Kyocera Launches New Cut-off Solution “KGZ“ for Small Parts machining

A newly developed unique clamp structure and new insert shape realize high efficiency and stable machining. New specialized PVD coating released at the same time.

Kyoto, 20th June 2024. KYOCERA Corporation announced that it has developed a new cut-off solution, "KGZ", for small parts machining.

Small parts machining involves cutting into the center of the workpiece with an insert that has a cutting width of several millimeters. Therefore, the load on the tool is large, and the generation of chatter and breakage of the holder are major problems. In addition, there are some challenges regarding the workability of the machine, such as the need for a skilled operator to quickly and accurately replace and install inserts in a narrow space.

"KGZ" uses a newly developed clamp structure with three unique mechanisms to firmly lock the insert in place to suppress chatter and achieve stable machining. In addition, the constraint surface of the holder, which is easily subjected to machining load, has a shape that distributes stress, improving durability and realizing high-efficiency machining. In addition, the new insert has a redesigned V-shape groove structure on the top surface to improve restraint and workability.

Also, within the insert grades lineup, a newly developed PVD coated grade, "PR 20 series," for the KGZ was released. The new coating, "MEGACOAT®*1 NANO EX," which is resistant to oxidation and abrasion caused by cutting heat, achieves high precision, long tool life, and stable machining of steel, stainless steel, and cast iron.

*1 "MEGACOAT" is a registered trademark of Kyocera Corporation.

Features of "KGZ"

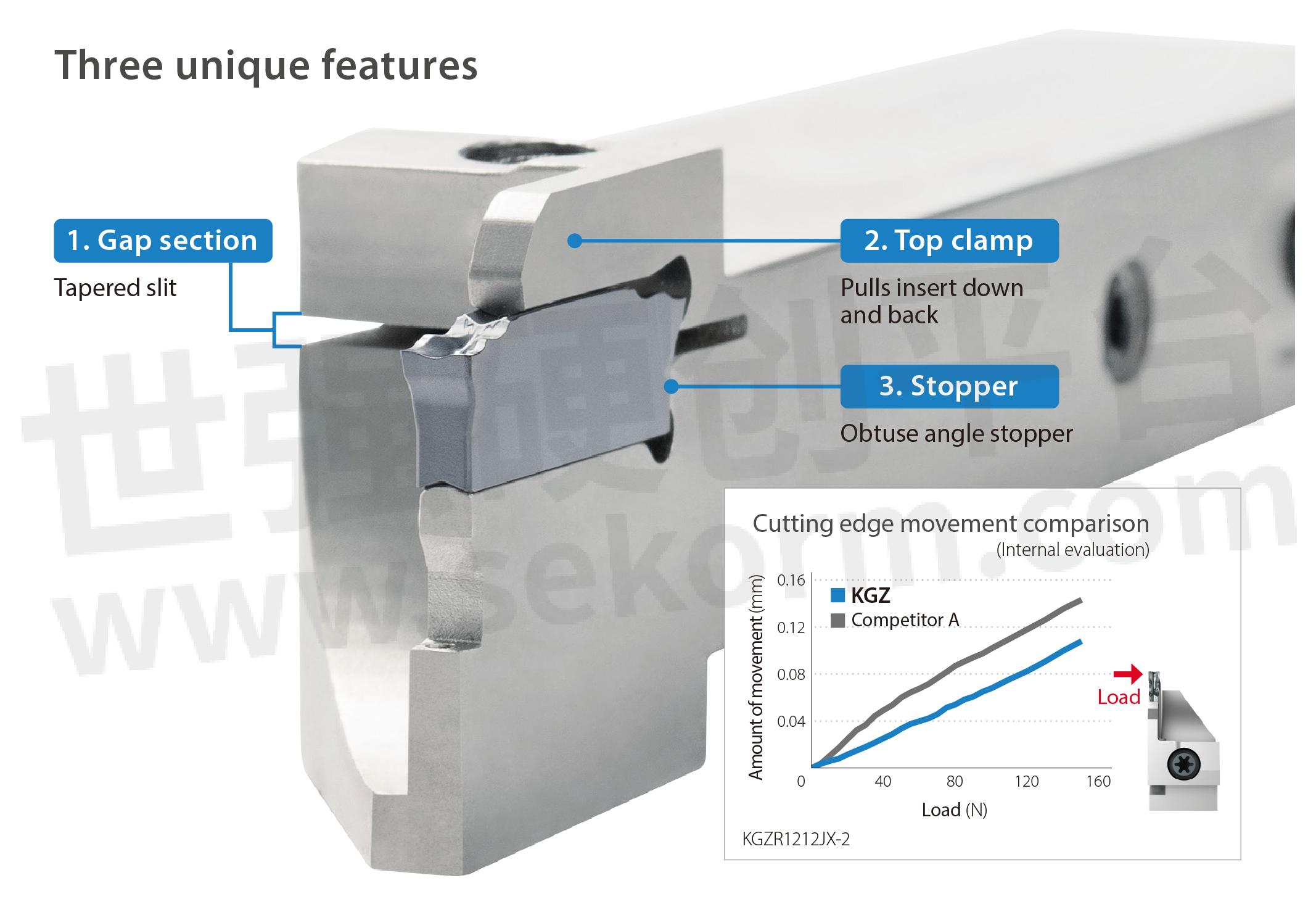

1. Stable and high-efficiency processing is achieved with a clamp structure equipped with three unique mechanisms.

The newly designed toolholder improves the holding force of the insert and the durability of the toolholder through three unique mechanisms: (1) Gap section, (2) Top clamp, and (3) Stopper.

