers filled with carbon black to make them electrically conductive. In other words, all three layers are made of elastic materials. “If you press these elements together like a sandwich or if you stretch the material lengthwise, that movement will produce a detectable change in capacitance. The basic sensor unit is nothing other than an elastic capacitor,” Glowacki points out. ®

Geared for Marketability

The actual technology has been in existence since the 1990s, and WACKER is among those companies that have been working with EAPs for some time. “But now the leap to industrial production is becoming a reality,” emphasizes Susanne Neueder, Global Marketing Manager for silicone films. That leap requires a market, and innovative start-ups like LEAP Technology.

When WACKER representatives met the LEAP Technology team at the 2014 EuroEAP Conference in Linköping, Sweden, the WACKER project managers were impressed by the determination of the Danish start-up to forge ahead with creating EAP components and manufacturing them on an industrial scale. “And thanks to WACKER, we now have a valuable partner on board – our areas of expertise complement each other perfectly,” says LEAP Technology founder Dr. Sarban. “ELASTOSIL Film is an outstanding material that is perfectly suited to our needs” – and one that can be used for manufacturing highly accurate sensors. “At the same time, WACKER silicone elastomers are immune to power surges and to electrical or physical shocks,” Sarban observes. ®

In building their components, lab experts at LEAP Technology use both silicone films and a further WACKER silicone rubber that has been modified for conductivity. LEAP team members then hook up the unit to electrical wiring and a textile mechanical attachment. “The last step is to embed this entire unit within another WACKER silicone to protect it from electrical interference and to obtain the desired surface,” Sarban explains. Before the components are sent on to customers, they are tested and calibrated at the Leap Technology laboratories.

On account of their excellent dielectric properties, ELASTOSIL® silicone films are LEAP Technology’s product of choice for its sensors.

Numerous Other Applications

In early 2014, electroactive polymers were added to what WACKER calls its New Solutions projects, a cross-divisional, interdisciplinary category that the Group has created for grouping together promising products and technologies. The team has grown steadily and Dr. Andreas Köllnberger received the 2015 Alexander Wacker Innovation Award for developing the film production process. “Smart textiles aren’t the only interesting application for EAPs,” Köllnberger emphasizes. “Intelligent sensors allow production employees to reliably operate industrial manufacturing processes based on human-machine communication. Electroactive polymers are also suitable for use as actuators in electronic, automotive and automation technologies, or as electricity generators – in other words, for anything relating to energy harvesting.”

The key to their material characteristics lies in the chemical properties of the silicones. “Proper crosslinking plays a special role,” Glowacki notes. The molecular structure is what allows individual polymer chains to move as well as they do, yielding films that are extremely extensible, but that can resume their original shape – without wearing out. “In order to produce ultrathin silicone films at the level of quality we need, WACKER has developed a complex process and applied to have it patented,” Glowacki explains. “Plus, producing these films has been an important way for us to reach out to manufacturers of EAP components.”

Source: IDTechEx Research, 2015

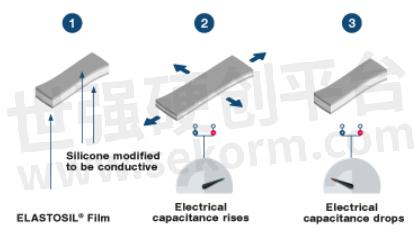

Sensor Design and Measurement Principle

In order to ensure that these precision silicone rubber films are pure and free of particle contamination, and that they can meet customers’ actuation and energy harvesting requirements, WACKER uses a continuous production process under cleanroom conditions. The process is already up and running in a small-scale plant, with full-scale production planned for the medium term. The first step involves applying the addition-curing silicone rubber compounds in a way that yields the desired ultrathin films at the highest possible level of purity. A major advantage here is that no solvents are required. The next step is to apply heat, which crosslinks the polymer chains and fixes the shape of the film. WACKER experts have also integrated a quality-control stage into the manufacturing process: “We take optical and ultrasound measurements to make sure that the layer thickness doesn’t vary by more than 5% across the entire surface,” Glowacki explains. ELASTOSIL Film is also available as a continuous roll, a format that rival production processes are unable to achieve. ®

A power source is attached to the conductively coated silicone film (1). If the film is deformed mechanically, the surface (2) changes or increases in size, resulting in altered capacitance. If the film relaxes again in that the pressure is relieved (3), the surface – and hence the capacitance – changes once more.

