An In-depth Look At 3D Sensing

The world is three dimensional. That statement is so obvious that most of us never question how we perceive it. But, in fact, each of our eyes captures a flat image – just like a camera. And it’s only in our brains that the magic of forming a 3D perception from those two flat images occurs.

Today, we increasingly ask digital systems to interact with the 3D world – whether it’s to interpret gestural controls, perform facial recognition, or automatically pilot a vehicle. To accomplish these tasks, we need to give them at least some of our ability to perceive depth.

DEPTH SENSING

There are two basic approaches used for 3D (depth) sensing in digital imaging: triangulation and time-of-flight (ToF) measurements. Sometimes these techniques are even combined.

Triangulation is based on geometry. One form of triangulation – binocular vision – is the way that human 3D (stereoscopic) vision operates. We have two eyes separated horizontally. This means that each eye sees the world from a slightly different angle. This difference in perspective creates a parallax, meaning a shift in the position of an object relative to the background depending on which eye you’re looking with. Our brains then use this parallax information to sense the depth (distance) of objects in our field of view and create our single, unified, 3D perception of the world.

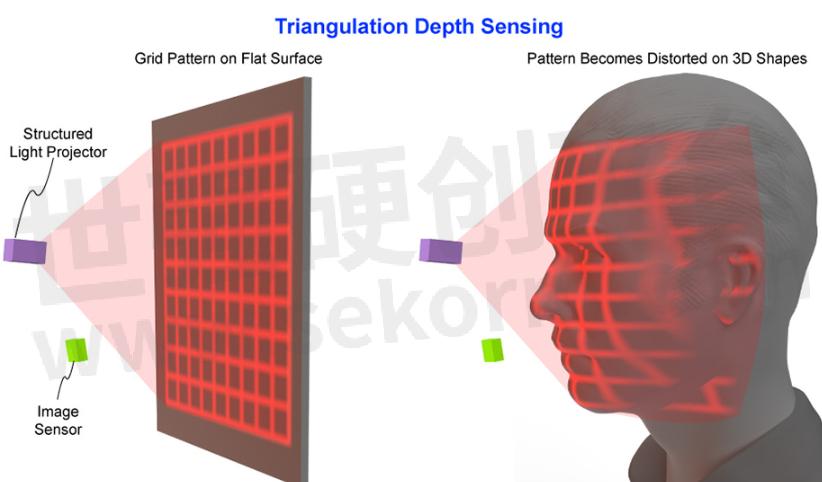

But stereo vision can be dependent on lighting conditions and requires distinct textured surfaces. These make it difficult to reliably implement. Instead, computer vision systems use another form of triangulation that relies on “structured light.” This is just a fancy name for projecting a pattern (like a series of lines or numerous spots of light) onto an object and analyzing the distortion of this pattern from a slightly different angle. This takes much less processing power than recreating true binocular vision, and it enables a computer to rapidly calculate depth information and reconstruct a 3D scene.

In one form of triangulation depth sensing a structured light pattern is projected onto the scene, and an imaging system analyzes the distortion of this pattern to derive depth information for the illuminated area.

Triangulation methods excel in high-resolution mapping of surfaces. They work best over shorter distances, making them very useful for tasks like facial recognition.

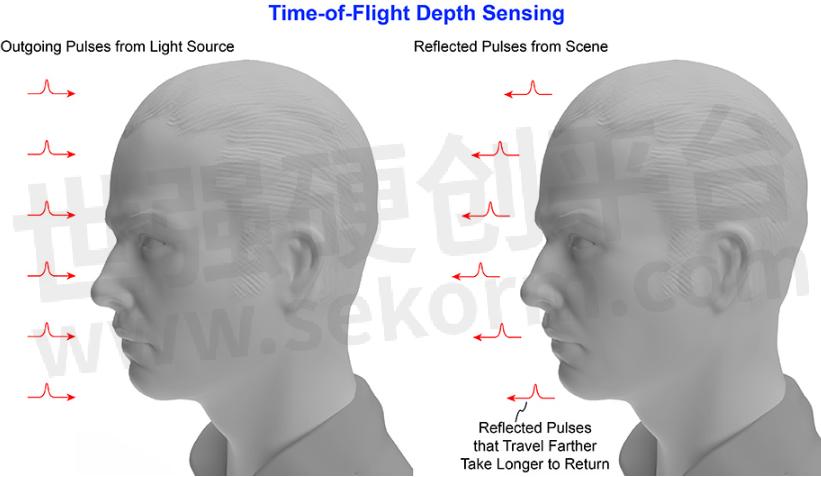

Time-of-Flight imaging (ToF) comes in two different forms. In “direct Time-of-Flight" (dToF) the scene is illuminated with pulses of light, and the system measures the time it takes for the reflected light pulses to return. Since the speed of light is known, this return time can be directly converted into distance. If this calculation is performed independently for each pixel in an image, then a depth value at each point in the scene can be derived.

