Wacker Offers Effective Solutions for Protecting Concrete from Water

A functioning infrastructure is the key to a society’s prosperity and well-being. But the roads and bridges in prosperous countries are getting old. In the United States, 56,000 bridges are deemed to be structurally deficient; in 2016, roughly 3.8 million square meters of bridges were found to be in urgent need of repair in Germany alone.

Built for Eternity?

Many of the bridges and roads in highly developed countries were built decades ago. Not only has the volume of traffic quadrupled since that time – extreme weather events with high temperatures and freezing conditions (including chloride pollution from road salt) are increasing as well. The enemy here? Water.

An Unwelcome Intruder

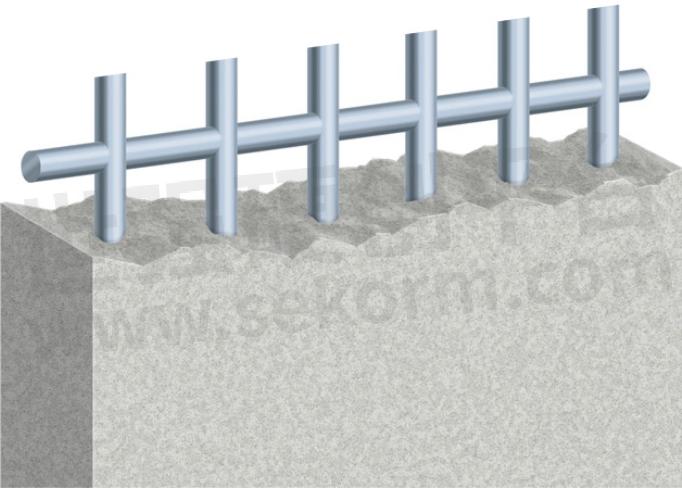

All of the damage that occurs in concrete is caused by moisture penetration. When it rains on a concrete road or when a concrete bridge is exposed to ocean spray, the water is literally drawn into tiny cavities (capillaries) in the concrete – and because of the capillary effect, this even works against gravity. Water can cause significant damage once it has invaded, whether due to freeze-thaw cycles or chemical reactions, or because it transports aggressive substances like road salt into the concrete.

Rust: An Explosive Phenomenon

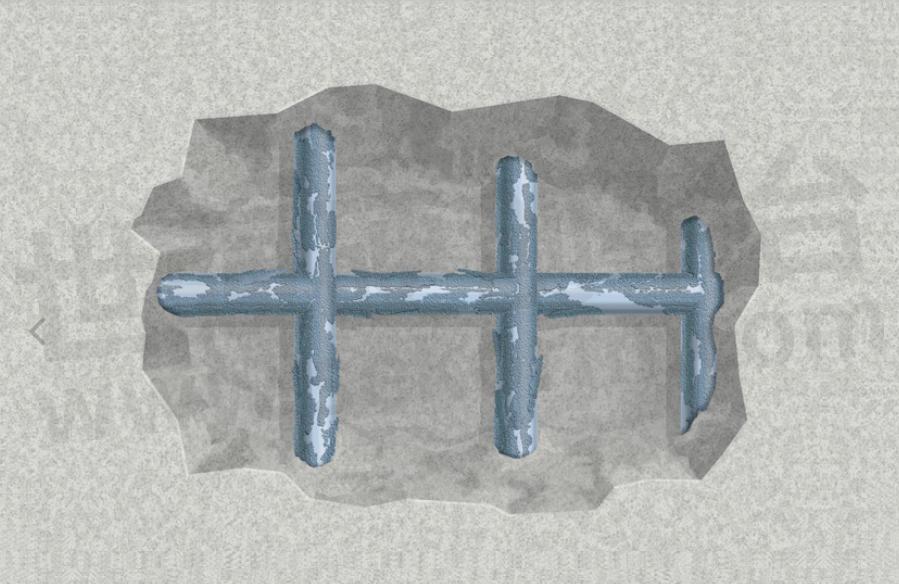

Concrete is usually reinforced with steel when installed. But the pH of fresh concrete is high, which protects the steel from rust. If, however, the concrete reacts with the CO2 in the air, its pH sinks and it no longer protects the steel as well as it once did. And if moisture is introduced on top of that, the reinforcing steel may corrode. The volume of rusted steel is many times greater than that of uncorroded steel, and this generates pressure that ruptures the surrounding concrete. Steel that has been compromised in this way by rust puts the integrity of bridges and buildings at an acute risk. That risk is particularly great for steel-reinforced concrete exposed to seawater or road salt, both of which contain chlorides. If spray or condensation transports these chlorides onto the concrete and they penetrate all the way down to the steel reinforcement, the rust will produce pits that eat deep into the metal. Known as pitting corrosion, this phenomenon is not visible from the outside – by the time it is discovered, the structure often will have already sustained lasting damage.