1) Gap section: Press down on the insert from directly above to firmly secure in place.

Generally, it is structurally difficult to fix the insert directly

above with a cut-off tool. KGZ has a tapered slit with a slanted cut, so

when the fastening screw is tightened, it applies a restraining force

from directly above the insert, effectively securing it in place.

2) Top clamp: Pulls the insert inward to increase the binding force.

Designing

the shape so that force is applied inward when clamping the insert

suppresses the displacement of the insert in the front and rear

directions.

3) Stopper: Disperses stress over a large area and improves the durability of the holder.

KGZ uses a stopper as part holder blunt to create a large surface to receive the load and impact from the insert and disperse stress on the holder. As a result, the wear amount of the stopper is reduced to about one-third*2 that of other companies' products. The improved durability of the holder also enables it to withstand high-efficiency processing with high processing loads.

*2 Comparison of holder damage after 100,000 cuts (comparison conducted by Kyocera).

2. Unique V-shape groove improves restraining force and ease of fitting of the insert.

The V-shape groove on the upper surface of the insert has different

angles and shapes at both ends and the center, which improves the

restraining force and ease of installation.

1) Insert groove end

The ends are made more acute than the central part of the groove.

This design helps to reduce the play during insert installation and

makes it easier for the insert and holder to fit together correctly,

therefore preventing incorrect insertion and contributing to improved

workability in narrow spaces.

2) Center of groove

The central part increases the angle of the groove and improves the

restraint force of the insert by receiving the clamping force from the

upper direction on a large surface.

3. Newly developed insert grades "PR20 series" uses a special nano-layered coating, "MEGACOAT® NANO EX," to enable high-precision, long-life, and stable processing of steel, stainless steel, and cast iron.

Along with KGZ, Kyocera simultaneously released a new PVD coating, "PR20 Series,"*3 specialized for grooving and cut-off processing. A special nano-layered coating, "MEGACOAT® NANO EX for Grooving / Cut-off," newly developed for the PR20 Series, is born from our unique coating process. This coating offers wear resistance approximately two times*4 better than other companies' products in steel machining comparison because it uses aluminum (Al) as the coating's main materials, which has high-temperature hardness and wear resistance characteristics. The PR20 Series achieves high precision, long tool life, and stable machining as the main insert grades for grooving and cut-off machining of steel, stainless steel, and cast iron.

*3 The "PR 20 Series" is a lineup of 3 grades: PR2015, PR2025, and PR2035.

*4 Machining of S45C (comparison conducted by Kyocera).

- |

- +1 赞 0

- 收藏

- 评论 0

本文由莫子若转载自KYOCERA Official Website,原文标题为:Kyocera launches new cut-off solution "KGZ" for small parts machining,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Low Clamp Automotive TransGuard® Multilayer Varistors with Low Clamping to Working Voltage

型号- VLAS060316A350RP,VLAS121016J350,VLAS060334B650,VLAS080530D570,VLAS120616E350,VLAS060316A350,VLAS080516C350,VLAS080534C650

Low Clamp Automotive TransGuard® Multilayer Varistors with Low Clamping to Working Voltage Ratio datasheet

型号- VLAS060316A350RP,VLAS121016J350,VLAS120616E350,VLAS060316A350,VLAS080516C350

Passive Component Advancements for SPE Connectors and Circuit Protection Devices TECHNICAL PAPER

型号- 6780,SMAJ33CA,SMXJ,6780 SERIES,SMXJ SERIES

Kyocera(京瓷)连接器选型指南(中英文)

目录- FPC/FFC Connectors(FPC/FFC用连接器) Board to Board Connectors(板对板连接器) Hard Metric Connectors(硬性公制连接器) Memory Card Connectors(记忆卡用连接器) Card Edge Connectors(电路插卡连接器) Interface Connectors(接口连接器) Power Terminals(电源端子) Miniature Wire to Board Connectors(超小型电线对电路板连接器) Power Supply Connectors(电源连接器) Shield Locks(屏蔽罩锁扣) Shunt Connectors(开关连接器) Wire to Wire/Board Connectors(电线对电线/电路板镀锡连接器) LED Connectors(LED用连接器) Rack and Panel Connectors(机柜连接器) Branch Connectors(分流用连接器) INDEX(型号一览表)

型号- 6274,9069,8014,6232,9067,8017,6277,5861,8016,9021,6227,5655,5897,5656,6866,6824,8387,8024,6240,6284,8069,6287,5077,6200,6244,6288,8029,6841,5036,6401,8027,9072,8263,8261,5863,7129,5867,6251,6210,6298,6892,8077,6212,5046,6214,5047,6411,8071,8072,8073,6293,6806,6809,6808,6403,9715,6402,6801,6844,6407,6208,6406,5638,6409,5690,6262,5650,6224,5015,8005,9215,5090,8042,8040,6260,8041,8283,5805,5806,5807,9090,6810,5600,5689,5843,6811,5647,9609,5846,6815,5804