Maintenance-Free Components

Yet another advantage is that ELASTOSIL Film products have all of the essential properties that otherwise characterize silicones: heat resistance, low-temperature flexibility, excellent dielectric properties and outstanding resistance to a large number of physical and chemical forces. “Their outstanding elastic properties are part of the reason why silicone films don’t wear out – even after years of mechanical stress,” Glowacki adds. “And that makes EAP components maintenance free.” ®

LEAP Technology is still producing EAP components either by hand or using partially automated processes. “Processing these ultrathin, soft, highly flexible silicone films is a challenge for our machines, but we are making good progress toward fully automated component fabrication,” Sarban explains. “That’s the only way we can meet our goal of reliably producing thousands of units per month,” observes the LEAP director.

Examples of electroactive-polymer-based sensors manufactured by LEAP Technology.

This positions LEAP Technology in the gap that currently exists between the product manufacturers and companies like WACKER, who make the materials. “This is precisely where we need companies that offer EAP components,” says Marketing Manager Susanne Neueder. “Not only does this meet sensor users halfway – it also helps establish a supply chain.”

“Thanks to their outstanding elastic properties, silicone films don’t wear out – even after years of mechanical stress.”Renate Glowacki, Application Technology, WACKER SILICONES.

Inquiries on the Rise

The experts at LEAP Technology have already received some 120 requests for information from sources that include multinational corporations, small businesses, and universities. As Sarban notes, “Examples of our partners include Ohmatex, Electricfoxy, several other similar companies, and some Danish universities.”

Having a reliable supply chain for the materials and individual components is a focus of every customer meeting. “WACKER is an important partner – capable of producing large quantities of silicone films,” explains Sarban. This partnership generates trust, he added, ensuring reliability along the entire supply chain.

Collaboration between these companies has set the stage for a future in which high-tech fabrics hug our skin – and sharpen our awareness of our health.

Textile-based sensors convert mechanical energy into electricity, enabling them to capture body movements.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由sr转载自WACKER Official Website,原文标题为:Smart Materials,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

一种电动汽车的绝配材料:有机硅弹性体,能承受高温及充电电流,持久而可靠地密封组件

电动汽车对高性能材料的需求不断增长,带动了汽车行业对有机硅弹性体的需求。有机硅弹性体作为出色的热导体,能够承受高温及充电电流,持久而可靠地密封组件。

瓦克生物甲醇基有机硅密封胶赋能建筑绿色发展

作为欧洲市场有机硅密封胶主要的原材料和支装胶生产商之一,瓦克为满足市场和客户对无需石化原料生产的环保产品日益增长的需求,日前已在其欧洲市场推出基于生物甲醇的有机硅密封胶产品——ELASTOSIL®eco系列。

瓦克医用ELASTOSIL®为肢体修复提供高标准的有机硅产品

医用ELASTOSIL®有机硅是您的理想选择,亦是守护健康的有力支持。我们的专家团队期待着随时为您提供服务,通过拓展医用ELASTOSIL® 的应用范围并发掘创新潜力以满足各种具体的需求,从而开发出个性化的产品解决方案,为提高人们的生活品质添砖加瓦。

WACKER(瓦克)固体和液体硅橡胶产品选型指南

描述- 瓦克是一家全球运营的特种化学品公司,产品的技术含量高且发展成熟,被广泛应用于人类日常生活的各个领域,上至太阳能电池,下至瓷砖胶粘剂,一应俱全。瓦克为100 多个国家和地区供应3000多种产品。