Effective Water Protection

Hydrophobic (water-repellent) surface impregnation with silanes is an efficient solution for preventing damage to concrete. This treatment stops water from penetrating from the outside while still allowing moisture to escape from within. Impregnation offers lasting resistance to UV light and the elements, and even provides protection when cracks form. This extends the service life of the concrete while avoiding the high costs of renovations.

Passivation Layer

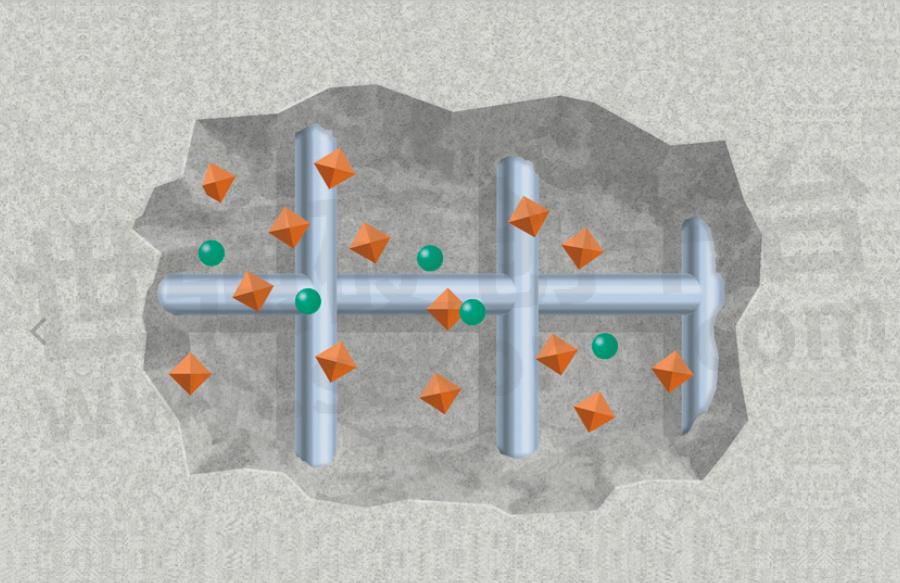

Fresh concrete is highly alkaline, which passivates the reinforcement steel.

Full-Surface Corrosion

Salts such as chlorides and acidic gases (e.g. CO2) penetrate concrete along with water. If they reach the steel, they dissolve the passivating layer of protection.

Pitting Corrosion

Spotty corrosion (pitting) is the first sign that steel has begun to corrode and will continue to spread. The process of rusting iron is associated with a drastic increase in volume (bursting force), causing the layer of concrete above the reinforcement to rupture.

The Best Protection? Hydrophobization

Effectively protecting concrete from water can extend its service life significantly. There are two ways to do this:

Integral treatment

This involves adding a polymer agent to the mix that will protect the concrete from water penetration and render it hydrophobic throughout. WACKER offers these binders under the brand name ETONIS®. Not only do these products make concrete water repellent, they also leave it highly resistant to the chlorides, acids, gases and other aggressive media dissolved in the water.

Hydrophobic coating

This involves adding a hydrophobic layer onto untreated concrete. Here WACKER’s weapons of choice are silanes and silicones. SILRES® BS is the brand name under which the company sells impregnation agents that penetrate deep into the surface of the concrete and become chemically anchored there. Unlike film-forming impregnation, treating concrete with these products will both retain the physical properties of the structure and produce a longer-lasting hydrophobic effect.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由Jo转载自WACKER Official Website,原文标题为:Straight to the Core,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

瓦克基于硅烷浸渍技术提供SILRES® BS CRÈME C CN膏体硅烷助力桥梁和隧道发展无惧风雨侵蚀

瓦克有丰富的产品,不仅有膏体硅烷SILRES® BS CRÈME C CN,还有SILRES® BS 1701 液体硅烷,都具备优异的性能,为混凝土的应用保驾护航。

WACKER’s SILRES® BS 6920 Silane-terminated Binder Provides A Reliable Protection from Stains and Wear for Concrete Floors

The SILRES® BS 6920 binder for impregnating concrete is based on WACKER’s alpha-silane technology, and combines outstanding soiling resistance with high mechanical strength.