【选型】Kyocera(京瓷)整流、快恢复、肖特基二极管选型指南

目录- 符号和术语 型号快速查询表 分立器件特性表 接线图 外观尺寸图 包装样式

型号- EA40QC04,EC10DS4,FCG20BU15,EA30QS04-F,KSF60F60N,FCH10A20,FSH05A20,FCU10A30,EA60QC10,FSH05A10,FSU05A30,FSH05A15,GSF15F60,10EHA20,C10T20F-11A,FSHS05A065,GCH40EU10,FCU10A20,EC10DA40,FCH10A15,EC10QS10,EC11FS4,FCF10A20,GCF06A20,EC11FS2,FSQS05AU06532,FCH10A10,FSU05A40,FCGS10A12,FSF10A20,FCF06F60,KSF60F60B,EC10QS04,EC10QS06,NA05QSA035,FCHS20A12,NSH05A03,TCF20B60,NB06HA20,EC30HA03L,FCH20E10,FCHS08A12,NB10QSA035,FSQS10A045,FCHS20A08,FCQS20A065,NSH03A03L,NA05QSA045,C16T20F,FCF16A20,FCHS10A065,NA05HSA045,EA40QC10,FCF10A40,FCF20H60,FSQS10A06532,KCF25A20,NSF03B60,NSF03A40,TSF05A20,NA03HSA065,NB06HA15,FCU10A40,EA60QC04-F,KCF16A40,EA20QC04-F,C16T20F-11A,EA30QS03L-F,FSD20A90,ESF08HU60B-F27,FCQ08A04,EC21QS10,EA20QS06-F,EA21FC2,FRF10A20,EA21FC4,FCQS10A045,FSF15H60,FCG30AU15,FSF08F60,FCHS20A045,FCQS20A045,NB06QSA045,FCH20BU15,KSU60D60N,FCH20BU10,NA05HSA065,EC10LA03,FCGS20A12,FRH20A10,GCF10A40,EA20QS10-F,FSQS15A045,FRH20A15,11EFS2,FSH04A10,11EFS4,FCHS30A065,FRH10A20,FSH10A15,FCGS20BU12,FSF05A40,NB10QSA045,NB10HSA12,FSH10A10,NB06QSA035,FCF16A40,NA03HSA08,EP05FA20,FCU20A20,FCH30A03L,FRH20A20,FSF05HU60,TCF10B60,11EQS03L,11EQS10,EA20QC10,FRF10A40,FSF05A20,FSU08D60,30GFA40,30GFB60,FCH40EU10,KCF20F60,GSF10HU60,EA60QC10-F,FSF10A20B,NA03QSA045,FCHS20A065,EA20QS10,EC10UA20,EC10QS03L,NB06QSA065,FRH10A15,FCH05A10,FSQS05A045,C16T40F,FCH20AU20,EA60QC03L-F,EC8FS6,FCF20F60,GCF10A20,TSF05B60-11A28,EA30QS04,FSF08H60,NB06HSA12,FCHS30A08,11EQS04,FCF10H60,VSF05A20,11EQS06,FCQS10A035,FCU10D60,EC31QS10,FCHS30A12,FCU20A40,FSF10A40,NB10QSA065,EA60QC06-F,FSQ05A03L,FCF06A20,FCHS30A045,GCF06F60,NA03QSA035,NA03HA20,NSH03A04,EC30HA04,20CFB60,EA20QS04-F,30GFA20,FSF05H60,20CFA40,EA31FS4,KSF30F60,FSF15F60,EP04RA60,FCH10AU10,ECU06B60-F,FCH10E10,NSH03A10,C16T40F-11A,NSH03A15,NA05QSA06531,FCF06A40,GSF08H60,NSF03E60,ECL06B03,GSF10A40,EA21FC4-F,EP05H10,FCGS30AU12,NA03HA15,C10T20F,EP10QY04,FSU15D60,EP10QY03,EP05DA40,FCG10AU15,FCQ06A04,FSH05A03L,FRQS20A065,FSF03F60,NSQ03A04,0.5EP05Q03L,FCQ06A06,EC30FH60,KSF60H60N,EP10LA03,FRH08A15,FSU20B60,GCH30E10,30GFD60,ECH06A20-F,NSQ03A06,FCQS10A065,FSQS05A06532,EA40QC10-F,SOD-323FL,EA61FC2-F,FCH20A15,NA03HSA12,EA61FC2,10EDB60,FSU10D60,ECQS10A035-F,FSF05A20B,ECL06B03-F,FCH20A10,NSHS05A065,EA30QS10-F,FCH06A10,10EDB40,EP05Q06,FCF10F60,EA61FC4,EP05Q04,FSF10HU60,GSF10A20,FRG20BU15,EA40QC06-F,FCH20A20,FSF10H60,FCU20D60,NA05HSA12,FRQS20A045,ESH05A15-F,EA30QS06-F,EC30FA20,FSF05F60,FCH20A03L,FSU20A60,KSF30H60,GSF15H60,FCQS30AU065,FSHS05A08,FSU10A20,GSF08F60,FCH10A03L,NA05HSA08,FSH10A03L,FCQ08A03L,FCQ30A03L,FCHS10A045,FCQS10AU045,FCQS30A045,NSU03A60,FCH08A10,NA03QSA06531,FCQ20A03L,TSF05B60,TSF05A40,FCQS30AU045,KCF25A40,NSF03A20,FSU05D60,C10T40F,NA03HSA045,KCF16A20,ECHS10A08-F,FSU10A30,GSF10H60,ECQS10A045-F,FCH08A15,EA21FC2-F,FSF03D60,ESF05H60-F,GSF05A20,FCHS10A12,FCH30A15,EC30FA40,FCH30A10,FSHS04A12,FCHS10A08,GCH20E10,EA20QC10-F,EP10HY03,FSU10A40,FCH08A06,FCU20D30,NSD03A40,EA31FS2-F,FSF05A40B,FCU06B60,FCQS30A065,FCGS10AU12,GCF06A40,FSQS30A045,FSU05A20,EA40QC04-F,GSF05B60,GSF05A40,EA60QC06,EA60QC04,EA20QC06-F,FSF10F60,NSQ03A03L

