NVMe SSD Thermal Management: What We Have Learned from Marathons

Part 1: Environmental Assessment

NVMe solid state drives (NVMe SSDs) are known to run at blistering speeds. They are 4X faster than Serial ATA (SATA) drives! As such, they are prone to overheating, especially when installed in systems with limited airflow. This series of articles explores the considerations and thermal solutions offered by ATP, so NVMe SSDs can beat the heat and thus deliver reliable sustained performance over extended periods of time.

Thermal Management is Like a Marathon

Thermal management can be likened to a marathon, which is a long-distance footrace that requires endurance and strategy. Here are five things that they have in common. These variables can affect the performance of both marathon runners and NVMe SSDs.

Fig.1 Marathons and the thermal management of NVMe SSDs have these five things in common, each of which can impact performance.

Environmental Assessment

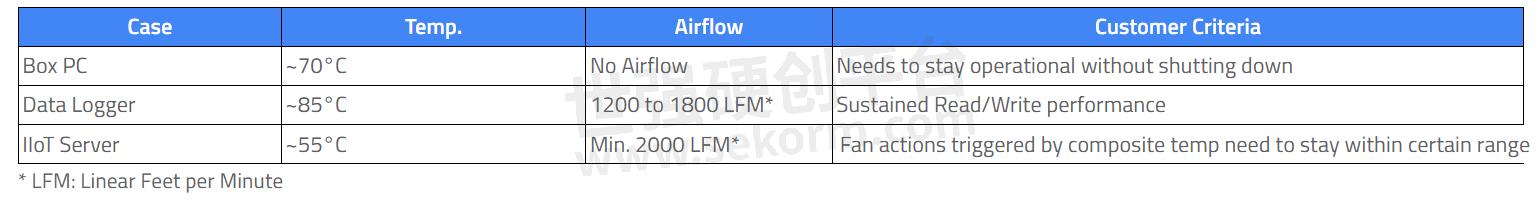

We start with understanding the system environment. It could be a box PC, data logger, or IIoT server operating under various temperatures, airflow conditions, and customer criteria.

Fig.2 In assessing the system environment, we check the airflow, as systems are normally already equipped with fans. To ensure sufficient ventilation, we also check if powerful fans or cooling plates are needed for heat dissipation at high temperatures.

The table below shows examples of various test environments as well as customers’ criteria.

Table.1

By knowing the environment and requirements to set up the thermal simulation and optimize the performance, we can meet customer’s expectations.

Part 2: Physical Conditions

Thermoregulation, which is the body’s ability to maintain its core or optimal temperature, is crucial and helps avoid potentially dangerous conditions. The same is true with an SSD — if it keeps heating up, the drive with trigger a thermal shutdown. Through thermal simulation, we would like to find the balance between temperature and performance.

Component-Level Simulation in Design Phase

Cadence Simulation software is used to perform component-level simulation of IR drop analysis (signal integrity) and thermal simulation during the product design phase.

Hardware engineers input important component and package information into the system, such as case dissipation, power loss, printed circuit board (PCB) dissipation in watts, as well as junction temperature, case and board temperature, and other relevant information.

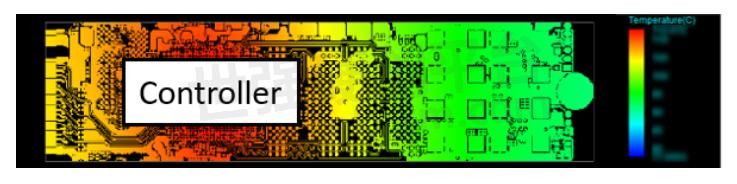

The Cadence Simulation software generates the results showing the distribution of heat in each PCB layer, which indicates which area(s) have the potential risk of heat accumulation.

Hardware engineers then consider adjusting the layout circuits, wire thickness, the quantity and/or position of through-holes, and other variables.

Fig.3

Sample temperature distribution result of the PCB top layer shows that heat accumulates on the Controller.