型号- R 701/80,R PLUS 4370/50,ELASTOSIL® R PUS 4001/40,R PLUS 4001/90,LR 3023/60,R PLUS 4020/50,LR 3271/45,R PLUS 4305/70,LR 3071/30,LR 3070/60,R 780/80 OH,LR 3093/65,LR 5040/30,R PLUS 4020/60,R 701/70,R 861/60 S,R 402/75 S,R PLUS 4066/60,R PLUS 4370/40,R PLUS 4001/80,LR 3844/30,6700/60,ELASTOSIL® LR 6320 F,R 401/10 OH,LR 3005/70,R PLUS 4305/80,LR 3003/20 TR,R 401/55 S,ELASTOSIL® LR 3003/30,R 420/70 S,R 755/60 OH,LR 5040/20,LR 3071/40,R 401/70 S,ELASTOSIL® LR 6250 F,LR 3092/65,R PLUS 4020/70,R PLUS 4050/55 MH,R 701/60,R 861/70 S,R PLUS 4001/70,ELASTOSIL ® RD 6620 F,LR 3842/60,LR 3843/30,R 756/60 OH,LR 3005/60,R PLUS 4806/20,R PLUS 4305/90,R PLUS 4060/50,LR 3070/40,R 401/60 S,R 701/50,R 752/70 OH,LR 3065/30,LR 3016/65,R 700/80,R 401/60 KX S,R 760/70 MH,R 781/80,LR 3842/70,LR 3005/50,LR 3022/60,R PLUS 4001/60,LR 34004/50,R PLUS 4060/60,LR 3070/50,R 701/40,LR 3040/40,LR 3834/50 ULTRA,ELASTOSIL ® 47007,R PLUS 4305/30,LR 3025/40,LR 3074/60,ELASTOSIL ® E50 N,LR 5040/70,6610/60,6760/50,R 402/65 OH,ELASTOSIL ® RD 3151 F,R 401/20 OH,R 401/80 S,LR 3003/25,LR 3070/20,R 510/70 S,LR 3040/50,ELASTOSIL® LR 6360 F,R 401/30 S,R PLUS 4305/40,R PLUS 573/70,6610/50,R 752/50 OH,LR 5040/60,LR 3070/30,LR 3011/50 FR,ELASTOSIL® LR 6200 A/B,ELASTOSIL® LR 6260 A/B,R 510/60 S,LR 3844/40,LR 3040/60,6000/05,R 865/40 S,R PLUS 4846/30,6610/40,R 101/25 OH,R PLUS 4305/50,LR 3003/03,LR 3003/05,AUX 8251 RO,LR 3856/20,LR 5040/50,R PLUS 4070/60,WACKER ® FINISH CT 51 L,R 570/70 OH,LR 3844/50,R PLUS 573/50,6400/40,LR 3040/70,R PLUS 4020/40,R 756/70 OH,LR 5040/45,LR 3856/30,LR 5040/40,R PLUS 4070/30,LR 3066/70,6000/20,LR 3043/70,6400/50,R 401/30 OH,R PLUS 4000/40,ELASTOSIL ® RD 6600 F,LR 3003/60,LR 3004/30,R 750/50 0H,LR 3675/30,LR 3078/60,R 101/65 OH,6600/60,R PLUS 4361/60,R PLUS 4070/20,R 401/40 S,LR 3852/50,6000/10,R PLUS 4366/60,R PLUS 4350/55,R 512/70 OH,LR 3066/60,LR 3020/60,6400/60,LR 3003/50,R 865/50 S,R PLUS 4303/60,LR 3078/70,6600/50,ELASTOSIL® R 401/40,R 750/40 OH,LR 3851/50,6000/40,LR 3170/40,LR 3675/50,LR 3846/20,LR 3003/40,R PLUS 4303/70,LR 3078/40,LR 7601/60,R 420/40 S,6600/40,R 101/35 OH,LR 3040/30,LR 7601/50,6000/30,ELASTOSIL ® E91,LR 3066/80,LR 3846/30,R 770/75 OH,R 770/50 OH,LR 3003/30,LR 3078/50,R PLUS 4360/60,R PLUS 4303/80,R 570/60 OH,AUX 8250 RO,LR 3066/30,ELASTOSIL® LR 3003/20 TR,LR 3004/70,LR 3005/40,ELASTOSIL ® E43 N,ELASTOSIL ® E92 N,LR 3842/40,R PLUS 4001/50,6740/40,LR 3078/20,R 865/60 S,LR 3671/30,R 420/60 S,LR 3072/40,LR 7601/80,6000/60,R 756/40 OH,LR 3065/50,R 501/75 OH,6000/50,R 420/30 OH,LR 3003/10 TR,ELASTOSIL® LR 3001/55 FR A/B,LR 3043/40,LR 3003/90,LR 3842/50,R PLUS 4001/40,R PLUS 4000/70,LR 3004/60,LR 3001/55 FR,LR 3841/50,LR 3005/30,LR 3078/30,LR 3671/40,R 401/90 OH,LR 3094/60,ELASTOSIL® NT 76,LR 7601/70,ELASTOSIL® LR 6240 A/B,LR 3072/50,LR 3015/70,LR 3066/50,R 502/75 OH,LR 3003/80,R PLUS 4001/30,6700/50,LR 3043/50,LR 3004/50,R 416/70 MH,R PLUS 4000/60,LR 3003/85,LR 3671/50,R 570/50 OH,LR 3162,R PLUS 4061/60,LR 3071/50,R 756/50 OH,R 700/40,R 770/60 OH,R PLUS 4050/55,LR 3066/40,R PLUS 4001/20,LR 3043/60,R PLUS 4000/50,LR 3003/70,6700/40,LR 3004/40,R 865/70 S,R 101/45 OH,LR 3076/70,LR 3153,R 420/50 S,LR 3072/30,6000/70,LR 3071/60,R 490/55 OH,R 401/50 S,R PLUS 4305/60 S,LR 3015/50

