UWB Prevents Collisions between Construction Personnel and Machinery

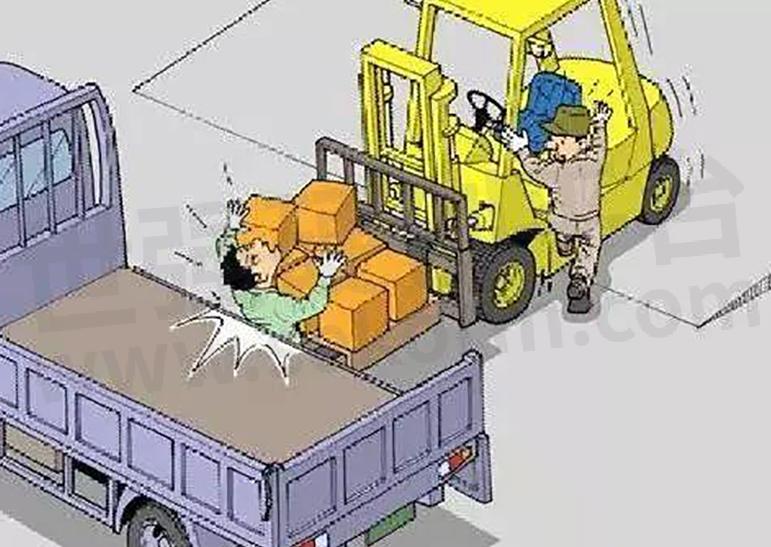

Nowadays, many types of heavy construction machinery are used in construction sites and warehouses, greatly improving the efficiency of engineering construction. However, there are also some drawbacks. For example, there are accident blind spots in the operation process of construction machinery, which can easily lead to safety accidents. These blind spots may exist within the rotation range of the hook excavator arm, on the excavation path of the excavator bucket, or on the side and rear of the vehicle. Due to the difficulty for operators to directly observe the situation of these blind spots, it is easy to make misjudgments about the surrounding environment.

In order to solve this problem, collision warning systems have emerged. The collision warning system can help construction machinery operators detect obstacles or personnel in blind spots in a timely manner, thereby avoiding collision accidents. These systems typically use sensors such as radar and cameras to detect the surrounding environment and issue warning signals to operators through sound and light alarms.

The installation of collision warning system can improve the safety of hook operation and reduce the occurrence of accidents. At the same time, these systems can also improve the work efficiency of operators, reduce downtime and maintenance costs caused by accidents.

Responding to and promoting the construction of smart construction sites

He finally emphasized the need to focus on safety production, further investigate safety hazards, strengthen early warning and monitoring, and implement emergency measures to ensure the safety of people's lives and property.

Construction site personnel and construction machinery uwb collision prevention solutions

This solution can solve the mutual distance measurement between construction machinery and construction machinery, as well as between construction machinery and personnel, to avoid collisions between them and reduce the occurrence of human accidents. Based on UWB high-precision ranging and advanced UWB positioning and ranging technology as the core, TOF multi group bidirectional ranging algorithms are used to achieve precise ranging, with an average ranging accuracy of up to 10cm. And combined with sound and light alarms to form a collision warning device, achieving collision warning function. When a collision is about to occur, an alarm is triggered to alert the operators of the construction machinery. At the same time, the anti-collision label (employee's work card, helmet, watch) also emits warning lights, vibrations, and warning beeps to alert relevant personnel.

Construction machinery and personnel collision prevention warning

Due to obstructed vision, the driver was unable to detect the presence of pedestrians in a timely manner. They can use UWB base stations to sense pedestrians wearing anti-collision labels (work cards, helmets, watches worn by employees) and the presence of construction machinery installed in UWB base stations, thereby achieving early warning.

Construction machinery and collision prevention warning for construction machinery

The UWB base station on construction machinery measures distance from other UWB base stations on nearby construction machinery, outputs control signals to relays, controls alarms and the power supply of the construction machinery itself, thereby achieving sound and light alarms and emergency braking.