NOTE: Pure hardware simulation at a worst-case scenario (full speed, not considering firmware-based thermal throttling mechanism)

Checking the System’s Mechanical Design

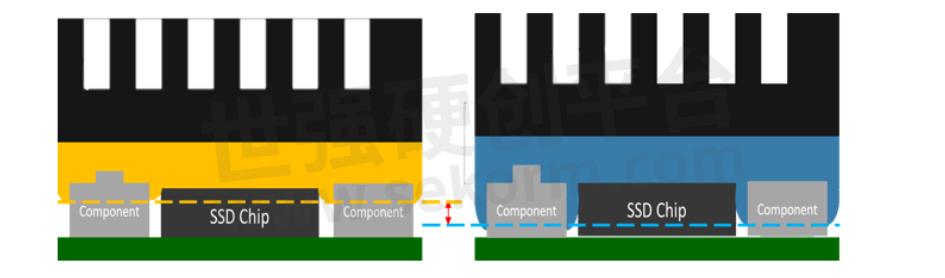

Apart from the SSD itself, we check the system’s mechanical design. We can add an additional heatsink to improve heat dissipation. Ideally, an 8 mm heatsink is better than a copper foil but not every system has enough space.

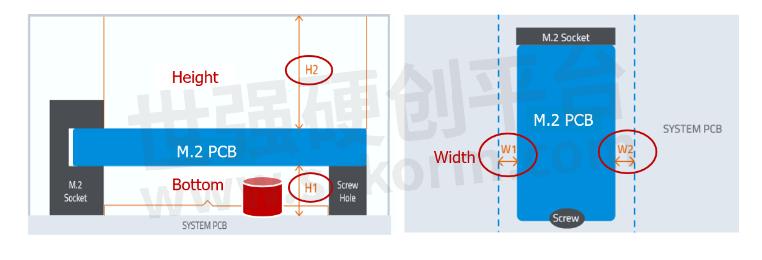

What factors do we consider when assessing heat dissipation for mechanical design within the system?

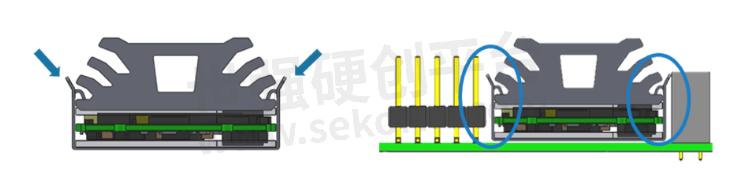

Space. In compact systems, space is very cramped, and heatsink solutions are not typically considered during design. How then can we make sure that the heatsink fits? Is there ample space for a heatsink? We need to consider the area surrounding the NVMe SSD, from the top (height) to the bottom, and the width (thickness/length).

Mechanical Interference. We also make a careful evaluation to make sure that all components on the system PCB do not physically interfere or overlap with the heatsink.

Fig.4 It is important to verify that the system has enough room for installing a heatsink.

ATP Heatsink Solutions: Design Considerations

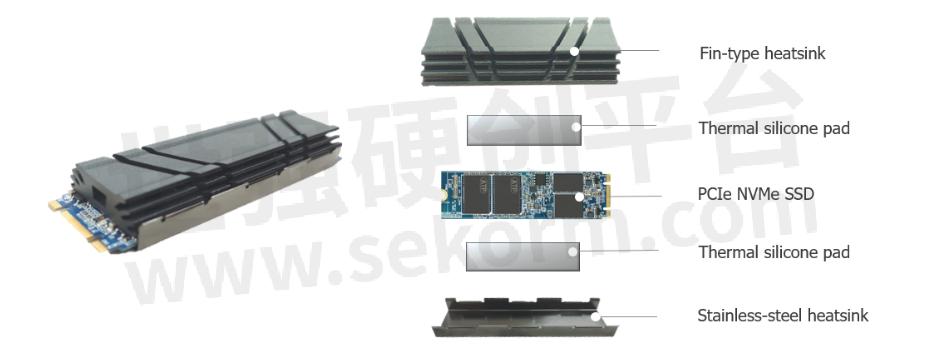

Upon consideration of the surrounding area, it is time to come up with the optimal heatsink solution. As an example, ATP’s specially designed 8 mm fin-type heatsink offers the following advantages for systems with limited space:

More surface area for heat dissipation

Lightweight aluminum material offers good thermal conductivity

Good adhesiveness of thermal pad for conductivity

Clips designed for assembly efficiency on SSDs

Fig.5

The figure above shows the top and bottom parts of an ATP 8 mm fin-type heatsink and how it looks when assembled onto an M.2 2280 NVMe SSD.