Kyocera(京瓷)工业TFT LCD显示屏选型指南

目录- TFT LCDs introduction TFT LCD,Value-Line TFT LCD LCD ToolKIT

型号- TVL-55731GD032J-LW-G-AAN,T-55548GD057JU-LW-ABN,T-55788GD121J-LW-AAN,T-55787GD104J-LW-ACN,TCG062HVLDA-G20,TCG057QVLGA-G00,TCG075VGLCE-G00,T-55149GD030J-MLW-AQN,TCG070WLPAANN-AN00,TCG084SVLQAPNN-AN20,T-51750GD065J-LW-AON,TCG075VGLDA-G00,TVL-55739GD032J-LW-G-AAN,TCG057QVLBA-G00,T-55619GD065J-LW-AAN,TCG057VGLCA-G00,TCG104SVLPAANN-AN20,TCG121SVLPAANN-AN*16,TCG121SVLQAPNN-AN20,TVL-55730GD035JU-LW-G-ABN,TVL-55789D133-LW-I-AAN,T-55786GD084J-LW-ACN,TCG084SVLP*ANN-AN*13,TVL-55724GD043J-LW-G-AAN,TVL-55684D140U-LW-I-AAN,T-55343GD035JU-LW-ADN,TCG121WXLP*PNN-AN*01,TVL-55737GD030J-LW-G-AAN,TVL-55729D090J-LW-I-AAN,TCG057QVLCA-G00,TCG057VGLCS-H50,T-55620GD057JU-LW-AAN,T-55520GD057J-LW-ACN,TCG085WVLQDPNN-GN00,TCG104VGLAAANN-AN20,T-55788GD121J-LW-ACN,TCG057QVLCS-H50,TCG070WVLPEANN-AN20,TCG084SVLPAANN-AN20,TVL-55682D101U-LW-I-AAN,TCG070WVLQAPNN-AN00,TCG075VGLEAANN-GN00,T-55787GD104J-LW-AAN,TCG043WQLBAANN-GN00,TVL-55733GD035J-LW-G-AAN,TCG057VGLGA-G00,TCG070WVLPAANN-AN50,TCG101WXLP*ANN-AN*03,TCG035VLPAANN-AN00,TVL-55683D116U-LW-I-AAN,TVL-55736GD032JR-LW-G-AAN,TCG104VGLABANN-AN50,TVL-55728D070J-LW-I-AAN,T-55265GD057J-LW-ADN,TVL-55738GD032J-LW-G-AAN,TCG121XGLP*PNN-AN*37,TCG085WVLCB-G00,TVL-55911D150-LW-I-AAN,TCG084VGLAAANN-AN50,TCG121SVLPAANN-AN20,T-55786GD084J-LW-AAN,TCG121SVLPBANN-AN00,TCG070WVLPEANN-AN30,TCG043WQLBAANN-GN50,T-55785GD070J-LW-ABN,TCG104SVLPEANN-AN30,TCG084VGLAAANN-AN00,TCG104SVLQAPNN-AN20,TVL-55790D133-LW-I-AAN,TCG084VGLACANN-AN00,T-51750GD065J-LW-ANN,TCG070WVLQEPNN-AN20,TVL-55806GD040J-LW-G-AAN,TCG057VGLBA-G00,TCG104VGLAAANN-AN00,TVL-55781GD050J-LW-G-AAN

【选型】Kyocera(京瓷)电容器选型指南(中文)

目录- 陶瓷电容器型号编制方法和形状、尺寸表 普通应用/薄型/低损耗/三端子陶瓷电容器 片状陶瓷电容器的试验方法和规格、结构图 产品包装介绍 使用注意事项 型号一览表