Microchips Are Manufactured Using Polysilicon and Specialty Chemicals Made by WACKER

Without polycrystalline silicon, digitalization would be unthinkable. Glossy and silvery in appearance, polysilicon is among the purest man-made materials and the most important raw material required in the semiconductor industry. Today, nearly one in two microchips are manufactured using polysilicon made by WACKER. And by no means is this WACKER’s only contribution to the industry. Apart from polysilicon, process chemicals by WACKER also play a key role – and the demands on purity and quality are high.

ITW(依工聚合)粘合剂/密封剂/点胶设备/耐磨化合物/环氧树脂/聚氨酯 选型指南

描述- ITW Performance Polymers offers a wide range of products to the mining, coal-fired power, alternative energy (wind), transportation, marine,composites, engineered construction and general industrial markets.

型号- DEVCON® HP 250,MA8120 GB,MA300,MA420,SC VELR 4000,SC 7315,PLEXUS® MA2000 SERIES,PDR 9000,PLEXUS® MA420W,MA8105 GB,SC PDR 9000,SC 1050,SC 1500-LS,PC-120,PLEXUS® MA2030,PLEXUS® MA2045,MA1020,MA2230,PLEXUS® PU2105,MA310,MA1025,MA550,PLEXUS® MA832,SC 2000-OS LS,PLEXUS® MA830,GPE 30,PLEXUS® MA205HV,PLEXUS® MA320,TE 2400,SC PDR 6000,MA425,SC 4055,SC 1060,MA422,AO420,SC ALPHACOA® 1700,PU2105,PLEXUS® MA8105 GB,MA2245,PLEXUS® MA420FS,SC 900,PLEXUS® MA422,PLEXUS® MA300,PLEXUS® MA425,ALPHACOAT® 1710,MA560-1,PLEXUS® MA550,PLEXUS® MA8000 SERIES,PLEXUS® MA310,EPOXY PLUS™ 25,PLEXUS® MA2290,MA530,MA2015,F-2,SC 2000-CM,PDR 6000,PLEXUS® MA560-1,PLEXUS® MA420,GPE 100,SC 4000 HDT,ALPHACOAT 1700,MA920,PLEXUS® H4110,SC ALPHACOAT® 1700,SC 5000,PLEXUS® MA2230,PLEXUS® MA1020,GPE 3,PLEXUS® MA1025,PLEXUS® MA920,MA8110 GB,TE 1000,PLEXUS® MA530,DEVCON® FLEXANE® 80,ALPHACOAT 1710,MA590,PLEXUS® MA2000,PLEXUS® MA2245,MA420W,H4110,PLEXUS® MA8110 GB,SC 4600 HTT,2000-OS LS,ALPHACOAT® 1700,MA420FS,DEVCON® FLEXANE® 94,MA2030,MA2045,SC 4500,MA320,PLEXUS® MA2015,FLEXANE® FL-10,DEVCON® EPOXY COAT™ 7000 AR,SC 2000-HS,PLEXUS® MA590,DEVCON® CLEANER BLEND 300,DEVCON® EPOXY COAT™ 7000 NON-VOC,MA832,PLEXUS® MA8120 GB,MA830,DEVCON® WEAR GUARD™ 300RTC,DEVCON® EPOXY PLUS™ 25,SC 2045,SC 1070,SC 6000,SC1070,SC 1800-LS,DEVCON® EPOXY COAT™ 7000,GPE 15,WR-2,FLEXANE® FL-20,DEVCON® DEV-THANE™ 5,MA205HV,1800-LS,SC 2000-OS,MA2290,SC 4750,PLEXUS® MA8000

WACKER Presents Silicone-Based Solutions for Electromobility and Medical Applications

At Silicone Expo Europe, the WACKER Group is showcasing silicone-based product solutions for specific industrial sectors. The focus is on silicone gels for wound care, non-postcuring liquid silicone rubber for the food industry and medical technology, and self-adhesive liquid silicone rubber grades that adhere to polycarbonate and other high-performance plastics.