Fig.6

The clips are made of thin 0.3 mm stainless steel for more reliable top and bottom heatsink fixing. The space-saving design is suitable for systems with limited space, as it does not interfere with other components on the system PCB.

Part 3: Ambient Simulation (Training)

“Ambient simulation” can be likened to a runner’s training program in preparation for a marathon. This means subjecting SSDs to different ambient conditions that mimic real scenarios to make sure that the SSDs are fit to perform well under such conditions.

System-Level Simulation Using Cadence Thermal Simulation System

The Cadence Thermal Simulation System runs system/module-level simulation. The customer inputs thermal elements such as ambient temperature, airflow, and ATP SSD parameters.

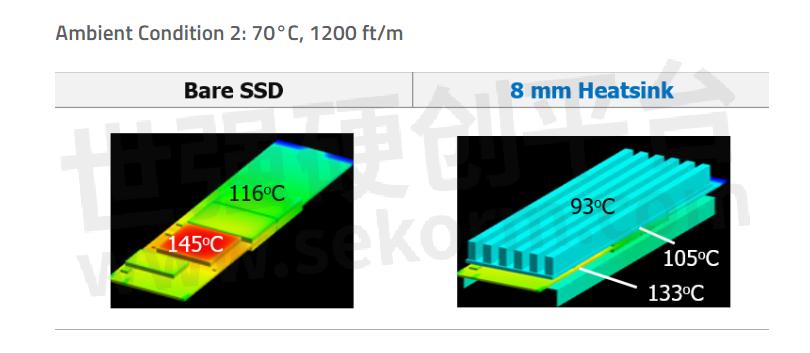

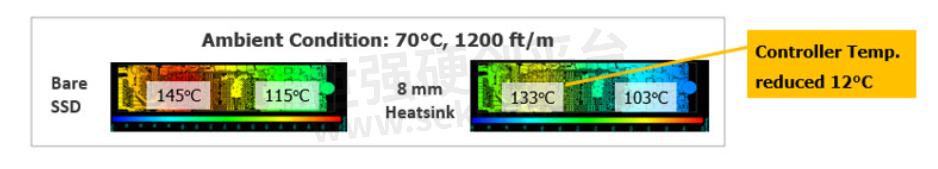

Given different ambient conditions and airflow, the Cadence system can estimate the SSD temperature with or without the heatsink. The following figures demonstrate the effectivity of ATP’s 8 mm heatsink in pure hardware, full-operation mode (worst-case scenarios).

Fig.7

In this scenario, the ambient temperature is higher but there is sufficient airflow, which helped lower the controller area temperature to 145℃. Sufficient airflow complemented by the 8 mm heatsink resulted in the reduction of the overall temperature.

NOTE: Pure hardware simulation test, full-operation mode (worst-case scenario)

ATP-Built Mini Chamber for SSD Testing

Aside from the Cadence software simulation tool, ATP also performs actual SSD tests using our own-built mini chamber. Sized just like a notebook/laptop, it is more compact and flexible as well as easier to use compared with typical giant test chambers.

Fig.8 The ATP-built mini chamber

The mini chamber allows us to perform SSD tests in a controlled environment. We can change the airflow, temperature setting, and test scripts via an external system and save the log files. The chamber is equipped with an alarm/alert, which enables an emergency stop and overheat protection in case the temperature goes over the threshold limits.

Part 4: Gear/Equipment

Choosing the right gear or equipment to dissipate heat is very important. For athletes participating in a marathon, choosing suitable clothing can provide protection and enhance breathability, and the right fabric allows easy evaporation of sweat for better cooling and comfort.

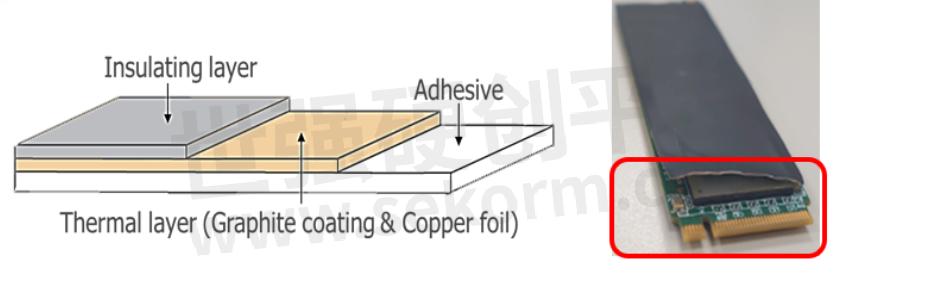

Material Selection

There are several factors to consider when choosing the right material for NVMe SSD heatsinks. In this article, we will discuss a few of the most important ones.