型号- CM105X6S106M10A#,CM316X7R226 □ 06A#,CM02CΔ8R0 □ 25A#,CU02CΔ220 □ 16A#,CM05X5R105 □ 16A#,CM03X7R472 □ 10A#,CM21X6S226M10A#,CM02X7R331 □ 16A#,CM316X7R106 □ 16A#,CM05系列,CM03X5R332 □ 25A#,CM21X5R475 □ 25A#,CU02CΔ5R0 □ 16A#,CU02CΔ9R0 □ 25A#,CM02X5R473 □ 06A#,CM21X7R225 □ 25A#,CM02X5R682 □ 16A#,CM05X5R225 □ 10A#,CT05系列,CT05,CU02CΔ4R0 □ 25A#,CT03,CM05X5R226M04AH,CT105,CM05X5R156M04A#,CM02CΔ1R0 □ 25A#,CM21,CM02CΔ820 □ 16A#,CM03CΔ5R0 □ 50A#,CM21X7R105 □ 50A#,CM316X7R226 □ 10A#,KNH05X5R156M04AH,CM32系列,CU系列,CT05X5R225M06A#033,CM系列,CM316X7S226 □ 10A#,CM105X7R105,CM21X5R476M06A#,CM03CΔ220 □ 50A#,CU02CΔ120 □ 25A#,KNH05,CM105X7R225 □ 06A#,CM21X7R105 □ 25A#,CM316X7R475 □ 50A#,CM03CΔ3R0 □ 50A#,CM21X7T226M06A#,CM02X5R333 □ 06A#,CM105X7R105 □ 10A#,CM32,CU02系列,CM02CΔ560 □ 16A#,CM02X5R102 □ 16A#,CM03X7R332 □ 10A#,CM03CΔ390 □ 50A#,CM02X5R153 □ 06A#,CM05X5R106M06AH,CM02X7R151 □ 16A#,CM32X5R106 □ 25A#,CM02X5R222 □ 16A#,CM03CΔ8R0 □ 50A#,CM,CM316X5R475 □ 50A#,CM105X5R475 □ 10A#,CM32X5R226 □ 25A#,CU02CΔ180 □ 16A#,CM03X5R683 □ 10A#,CU02CΔ7R0 □ 25A#,CT21,CM105X5R106M25A#,CM316X7S225 □ 100A#,CT,KNH05X6S435M02AH,CU,CM03X5R225M06A#035,CU02CΔ2R0 □ 25A#,CM03X5R105M16AH,CM05X5R475M10AH,CM03X5R473 □ 10A#,CT03X5R104 □ 06A#022,CM02CΔ470 □ 16A#,CM02X5R471 □ 16A#,CM02CΔ101 □ 16A#,CT系列,CM21X7S105 □ 100A#,CU02CΔR50 □ 25A#,CM02X7R222 □ 16A#,CM105X7T106,CM03X7R682 □ 10A#,CM02CΔ270 □ 16A#,CM03CΔ270 □ 50A#,CM05X5R105 □ 10A#,CM03CΔ1R5 □ 50A#,CM105X5R105 □ 25A#,CM03CΔ101 □ 50A#,CM105,CM05X5R225 □ 16A#,CT03系列,CU02CΔ3R0 □ 16A#,CM02X5R224M06A#,CM03X6S105M04AH039,CU02CΔ100 □ 16A#,CT105X5R105 □ 16A#055,CU02CΔ5R0 □ 25A#,CM05X5R104 □ 25A#,CM105系列,CM02CΔ6R0 □ 25A#,CM02X5R332 □ 16A#,CM02X7R681 □ 16A#,CT21X5R225 □ 50A#095,CM02X5R223 □ 06A#,CM05X5R474 □ 10A#,CM105X6T226M04AT,CM32X7R106 □ 50A#,CU02CΔ7R0 □ 16A#,CM02CΔ221 □ 16A#,CU02CΔR20 □ 25A#,CU02CΔ1R5 □ 25A#,KNH系列,CM03CΔ9R0 □ 50A#,CU02CΔ1R0 □ 25A#,CM02X7R471 □ 16A#,CM21X7R475 □ 16A#,CM21系列,CM02X7R152 □ 16A#,CM03X5R475M06AH055,CM03X5R475M04AH,CM316X5R225 □ 25A#,CM02CΔ3R0 □ 25A#,CM02X5R474M06A#,CM03X5R224 □ 10A#,CM32X5R106 □ 50A#,CM02CΔ220 □ 25A#,CM03X5R333 □ 10A#,CU02CΔ8R0 □ 25A#,KNH05X6S435M04AH,CM03X5R105M06A#,CM21X6S226M06A#,CM02CΔ330 □ 16A#,CM02X5R152 □ 16A#,CM05X5R475M16AH,CM03CΔ2R0 □ 50A#,CM03CΔ330 □ 50A#,CM02CΔ100 □ 25A#,CM105X5R475,CM02CΔ2R0 □ 25A#,CM32X5R106 □ 16A#,CM316X5R226 □ 16A#,CM03X5R225M10AH,CM02CΔ180 □ 25A#,CU02CΔ3R0 □ 25A#,CM03CΔ4R0 □ 50A#,CM03X5R104 □ 10A#,CM05X7R104 □ 25A#,CM03CΔ120 □ 50A#,CM05X5R105 □ 35A#,CM02X5R681 □ 16A#,CM03CΔ150 □ 50A#,CM02X5R221 □ 16A#,CM03X5R225M06AH,CM105X5R106,CU02CΔ120 □ 16A#,CM02X7R102 □ 16A#,CM32X7R106 □ 25A#,CT21X5R475 □ 16A#095,CM03CΔ820 □ 50A#,CM316,KNH,CU02CΔ4R0 □ 16A#,CM105X5R475 □ 25A#,CT105系列,CM02CΔ7R0 □ 25A#,CM02CΔ150 □ 25A#,CM02CΔ390 □ 16A#,CM02X5R103 □ 16A#,CM21X5R105 □ 50A#,CM316X5R225 □ 100A#,CM05X5R475M25AH,CM05X5R226M06AH080,CM03CΔ6R0 □ 50A#,CM03X5R474 □ 06A#,CM02X5R104 □ 10A#,CM21X5R106 □ 16A#,CT05X5R105 □ 06A#033,CU02CΔ150 □ 16A#,CM03CΔ560 □ 50A#,CM03CΔ470 □ 50A#,CM03CΔ180 □ 50A#,CU02CΔ6R0 □ 16A#,CM02CΔ120 □ 25A#,CM02CΔ4R0 □ 25A#,CM05X5R224 □ 16A#,CM316系列,CM05X7S225M04A#065,CT05X5R475M06AH033,CM02CΔ9R0 □ 25A#,CM02X5R331 □ 16A#,CM03X7R103 □ 10A#,CU02CΔ1R0 □ 16A#,CM03X5R103 □ 25A#,CM03CΔ1R0 □ 50A#,CM02X7R221 □ 16A#,CM SERIES,KNH05X5R435M04AH,CM02CΔ5R0 □ 25A#,CM02X5R472 □ 16A#,CM05X5R225,CM02X5R683 □ 06A#,CU02CΔ6R0 □ 25A#,CM03CΔ7R0 □ 50A#,CM03CΔ680 □ 50A#,CU02CΔ2R0 □ 16A#,CT SERIES,CU SERIES,CU02CΔ8R0 □ 16A#,CM02CΔ680 □ 16A#,CM03CΔ100 □ 50A#,CM03系列,CM21X5R226M10A#,CM316X5R106 □ 25A#,CM03X5R223 □ 10A#,CM03X5R225M06AH□□□,CU02CΔR20 □ 16A#,CU02CΔ1R5 □ 16A#,CM02X5R104 □ 06A#,CU02CΔ9R0 □ 16A#,CM05X7S105M04A#,CM05X5R156M06A#,CM02X5R151 □ 16A#,CM21X6S476M04A#,CM03X5R682 □ 25A#,KNH SERIES,CM105X5R225 □ 16A#,CM21X5R225 □ 25A#,CM21X7R106 □ 06A#,CM105X7R105 □ 16A#,CU02CΔ100 □ 25A#,CM02X5R101 □ 16A#,CM03X5R472 □ 25A#,CM02系列,CM02CΔ1R5 □ 25A#,CU02CΔR50 □ 16A#,KNH05X5R106M04AH,CU02,CM03X6S105M06AH039,CM32X7R226 □ 16A#,CM05,CM05X5R105 □ 25A#,CM316X7R106 □ 25A#,CM03,CM02X7R101 □ 16A#,CM02,CT21系列,CM316X7S475 □ 100AT,CM105X7T475 □ 10A#

