Microchips Are Manufactured Using Polysilicon and Specialty Chemicals Made by WACKER

Without polycrystalline silicon, digitalization would be unthinkable. Glossy and silvery in appearance, Polysilicon is among the purest man-made materials and the most important raw material required in the semiconductor industry. Today, nearly one in two microchips are manufactured using polysilicon made by WACKER. And by no means is this WACKER’s only contribution to the industry. Apart from polysilicon, process chemicals by WACKER also play a key role – and the demands on purity and quality are high.

Purity Is Everything

Several hundred steps are required for transforming a silicon wafer to a ready-to-use microchip. Production can take many months and involves extremely challenging technical processes and highly complex equipment. Clearly, constructing a microchip production facility is a costly affair. To be certain their investments pay off, manufacturers must put in every effort to achieve as high a production volume of operational microchips as possible.

That’s not all. Things are made tougher as proper functioning of the semiconductor components can only be verified at the end of the production process. It is therefore no wonder that the microchip industry places the highest demands on the quality of the raw materials and process chemicals supplied and closely monitors the reliability of its suppliers.

Nearly One in Two Microchips Are Manufactured Using Polysilicon Made by WACKER

Microchip manufacturing begins with hyperpure silicon wafers. In almost every case, polycrystalline silicon, or polysilicon, is the raw material required for making these wafers. WACKER is the only semiconductor-grade polysilicon manufacturer in Europe. In fact, WACKER is a global leader when it comes to quantity, quality and material purity. Nearly one in two microchips are manufactured using polysilicon made by WACKER.

Not many though are aware that, in addition to hyperpure polysilicon, WACKER also produces specialty chemicals that are vital in manufacturing computer chips. WACKER silanes, for instance, are used for dispersing and depositing silicon or insulation layers on the wafer surface. Pyrogenic silica from WACKER is used for polishing and leveling the applied layers. And when it comes to cleaning the metalizing chambers, hydrogen chloride, yet another WACKER product, is indispensable.

All electronic chemicals from WACKER are precisely customized to the processes and requirements of the semiconductor industry. Statistical process controls are implemented to continuously monitor the production of these chemicals. After all, the purity of the products must always lie within a very narrow tolerance range that is specified in consultation with the microchip manufacturer. A stringent risk management process is essential, too, to ensure that the product quality is always consistent, even if there are deviations in specific process parameters during production, such as temperature or pressure, or in the event of changes in the production lines.

The majority of the upstream products required for such chemicals are manufactured by WACKER. This makes us less dependent on external suppliers. What’s more, our in-house analytical experts are in a position to precisely detect and quantify even the minutest traces of impurities.

Functional Chemicals and Their Areas of Application

Chemical Vapor Deposition

Process Chamber Cleaning

Chemical-Mechanical Polishing

Silanes for Tomorrow’s Microchips

Every new generation of digital devices tends to display higher switching frequencies and smaller components. Without increasing in size, such devices become faster and more efficient. This is possible thanks to advances involving the miniaturization of the components that constitute a chip.

At the same time, this development becomes more complicated as we move on to the next generation. Today’s microchips have more than one hundred layers superimposed on each other. Design rules of five nanometers – ten thousand times thinner than a human hair – are already standard practice. Such minute dimensions are gradually pushing microchip manufacturers to the limits of what is physically possible.

Things get tougher when, for instance, interconnects on a microchip and the insulating layers continue to be packed more closely than ever. High switching frequencies lead to an intensive acceleration of the electric charges in the interconnects whereby relatively strong electric fields are built up. “In the area between the interconnects, the electric fields interfere with each other and thus slow down the charges,” Arne Meier explains. The thinner the insulating layer and the higher the frequency, the greater the slowdown. In extreme cases, the charges do not reach their intended destination in time and the chip fails.

Insulating materials with a lower dielectric constant, represented as “k” in the semiconductor industry, offer a viable solution. WACKER is committed to developing silanes that allow materials with particularly low dielectric constants to be deposited. These silanes can play a key role in tomorrow’s semiconductor industry. According to Arne Meier, WACKER is in the final stages of developing such ultra-low-k materials. “These silanes will be WACKER’s contribution in making the latest generation of computer chips reality.”

Microchips

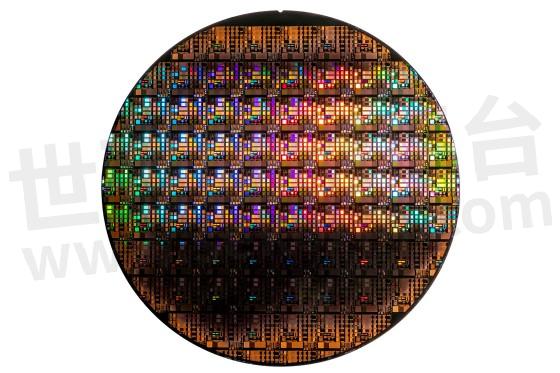

A microchip is an electronic semiconductor component that contains a fully integrated electrical circuit consisting of thousands to billions of tiny transistors, capacitors, resistors and other electronic components. All these elements are arranged in several levels on a semiconductor wafer as microscopically small structures in the form of thin layers that are firmly anchored on the substrate.