Fig.9

Reliability Test for Copper Foil

To evaluate the reliability of our copper foil solution, we perform resistance testing at high/low temperatures on the adhesive layer to make sure that there is no deformation.

Fig.10

The adhesive strength of the copper foil heatsink is tested to ensure reliability and excellent retention of the heatsink to the SSD.

Shore Hardness Scale of Thermal Pad

The Shore Durometer is a way of measuring the hardness of materials such as plastics and rubber. Flexible, soft thermal pads should attach closely between the heatsink and SSD components to transfer heat away from the SSD and keep the operating temperature cool. If the pads are too soft, it means that the percentage of the silicone is high, and the heat dissipation substance is low. This could lead to poor thermal conductivity.

Fig.11

This illustration shows that if the thermal pad is too soft, it compromises the heatsink’s attachment to the SSD components, resulting in lower heat dissipation.

Cadence Simulation Tool

The Cadence Simulation software can be used to run component-level thermal simulations. With this software, you can compare which material and/or heatsink solution is the best option. Component-level simulation consists of several factors, including ambient temperature, airflow, and thermal resistance/power consumption of main components. Cadence Simulation is pure hardware simulation based on full-speed operation (worst-case scenario). The thermography below compares thermal data for bare SSD and SSD using ATP’s 8 mm heatsink. In the following example, the ambient temperature is higher at 70℃ but with 1200 ft/m airflow. At full speed, the controller temperature for the bare SSD rises to 145℃. With the 8 mm heatsink plus sufficient airflow, the temperature goes down to 133℃, giving a 12℃ reduction.

Fig.12

NOTE: Pure hardware simulation test at a worst-case scenario (full speed without firmware-based thermal throttling mechanism)

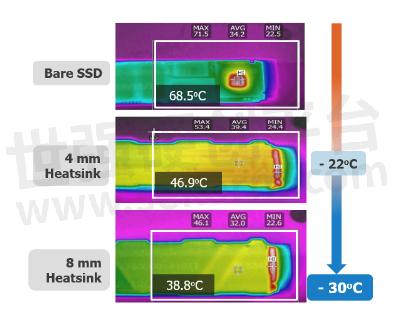

What You Wear Keeps You Cooler

Special quick-dry outfits worn by athletes provide protection and keep moisture or sweat away from the skin to keep it cool. The same is true for NVMe SSDs. ATP’s special heatsink solutions keep heat away from the SSD and reduce the temperature of the controller, where heat typically accumulates.

The graph below shows the controller temperature is reduced from a bare SSD’s 68.5℃ to 46.9℃ with ATP’s 4 mm heatsink, and further down to 30℃ with the 8 mm heatsink. These images were taken at room temperature with minimal airflow of 450 linear feet per minute (LFM), and 100% Sequential write after the 30-minute test.

Fig.13

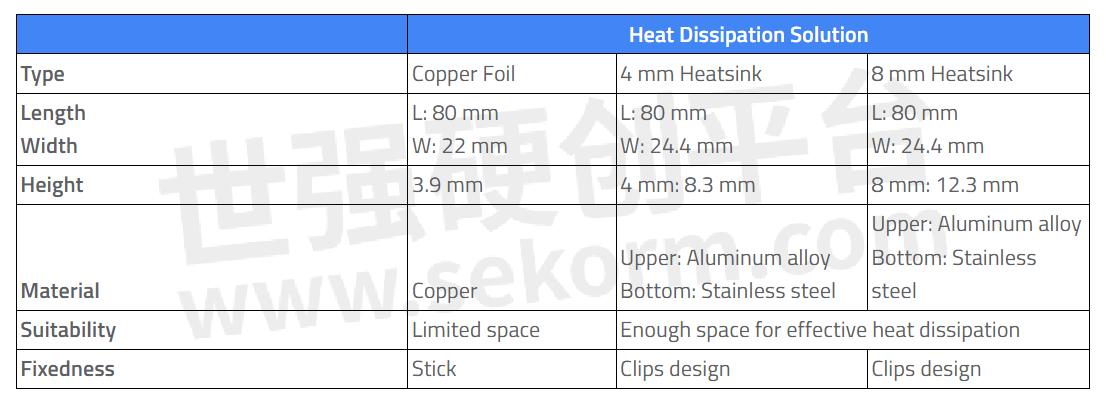

ATP Heat Dissipation Solutions

Not every system has room or space for a powerful heatsink. Considering space constraints, ATP offers different heat dissipation solutions described in the table below.