The second form of ToF is "indirect Time-of-Flight" (iToF). Here, the illumination is a continuous, modulated signal. The system measures the phase shift of this modulation in the returned light. This provides the data used to calculate object distances.

ToF technology shines in its ability to measure over larger areas and distances quickly. This makes it ideal for tasks like room scanning in virtual reality headsets or obstacle detection for robot navigation.

Direct Time-of-Flight sensing measures the round-trip travel time of light pulses and converts the time intervals into distance measurements.

3D SENSING LIGHT SOURCE REQUIREMENTS

The characteristics of the light source are crucial in determining the effectiveness and accuracy of both triangulation and ToF 3D sensing methods. Each application has unique illumination requirements, although they also have certain common needs.

Triangulation benefits from a COHERENT light source. This provides greater flexibility in terms of the patterns that can be created. It also enables them to form higher-resolution structured patterns and to maintain pattern integrity over longer distances.

A triangulation light source also needs to have stable beam-pointing characteristics. Any fluctuations in these can lead to inaccurate depth measurements.

ToF systems require a light source capable of emitting either short, precise pulses of light (dToF) or continuous output that can be modulated at high frequencies (iToF). The precision in pulse timing and modulation frequency with short rise and fall times is paramount for accurate distance measurement.

ToF systems, especially those using flood illumination to cover large areas or long distances, generally require higher output powers than triangulation systems. This ensures that the return light will have sufficient intensity to be detected, and that the system will function well with high levels of ambient light.

As output power scales up, the need for power efficiency (the ratio of optical output power to input electrical power) becomes more important. Efficiency becomes particularly relevant for portable (battery operated) devices.

LASERS FOR BETTER DEPTH SENSING

Diode lasers provide a better match to these requirements (for both triangulation and TOF sensing) than any other light source. Light emitting diodes (LEDs) have been deployed in the past for some 3D sensing uses because they’re readily available and relatively low cost. But, as the demands on 3D sensing system performance and efficiency increase, LEDs can’t really measure up.

One reason is that diode lasers offer a unique combination of narrow spectral output, coherence, and brightness. Together, these make them ideally suited for creating precise, high-contrast, stable structured light patterns.

The narrow spectral output of lasers also makes it much easier to filter out ambient light in the detection system. This improves performance for all types of sensing systems in bright sunlight or other well-lit scenes.

The higher brightness of diode lasers further boosts the power of the returned signal. Especially for TOF applications, this translates into shorter shutter times, higher frame rates, and improved ability to see objects which aren’t highly reflective, and, again, improved performance in brightly lit scenes. LEDs, with their lower intensity, struggle to achieve the same level of detail and depth resolution.

Additionally, diode lasers boast a significant advantage over LEDs in terms of power consumption and size. Their ability to emit a strong signal from a small form factor makes them ideal for compact, battery-operated devices.

Finally, diode lasers can be switched or modulated at much faster rates than LEDs. This rapid modulation allows for advanced ToF techniques which can deliver improved accuracy.

COHERENT SHINES IN 3D SENSING

Coherent is the world leader in illumination sources for 3D sensing – we’ve shipped over 2 billion units! Our portfolio includes lasers, optics, and complete illumination modules.

Our sources comprise vertical cavity surface emitting lasers (VCSELs), VCSEL arrays, and edge-emitting diode lasers (EELs).

In particular, VCSEL arrays – typically with output at 940 nm – have become the dominant light source for 3D sensing today. There are several reasons for this. One is that the light exits a VCSEL from the top of the device, rather than from the side like in an EEL. This makes it easier to integrate them on a circuit board with other components. Also, VCSELs cost less than EELs at the power levels used in 3D sensing. As a result, EELs are typically only employed at longer wavelengths (>1200 nm) where VCSELs with good performance are not yet available. The key advantage of these longer wavelengths is more robust performance in bright sunlight (they allow virtually all sunlight to be filtered out) and enhanced eye safety (10X higher power levels are possible compared near-IR wavelengths).

Coherent has a mature platform for VCSEL and EEL fabrication based on 6-inch GaAs wafers. This has enabled us to become the volume leader in this technology and to consistently deliver devices with outstanding reliability and performance.

Light sources for 3D sensing are usually configured as either flood illuminators or pattern projectors. Flood illuminators provide homogeneous light coverage over a specific angle. They are used in applications like facial recognition and gesture detection where uniform light distribution over the entire field of view is key to measurement accuracy.