LIOSIL®HC 621 E:一种基于硅树脂的水基无氟浸渍剂

描述- LIOSIL® HC 621 E是一种水性、无氟硅基浸渍剂,主要用于提高现代纺织品的防水性能。该产品适用于户外服装等高性能纺织品,能够通过洗涤过程实现显著的防水效果,同时保持织物的透气性。LIOSIL® HC 621 E还具有耐湿度、防污渍、表面增强和更新等功能,适用于多种基材,如木材、石材、地板、纺织品等。

型号- LIOSIL ®,LIOSIL ® HC 621 E

Devcon(得复康)/Permatex(泰扬)MRO & OEM胶粘剂选型指南

目录- Maintenance and Repair Products MRO Applications Product Selector Guide Surface Preparation Metal Repair Putties Metal Repair Liquids Abrasion Resistant Wearing Compounds Urethane Casting Compounds Urethane Repair Compounds Flooring Repair & Resurfacing And Product Selector Guide Emergency Repair Products Assembly and Repair Threadlockers Liquid and Gel Threadlockers Retaining Compounds Thread Sealants Gasket Makers Permatex Anti-Seize Lubricants Gasket Sealants Specialty Adhesives OEM Adhesives Epoxy Adhesives Instant Adhesives Urethane Adhesives Dispensing Systems Mix Nozzle Selector Guide Agency Approvals and Reference Charts Item Numbers

型号- 15260,14210,10130,11340,11460,13120,25224,DF039,25228,81724,81725,80003,24250,27125,24010,29025,10770,81173,15820,15940,13800,11500,12710,19510,10260,11470,12560,13130,85080,11350,30095,85519,85915,13090,80628,27010,09128,27250,80078,80633,80632,51531,14500,10780,80071,81160,51813,14503,14270,19600,13100,14277,70213,17140,70450,26250,80022,24350,10110,11320,FL-20,10230,14278,14279,15800,10080,15250,13110,14200,10240,11450,14285,17150,14280,27110,57535,77124,80011,81860,31163,80017,80016,25210,80015,15810,15656,10120,11330,14289,10760,FL-10,11730,56725,14250,14251,82180,10050,14255,11780,15980,81409,70350,72250,27725,54550,80045,60950,24210,33694,11781,15985,11420,10210,12750,51845,10610,81095,DA999,15350,17130,14265,15990,81915,24225,24105,81878,72261,81913,10220,10620,15043,14350,82080,15047,10270,11480,17100,80855,51580,85913,11767,11800,26210,59225,56750,3333,11760,11762,15049,68050,14630,10710,11765,14240,11490,15850,13550,19770,70144,15330,26225,80208,15050,DA052,24325,77164,72161,56525,DA051,27036,31120,59235,27037,56521,80050,11770,11495,11410,85224,27150,82194,10720,14404,29050,82195

瓷砖的三大趋势及其对瓷砖胶粘剂的影响

描述- 瓷砖在全球范围内流行,现代瓷砖种类繁多,包括瓷质、玻璃、复合材料和合成材料等,外观多样。瓷砖粘合剂的需求也随之增加,传统粘合剂难以满足现代瓷砖的需求。聚合物改性技术能够提升粘合剂的性能,适应不同瓷砖的粘合需求。新型瓷砖粘合剂不仅提高了施工效率,还降低了材料消耗和碳排放。瓷砖趋势包括自然石材和木纹瓷砖、新型形状和结构、大尺寸瓷砖等,对粘合剂的要求也越来越高。

用于光学粘合的LUMISIL®产品–高度可靠的硅树脂解决方案

描述- 本资料介绍了WACKER LUMISIL®系列光学粘合硅酮产品,包括UV系列和热固化系列。这些产品具有高透明度、低黄变、低收缩率、低介电常数等特点,适用于光学粘合、封装、减震元件等应用。

型号- UV,LUMISIL® SERIES,307 UV DAM,203 UV,612 PT,LUMISIL ® 205 UV,205 UV,LUMISIL ® 203 UV,LUMISIL ® UV SERIES,LUMISIL ® 102,LUMISIL ® 202 UV,245 UV,LUMISIL ® 100,LUMISIL ® 245 UV,LUMISIL ® 105,LUMISIL ® UV,100,102,102 FC,LUMISIL ® 307 UV DAM,SILGEL® 612 PT,105,LUMISIL ® 102 FC

