How to Choose from Silicone Thermal Pad and Phase Change Thermal Pad?

In the fields of electronic product manufacturing and the automotive industry, thermal management solutions are crucial for the performance and longevity of devices. The choice of thermal conductive materials directly affects the efficiency of heat dissipation. This article compares two commonly used thermal conductive materials: silicone thermal pads and phase change thermal pads.

Silicone Thermal Pads (SF Series)

Silicone thermal pads are soft materials made of silicone infused with thermal conductive fillers. Their thermal conductivity ranges from 1.0 to 15.0 W/m·K, with thicknesses ranging from 0.3 to 10.0mm. These materials have excellent flexibility and rebound properties, providing effective shock absorption and support. The pads are self-adhesive, making them easy to install and rework, and can be customized for color, hardness, silicone oil migration, and siloxane volatility according to customer requirements. They are primarily used in chips, capacitors, memory modules, and control boards.

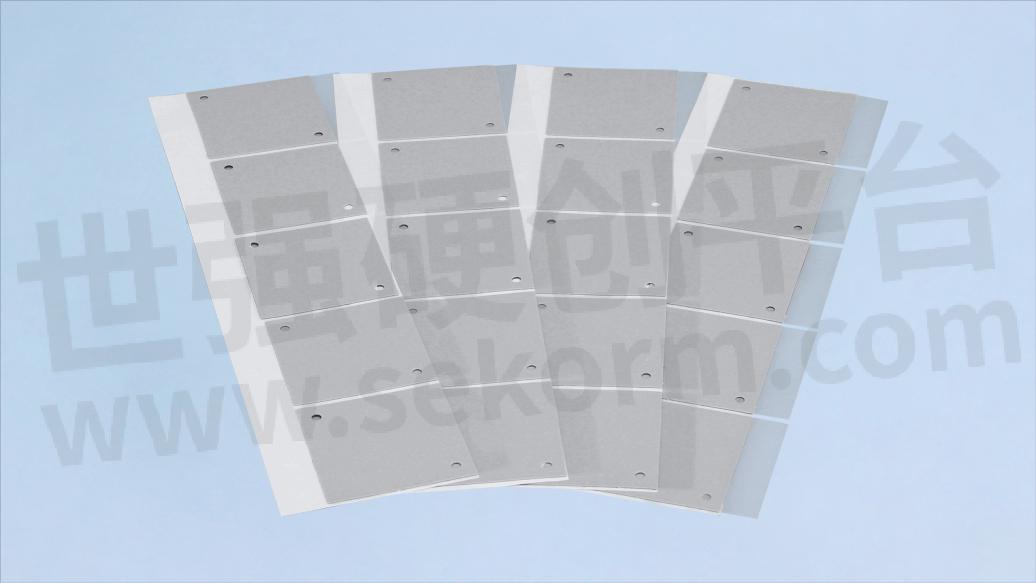

Phase Change Thermal Pads (SP Series)

Phase change thermal pads are designed to change their state within a specific temperature range (45~55℃). Their thermal conductivity ranges from 1.8 to 8.0 W/m·K, with thicknesses ranging from 0.13 to 0.5mm. In their solid state at room temperature, these materials soften and become fluid when the temperature rises to the phase change point, filling interface gaps and achieving optimal thermal performance. These materials can be supported with PI film or aluminum foil to enhance electrical insulation and mechanical strength, and are mainly used in thin-gap applications such as UPS uninterrupted power supplies, CPUs, and GPUs.

Comparison of Advantages and Disadvantages

Thermal Performance: Silicone thermal pads have a wide range of thermal conductivity suitable for various heat dissipation needs. Phase change thermal pads provide extremely low thermal resistance after phase change, suitable for efficient heat dissipation and better wetting performance under heatsink pressure.

Ease of Installation and Cleanliness: Silicone thermal pads are self-adhesive, easy to install, and rework. They also provide some rebound, offering support. Phase change thermal pads, lacking elasticity, require constant pressure during use to ensure full contact with the thermal interface. When melted at phase change temperature, they offer better wetting performance and smaller minimum bond than silicone thermal pads. Unlike thermal grease, they are more resistant to pump out and maintain the cleanliness of electronic devices.

Applications: Silicone thermal pads are widely used in various electronic components, while phase change thermal pads are more similar to thermal grease in applications, suitable for high-heat, thin-gap scenarios such as CPUs and GPUs. Phase change thermal pads remain solid at room temperature, making them easier for manual handling and maintaining device cleanliness.