Pattern projectors are actually used for both triangulation and ToF systems. Combining light patterns with ToF measurements improves signal-to-noise ratio and reduces multipath-induced measurement errors. These are inaccuracies that occur when the light bounces off more than one surface before reaching the sensor.

In each case, optics are used to shape and transform the laser output to meet the exact requirements of the application. Producing a flood illuminator can usually be accomplished with relatively simple, low-cost, molded plastic lenses. But the demands for structured light sources are more stringent.

Coherent meets the needs for structured light illumination with diffractive optical elements (DOEs) and meta-optics. The latter utilize nanostructures – physical features that are smaller than the wavelength of the light – to alter its propagation properties. This can include changing the beam shape, divergence angle, and intensity distribution, as well as splitting the beam to create structured light patterns.

One great thing about Coherent meta-optics is that they can combine multiple optical functions – like beam collimation and splitting – into a single compact element. Doing this reduces the size and complexity of the optical system and also improves the overall performance of the 3D sensing module.

Another key differentiator for Coherent is our ability to engineer and vertically integrate an entire illumination module solution. This integration ensures that the light source, optics, driver IC and packaging are all optimized to work seamlessly together, providing our customers with a reliable, high-performance, yet cost-effective product that is ready for mass deployment in the most demanding applications.

Coherent manufactures flood illumination and dot projection modules.

For example, our illumination modules for 3D sensing are engineered to minimize electronic parasitics (unwanted capacitance, inductance, or resistance). This is essential for delivering the nanosecond pulse width and sub-nanosecond rise/fall times on which high-accuracy ToF sensors depend. Additionally, we emphasize the importance of eye safety, integrating features that monitor the integrity of the device and the output power to ensure that light output always stays within established safe levels under all circumstances. This is imperative for consumer devices.

When you put it all together, Coherent provides more than just superior components: You get a team who understands the intricacies of 3D sensing technology and can deliver a complete, integrated solution that enhances device performance and ensures user safety. By partnering with us, you can rely on our legacy of excellence and our continuing development of photonic innovations.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由sr转载自COHERENT Official Website,原文标题为:AN IN-DEPTH LOOK AT 3D SENSING,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

VCSEL Illuminators Deliver Higher Efficiency and Performance for Improved ADAS

The article will explore the integral role of illumination in DMS and OMS, examine the limitations of LED technology, and discuss the transformative potential of VCSELs in enhancing the function of ADAS in automotive safety.

Coherent HighLight FL-ARM系列光纤激光器告诉你,为何电动汽车焊接要讲究技巧,而不仅靠力量

Coherent HighLight FL-ARM系列光纤激光器的总功率高达10kW。这一功率量级对于以高效的产量的所有应用已经绰绰有余。事实上,大多数高精度、要求最高的产品通常使用的量不到该功率量级的一半。因此,Coherent高意公司ARM激光器能够在必要时将足够的激光功率精确地定向传递到焊接位置。

Coherent Introduced 100G PAM4 VCSEL and Photodiode Arrays for 800G Transceivers and Active Optical Cables

Coherent, a leader in datacom transceiver components, today announced the introduction of its 100G PAM4 vertical-cavity surface-emitting laser (VCSEL) and photodiode (PD) arrays for 800G short-reach datacom pluggable transceivers and active optical cables (AOCs.)

Chip Forum 41st Session:Berxel Made a Speech of The Application of VCSEL Chip in the Digital and AI Era

In this talk, we reviewed Berxel’s recent advances and commercialization of high-speed 106 Gbps PAM4 VCSELs for datacom applications and high efficiency VCSEL arrays for 3D sensing applications.

Coherent Reports Significant Advancement in VCSEL Performance for Next-gen AI Networks

Coherent Corp. has made a significant breakthrough in improving the bandwidth of its vertical-cavity surface-emitting laser (VCSEL), paving the way for use in next-generation optical interconnects that will operate at 200 Gbps per lane and thereby enabling optical transceivers with 1.6 Tbps capacity.

II-VI‘s New Double-junction VCSEL Arrays Improves The Power Conversion Efficiency to 56%

II‐VI Incorporated (Nasdaq: IIVI), a leading provider of semiconductor lasers and micro-optics for consumer electronics, today announced its double-junction vertical cavity surface-emitting laser (VCSEL) arrays, the first of its multi-junction VCSEL array platforms for next-generation world-facing 3D sensing applications.

