Infineon Continues to Partner with Boyd to Develop Improved Systems and Solutions for Cooling Electronics in HEV/EV

Infineon Technologies continues to partner with BOYD to develop improved systems and solutions for cooling electronics in hybrid and electric vehicles (HEV/EV). We see that EV and HEV production and consumer adoption is exponentially growing and will continue to as environmental standards push for cleaner, more compact, and less expensive transportation.

Customer demands require greater connectivity and more powerful internal electronics and vehicle operating systems in addition to already increased power requirements. New technologies and improved electronics ultimately result in additional waste heat. Without adequate thermal management, electronic reliability and lifetime required for vehicles running safely is significantly impaired to the point of device and system failure. Solutions like liquid cold plates and heat sinks safely remove heat from these crucial electronics to ensure reliable performance.

The Infineon/Boyd partnership enables our team to jointly design and produce fully optimized, highly effective cooling solutions for Infineon’s high-performance electronics for electric vehicles and hybrids.

Thermal Characterization of Infineon’s Double Side Cooled (DSC) MOSFETs and Boyd’s Dual Sided Liquid Cold Plates

The latest efforts of the Infineon/Boyd partnership produced a paper detailing the manufacturing of Boyd’s dual sided liquid cold plates, its thermal and hydraulic characteristics, and its impact on Infineon’s DSC Module. Engineers at both Infineon and Boyd collaborated in explaining the manufacturing process of the liquid cold plates, modeling and testing the DSC modules with a lab cooler and with Boyd’s DSC liquid cold plates, and comparison of a Si-IGBT DSC versus a SiC-MOSFET DSC module.

The Introduction of the HybridPACK™ and HybridKIT™

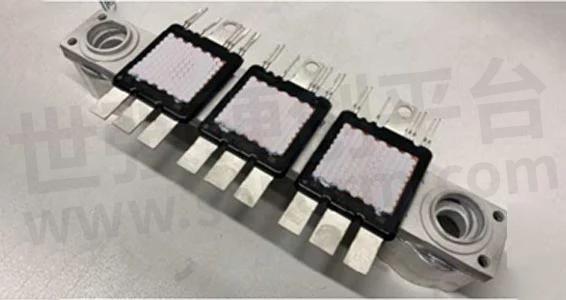

Boyd previously collaborated with Infineon to develop liquid cold plates for Infineon’s Double Side Cooled MOSFETS, the HybridPACK™ specifically designed for electric vehicles. Additionally, Boyd helped introduce the HybridKIT™, an all in one test kit ideal for research & development and initial prototyping. Due to excessive heat loads, sufficient cooling is necessary even for initial testing. Boyd’s specialty liquid cold plates dissipate large amounts of heat in a compact, lightweight form factor and offer greater design flexibility for developing prototype systems.

The HybridKIT™ includes electric drive modules, evaluation boards and drivers, and Boyd’s DSC liquid cold plate, which was designed specifically for this kit to represent production manufacturing performance and envelope.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由莫子若转载自BOYD Official Website,原文标题为:Infineon EV Liquid Cold Plate,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

The BOYD Specialty Vehicle Battery Liquid Cold Plate Increases Thermal Performance While Decreasing the Weight of the Battery Pack by over 40%

When creating a new series of batteries for electric vehicles (EVs), a leading battery producer approached Boyd to design new liquid cold plates for the battery packs. The new battery packs would be featured in large electric specialty vehicles (such as fire and refuse vehicles) which require extensive amounts of power, leading to strict thermal and weight management requirements.

BOYD Provides a Simple, Effective and Compact Cooling Solution for Portable Cold Therapy Medical Devices

Boyd engineered and optimized the heat dissipation assembly for prototyping. The cooling solution was designed with thermoelectric modules placed on a cold plate and an active cooling consisting of heat sinks and a fan.

BOYD Improves the Thermal Performance of Networking Equipment Manufacturer‘s Wireless Remote Access Point

A manufacturer of high performance wired and wireless networking equipment asked Boyd, to evaluate and improve the thermal performance of their wireless remote access point, with an eye toward future product generations.

Datasheet - Board Level Cooling High Power Extruded 6390

型号- 6396BG,6400BG,6396B-P2G,6400B-P2G,6390,6399BG,6398BG

Boyd Thermal Management Solution Using CFD Analysis and High Density Casting Process for Laser Light Sources

Heat flows from the device to the base plate then to the heat sink, gets sucked by the fans and eventually released in ambient air. The thermal target was very tight and the geometry required an advanced casting solution. While the thermal target for this design had to be adjusted due to physical constrains, the California team of Boyd, was able to assist with finding the best thermal management solution using CFD analysis and high density casting process.

Boyd’s Solution Including a Counter Intuitive Reduction of Heat Sink Size Solved Customer’s Tablet Temperature Problem

Boyd’s solution solved the customer’s tablet temperature problem. The solution included a counter intuitive reduction of heat sink size. Boyd’s expertise provided a cost-effective alternative to a customer that had no need for full time thermal engineering.

电子商城

登录 | 立即注册

提交评论