Cost Considerations: Price is a significant factor when selecting thermal interface materials. For materials less than 1mm thick, silicone thermal pads are generally more cost-effective. However, phase change thermal pads, although slightly more expensive, offer higher thermal efficiency in specific applications.

Conclusion

When choosing thermal conductive materials, it is essential to consider the specific application and requirements. Silicone thermal pads, with their cost advantage and convenience, are suitable for most general heat dissipation needs. On the other hand, phase change thermal pads excel in efficient heat dissipation and thin-gap applications, providing better wetting performance and resistance to pump out compared to thermal grease. Choosing the right thermal conductive material can significantly enhance the performance and lifespan of the equipment.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由Natalia转载自SHEEN Official Website,原文标题为:How to Choose from Silicone Thermal Pad and Phase Change Thermal Pad?,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Maximizing Device Performance: How to Choose the Right Thermal Pad

This article explains what thermal pads are, their key features, and how to choose the best one for your needs.

An Introduction and Comprehensive Guide to Thermal Interface Materials

This article is mainly SHEEN‘s comprehensive guide to what is a thermal interface material, introduces a number of thermal interface materials, and introduces a number of SHEEN applications.

Thermally Conductive Materials with Ultra-high Thermal Conductivity

The thermally conductive material is a general term for materials that are coated between the heating device and the cooling device of the equipment and reduce the contact thermal resistance between the two.

Parker Chomerics(派克固美丽)热界面材料(用于电子产品散热)选型指南

目录- Company Profile Heat Transfer Fundamentals Thermal Gels Gap Filler Pads Phase Change Materials Thermal Tapes Potting and Underfill Materials Dielectric Pads Heat Spreaders Thermal Greases Glossary

型号- PAD30G,60-XX-D065-ZZZZ,60-XX-4353-ZZZZ,60-XX-D379-ZZZZ,60-XX-D417-ZZZZ,G570,PAD30A,GEL 75,T500,60-XX-6875-ZZZZ,60-XX-D420-ZZZZ,G974,60-XX-D381-ZZZZ,60-XX-4305-ZZZZ,60-XX-D382-ZZZZ,G579,579PN,A580,60-XX-D396-ZZZZ,T630,60-XX-4997-ZZZZ,60-XX-4306-ZZZZ,PAD 30,60-XX-D416-ZZZZ,6W-XX-YYYY-ZZZZ,60-XX-4996-ZZZZ,60-XX-D421-ZZZZ,60-XX-D402-ZZZZ,60-XX-6956-ZZZZ,60-XX-D404-ZZZZ,G569,60-XX-D415-ZZZZ,60-XX-D418-ZZZZ,60-XX-D429-ZZZZ,65-00-T670-3790,65-1P-CIP35-5600,60-XX-D395-ZZZZ,60-XX-D398-ZZZZ,60-XX-5792-ZZZZ,69-1X-YYYYY-ZZZZZZ,65-00-CIP35-0400,60-XX-D406-ZZZZ,T404,T647,60-12-20264-TW10,PAD60A,T405,T646,60-XX-D400-ZZZZ,T766,T644,T642,60-XX-4511-ZZZZ,60-XX-D384-ZZZZ,60-XX-D428-ZZZZ,60-XX-5791-ZZZZ,65-00-YYYY-ZZZZ,60-XX-D419-ZZZZ,T650,60-XX-D385-ZZZZ,60-XX-D391-ZZZZ,T636,T635,60-XX-D394-ZZZZ,G580,TC50,60-XX-D397-ZZZZ,60-XX-D378-ZZZZ,60-XX-D375-ZZZZ,60-XX-D425-ZZZZ,1641,65-5P-CIP35-10452,60-XX-D422-ZZZZ,60-XX-D372-ZZZZ,60-XX-D403-ZZZZ,60-12-20267-TW10,GEL 37,6W-XX-1015-ZZZZZZ,60-XX-D373-ZZZZ,60-XX-D409-ZZZZ,PC07DM-7,60-XX-4661-ZZZZ,579KT,60-XX-D387-ZZZZ,60-XX-YYYY-ZZZZ,60-XX-D412-ZZZZ,65-00-1641-0000,60-XX-D388-ZZZZ,65-00-T644-0045,65-00-T644-0200,GEL 30,64-XX-YYYY-ZZZZ,60-XX-D374-ZZZZ,60-XX-D390-ZZZZ,60-XX-4659-ZZZZ,60-XX-D408-ZZZZ,T670,65-00-T642-0035,T405-R,60-XX-4374-ZZZZ,T418,60-XX-D424-ZZZZ,60-XX-D410-ZZZZ,GEL 45,T777,1642 65-00-1642-0000,60-XX-D413-ZZZZ,T414,T411,T412,1671,60-12-20266-TW10,60-XX-8531-ZZZZ,60-12-20269-TW10,60-XX-D407-ZZZZ,PAD 60,569PN,60-XX-5527-ZZZZ,65-XX-YYYYY-ZZZZ,60-XX-5442-ZZZZ,60-XX-D426-ZZZZ,569,65-00-CIP35-0200,65-00-CIP35-0045,T660,PAD30PN,HCS10,T725,60-XX-D370-ZZZZ,60-XX-D376-ZZZZ,67-XX-YYYY-ZZZZ,65-00-T642-0250,60-XX-8302-ZZZZ,T444,GEL 8010,T766-06,65-00-T646-0045,A569,65-01-1641-0000,60-XX-D423-ZZZZ,PAD30KT,60-XX-D392-ZZZZ,60-XX-4969-ZZZZ,T609,570,65-00-T646-0200,1678,1674,60-XX-D371-ZZZZ,974,60-XX-D399-ZZZZ,60-XX-D405-ZZZZ,579,60-XX-D401-ZZZZ,976,60-XX-D377-ZZZZ,65-00-CIP35-1200,65-00-T647-0200,65-00-T647-0045,60-XX-D393-ZZZZ,60-XX-D427-ZZZZ,65-00-T650-0160,T558,HCS10G,6W-XX-0909-ZZZZZZ,T710,T557,CIP 35,60-XX-D383-ZZZZ,A579,PAD60,60-XX-D386-ZZZZ,580,60-XX-D389-ZZZZ,A570,60-XX-D430-ZZZZ,GEL 25NS,60-XX-D411-ZZZZ,HCS10A,60-XX-D414-ZZZZ,60-12-20268-TW10,T441,60-XX-D380-ZZZZ,60-12-20265-TW10