WACKER Presents Silicone-Based Solutions for Electromobility and Medical Applications

At Silicone Expo Europe, the WACKER Group is showcasing silicone-based product solutions for specific industrial sectors. The focus is on silicone gels for wound care, non-postcuring liquid silicone rubber for the food industry and medical technology, and self-adhesive liquid silicone rubber grades that adhere to polycarbonate and other high-performance plastics.

硅胶模具真空铸造

描述- 真空铸造技术,特别是使用硅橡胶模具,是快速原型制作的关键技术。它具有低成本、快速生产、高功能性、多种表面处理选项等特点,适用于生产原型和小批量产品。与3D打印相比,真空铸造在几何自由度、功能性和外观质量方面具有显著优势。ELASTOSIL® M硅橡胶因其优异的流动性和耐久性,成为真空铸造的理想材料。

型号- ELASTOSIL® M 4644 A/B,ELASTOSIL® M 4645 A/B,ELASTOSIL® M 4670 A/B,M 4645,ELASTOSIL® M 4641 A/B,ELASTOSIL®,ELASTOSIL® M,M 4670

WACKER Presents Silicone Resins SILRES® H60 A/B and SILRES® H62 C for the Impregnation of Electric Motors

At CWIEME, the international trade fair for coil winding, insulation and electrical manufacturing, WACKER is presenting silicone-based specialty resins for impregnating electric motors. Highlights at CWIEME also include the room-temperaturecuring silicone rubber ELASTOSIL® N 2076.

Form Has No Limits-ELASTOSIL®FX硅橡胶,用于特殊效果成型

描述- Elastosil® FX铂金固化硅橡胶用于电影、电视和剧院中的逼真皮肤效果制作。产品包括多种基础橡胶、凝胶和添加剂,适用于FX化妆/生命铸造、面具、身体部位/假体效果、伤口和疤痕等。产品特点包括:安全用于皮肤、非常柔软、优异的延伸性、出色的再现细节。产品系列包括ELASTOSIL® FX 30凝胶、FX 10、FX 20和FX 28,可根据需求调整硬度。此外,还提供Elastosil® FX软化和添加剂,以适应不同的加工需求。

型号- ELASTOSIL ® FX 10,ELASTOSIL ® FX 20,ELASTOSIL ® FX,ELASTOSIL ® FX 30 GEL,ELASTOSIL ® FX 28

为您的硅树脂增添一抹色彩

描述- 本资料介绍了WACKER公司生产的ELASTOSIL®彩色硅橡胶浆料,包括FL和PT两种类型。这些浆料适用于多种硅橡胶产品,提供丰富的颜色选择。资料详细列出了各种颜色的RAL编号、适用标准和认证信息,并强调了产品在食品接触和生物相容性方面的合规性。此外,资料还提到了特殊颜色浆料和透明浆料的可用性,以及如何定制特殊颜色配方。