Table.2

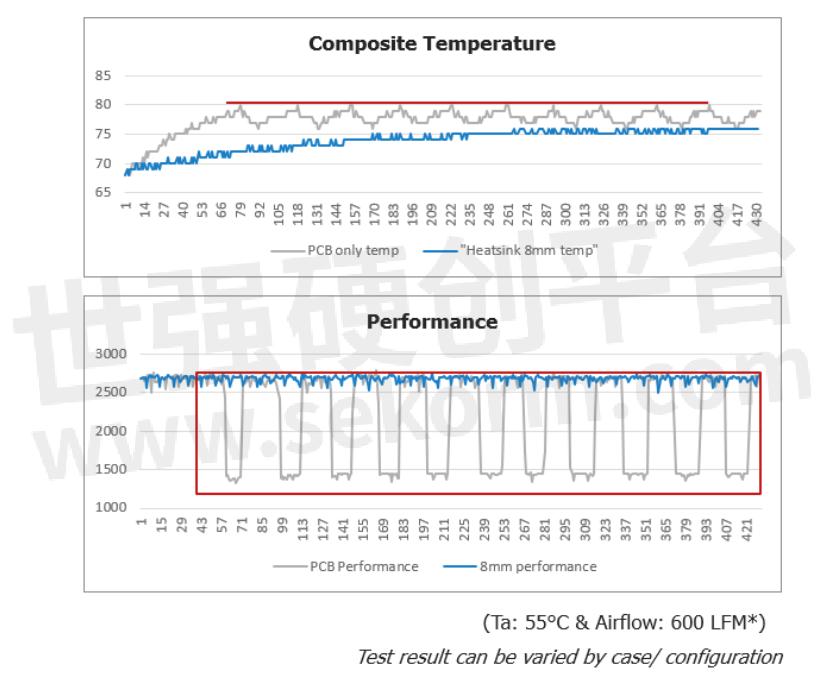

Here is another example showing the importance of choosing the right gear. The figures on below show that the bare SSD repeatedly slows down to cool whenever the composite temperature keeps increasing. The 8 mm heatsink helps to keep the SSD cool by dissipating heat complemented by airflow support.

As the heatsink continues to reduce the composite temperature of the NVMe SSD, steady performance is achieved with ATP’s unique firmware (FW) algorithm, resulting in better-sustained performance.

Fig.14

Part 5 : Pacing Strategy

We will discuss the importance of having a pacing strategy. For marathon runners, this means managing their energy throughout the race. At ATP, we use the Dynamic Thermal Throttling mechanism to manage the heat of our NVMe SSDs to ensure sustained performance at optimal levels.

Steady Wins the Race!

When running a heavy workload at high temperatures, the drives will trigger “thermal throttling” to slow down the drive and prevent overheating. The downside is that the SSD is unable to sustain the optimum operation required to perform and finish the tasks at hand.

ATP Dynamic Thermal Throttling Mechanism

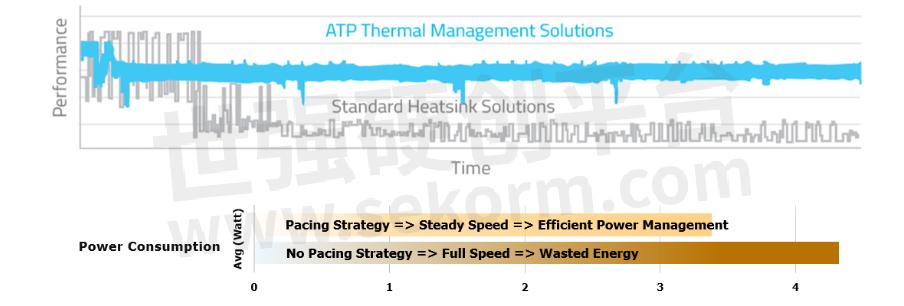

Contrary to standard throttling mechanisms, the ATP Dynamic Thermal Throttling mechanism does not push the SSD to its temperature limits and then sharply drop speed to cool it down. Instead, it provides a delicate balance between performance and temperature by continuously detecting device temperature and adjusting the pace.