Ziitek(兆科)导热材料选型指南

目录- 公司介绍 TIC系列低熔点导热界面材料 TIF系列热传导间隙填充材料 TIG系列导热膏 TIS系列导热绝缘材料 TIR系列超高导热导电材料 TIA系列导热双面胶 TCP™100系列导热工程塑料 Z-Paster100无硅导热片 TIF™100导热泥/导热粘土 TIE/TIS™导热灌封粘合剂(导热灌封胶) Kheat™发热材料 导热界面材料应用介绍 模切产品

型号- Z-PASTER100-30-02E,TIS680-15AB,TIR300-CU SERIES,TIR600-06 SERIES,TIE280-12AB,TIA600FG,TIC800A,TCP300-18-06B,TIR300CU,TIS580-12,Z-PASTER100-15-02E,TIS580-10,TIF500,TIF100-35,TIF300 SERIES,TIC800G,TIF100,TIF100-30,TIF300,TIF600GP SERIES,TIC800B,TIG780-50,TIG780-10,TIF100-25,TIS680-28AB,TIG780-52,TIF100-15-10F SERIES,TIS100B,TIA800FG,TIS100G,TIF200 SERIES,TIA800,TIS100P,TCP100-50-01A,TIF100-32-05S SERIES,TIG780-18,TIF100-20,TIF100-02S SERIES,TIS680-10AB,TIE380-25,TIC800P SERIES,TIF100-30-10F SERIES,TIF600GP,TIS100Y,TC800G SERIES,TIF100-02S,TIF100-15,TCP200-18-06A,TCP200-25-06A,TIF100-12U SERIES,TIF800 SERIES,TIF100-05E SERIES,TIF100-05F SERIES,TIF700GP,TIR300,TIA800AL,TIS800K,TIF600,TIG780-25,TIF800,TIF200,TIF100-20-10F SERIES,TIF100-50,TIF400,TIC800P,TIF700GP SERIES,TIF400 SERIES,TCP300-12-06B,TIR300 SERIES,TIS800 SERIES,TIE280-25AB,TIA800 SERIES,TIS580-13,Z-PASTER100-20-02E,TIS680 SERIES,TIR600-06,TCP100-40-02A,TIS580 SERIES,TIS800,TIS800K SERIES,TIE380-45,TIC800A SERIES,TIC800G SERIES,TIC800K SERIES,TIF500S,TIG780-38

SP205A 3W导热相变片,填充热源与散热器间的空隙,提高导热效率

各种各样的电器设备充斥着人们的生活与工作,它们的存在很大程度上解放人们的双手,并提高的工作效率,但是电器设备使用过程中会产生热量,并且如果没有控制温度,电器设备极其容易被烧毁。盛恩研发生产SP导热相变片,导热系数在1.8-3.0W/MK,其中SP205A导热相变片,导热系数达3W/MK,通过1000小时可靠性测试。