Principle of anti-collision warning scheme for construction site personnel and machinery

Install UWB base station VDU2508J on construction machinery, combined with sound and light alarm devices, to form a collision warning device. Personnel should wear matching anti-collision labels VDU1506R (safety helmet label), VDU1502 (watch), and VDU1521 (work card). Through the installation of UWB base stations on construction machinery and the high-precision distance measurement between UWB tags and work cards carried by personnel, it is possible to simultaneously achieve precise distance measurement between multiple construction machinery vehicles and between multiple personnel and construction machinery. This can achieve collision warning between construction machinery and construction machinery, as well as between construction machinery and personnel.

In addition, the ranging accuracy between UWB base stations and UWB base stations, as well as between UWB base stations and UWB tag work cards, is as high as 10CM, with precise ranging and small errors.

The UWB base station can set its own ranging range and warning threshold according to the scene. When the distance between two construction machinery is lower than the set safety warning threshold, the UWB base station outputs a control signal to the relay after measuring distance with another UWB base station, which then controls the alarm and the power supply of the construction machinery itself, thereby achieving sound and light alarm and emergency braking.

Core products of anti-collision solutions for construction personnel and machinery

UWB base station: VDU2508J is a long-distance UWB base station launched by Microenergy Information. The bidirectional distance between base stations can reach 500 meters, making it very suitable for applications that achieve collision warning through precise distance measurement.

UWB labels: VDU1506R (safety helmet label), VDU1502 (watch), VDU1521 (work card).

System: Our independently developed device software management platform supports deployment.

Why do construction workers and machinery need collision prevention?

Ensure personnel safety: prevent personnel from being injured by mechanical collisions and avoid serious personal injury accidents.

Protecting construction machinery: avoiding damage caused by collisions, reducing maintenance costs and downtime.

Ensure construction progress: reduce downtime and delays caused by accidents, and ensure that the project proceeds as planned.

Improving construction environment safety: reducing collision risks and creating a safer construction operation environment.

Which mechanical equipment on construction sites and docks requires collision avoidance systems?

Excavators, loaders, bulldozers, tower cranes, construction elevators, concrete mixers, rollers, etc.

Which mechanical equipment for indoor work requires collision avoidance systems?

Construction machinery, pallet handling vehicles, conveyor belts, cranes, winches, electric tractors, etc.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由sr转载自SKYLAB Official Website,原文标题为:UWB prevents collisions between construction personnel and machinery,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

【应用】全套UWB定位系统解决方案,为物联网应用提供精准位置信息

天工测控的UWB定位系统由UWB基站,UWB标签,UWB定位引擎和终端显示器构成。UWB(超宽带)的实时定位系统可以在UWB基站覆盖区域范围内,结合UWB标签,配合UWB的TDOA算法及终端显示设备,实现复杂的人员定位、监测和追踪任务并准确找寻到目标对象,定位精度达到10~30厘米。本文介绍了一些用在该处应用的相关产品。

Fire Rescue Personnel UWB Ad Hoc Network Positioning Solution

This article introduces the SKYLAB UWB ad hoc network positioning solution for fire rescue personnel and suggests some UWB ad hoc network products for this solution.

UWB Positioning Application Solution for VR/AR Game

SKYLAB has developed and launched the UWB high-precision navigation and positioning system. It only needs to set up 4 base stations and wear relevant rated position tags to achieve high-precision positioning for indoor games. Pain points such as expensive price.

Personnel Positioning in the Blasting Area and Electronic Fence System to Ensure Safe Operations

In the blasting area, the use of UWB ultra wideband, Bluetooth and other personnel positioning technologies combined with virtual (boundary setting based on positioning technology) and physical (physical protection with sensors) electronic fence technology can achieve real-time monitoring, permission management, abnormal warning and historical data recording analysis of personnel, ensuring the safety of blasting operations. It is necessary to deploy base stations and tags reasonably and set and maintain electronic fence parameters.

SKYLAB UWB Indoor Positioning and Tracking Solution

The high-precision UWB positioning tracker system developed by SKYLAB adopts the TDOA high-precision positioning algorithm. It supports positioning accuracy of up to 10 cm and can be applied to 0-dimensional presence detection, and two-dimensional, and three-dimensional positioning modes.