用于热管理的硅树脂解决方案

型号- WACKER SILICONE PASTE P12,SEMICOSIL ® 961 TC,SEMICOSIL ® 962 TC,SEMICOSIL® 962 TC,SEMICOSIL® 961 TC,SEMICOSIL® 9712 TC,SEMICOSIL ® 975 TC,SEMICOSIL® TC,SEMICOSIL® 970 TC,SEMICOSIL ® 970 TC,SEMICOSIL ® 973 TC,ELASTOSIL ® RT 607,SEMICOSIL ® 971 TC,SEMICOSIL ® 973 T,ELASTOSIL ® RT 743 LV-K,ELASTOSIL ® RT 747 TC,SEMICOSIL® 971 TC,ELASTOSIL ® RT 740,SEMICOSIL ® PASTE P40 TC,SEMICOSIL ® 963 TC,ELASTOSIL ® RT 675,SEMICOSIL ® 9712 TC

为您的硅树脂增添一抹色彩

描述- 本资料介绍了WACKER公司生产的ELASTOSIL®彩色硅橡胶浆料,包括FL和PT两种类型。这些浆料适用于多种硅橡胶产品,提供丰富的颜色选择。资料详细列出了各种颜色的RAL编号、适用标准和认证信息,并强调了产品在食品接触和生物相容性方面的合规性。此外,资料还提到了特殊颜色浆料和透明浆料的可用性,以及如何定制特殊颜色配方。