盛恩SF系列导热硅胶垫革新电动汽车热管理,具有良好耐高温和低挥发性特点,介电强度达8kV/mm

盛恩SF系列导热硅胶垫在电动汽车热管理中扮演了一个关键角色。这些导热垫具有从1.5至15.0W/m·K的导热系数,可以迅速有效地将充电器内部产生的热量传导至外部散热器。更重要的是,导热硅胶垫能够被定制成各种厚度和形状,以确保与充电器内部各种复杂组件的完美贴合,从而最大化热传导效率。

导热硅胶片,电动汽车逆变器的热管理优化解决方案

逆变器在电动汽车的动力系统中扮演着核心角色,将电池储存的直流电转换为驱动电动机所需的交流电。随着电动汽车技术的不断进步,对逆变器的性能和效率要求日益提高。然而,逆变器在操作过程中会产生大量热量,若不妥善处理,可能导致效率降低、性能下降,甚至损坏设备。在这方面,盛恩SF系列硅胶导热垫提供了一种高效的热管理解决方案。

Parker Chomerics(派克固美丽)热界面材料(热传导性凝胶/在位灌封材料/润滑脂)选型指南

目录- Company Profile Overview of Dispensable Materials Material Selection Equipment Types Technical Parameters Packaging Options

型号- T636,T647,T635,T646,CIP 35,GEL 30,T642,TC 50,GEL 25NS,1642,1641,GEL 8010,T630,GEL 75,T650,GEL 45,T660,T670,GEL 37

Thermal Interface Material Supplier Offers High-Quality TIM Solutions

When it comes to thermal management solutions, choosing a reliable thermal interface material (TIM) manufacturer is essential. Sheen Technology is a leading provider of high-quality TIMs, offering innovative solutions to meet the diverse needs of industries such as automotive, electronics, and telecommunications.

SP导热相变片,导热系数在1.8-3.0W/MK,通过1000小时可靠性测试

导热材料是一种专门解决热传导问题的新型材料,其作用在发热源与散热器间,改善两者间热传导效率,提高散热效果,保证设备能够有效地运行。导热材料有很多种,如导热硅胶片、无线导热垫片、导热相变片、导热矽胶布、导热硅脂、导热凝胶、碳纤维导热垫片、导热相变材料,每种导热材料都其独特的卖点,根据产品要求进行选择。

盛恩SF500导热硅胶片在新一代笔记本电脑散热中的革命性应用

随着笔记本电脑性能的大幅提升,对于高效散热解决方案的需求也日益增长。厚度日渐减薄的设计趋势对散热技术提出了更高的挑战。在这种背景下,导热硅胶片凭借其卓越的导热性能和灵活的应用特性,成为笔记本电脑散热设计中的重要组成部分。本文将探讨盛恩SF系列导热硅胶片在新一代笔记本电脑散热中的应用及其带来的优势。

盛恩1-12W/MK导热硅胶片SF系列,柔软有弹性、出油率可控,品质媲美国际品牌

近期很多通过世强平台寻找盛恩的客户表示,近年原材料价格上升和运输成本上涨,所以导致外国品牌的导热材料价格有所上升,需要选择可以替代它们的国产导热材料。盛恩向客户推荐SF系列导热硅胶片,导热系数在1-12W/MK,能够满足目前大部分的热传导问题解决要求,其通过1000小时可靠性参数,硬度柔软有弹性,出油率可控,垫片应力小,降低损坏电子元器件的可能性。

55 Top Electronic Materials Brands Authorized Sekorm as Main Distributor

In order to enrich the choice of electronic materials for Hard & Core Technology enterprises, Sekorm has continuously expanded its electronic material brand. At present, Sekorm is an authorized distributor of 40 electronic material brands.

盛恩SF系列高导热硅胶垫片为BMS热管理提供极大支持,具备出色柔韧性、适应性和电绝缘特性

BMS的热管理系统尤为重要,导热硅胶垫片的应用是一种有效的解决方案。特别是盛恩SF系列的导热硅胶垫片,以其出色的导热性能和物理特性,为BMS的热管理提供了极大的支持。这些导热硅胶垫片具有1.5至15.0W/m·K的导热系数,可以迅速将BMS产生的热量有效地传导至散热器或车辆外壳,从而避免热量积聚并维持系统的理想工作温度。

电子商城

登录 | 立即注册

提交评论