型号- ELASTOSIL® COLOR PASTE FL OCHRE BROWN,ELASTOSIL ® COLOR PASTE FL LIGHT GREEN,ELASTOSIL® COLOR PASTE FL ZINC YELLOW,ELASTOSIL ®,ELASTOSIL® COLOR PASTE PT DARK BROWN,ELASTOSIL® COLOR PASTE FL RED BROWN,ELASTOSIL® COLOR PASTE FL UV FLUORESCENT,ELASTOSIL® COLOR PASTE FL BLACK,ELASTOSIL® COLOR PASTE FL TRAFFIC GREEN,ELASTOSIL® COLOR PASTE PT TRAFFIC RED,ELASTOSIL® COLOR PASTE FL SILVER,ELASTOSIL® COLOR PASTE PT BASIC BLACK,ELASTOSIL® COLOR PASTE PT DARK BLUE,ELASTOSIL ® COLOR PASTE FL YELLOW GREEN,ELASTOSIL® COLOR PASTE PT LASER MARKING BLACK,ELASTOSIL® COLOR PASTE FL WHITE,ELASTOSIL® COLOR PASTE FL PAPYRUS WHITE,ELASTOSIL ® COLOR PASTE FL SIGNAL VIOLET,ELASTOSIL® COLOR PASTE FL GERBERA RED,ELASTOSIL® COLOR PASTE PT PURE ORANGE,ELASTOSIL® COLOR PASTE PT RASPBERRY RED,ELASTOSIL® COLOR PASTE PT HELIOGREEN,ELASTOSIL® COLOR PASTE FL RED IRON OXIDE,ELASTOSIL® COLOR PASTE PT ULTRAMARINE BLUE,ELASTOSIL® COLOR PASTE FL L7\SER MARKING WHITE,ELASTOSIL ® COLOR PASTE FL BLOOD ORANGE,ELASTOSIL ® COLOR PASTE FL LIGHT BLUE,ELASTOSIL® COLOR PASTE FL GRAY,ELASTOSIL® COLOR PASTE PT ULTRAMARINE BLUE ELASTOSIL® COLOR,ELASTOSIL® COLOR PASTE FL BEIGE RED PANTONE 7514 C,ELASTOSIL® COLOR PASTE FL AZORES BLUE,ELASTOSIL® COLOR PASTE FL ULTRAMARINE BLUE,ELASTOSIL® COLOR PASTE FL PURPLE VIOLET,ELASTOSIL® COLOR PASTE FL BLUE 5002 TRANSLUCENT,ELASTOSIL® COLOR PASTE FL DEEP BLACK,ELASTOSIL® COLOR PASTE PT SILVER,ELASTOSIL® COLOR PASTE FL RED,ELASTOSIL® COLOR PASTE PT GREEN,ELASTOSIL® COLOR PASTE FL PARLOUR RED,ELASTOSIL® COLOR PASTE PT LASER MARKING WHITE,ELASTOSIL® COLOR PASTE FL ORANGE,ELASTOSIL® COLOR PASTE PT BLUE,ELASTOSIL® COLOR PASTE PT TRAFFIC WHITE,ELASTOSIL® COLOR PASTE FL IVORY,ELASTOSIL® COLOR PASTE FL MAIZE YELLOW,ELASTOSIL® COLOR PASTE PT WHITE,ELASTOSIL® COLOR PASTE FL SQUIRREL GRAY,ELASTOSIL® COLOR PASTE PT TRAFFIC GREEN,ELASTOSIL® COLOR PASTE FL GFW,ELASTOSIL® COLOR PASTE FL PEARL ORANGE,ELASTOSIL® COLOR PASTE FL RED VIOLET,ELASTOSIL® COLOR PASTE FL RASPBERRY RED,ELASTOSIL® COLOR PASTE FL IRON GRAY,ELASTOSIL® COLOR PASTE FL BLUE LILAC,ELASTOSIL® COLOR PASTE PT VIOLET,ELASTOSIL® COLOR PASTE FL ICEBLUE 34070,ELASTOSIL® COLOR PASTE FL YELLOW GREEN,ELASTOSIL® COLOR PASTE FL LIGHT BUJE,ELASTOSIL® COLOR PASTE FL HYGIENE GREEN,ELASTOSIL® COLOR PASTE PT YELLOW,ELASTOSIL® COLOR PASTE PT RED VIOLET,ELASTOSIL® COLOR PASTE PT RED,ELASTOSIL® COLOR PASTE FL GREEN,ELASTOSIL® COLOR PASTE PT LIGHT BLUE,ELASTOSIL® COLOR PASTE PT GRAY,ELASTOSIL® COLOR PASTE FL LIGHT GREEN,ELASTOSIL® COLOR PASTE PT ORANGE,ELASTOSIL ® COLOR PASTE FL ZINC YELLOW,ELASTOSIL® COLOR PASTE FL TRAFFIC WHITE,ELASTOSIL® COLOR PASTE FL PURE ORANGE,ELASTOSIL® COLOR PASTE PT DEEP BLACK,ELASTOSIL® COLOR PASTE PT LIGHT BROWN,ELASTOSIL ® COLOR PASTE FL PURPLE VIOLET,ELASTOSIL® COLOR PASTE PT RED BROWN,ELASTOSIL® COLOR PASTE FL L7\SER MARKING BLACK,ELASTOSIL® COLOR PASTE FL MOUNTAIN BLUE,ELASTOSIL ® COLOR PASTE FL TRAFFIC GREEN,ELASTOSIL® COLOR PASTE FL SIGNAL VIOLET,ELASTOSIL® COLOR PASTE FL MAY GREEN,ELASTOSIL® COLOR PASTE FL DARK BLUE -,ELASTOSIL® COLOR PASTE FL PASTEL ORANGE,ELASTOSIL ® COLOR PASTE FL MAIZE YELLOW,ELASTOSIL ® COLOR PASTE FL BLUE LILAC,ELASTOSIL® COLOR PASTE FL BUJE,ELASTOSIL® COLOR PASTE FL L7\SER MARKING BLACK TRL,ELASTOSIL® COLOR PASTE PT BLACK,ELASTOSIL® COLOR PASTE FL HELIOGREEN,ELASTOSIL® COLOR PASTE FL YELLOW,ELASTOSIL® COLOR PASTE FL BLOOD ORANGE,ELASTOSIL ® COLOR PASTE FL MAY GREEN,ELASTOSIL ® COLOR PASTE FL PEARL ORANGE,ELASTOSIL® COLOR PASTE FL WINDOW GRAY,ELASTOSIL® COLOR PASTE FL PINE GREEN,ELASTOSIL® COLOR PASTE FL BLUE 5026 D,ELASTOSIL® COLOR PASTE FL SIGNAL GREEN,ELASTOSIL® COLOR PASTE PT LASER MARKING BLACK TRL,ELASTOSIL® COLOR PASTE FL LIGHT GRAY,ELASTOSIL® COLOR PASTE FL DUST GRAY,ELASTOSIL ® COLOR PASTES,ELASTOSIL® COLOR PASTE FL LIGHT BLUE,ELASTOSIL ® COLOR PASTE FL RED BROWN