型号- ELASTOSIL® COLOR PASTE FL OCHRE BROWN,ELASTOSIL ® COLOR PASTE FL LIGHT GREEN,ELASTOSIL® COLOR PASTE FL ZINC YELLOW,ELASTOSIL ®,ELASTOSIL® COLOR PASTE PT DARK BROWN,ELASTOSIL® COLOR PASTE FL RED BROWN,ELASTOSIL® COLOR PASTE FL UV FLUORESCENT,ELASTOSIL® COLOR PASTE FL BLACK,ELASTOSIL® COLOR PASTE FL TRAFFIC GREEN,ELASTOSIL® COLOR PASTE PT TRAFFIC RED,ELASTOSIL® COLOR PASTE FL SILVER,ELASTOSIL® COLOR PASTE PT BASIC BLACK,ELASTOSIL® COLOR PASTE PT DARK BLUE,ELASTOSIL ® COLOR PASTE FL YELLOW GREEN,ELASTOSIL® COLOR PASTE PT LASER MARKING BLACK,ELASTOSIL® COLOR PASTE FL WHITE,ELASTOSIL® COLOR PASTE FL PAPYRUS WHITE,ELASTOSIL ® COLOR PASTE FL SIGNAL VIOLET,ELASTOSIL® COLOR PASTE FL GERBERA RED,ELASTOSIL® COLOR PASTE PT PURE ORANGE,ELASTOSIL® COLOR PASTE PT RASPBERRY RED,ELASTOSIL® COLOR PASTE PT HELIOGREEN,ELASTOSIL® COLOR PASTE FL RED IRON OXIDE,ELASTOSIL® COLOR PASTE PT ULTRAMARINE BLUE,ELASTOSIL® COLOR PASTE FL L7\SER MARKING WHITE,ELASTOSIL ® COLOR PASTE FL BLOOD ORANGE,ELASTOSIL ® COLOR PASTE FL LIGHT BLUE,ELASTOSIL® COLOR PASTE FL GRAY,ELASTOSIL® COLOR PASTE PT ULTRAMARINE BLUE ELASTOSIL® COLOR,ELASTOSIL® COLOR PASTE FL BEIGE RED PANTONE 7514 C,ELASTOSIL® COLOR PASTE FL AZORES BLUE,ELASTOSIL® COLOR PASTE FL ULTRAMARINE BLUE,ELASTOSIL® COLOR PASTE FL PURPLE VIOLET,ELASTOSIL® COLOR PASTE FL BLUE 5002 TRANSLUCENT,ELASTOSIL® COLOR PASTE FL DEEP BLACK,ELASTOSIL® COLOR PASTE PT SILVER,ELASTOSIL® COLOR PASTE FL RED,ELASTOSIL® COLOR PASTE PT GREEN,ELASTOSIL® COLOR PASTE FL PARLOUR RED,ELASTOSIL® COLOR PASTE PT LASER MARKING WHITE,ELASTOSIL® COLOR PASTE FL ORANGE,ELASTOSIL® COLOR PASTE PT BLUE,ELASTOSIL® COLOR PASTE PT TRAFFIC WHITE,ELASTOSIL® COLOR PASTE FL IVORY,ELASTOSIL® COLOR PASTE FL MAIZE YELLOW,ELASTOSIL® COLOR PASTE PT WHITE,ELASTOSIL® COLOR PASTE FL SQUIRREL GRAY,ELASTOSIL® COLOR PASTE PT TRAFFIC GREEN,ELASTOSIL® COLOR PASTE FL GFW,ELASTOSIL® COLOR PASTE FL PEARL ORANGE,ELASTOSIL® COLOR PASTE FL RED VIOLET,ELASTOSIL® COLOR PASTE FL RASPBERRY RED,ELASTOSIL® COLOR PASTE FL IRON GRAY,ELASTOSIL® COLOR PASTE FL BLUE LILAC,ELASTOSIL® COLOR PASTE PT VIOLET,ELASTOSIL® COLOR PASTE FL ICEBLUE 34070,ELASTOSIL® COLOR PASTE FL YELLOW GREEN,ELASTOSIL® COLOR PASTE FL LIGHT BUJE,ELASTOSIL® COLOR PASTE FL HYGIENE GREEN,ELASTOSIL® COLOR PASTE PT YELLOW,ELASTOSIL® COLOR PASTE PT RED VIOLET,ELASTOSIL® COLOR PASTE PT RED,ELASTOSIL® COLOR PASTE FL GREEN,ELASTOSIL® COLOR PASTE PT LIGHT BLUE,ELASTOSIL® COLOR PASTE PT GRAY,ELASTOSIL® COLOR PASTE FL LIGHT GREEN,ELASTOSIL® COLOR PASTE PT ORANGE,ELASTOSIL ® COLOR PASTE FL ZINC YELLOW,ELASTOSIL® COLOR PASTE FL TRAFFIC WHITE,ELASTOSIL® COLOR PASTE FL PURE ORANGE,ELASTOSIL® COLOR PASTE PT DEEP BLACK,ELASTOSIL® COLOR PASTE PT LIGHT BROWN,ELASTOSIL ® COLOR PASTE FL PURPLE VIOLET,ELASTOSIL® COLOR PASTE PT RED BROWN,ELASTOSIL® COLOR PASTE FL L7\SER MARKING BLACK,ELASTOSIL® COLOR PASTE FL MOUNTAIN BLUE,ELASTOSIL ® COLOR PASTE FL TRAFFIC GREEN,ELASTOSIL® COLOR PASTE FL SIGNAL VIOLET,ELASTOSIL® COLOR PASTE FL MAY GREEN,ELASTOSIL® COLOR PASTE FL DARK BLUE -,ELASTOSIL® COLOR PASTE FL PASTEL ORANGE,ELASTOSIL ® COLOR PASTE FL MAIZE YELLOW,ELASTOSIL ® COLOR PASTE FL BLUE LILAC,ELASTOSIL® COLOR PASTE FL BUJE,ELASTOSIL® COLOR PASTE FL L7\SER MARKING BLACK TRL,ELASTOSIL® COLOR PASTE PT BLACK,ELASTOSIL® COLOR PASTE FL HELIOGREEN,ELASTOSIL® COLOR PASTE FL YELLOW,ELASTOSIL® COLOR PASTE FL BLOOD ORANGE,ELASTOSIL ® COLOR PASTE FL MAY GREEN,ELASTOSIL ® COLOR PASTE FL PEARL ORANGE,ELASTOSIL® COLOR PASTE FL WINDOW GRAY,ELASTOSIL® COLOR PASTE FL PINE GREEN,ELASTOSIL® COLOR PASTE FL BLUE 5026 D,ELASTOSIL® COLOR PASTE FL SIGNAL GREEN,ELASTOSIL® COLOR PASTE PT LASER MARKING BLACK TRL,ELASTOSIL® COLOR PASTE FL LIGHT GRAY,ELASTOSIL® COLOR PASTE FL DUST GRAY,ELASTOSIL ® COLOR PASTES,ELASTOSIL® COLOR PASTE FL LIGHT BLUE,ELASTOSIL ® COLOR PASTE FL RED BROWN