Selecting KYOCERA AVX RF Chip Capacitors for Wireless Applications TECHNICAL DOCUMENT

型号- ATC100A4R7BW,KYOCERA AVX 100 SERIES,KYOCERA AVX 100

【选型】Kyocera(京瓷)喷墨打印头选型指南

目录- 喷墨打印头产品介绍 喷墨打印头(UV/水性/油性)选型表

型号- KJ4A-RH,KJ4B-0150,KJ4B-0360,KJ4B-QA,KJ4A-0300,KJ4B,KJ4A,KJ4C-0360,KJ4A-AA,KJ4B-1200,KJ4A-TA,KJ4B-YH,KJ4B-0300

【选型】Kyocera(京瓷)SKC TFT型号参数快速参考选型指南

目录- SKCTFT显示器 TFT显示器 TFT显示器高亮产品 SKC开发中型号(-S)

型号- TG060AALPAANN-GN20,TCG075VGLCX-G00,TCG062HVLDA-G20,TCG084VGLACANN-AN00-S,TCG084VGLAAANN-AN20,TCG057QVLPBAFB-GA00,TCG057VGLBA-H50,TCG084SVLPAAFA-AA30-S,TCG057VGLBD-G00,TCG075VGLCF-G00,TCG121XGLPAPNN-AN20,GTCG084SVLQAPNN-AN20,TCG057VGLGC-G00-S,TCG084SVLQAPFA-AA20,TCG057VGLCB-G00,TCG085WVLCL-G00,TCG084SVLPAANN-AN30,STCG057QVLAC-G00,TCG121SVLQAPNN-AN20,TCG121SVLPAANN-AN00,TCG035QVLPDANN-AN50,TCG104SVLQ*PFA-AA*53,TCG075VGLEAAFA-GA00-S,TCG057VGLGC-G50-S,TCG057QVLCA-G00,TCG057QVLCA-G01,TCG075VGLDA-G50,TCG057QVLAL-G00,TCG057VGLCAM-C50,TCG057VGLBA-G20,TCG070WVLQ*PNN-AN*180,TCG084SVLPAANN-AN20,TCG121WXLR*VNN-AN*26,STCG057QVLAF-G00,TCG084SVLQ*PNN-AN*32,TCG084SVLQ*PNN-AN*33,TCG070WVLPCANN-GN01,TCG070WVLPEAFA-AA20,TCG084SVLPAAFA-AA20,TCG070WVLQ*PGA-AC*181,TCG104VGLP*ANN-AN*46,TCG084SVLPAANN-AN30-S,TCG070WVLPEAFA-AA30,TCG101WXLPAANN-AN20-S,TCG121WXLR*VNN-AN*19,TCG121WXLR*VNN-AN*18,TCG121WXLR*VNN-AN*35,TCG070WVLPAANN-AN00-S,TCG104VGLA*ANN-AN*24,TCG104VGLAAANN-AN20-S,TCG104XGLPBPNN-AN70,TCG090WVLPBANN-GN00-S,TCG121SVLPAANN-AN20-S,TCG121XGLPAPNN-AN22-S,TCG043WQLBCBFA-GA50,TCG104SVLPAANN-AN20-S,TCG104SVLPBANN-AN20,TCG121XGLPCPNN-AN70,TCG104SVLPEANN-AN30,TCG084VGLAAANN-AN00,TCG062HVLDA-G22,TCG070WVLQEPFB-AA20,TCG057VGLCAJ-G00,TCG084VGLAAANN-AN00-S,TCG085WVLCA-G00,TCG121WXLR*VNN-AN*27,TCG057VGLBA-G00,TCG070WVLPAANN-AN00,TCG084SVLQAPNN-AN20-S,TCG057VGLBB-H50,TCG070WVLS*QP*-AN*202,TCG070WVLPAAFA-AA00,TCG075VGLCE-G00,TCG057QVLGC-G00GP,TCG057QVLPBANN-GN00,TCG104XGLP*PC*-AD*10,TCG075VGLDA-G00,TCG057QVLPEANN-GN00-S,TCG070WVLQ*PNN-AN*154,TCG075VGLDB-G00-S,TCG104XGLP*PC*-AD*17,TCG070WVLPEAFB-AA00,TCG062HVLQ*VNN*-GN*01,TCG043WQLBBANN-GN50,TCG043WQLBAAFA-GA50,TCG057QVLGC-G00,TCG057VGLBB-G20,TCG104SVLPBANN-AN00,STCG057QVLAA-G00-S,TCG121WXLRDVNN-AN70-E1,STCG057QVLAB-G00,TCG084SVLPAANN-AN20-S,TCG057QVLCT-H50,STCG057QVLAD-G00-S,TCG104XGLPAPNN-AN30,TCG057QVLAD-G02,TCG057QVLBA-H50,TCG057QVLAD-G00,STCG057QVLAB-G00-S,TCG057QVLCS-H50,TCG057QVLPEANN-GN00,TCG070WVLPEANN-AN20,TCG070WVLQGPGK-AD70,TCG104SVLQGPNN-AN40,TCG121WXLP*PC*-AD*20,TCG084VGLAAAFA-AA00,TCG043WQLBAANN-GN00,TCG075VGLP*ANN-GN*12,TCG035QVLPCANN-AN00,TCG035QVLPDAFA-GA50-S,TCG057VGLGA-G00,TCG104XGLPAPNN-AN40,TCG057QVLGA-G00GP,TCG035QVLPDANN-GN50-S,TCG075VGLDA-G20,TCG057VGLGA-G00-S,TCG057QVLCE-G00,TCG057QVLPPANN-GN00,TCG084SVLPAAGL-AB20,TCG057VGLBB-G00,TCG121SVLPBANN-AN00,TCG070WVLPEANN-AN30,TCG057VGLBB-G01,TCG121XGLPAPNN-AN20-S,STCG057QVLAG-G00,TCG035QVLPDANN-GN50,TCG084SVLPAAFA-AA20-S,TCG104SVLQAPNN-AN20,TCG085WVLCAANN-GN00,TCG075VGLDA-H50,TCG070WVLPEANN-AN00,STCG057QVLAA-G00,TCG057QVLHA-G50,TCG057VGLGA-G50-YA,TCG121SVLQEPNN-AN20,TCG062HVLQ*VC*-GD*06,TCG075VGLDB-G00,TCG070WVLPEANN-AN00-S,TCG121XGLPBPNN-AN40,TCG104SVLPAAGP-AC20,TCG104SVLQAPFA-AA20,TCG057QVLAJ-G00,TCG057QVLBA-G00,TCG121SVLRAPNN-AN20,TCG085WVLCU-G00,TCG104SVLPAANN-AN20,TCG084VGLAAAFA-AA50,TCG121SVLPAAFA-AA20,TCG057VGLAD-G00,STCG057QVLAM-G02-S,TCG070WVLQ*PF*-AA*162,TCG104SVLPAAGP-AB20,TCG057QVLAC-G01,TCG121SVLPBANN-AN20,TCG057QVLAC-G00,TCG070WVLPAAFA-AA50,TCG104SVLQ*PNN-AN*37,TCG057VGLCS-H50,TCG057VGLCS-H50-S,TCG070WVLQ*PGK-AD*182,TCG104VGLAAANN-AN20,TCG057VGLGC-G00,TCG043WQLBAAFA-GA00,TCG104SVLQAPCA-AD20,TCG057QVLCB-G00,TCG075VGLEAANN-GN00,TCG057QVLCB-G02,TCG057QVLBB-H50,TCG121XGLPBPNN-AN40-S,STCG057QVLAD-G00,TCG075VGLEAAFA-GA00,TCG035QVLPAANN-AN00,TCG057QVLBA-G20,TCG085WVLDT-G00,TCG104XGLPBPNN-AN701,TCG075VGLDB-H50,TCG070WVLPAAFB-AA00,TCG121SVLQ*PNN-AN*47,TCG121WXLPAPNN-AN20,TCG121SVLQ*PNN-AN*48,TCG104XGLPAPFA-AA30,TCG070WVLPCANN-GN01-S,TCG070WVLQEPNN-AN20,TCG075VGLEAANN-GN00-S,TCG062HVLDB-G20,TCG057QVLAK-G00,TCG057QVLBB-H30,TCG070WVLPAANN-AN50-S,TCG104VGLP*ANN-AN*25,TCG057QVLGA-G00,TCG070WVLPCANN-AN00,TCG057QVLCL-G00F,TCG057VGLCT-H50-S,TCG084SVLQAPNN-AN20,TCG104VGLPCANN-AN40,TCG121WXLPAPNN-AN20-S,TCG104SVLPAAFA-AA20-S,TCG057QVLPEANN-GN60,TCG057QVLCP-G00,TCG057VGLCA-G00,TCG121SVLPJANN-AN50,TCG085WVLCF-G00,TCG121SVLPAANN-AN*16,TCG057QVLBB-G20,TCG104VGLAAAFA-AA00,TCG084VGLAAAFA-AA00-S,TCG104XGLPAPNN-AN30-S,TCG070WVLQGPNN-AN40,TCG070WVLQGPNN-AN41,TCG070WVLPCANN-AN00-S,STCG057QVLAG-G00-S,TCG085WVLQDPNN-GN00,TCG035QVLPAAFA-AA00,TCG070WVLQAPNN-AN01,TCG070WVLQAPNN-AN00,TCG062HVLQ*VNN-GN*01,TCG057VGLCT-H51-S,TCG057QVLCC-G00,TCG070WVLPAANN-AN50,TCG070WVLQAPFA-AA00,TCG057QVLAF-G00,TCG057QVLPAAFB-GA00,TCG057QVLCL-G00,TCG104VGLABANN-AN50,TCG104SVLPAANN-AN00,TCG057VGLAAANN-GN20,TCG085WVLCB-G00,TCG057QVLBB-G00,TCG084VGLAAANN-AN50,TCG104VGLAAAFA-AA20,TCG121SVLPAANN-AN20,TCG101WXLPAANN-AN20,TCG104XGLPAPNN-AN31-S,TCG104SVLQ*PNN-AN*55,TCG104SVLQ*PNN-AN*52,TCG057QVLPEAFC-GA60,TCG084VGLACANN-AN00,TCG104SVLPAAFA-AA20,TCG104VGLAAANN-AN00

