NMC vs NCA Battery Cell: What’s the Difference?

In the world of rechargeable batteries, NMC (Nickel Manganese Cobalt Oxide) and NCA (Nickel Cobalt Aluminum Oxide) cells are two prominent chemistries widely used in various applications, particularly in electric vehicles (EVs), unmanned aerial vehicles (UAVs) and consumer electronics. Both types offer distinct advantages and are chosen based on specific requirements of energy density, power output, and longevity. Understanding the differences between NMC and NCA cells can help in selecting the right battery for a given application.

What is an NMC Cell?

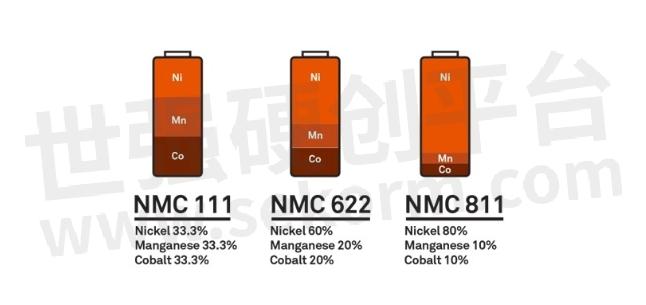

An NMC battery cell, or Nickel Manganese Cobalt Oxide cell, is a type of

lithium-ion battery that uses a cathode made from a combination of nickel,

manganese, and cobalt. The specific ratio of these elements can vary, with

common compositions being NMC 811 (8:1:1), NMC 532 (5:3:2), and NMC 622 (6:2:2).

These ratios represent the proportion of nickel, manganese, and cobalt used in

the cathode material. NMC cells cathodes typically contain large proportions of

nickel, which increases the battery’s energy density. However, high nickel

content can make the battery unstable, which is why manganese and cobalt are

used to improve thermal stability and safety. NMC cells are known for their

balance between energy density, power output, and stability.

What is an NCA Cell?

An NCA battery cell, or Nickel Cobalt Aluminum Oxide cell, is another type

of lithium-ion battery that uses a cathode composed of nickel, cobalt, and

aluminum. Instead of manganese, NCA uses aluminum to increase stability. The

typical composition for NCA cells is usually around 80% nickel, 15% cobalt, and

5% aluminum. This high nickel content contributes to the cell's high energy

density and specific energy. NCA cells are renowned for their long cycle life

and high energy output, making them suitable for high-demand applications.

What is the Difference Between NMC and NCA Cells?

While both NMC and NCA cells are used in lithium-ion batteries, they have

distinct differences in terms of composition, performance characteristics, and

applications:

●Energy Density: The energy density of an NMC battery is typically in the range of 150 to 220 Wh/kg. The energy density of an NCA battery is generally higher than NMC batteries, ranging from 200 to 260 Wh/kg. However, with advancements in technology, the energy density of NMC batteries has now increased. For example, Grepow can produce NMC battery cell with an energy density of up to 350 Wh/kg.

●Thermal Stability: NMC cells tend to have better thermal stability, making them safer and more suitable for applications where battery safety is a significant concern.

●Cost: NCA cells are often more expensive due to the higher cost of cobalt and the manufacturing processes required.

●Cycle Life: NMC cells typically have a longer cycle life compared to NCA cells, making them more durable in long-term applications.

What is the Use of NMC Battery?

NMC batteries are widely used in applications where a balance of energy

density, power, and cost is crucial. Some common uses include:

●Electric Vehicles (EVs): NMC cells are popular in EVs due to their balanced performance, providing both range and power.

●Drones and UAVs: Unmanned Aerial Vehicles and drones, especially those designed for long flight times and heavy payloads, can benefit from the high energy density of NCA batteries.

●Medical Devices: Medical equipment, such as portable defibrillators, infusion pumps, and monitoring devices, often use NMC batteries due to their reliability and long-lasting power supply.

What is the Use of NCA Battery?

NCA batteries are chosen for applications where high energy density and

long cycle life are critical. Their common uses include:

●Electric Vehicles (EVs): High-performance EVs, such as those produced by Tesla, often use NCA cells for their superior energy density and longevity.

●Consumer Electronics: NCA cells are used in laptops, smartphones, and other gadgets that require long battery life and high energy storage.

●Aerospace: Due to their high energy density and reliability, NCA batteries are used in aerospace applications.

Conclusion

Choosing between NMC and NCA battery cells depends on the specific

requirements of the application. NMC cells offer a versatile and cost-effective

solution with balanced energy and power characteristics, making them ideal for a

wide range of uses from EVs to power tools. On the other hand, NCA cells provide

higher energy density and longer cycle life, making them suitable for

high-performance EVs, consumer electronics, and aerospace applications.

Understanding these differences can guide you in selecting the right battery

technology for your needs. As a global leading lipo battery manufacturer, Grepow

offers professional standard and customizable NMC battery solutions to meet the

needs of all kinds of consumer and industrial applications.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由莫子若转载自Grepow Official Website,原文标题为:NMC vs NCA Battery Cell: What’s the difference?,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

What is a Silicon Anode Lithium-Ion Battery?

This article delves into the specifics of silicon anodes, their benefits, and the challenges they present.

