What Is an Ultra Thin LiPo Battery?

The Lithium-ion battery (LIB) has revolutionized our lives and is widespread from small-scale devices such as mobile phone to emergency distributed power supply, electric vehicle, etc. Lithium-ion batteries are evolving even now. Many current types of research for LIB focus on life extension, energy density, safety, cost reduction, and charging speed. thin film LIB is one of the forms of LIB, it has attracted much interest for use as power sources of smart cards, implantable medical devices, micro-sensors, and soon.

Fig.1

What is an Ultra Thin LiPo Battery?

The thin film LIB is composed of the anode, cathode, and electrolyte with thick-nesses on the order of microns. As the demands for safety, higher energy density and other performance metrics increase, research into anode, cathode, and elec-trolyte materials has been rapidly progressing. Cathode materials are often mixed metal oxides involving lithium ion such as LiCoO, and LiMnO. Anode materials are lithium metal, carbon-based materials, and inorganic compounds. Both the cathode and anode materials are film, chosen for their ability to intercalate, and de-intercalate lithium ion while maintaining their structural integrity.

Established Techniques for Ultra Thin LiPo Battery

The use of highly functionalized thin films in various electronic devices has made life comfortable and this is due to the enhanced functional properties of materials at the nano-scale level. At present, the miniaturization of various electronic devices is inevitable as the electronics industry looks at manufacturing thinner and lighter devices , in addition to reduced power consumption. For example, in secondary lithium-ion batteries (LIBs), electrodes employing thinfilms of active materials are preferred over their bulk counterparts due to the muchimproved electronic and ionic conductivity, increased specific surface area andthe ease of controlling the morphology. This means that light and compact power sources with identical energy capacity to their heavier and large counterparts can beeasily manufactured through thin films applications. Owing to the above-mentioned benefits of thin films'applications in LIBs and electrical devices, a considerable number of techniques have been established for the fabrication of these thin films. In this chapter, some of the effective techniques used in the deposition of thin films are described and discussed. The fabrication techniques can be divided into two categories representing gas phase and liquid phase fabrication methods for thin films.

Gas phase fabrication methods

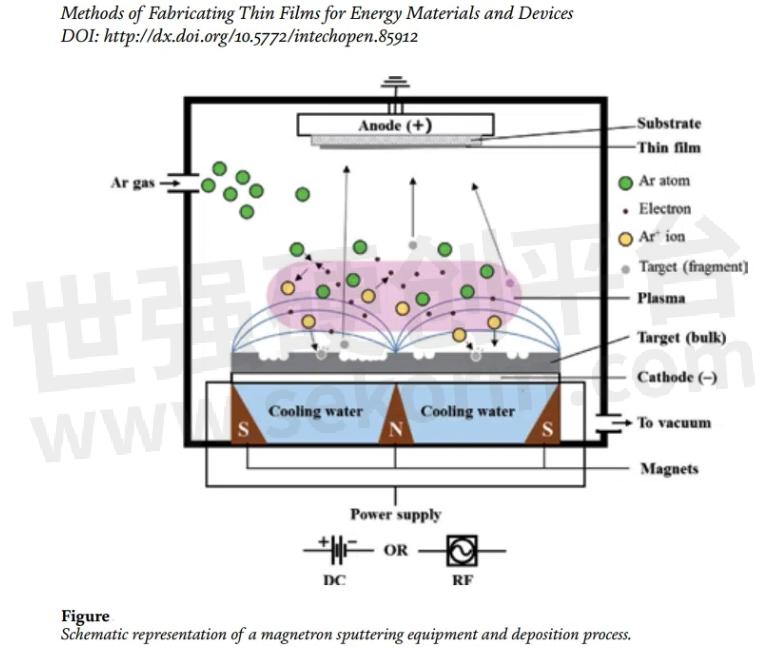

Magnetron sputtering is one of the most well-established techniques that is widely used in the industries to fabricate coatings of many different materials, including metals, semiconductors, and alloys. Thin films fabricated via magnetron sputtering prove to be of superior quality in comparison to those fabricated using other gas phase methods. The schematic representation of the magnetron sputtering set-up is shown in Figure below.