瓦克Silgel®612 A/B硅凝胶

描述- WACKER SilGel® 612 A/B 是一种可流动性、室温硫化、RTV-2 硅橡胶,硫化后形成非常柔软的硅凝胶。该产品具有低粘度、快速热固化、非常低的硬度、透明度高、粘性显著、阻燃性等特点,适用于电子控制单元、电子、供暖、通风、空调、灌封和封装、电力控制单元等领域。

型号- WACKER SILGEL® 612 A/B

瓦克2022年秋天推出ELASTOSIL® eco系列8种生物甲醇基硅橡胶

瓦克eco系列的环保型有机硅产品在生产过程中使用以植物残留物为原料制成的生物甲醇,因此尤其节约资源。现在,ELASTOSIL®和SILMIX®品牌的硅橡胶亦新增eco类产品。化学工业正致力于持续削减化石原料的用量,方法之一,是在生产中使用与石化原料完全相同,但取自可再生资源的原料。此时,物料衡算是最佳途径。这一工艺可同时使用来自化石资源和可再生资源的原料,之后再根据具体产品,按比例进行分配。

使用我们的热界面材料进行冷却

描述- WACKER公司提供多种热界面材料(TIMs),包括ELASTOSIL®和SEMICOSIL®硅橡胶产品,用于电子设备的热管理。这些产品具有高导热性、耐高温和良好的粘附性,适用于汽车、工业、消费电子、电力电子、微电子、照明、能源、航空航天和电信等领域。

型号- SEMICOSIL®,ELASTOSIL®

ELASTOSIL®N9111灰色湿固化硅橡胶(RTV-1)

描述- ELASTOSIL® N9111 GREY 是一种非下垂、醇氧固化单组分室温硫化硅橡胶,可在大气湿度的作用下室温固化。该产品具有优异的粘附性、无抑制铂催化等级、无使用有机锡催化剂等特点,适用于多种基材,推荐使用温度范围为 -45°C 至 +180°C。

型号- ELASTOSIL® N9111 GREY

ELASTOSIL®RT 7620 TC CN A/B热固化硅橡胶(RTV-2)

描述- ELASTOSIL® RT 7620 TC CN A/B 是一种可流动、室温硫化、热导性双组分硅橡胶,具有良好的流动性和热导性能,适用于电子元件的灌封保护。

型号- ELASTOSIL® RT 7620 TC CN A/B

VINNEX®8880改善了透明PLA薄膜的性能

描述- 该资料主要介绍了VINNEX® 8880生物聚合物在透明PLA薄膜中的应用,强调了其在提高透明PLA薄膜性能方面的优势,包括改善热封性能和增强冲击强度。

型号- VINNEX® 8880

电子商城

登录 | 立即注册

提交评论