【技术】格瑞普解析刀片电池的特点和优势

关于刀片电池相信各位一定有所耳闻,那么什么是刀片电池?它有什么特点和优势呢?本文格瑞普将为您进行介绍。

【技术】格瑞普解析导致锂电池电芯低容的原因有哪些

容量是电池的第一属性,锂电池电芯低容也是样品、量产中经常遇到的问题,在遇到低容问题后要怎么立刻分析出原因呢,本文格瑞普就来给大家介绍一下导致锂电池电芯低容的原因有哪些。材料的匹配特别是负极与电解液的匹配对电芯容量的影响尤为重大。

NMC 532 with Super-fast Charging Set to Be the Best Drone Fast Charging Battery

Grepow‘s Batteries to retain an above 90% capacity, even after 1000 full charge cycles (single cell), and at least 80% capacity after 700 cycles (Battery packs).

格瑞普电池选型表

格瑞普锂电池,磷酸铁锂电池,高压锂电池,镍氢电池,低温锂电池,快充电池,三元锂电池选型表。倍率(C):1~50C,容量(mAh):48~40000mAh,电压:1.2V~4.35V

|

产品型号

|

品类

|

倍率Rate(C)

|

Thickness(mm)

|

Width(mm)

|

Length(mm)

|

容量(mAh、mA)

|

Voltage(V)

|

|

CP6431122-R1A

|

三元锂电池

|

1C

|

6.4mm

|

31mm

|

122mm

|

3000mAh

|

3.7V

|

选型表 - 格瑞普 立即选型

2024无人机竞速联赛柯桥站,格瑞普R-LINE 5.0系列TATTU电池大放异彩,成为众多飞手信赖的选择

格瑞普研发生产的多款TATTU电池大放异彩,尤其是R-LINE 5.0系列的1550mAh、1480mAh及1400mAh型号,成为众多飞手信赖的选择。资格赛中,Minjae、王淼等一众顶尖飞手凭借卓越技术和装备优势,纷纷展现出非凡实力。

【经验】格瑞普解析MSD及MSD电池系统的作用

MSD电池系统作为一种高能量密度、长寿命、环境友好的新型电池系统,在电子设备领域具有广泛的应用前景。它的独特优势使得电子设备可以更长时间地保持高效工作,给用户带来更好的使用体验。同时,它的环保性能也符合当今社会对绿色可持续发展的要求。

揭秘格瑞普电芯:从电池原料到成品的制作工艺

格瑞普作为电池领域的先锋品牌,其技术部汇聚了超过200位资深工程师与技术精英,致力于电池技术的尖端研发与创新。公司配备了全面的电池产品测试与验证设备,确保每一款产品的卓越性能,更在产品研发、生产制造及技术创新上不断突破,为市场带来了一系列高性能、高安全性的电池产品。在生产层面,格瑞普坐拥四大现代化厂区,依托先进设备,能够灵活生产及定制包括镍氢电池、聚合物锂电池。

格瑞普负40度还能正常工作的磷酸铁锂电池,尺寸灵活,可进行专业化定制

深圳市格瑞普电池有限公司研发出了负40度还能正常工作的磷酸铁锂电池,一举打破了市场上的空缺,值得一提的是这负40度跟市场上大部分低温电池(可定制)产品不一样,格瑞普低温电池是实打实的低温。

电池pack厂格瑞普的pack原则

pack通过柔性(热缩膜或胶带),壳体或支架,辅以胶水,螺丝,卡扣或超声焊接等工艺,选配合适的保护板(BMS),做好绝缘与散热来实现电芯的多串并方案,由此满足终端客户的电气性能,寿命与环境使用要求。Pack是电芯实现使用价值的手段。今天就来看一下电池pack厂格瑞普的pack部分原则

【元件】格瑞普钢壳异形电池全新上市,为未来智能产品创新提供助力

格瑞普带着全球领先的钢壳异形电池产品和服务再次来到大众的视野!随着科技的进步,智能可穿戴设备愈发增多,且对产品空间的需求更加严格;因此,深圳市格瑞普特推出全新的,钢壳异形电池,为新时代的AI产品增加助力!

【技术】格瑞普解析无人机电池循环次数是多少及如何计算?

近年来随着短视频的兴起,无人机也越来越流行了,但很多朋友都对无人机电池使用寿命短而感到苦恼,因此很多小伙伴都关心无人机电池循环次数,想了解无人机电池循环次数是多少及怎么样计算无人机电池循环次数?本文格瑞普将为你详细介绍。

【经验】格瑞普解析锂电池出现鼓包的原因

锂电池的安全性有时候会得不到保证,另外如果使用不当或者是制作水平有限的话还是有一定的安全隐患的,就比如锂电池鼓包,那么锂电池为什么会出现鼓包现象呢?今天格瑞普来为大家讲解。

格瑞普-20度低温电池采用专有电池原料配方和创新生产制造技术,低温放电性能高,效率60%以上

格瑞普低温电池使用专有电池原料配方和创新生产制造技术,能有效提高电池在低温环境下的放电性能,降低电池内阻,达到高速放电的效果。因此,低温电池的寿命更长,动力更强。在-30°C的低温下以0.2c放电,格瑞普的低温电池放电容量仍然超过80%,这也是格瑞普的核心技术之一。

智能戒指或将成为可穿戴技术的未来,格瑞普提供多款高压弧形电池助力智能戒指消费应用发展

智能戒指属于可穿戴设备里最适于未来人机交互的入口,随着更多大科技公司的进入,其他公司很快就会效仿,并最终将智能戒指细分市场推向消费市场的顶端。格瑞普可提供12款高压弧形电池,助力智能戒指消费应用发展。

电子商城

登录 | 立即注册

提交评论