ATP Thermal Management Solutions combines both hardware (heatsink) and firmware (Dynamic Throttling mechanism) to make sure that the SSD delivers optimum sustained performance throughout its operation.

By continuously detecting the device temperature and adjusting the pace, lower power consumption is achieved, unlike SSDs that always run at full speed and waste a lot of energy. With fewer fan operations, less energy is required, and less noise is generated.

Fig.15

ATP Thermal Management Solutions combine HW and FW to provide a pacing strategy that results in steady speed and efficient power management.

By continuously detecting the device temperature and adjusting the pace, lower power consumption is achieved, unlike SSDs that always run under full speed and waste a lot of energy. With fewer fan operations, less energy is required, and less noise is generated.

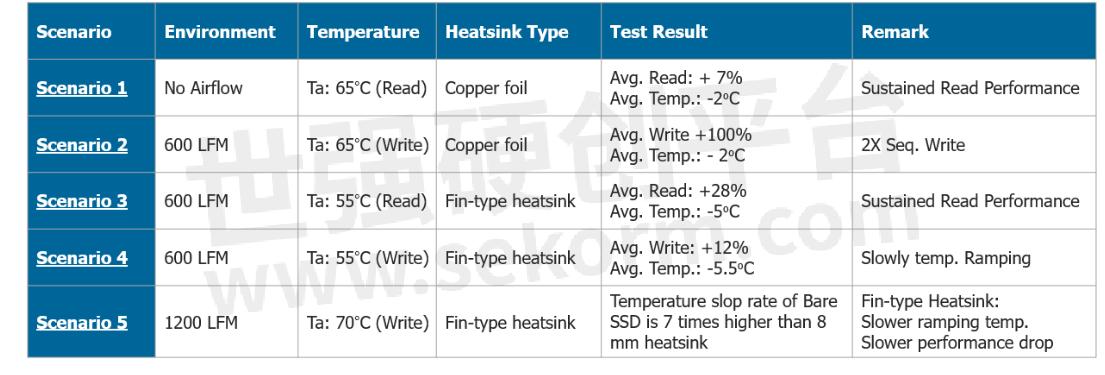

Simulation and Customization: One Scenario Does Not Fit All

At ATP, we believe that every application scenario presents unique thermal requirements. This is why we carefully consider different factors to come up with a solution that fits the specific needs. One scenario does not fit all, so we offer customization options.

The following table summarizes some of the scenarios presented by customers — different airflow environments, ambient temperatures, workloads, heatsink types according to available space in the system design, and respective test results.

Table.3 Simulation and Customization Table

With customers’ varied application requirements, ATP welcomes inquiries for customization. For more information on ATP’s customizable thermal management solutions for M.2 and U.2 NVMe drives, contact an ATP Representative sekorm.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由三年不鸣转载自ATP Official Website,原文标题为:NVMe SSD Thermal Management: What We Have Learned from Marathons,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

【经验】什么是SSD的M.2标准?M.2 SSD和mSATA SSD之间又具体有哪些差异?

近年来发布的固态驱动器(SSD)变得更快,并且能够处理大量数据。但是,它们的全部功能受到与其连接的接口的阻碍或限制。Mini-SATA(mSATA)接口虽然专为提供最小的SSD尺寸而设计,但受到SATA 6 Gb / s的限制。M.2标准是内部安装的计算机附加卡的规范,旨在解决mSATA的局限性,并为小型卡(包括不同大小和容量的SSD)提供更多选择。

【经验】过度配置如何提高基于NAND的ATP SSD的耐用性和性能介绍

过度配置(overprovisioning, OP)为固态硬盘(SSD)的垃圾收集过程提供了额外的空间,有助于提高性能,并增加其耐久性,从而有助于延长驱动器寿命。本文ATP ELECTRONICS深入介绍OP及其大小如何影响写入(TBW),以及SSD的随机写入性能。

How Over-provisioning Improves NAND-based ATP SSDs’Endurance and Performance

Over-provisioning (OP) provides additional space for garbage collection process of solid-state drives (SSDs), aids in improving the performance, and increases their endurance, hence contributing to extended drive life. This article ATP provides an in-depth view of OP and how its size affects the terabytes written (TBW), along with random write performance of SSDs.