Fig.2

Before deposition, the chamber is evacuated to ca. 10-4 kPa and then refilled with Ar gas which is used as the sputter gas. Using strong electrical and magnetic field, magnetron sputtering employs the bombardment of the selected target's surface by Ar+ ions which are formed as a result of the collision between Ar gas atomsand electrons trapped within the magnetic field. The Ar+ ions are attracted toward the negatively charged target (cathode) and the bombardment leads to the ejection of the targets particles which are then redeposited as a thin film on the substrate placed on the anode, opposite to the target. Depending on the type of power source utilized, magnetron sputtering can be divided into two types namely, direct current (dc) magnetron sputtering and radio frequency (rf) sputtering. While dc magnetron sputtering is relatively cheaper in comparison to rf, only electrically conductive targets like metals or doped semiconductors are used. Additionally, reactive gases such as oxygen or nitrogen gas are used to react with the sputtered materials, in the fabrication of thin films for metal oxides or nitrides, respectively. The technique is referred to as "reactive magnetron sputtering”.

Liquid phase processes

Electrospray deposition (ESD) involves the deposition of charged particles formed as a result of liquid atomization by an electrical force. The atomization of the liquid by electrical force allows for the generation of small particles, of narrow size distribution which can be uniformly dispersed over the substrate and, ESD has been considered as apromising technique for the formation of high-quality layers and films. If the ESD process is carried out at elevated temperatures, thin film formation is achieved through the thermal decomposition of the precursor solution during deposition and the process is referred called “electrospray pyrolysis (ESP).” The schematicrepresentation of the ESD setup is shown in the figure below.

Fig.3

As shown in figure, the ESD method is based on supplying a precursor solution through a metallic capillary which is maintained at high electrical potential. Ideally, the solution forms a Taylor cone at the tip of the capillary and emitted as a solution jet composed of many highly charged droplets that are homogeneously dispersed in the space between the nozzle and the counter metallic plate (substrate holder) by Coulomb repulsion forces. The quality of the resultant thin films can be easily controlled by adjusting variables such as the applied voltage, distance between the atomizing nozzle and, the flow rate, concentration and amount of the precursor solution.

In addition to a very low throughput associated with the ESD technique, thin film deposition on insulating substrates is generally not possible due to charge accumulation on the substrate, which leads to the repulsion of more incoming charged particles. Modifications such as the use of alternating current (ac) and extractor electrodes have been employed to solve the charge repulsion issue and ensure the thin film deposition on insulating substrates via ESD. However, thiscomplicates an initially simple experimental setup.

Ultra Thin LiPo Battery Applications

Due to their unique features, ultra thin LiPo batteries are used in a variety of applications, including:

●Wearable Technology: Smartwatches, fitness trackers, and health monitoring devices benefit from the lightweight and slim design.

●Medical Devices: Ultra thin batteries power medical implants, hearing aids, and other portable medical devices.

●Consumer Electronics: Smartphones, tablets, and other portable gadgets utilize these batteries for their slim profile.

●Smart Cards: Credit cards, ID cards, and other smart cards integrate ultra thin batteries to power embedded electronics.

●Flexible Electronics: Emerging technologies like foldable phones, e-papers, and flexible displays use these batteries for their flexibility and thinness.

●IoT Devices: Small, interconnected devices in the Internet of Things (IoT) ecosystem often rely on ultra thin batteries for power.

Grepow Ultra Thin LiPo Battery Solutions

Grepow's Ultra Thin LiPo Battery is a cutting-edge pouch cell type battery with an incredibly slim profile, measuring just 0.4mm in thickness. This makes it perfect for ultra-narrow applications where space and weight are critical. The battery can be customized in various shapes and sizes to meet specific customer requirements, making it ideal for use in wearable devices, medical equipment, miniature electronics, and IoT devices. Despite its compact size, it delivers reliable performance and offers a space-saving solution for modern electronic devices. Some of their solutions include:

●Customizable Designs: Grepow offers bespoke battery designs to meet specific customer requirements, including unique shapes and sizes.

●High Performance: Their batteries are designed to deliver high energy density and long cycle life, ensuring reliable performance.

●Safety and Reliability: Grepow incorporates multiple safety features in their batteries to prevent overcharging, overheating, and other potential hazards.

●Wide Range of Applications: Their ultra thin batteries are used in medical devices, consumer electronics, wearables, and more.

●Advanced Manufacturing: Grepow uses state-of-the-art manufacturing processes to produce high-quality batteries that meet stringent standards.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由三年不鸣转载自Grepow Official Website,原文标题为:What Is an Ultra Thin LiPo Battery?,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

What is the Impact of Long Coldness on Agriculture Spraying UAVs Batteries and How to Deal with it

Agricultural drones are not only used for spraying and applying medicine, but also for spreading fertilizer, seeds, and feeds to meet the diversified needs of farmers and improve production efficiency.

Thin Film Lithium-ion Battery Vs Lithium-ion Battery: What’s the Difference?