硅酮燃料电池的创新

描述- 本文介绍了燃料电池在电动汽车中的应用及其密封技术。文章强调了硅橡胶在燃料电池密封方面的作用,包括其在不同生产过程中的应用,如注塑、丝网印刷和点胶等。此外,还提到了WACKER公司提供的多种硅橡胶产品,这些产品具有优异的耐热性、降解抵抗力和机械性能,适用于燃料电池的各种密封需求。

型号- ELASTOSIL® LR 3005/30,ELASTOSIL® LR 3005,ELASTOSIL® RT 624,ELASTOSIL® LR 3005/60,ELASTOSIL® LR 3025/40,ELASTOSIL® RT 621,ELASTOSIL® LR 3005/50,ELASTOSIL® LR 3005/40,ELASTOSIL® LR 3003,ELASTOSIL® LR 3025

硅树脂——无限可能的世界

描述- 硅化学在技术进步中扮演着重要角色,尤其是以石英砂为原料的硅。资料介绍了硅及其化合物(如硅烷、硅油、硅橡胶)的结构、性质和应用。从基础材料到最终产品,包括汽车、建筑、纺织、电子等行业中的应用。此外,还讲述了Wacker公司在硅化学领域的先驱地位和发展历程。

用于制药、农业和工业应用的生命科学化学品

描述- WACKER提供高品质精细化学品,包括环糊精、有机酯、二酮、硅烷化剂等,应用于制药、农业和工业领域。公司拥有百年专业经验,全球生产网络,致力于可持续发展。WACKER提供定制合成服务,并拥有高度集成的生产系统,确保高质量和供应安全。

型号- CAVASOL® W7 M LIFE SCIENCE,CAVAMAX® W8 PHARMA,HCA H.P.,SILAZANE HMDS,DIMEXAZOLE,CAVASOL® W7 HP TL,CADEA,CAVASOL® W7 HP PHARMA,CLACH,ACAN,METAC,CAVASOL® W6 HP TL,CAVAMAX® W6 PHARMA,CAVAMAX® W7 PHARMA,2-CL-ACE,VERSA® 12,2,5-DMP,MDO,CAVASOL® W7 M,BTTBS,ACAC,1,1,1-TCA,CAVASOL® W7 HP,MADMA,1,1-DCA,SILANE ODM2 IN TOLUENE,3,5-DMP,HCA,SILANE ODM-DMO,MCA,CMDO,SILANE ODM,CAVASOL® W8 HP PHARMA,SILANE M3, TMSCL,SILANE M2,CAVAMAX® W6,CAVAMAX® W7,SILANE CMM3,CAVAMAX® W8,SILANE CMM2,SILANE E3, TESCL,SILANE CMM1,CADMA,1,1,3-TCA,CAVASOL® W7 M TL,3-CL-MEK,IPA,SILANE OM-DMO

ELASTOSIL®e-novation适用于由硅树脂制成的电缆和连接器

型号- ELASTOSIL ® LR 3842/60,ELASTOSIL ® LR 3844/40,ELASTOSIL ® LR 3841/50,ELASTOSIL ® LR 3842/40,ELASTOSIL ® LR 3846/20,ELASTOSIL ® R 401/60 S,ELASTOSIL ® LR 3843/30,ELASTOSIL ® LR 3844/20,ELASTOSIL ® LR 3072/40,ELASTOSIL ® LR 3856/30,ELASTOSIL ® R PLUS 4806/20,ELASTOSIL ® LR 3070/50,ELASTOSIL ® R 420/70 S,ELASTOSIL ® R 510/60 S,ELASTOSIL ® LR 3844/30,ELASTOSIL ® LR 3842/50,ELASTOSIL ® R 401/70 S,ELASTOSIL ® LR 3846/30,ELASTOSIL ® LR 3844/50,ELASTOSIL ® LR 3842/70,ELASTOSIL ® LR 3072/50,ELASTOSIL ® LR 3072/30,ELASTOSIL ® R PLUS 4070/60,ELASTOSIL ® LR 3856/20,ELASTOSIL ® R PLUS 4305/60 S,ELASTOSIL ® R 420/60 S,ELASTOSIL ® LR 3065/30,ELASTOSIL ® LR 3070/60,ELASTOSIL ® LR 3065/50,ELASTOSIL ® R 510/70 S,ELASTOSIL ® R PLUS 4305/70,ELASTOSIL ® R PLUS 4846/30

电子商城

登录 | 立即注册

提交评论