PCIe®Gen 3 NVMe M.2 2280/2242/2230 SSD专业存储和内存解决方案的全球领导者

描述- ATP推出PCIe Gen 3 NVMe M.2 SSD,具备数据保护、加密和散热解决方案。产品支持多种容量和温度范围,提供高性能和可靠性,适用于嵌入式和工业应用。

型号- FT960GP38AG8BPC,N750PI,FT480GP38ANDBFC,FT120GP38AG8BPC,FT480GP38AG8BPC,FT480GP34ANDBFC,FT960GP38AG8BPI,FT240GP38AG8BPC,FT120GP38ANDBFC,N700PC,FT240GP38AG8BPI,FT120GP38AG8BPI,N600SC,N650SI,N600VI,FT960GP34ANDBFC,N700PI,FT240GP38ANDBFC,N600SI,FT120GP34ANDBFC,N650SC,FT240GP34ANDBFC,N600VC,FT480GP38AG8BPI

笔记本需要更换大容量硬盘,求推荐性价比更的SSD固态硬盘。

您好,推荐ATP(华腾国际)的SSD固态硬盘,M.2 NVMe接口最高容量可达1TB,M.2 2280接口最高容量1TB,SATA接口最高容量1TB,具体可参考【选型】ATP(华腾国际)内存及存储产品选型指南

ATP工业企业SSD系列产品宣传单

描述- ATP Industrial Enterprise SSD系列结合了工业级和企业级存储解决方案的优点,适用于边缘计算环境。该系列SSD采用NVMe PCIe Gen4x4接口,提供M.2、U.2和E1.S三种形态,适用于数据中心向边缘计算转移的趋势。产品具备高耐用性、数据保留能力、一致性能、高质量服务和高可靠性,同时支持宽温度范围和硬件电源丢失保护。ATP还提供固件定制服务,以满足不同企业客户的需求。

型号- FT400GP48APHBSI-ERS2,FT480GP48APHBSI-ERS3,N651SIE SERIES,FT800GP48APHBSI-ERS2,FT240GP48APHBSI-ERS3,FT800GES4APHBSI-ERS2,FT1T60ES4APHBSI-ERS2,FT240GP48APHBSI-ERS1,FT120GP48APHBSI-ERS3,FT6T40U24APHBSI-ERS2,FT3T20ES4APHBSI-ERS2,FT3T84ES4APHBSI-ERS1,FT7T86ES4APHBSI-ERS1,FT1T60P48APHBSI-ERS2,FT3T20U24APHBSI-ERS2,FT480GP48APHBSI-ERS1,FT1T92P48APHBSI-ERS1,FT960GES4APHBSI-ERS1,FT960GES4APHBSI-ERS3,FT1T60U24APHBSI-ERS2,FT960GU24APHBSI-ERS1,N651SIE,FT960GU24APHBSI-ERS3,FT200GP48APHBSI-ERS2,FT7T86U24APHBSI-ERS1,FT3T84ES4APHBSI-ERS3,FT3T84U24APHBSI-ERS3,FT3T84U24APHBSI-ERS1,FT960GP48APHBSI-ERS3,FT800GU24APHBSI-ERS2,FT1T92U24APHBSI-ERS3,FT480GU24APHBSI-ERS3,FT6T40ES4APHBSI-ERS2,FT1T92U24APHBSI-ERS1,FT480GES4APHBSI-ERS3,FT1T92ES4APHBSI-ERS3,FT960GP48APHBSI-ERS1,FT1T92ES4APHBSI-ERS1

ATP对所有SSD进行数千小时RDT测试,确保产品严格遵守最高质量标准

可靠性验证试验(RDT)是对ATP固态驱动器(SSD)进行的一项长期严格测试,旨在证明每个SSD符合最严格的质量要求。ATP在较长时间内对其 SSD执行完整的实际驱动器级别测试,以验证额定MTBF值,而不是依赖可靠性预测系统。