Coherent Introduces Dot Projector Modules for Depth Sensing in Consumer Electronics, Robotics, and Autonomous Vehicles

Coherent Corp. announced the introduction of dot projector modules for depth sensing in consumer electronics, robotics, and autonomous vehicles. The module is based on 940 nm vertical-cavity surface-emitting lasers (VCSELs) with designs ranging from 600 to 13,000 dots, to match various depth range and spatial resolution requirements of spot-assisted time-of-flight (TOF) 3D cameras.

Coherent Unveils Patented Module Architecture for UltraCompact Dynamic Illumination and Sensing with Backside-Emitting VCSEL ARRAYS

Coherent, a leader in optical sensing, today unveiled a patented module architecture for ultracompact dynamic illumination and sensing with backside-emitting vertical-cavity surface-emitting laser (VCSEL) arrays.

V940-8904-G02 940nm多模双结VCSEL阵列光电器件

描述- 该资料介绍了Coherent公司生产的940 nm多模双结VCSEL阵列(型号V940-8904-G02),这是一种专为满足光学3D传感应用而设计的高功率激光器。该产品采用垂直堆叠两个活性区域的设计,能够在低电流下实现高功率输出(2.7 A时为4.6 W)。其特点是高功率转换效率、高斜率效率和多功能发射模式。

型号- V940-8904-G02

VGP00014V5 940nm多模单发射极VCSEL光电器件

描述- 该资料介绍了Coherent公司生产的940 nm多模单发射器垂直腔面发射激光二极管(VCSEL)产品。该产品适用于广泛的3D传感应用,具有高效率和可靠性,支持多种横模发射和多环远场分布。主要特性包括典型输出功率20mW、非密封操作和高体积生产。

型号- VGP00014V5-001,VGP00014V5

VGP00020V5 940nm多模高功率VCSEL阵列光电器件

描述- 该资料介绍了Coherent公司生产的940 nm多模高功率VCSEL阵列(VGP00020V5),适用于广泛的3D传感应用。产品具有高达4.5W的输出功率,效率高且光束分布对称,适合大规模消费类应用。芯片设计紧凑,特别适用于直接飞行时间(dTOF)系统所需的高调制频率。

型号- VGP00020V5

High-performance Multi-junction VCSEL Laser Chips Boost Lidar and 3D Sensing

Multi-junction VCSEL laser arrays are one of the next-generation solutions for LEMON Photonics to optimize automotive lidar and industrial 3D sensing applications. Its small body size, high power density, and 905nm 120W multi-junction VCSEL are very suitable for short to long-range LiDAR solutions.

VCSEL作为小型双目摄像机的辅助照明用于活体面部识别

型号- VD-0940P-00XW-1X-5AX,VP-0940P-004W-1C-2AX,VP-0850P-00XW-1C-1AX,VD-0850P-00XW-1X-5AX

使用2602B系统SourceMeter®仪器和DMM7510图形采样DMM进行三维传感的激光二极管阵列测试

描述- 本文介绍了使用2602B System SourceMeter®仪器和DMM7510图形采样DMM对激光二极管阵列进行3D传感测试的方法。文章详细阐述了3D传感技术,特别是垂直腔面发射激光器(VCSELs)在3D传感中的应用,以及如何通过时间飞行(TOF)技术测量距离和速度。文章重点介绍了使用SourceMeter®仪器进行激光二极管阵列测试的优势,包括其内置测试脚本处理能力、触发同步和高速数据采集。此外,还讨论了DMM7510在温度和光电二极管电流测量中的应用,以及如何在生产环境中实现高效的电气测试。

型号- DMM7510,2602B

电子商城

品牌:COHERENT

品类:Single-Stage Thermoelectric Module

价格:¥138.0250

现货: 1,250

品牌:COHERENT

品类:Single-Stage Thermoelectric Module

价格:¥745.0191

现货: 600

品牌:COHERENT

品类:Single‐Stage Thermoelectric Module

价格:¥192.4021

现货: 524

品牌:COHERENT

品类:Single‐Stage Thermoelectric Module

价格:¥252.6552

现货: 518

品牌:COHERENT

品类:Single-Stage Thermoelectric Cooler

价格:¥1,971.8640

现货: 508

品牌:COHERENT

品类:Single-Stage Thermoelectric Module

价格:¥488.7889

现货: 500

品牌:COHERENT

品类:Single-Stage Thermoelectric Module

价格:¥107.1444

现货: 486

品牌:COHERENT

品类:Single-Stage Thermoelectric Module

价格:¥432.0068

现货: 475

品牌:COHERENT

品类:Single-Stage Thermoelectric Module

价格:¥485.0000

现货: 460

现货市场

登录 | 立即注册

提交评论