【选型】Kyocera(京瓷)陶瓷发热件选型指南

目录- 陶瓷发热件特点 陶瓷发热件结构 陶瓷发热件形状尺寸和热特性 陶瓷发热件升温特性列举 陶瓷发热件产品列举

型号- SN220,A473,SN362

【选型】Kyocera(京瓷)连接器汽车产品系列选型指南

目录- 连接器汽车产品应用 板对板连接器 FPC/FFC连接器 线对板连接器 记忆卡连接器 卡边连接器

型号- 5690,6251,6288,5036,6411,9215,5608,6806,6809,6810,5656,5678,6801,9515,5846

电子商城

品牌:硕凯电子

品类:Surface Mount Transient Voltage Suppressors

价格:¥0.1800

现货: 321,221

品牌:硕凯电子

品类:Surface Mount Transient Voltage Suppressors

价格:¥0.2800

现货: 278,016

品牌:硕凯电子

品类:Surface Mount Transient Voltage Suppressors

价格:¥0.2800

现货: 271,389

品牌:硕凯电子

品类:Surface Mount Transient Voltage Suppressors

价格:¥3.1500

现货: 256,351

品牌:硕凯电子

品类:Surface Mount Transient Voltage Suppressors

价格:¥0.2240

现货: 255,065

品牌:硕凯电子

品类:Surface Mount Transient Voltage Suppressors

价格:¥0.1656

现货: 239,840

品牌:硕凯电子

品类:Surface Mount Transient Voltage Suppressors

价格:¥0.2320

现货: 236,956

现货市场

服务

可定制丙烯酸酯胶粘剂的粘度范围:250~36000 mPa·s,硬度范围:50Shore 00~85Shore D,其他参数如外观颜色,固化能量等也可按需定制。

最小起订量: 1 提交需求>

可定制环氧胶的粘度范围:9000~170000 mPa·s;固化方式:可加热、仅室温、可UV;其他参数如外观颜色、硬度等也可按需定制。

最小起订量: 1支 提交需求>

登录 | 立即注册

提交评论