ATP NVMe BGA pSLC SSD安全保护及加密功能特点

硬件写保护* 写保护功能将ATP NVMe BGA SSD置于“只读”模式,以防止数据写入设备,并保护重要数据不被意外删除、移动或修改。通过在控制器印电路板(PCB)上的通用输入/输出(GPIO)信号引脚的特定引脚上放置跳线,在存储设备上启用写保护。硬件快速擦除*对于特定应用,主机可以使用GPIO连接器触发“擦除数据”行动。

ATP AcuCurrent: Innovative Signal Integrity Optimization Technology

ATP‘s AcuCurrent Technology is an innovative signal optimization technology, enabling dynamic, real-time temperature-responsive drive setting adjustments across a wide operating range, up to 125℃. AcuCurrent Technology is temperature-responsive, dynamically adjusting settings in real time to ensure that the SSD operates at great efficiency across various scenarios, effectively minimizing unnecessary read-retry cycles, and substantially reducing error rates.

ATP推出工业宽温企业级SSD系列产品N651Sie,包含U.2,M.2,E1.S三种接口类型

ATP推出工业宽温企业级SSD系列产品N651Sie,结合了工业级固态硬盘和企业解决方案的优点,专为在不受控制的恶劣环境中处理企业级工作负载而设计。

PCIe®Gen 3 NVMe M.2 2280/2242/2230固态硬盘

描述- ATP推出的PCIe Gen 3 NVMe M.2 2280/2242/2230 SSD,基于NVMe协议和PCIe Gen3 x4接口,提供高速、可靠和持久的性能,满足嵌入式和工业应用日益增长的数据存储需求。这些模块采用3D TLC NAND闪存,容量从40GB到960GB不等,适用于不同的数据存储需求。

型号- FT960GP38AG8BPC,N750PI,FT480GP38ANDBFC,FT120GP38AG8BPC,FT480GP38AG8BPC,FT480GP34ANDBFC,FT960GP38AG8BPI,FT240GP38AG8BPC,FT120GP38ANDBFC,N700PC,FT240GP38AG8BPI,FT120GP38AG8BPI,N600SC,N650SI,N600VI,FT960GP34ANDBFC,N700PI,FT240GP38ANDBFC,N600SI,FT120GP34ANDBFC,N650SC,FT240GP34ANDBFC,N600VC,FT480GP38AG8BPI

ATP推出业界最高擦写寿命的工业级固态硬盘(SSD),具有出色的耐久性和在极端温度下工作的能力

ATP推出N751Pi系列PCIe Gen4 NVMe M.2 2280 SSD,该SSD在配置了pSLC NAND的工业级固态硬盘(SSD)中具有出色的耐久性和在极端温度下工作的能力,是恶劣环境、恶劣条件和高负荷工作负载下关键任务和写入密集型应用的理想选择。

ATP‘s Power Loss Protection Just Got Smarter with MCU-based SSD Design

ATP customers want constant assurance that power loss events will not cause massive downtime or lost data that could affect business operations and lead to higher operating costs. The MCU intelligently monitors sudden power failure conditions from a glitch to a surge or a complete outage...

ATP Industrial Enterprise SSD Series: The Best of Both Worlds, Engineered for Uncontrolled Environments at the Edge

ATP offers the best of both of industrial and enterprise worlds: THE NEW INDUSTRIAL ENTERPRISE Series, which leverage NVMe PCIe Gen4x 4 and are available as M.2, U.2, and E1.S. They combine the best of enterprise and industrial features, making them excellent as boot drives, data storage drives, or mixed-use drives.

ATP Launches Its Tiniest PCIe Gen3 x4 NVMe™ SSDs in M.2 Type 1620 HSBGA Package

ATP Electronics, the global leader in specialized storage and memory solutions, has announced the launch of its tiniest NVMe flash storage offering: the N700 Series PCIe® Gen3 x4 NVMe™ solid state drives (SSDs, which are available as M.2 Type 1620 heatsink ball-grid array (HSBGA) package.

电子商城

服务

可定制ATP TE Cooler的冷却功率:40~200W;运行电压:12/24/48V(DC);控温精度:≤±0.1℃; 尺寸:冷面:20*20~500*300;热面:60*60~540*400 (长*宽;单位mm)。

最小起订量: 1 提交需求>

登录 | 立即注册

提交评论