In the rapidly evolving world of battery technology, thin film lithium-ion batteries have emerged as a promising alternative to traditional lithium-ion batteries. These batteries, with their ultra-thin structure and solid-state electrolyte, offer distinct advantages in flexibility, safety, and application potential. This article delves into the fundamental differences between thin film lithium-ion battery and conventional lithium-ion battery, exploring their respective structures, manufacturing processes, and applications across various industries.

Can Lipo Battery Cells Be Shipped by Air?

With the widespread use of electronic products, batteries nowadays have become household items that we can see everywhere. The most commonly encountered type of battery is the lithium-ion battery.

Recycling and Regeneration of Lithium Batteries

Under the pursuit of economic and environmental protection, the production and demand of lithium batteries have grown in recent years. Decommissioned lithium batteries are known as high-grade mines, coupled with the price and mining of raw materials, so the recycling value is obvious.

NMC vs NCA Battery Cell: What’s the Difference?

Choosing between NMC and NCA battery cells depends on the specific requirements of the application. NMC cells offer a versatile and cost-effective solution with balanced energy and power characteristics, making them ideal for a wide range of uses from EVs to power tools. On the other hand, NCA cells provide higher energy density and longer cycle life, making them suitable for high-performance EVs, consumer electronics, and aerospace applications.

What are the Best Intelligent Lithium Battery Manufacturers in Shenzhen?- Grepow Battery

At one time, a survey by the Japan Economic Research Institute showed that Chinese battery manufacturers accounted for more than 60% of the global automotive lithium-ion battery market.

What Caused The Lithium Battery to Explode?

With over 20 years of customer service experience, Grepow has developed a very complete service system, specifically tailored for Grepow customers, which helps Grepow in better understanding your needs in the first step of our communication, in a highly time-efficient way.

Grepow covers a wide range of shaped batteries to maximize the use of product space, perfectly adapted to small portable electronic products

Grepow covers a wide range of shaped batteries: round lipo batteries, C-shaped batteries, curved lipo batteries, hexagonal batteries, fan-shaped batteries, triangular batteries, ultra-thin batteries, etc., to maximize the use of product space, perfectly adapted to small portable electronic products.

What Is the Beauty Gadget and How to Pick the Built-In Battery

What Are Beauty Gadgets?Beauty gadgets are electronic devices designed to enhance personal care and aesthetic treatments, making professional-grade beauty routines accessible at home. These devices address various needs, such as improving skin texture, reducing wrinkles, cleansing pores, and enhancing hair care.Types of Beauty GadgetsBeauty gadgets cater to specific beauty and skincare needs:● Cleansing Devices: Facial brushes and ultrasonic scrubbers remove dirt, oil, and makeup residue through deep cleansing.

What is the packaging technology of soft pack Li Ion battery?

Soft pack lithium-ion batteries are always found in consumer electronics, as UAV/drone batteries, and the high-performance batteries of RCs, for military, and automotive industries. This article talks about the packaging technology of soft pack Li Ion battery.

Lithium-ion Battery Cycle Life VS. Calendar Life VS. Shelf Life

Lithium-ion batteries have become an integral part of our daily lives, powering everything from smartphones to electric vehicles. As these batteries play a crucial role in various applications, understanding their life expectancy is essential. In this article, we will explore the concepts of cycle life, calendar life, and shelf life of lithium-ion batteries, shedding light on their individual characteristics and implications.

LiFePO4 vs. LiPo: What’s the Difference?

When it comes to choosing the right battery for your application, understanding the differences between LiFePO4 and LiPo batteries is crucial. Both types belong to the lithium-ion family but differ significantly in their chemistry, performance, and suitability for various uses. This article delves into the specific characteristics, advantages, and disadvantages of LiFePO4 and LiPo batteries, providing insights to help you make an informed decision for your power needs.

【经验】解析锂离子电池常见的五个安全标准

锂离子电池 (LIB) 是复杂的电化学和机械系统,是数十个国际安全标准的主题。本文格瑞普将为您介绍LIB安全的关键环境方面,回顾锂离子电池常见的安全标准,并考虑使用定制电池测试室来保障测试人员的安全。

5 Factors That Affect the Lithium Ion Battery Life

Grepow talks about 5 Factors That Affect the Lithium-Ion Battery Life.

What is a Silicon Anode Lithium-Ion Battery?

This article delves into the specifics of silicon anodes, their benefits, and the challenges they present.

电子商城

现货市场

服务

可自由定制电池形状,锂离子聚合物/磷酸铁锂成分,放电倍率Max. 50C (持续放电倍率) / 150C (脉冲放电倍率),充电倍率:Max. 5,厚度可达0.5mm。

最小起订量: 5000 提交需求>

登录 | 立即注册

提交评论