UWB Personnel Positioning Solution for Drug Rehabilitation Centers: Precise Supervision, Safety Protection

As a special supervision place, drug rehabilitation centers have extremely high requirements for personnel management. Traditional regulatory methods have certain limitations and are difficult to achieve precise positioning and real-time monitoring of regulated personnel. UWB (Ultra Wideband) technology provides a new solution for locating drug rehabilitation center personnel due to its advantages of high precision, low power consumption, and strong anti-interference ability.

SKYLAB has developed and produced the TWR UWB positioning system kit including two parts: UWBpositioning base station and UWB label

SKYLAB is the world‘s leading manufacturer of UWB indoor positioning systems. SKYLAB has developed and produced the TWR UWB positioning system kit. The system kit includes two parts: UWBpositioning base station and UWB label. The positioning system can use the TWR ranging base station VDU2506 or the core board SKU620. UWB positioning labels are in the form of badges, helmets, bracelets, and other products.

Chemical Plant Personnel UWB Positioning Solution

The UWB positioning chemical plant personnel positioning management solution developed by SKYLAB adopts ultra-wideband positioning technology. By deploying UWB positioning base stations in the chemical plant personnel activity area, staff, vehicles, and assets are equipped with UWB positioning tags.

Uwb Creates Smart Port Personnel Positioning, Safe and Efficient New Upgrade

The port personnel positioning system adopts UWB technology and meets the safety management, operation scheduling, attendance, and asset management needs in complex port environments through explosion-proof/flameproof base stations VDU2613 and positioning tags VDU1501. It has advantages such as high precision, strong real-time performance, high reliability, easy deployment and expansion, and can be integrated with other systems.

Introduction of SKYLAB UWB TWR Passive Positioning System

In response to the TWR ranging needs of some industry customers, SKYLAB has launched TWR active positioning system and TWR passive positioning system. In this article, we will introduce the TWR passive positioning system in detail.

Introduction to TWR Active and Passive Positioning Systems, UWB Positioning Technology

This paper briefly describes the range location of TWR positioning, and introduces the application in indoor positioning, wireless sensor network positioning and other specific scenarios, and introduces the application advantages of accuracy and reliability.

High Precision Personnel Positioning Solution for Indoor and Outdoor Use in Cement Plants

Ultra-wideband (UWB) technology enhances safety and efficiency in cement plants by offering precise indoor and outdoor personnel positioning. It detects hazardous areas in real-time, aids in emergency rescues, optimizes production management, and integrates with other systems for intelligent management. This technology improves safety, boosts efficiency, and reduces management costs.

UWB Positioning Solution for Power Plant Substation Workers

SKYLAB develops and provides UWB positioning personnel positioning management solutions for power plants. Relying on UWB positioning technology, by installing UWB positioning base stations in the activity area of substation personnel, UWB positioning tags, such as UWB positioning badges or bracelets, are worn for staff.

Recommend 5 Kinds of UWB Ranging And Positioning Modules

SKYLAB develops and produces UWB base stations, UWB tags and UWB modules which are widely used in asset location tracking, personnel indoor positioning, warehouse forklift anti-collision and other fields. In this article SKYLAB will recommend 5 kinds of UWB ranging and positioning modules.

Analysis of Indoor and Outdoor Integrated Positioning Scheme, GNSS/UWB/BLE Positioning Technology

Our indoor and outdoor integrated positioning solution aims to provide users with seamless positioning services, enabling high-precision and high reliability positioning in both indoor and outdoor environments. By integrating multiple positioning technologies and combining advanced sensors and algorithms, precise positioning and tracking of personnel, items, and equipment can be achieved.

电子商城

现货市场

服务

Ignion可支持多协议、宽频段的物联网天线方案设计,协议:Wi-Fi、Bluetooth、UWB、Lora、Zigbee、2G、3G、4G、5G、CBRS、GNSS、GSM、LTE-M、NB-IoT等,频段范围:400MHz~10600MHz。

最小起订量: 2500 提交需求>

登录 | 立即注册

提交评论