Each layer has a function: for example, it can take on the role of an interconnect, be a component of a transistor or act as a resistor. As we move on from generation to generation, we observe a greater miniaturization of the components and, at the same time, an increase in the number of superimposed layers and consequently the number of transistors. A greater number of transistors is what creates a more powerful chip.

Polysilicon is the most important material required to begin wafer production. In this regard, material purity is absolutely crucial. Foreign atoms such as boron or phosphorus are a source of impurities in the semiconductor material and could impact the electrical properties of the semiconductor. This would ultimately lead to the failure of the chips produced from the wafers. The entire focus is therefore on maximum purity.

WACKER’s polysilicon for semiconductor applications has a purity of 12N. This refers to a material that contains no more than one critical foreign atom per trillion silicon atoms, which corresponds to a purity of 99.9999999999 percent. This makes WACKER’s polysilicon the purest man-made material.

WACKER supplies hyperpure silicon in the form of irregularly shaped chip-size material to wafer manufacturers, who produce large cylindrical single crystals from the polycrystalline material and saw them into thin discs that are later planarized, cleaned and polished. The discs are thus transformed into wafers, i.e. the substrates on which the circuit components are mounted. Depending on the chip design and size of the silicon wafer, hundreds of chips are often created from a single wafer. Initially, these chips are laid out next to each other on the wafer like postage stamps and are only separated after the configuration is complete.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由雪飘梦飞转载自WACKER Official Website,原文标题为:The Role of Specialty Chemicals in Chip Manufacturing,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

让光变成字:有机硅激光打标

光消失了,字留下了——精准地对有机硅产品进行永久性标记的绝佳方法,是用激光束打标,简称“激光打标”。这种技术可应用于医疗产品、电缆或家用电器等领域,亦即适用于任何需要留下清晰、精细而持久的标记的地方。

应用方案 发布时间 : 2024-10-19

瓦克的有机硅添加剂GENIOPLAST® Pellet S,具有耐刮擦、性价比高等特点

塑料是现代汽车内饰的主要材料。为了节约成本,小型轿车往往采用易刮擦的由聚丙烯制成的零部件。但是,如果塑料中添加了瓦克的有机硅添加剂GENIOPLAST® Pellet S,则塑料表面即使在经过长期的频繁使用后,也可基本保持原貌。

应用方案 发布时间 : 2024-07-26

一种电动汽车的绝配材料:有机硅弹性体,能承受高温及充电电流,持久而可靠地密封组件

电动汽车对高性能材料的需求不断增长,带动了汽车行业对有机硅弹性体的需求。有机硅弹性体作为出色的热导体,能够承受高温及充电电流,持久而可靠地密封组件。

应用方案 发布时间 : 2024-07-04

WACKER’s Polysilicon Production Successfully Certified to IATF 16949

WACKER’s facilities for the production of semiconductor-grade polysilicon in Burghausen, Germany, and at its US site in Charleston, Tennessee, have now also been awarded the IATF 16949 certificate. This underscores WACKER’s position as a world-leading supplier of ultrapure polysilicon for semiconductor applications in the electronics and automotive industry.

原厂动态 发布时间 : 2024-04-26

德国有机硅热管理解决方案商WACKER授权世强硬创代理全线有机硅热管理产品

瓦克有机硅产品广泛应用于光伏、电子、医药、护理等各类发展迅速的最终消费者市场。

签约新闻 发布时间 : 2024-08-14

【材料】瓦克新型硅树脂SILRES® LR 700或POWERSIL® Resin 700可供制备耐高温成型件

工业领域正面临着一项日具挑战的任务:生产耐机械负荷,并能够持久承受200摄氏度以上高温的塑料零件。瓦克为此开发出一种新型材料解决方案。生产商可借助SILRES® LR 700 或 POWERSIL® Resin 700硅树脂基料,以及在此基础上制备的POWERSIL® Resin 710有机硅成型材料。

产品 发布时间 : 2024-10-25

【选型】中电国基南方SiC电力电子器件(SiC MOSFET/SiC SBD)选型指南(英文)

目录- Company profile SIC MOSFET/SIC SBD Introduction SIC MOSFET SIC SBD

型号- WM1A280120B,WM1A030065K,WS4A004065WB,WM2A017065B,WM1A030065L,WS3A003065E,WM1A080170B,WS3A003065A,WS3A050120D,WM1A160065B,WS3A015065F,WM1A01K170B,WS3A015065J,WS3A010170A,WM1A080170K,WS3A003065J,WM1A080170L,WS3A008120E,WS4A002065WB,WM1A280120N,WS3A008120A,WM1A280120K,WS3A030120K,WS4A008065A,WS3A030120D,WM1A025120K,WM1A025120L,WS3A008120J,WS3A060120K,WS4A008065E,WSXAXXXXXX0,WS4A012065A,WS4A004065E,WS3A005120J,WS3A003120A,WS3A005120E,WS3A003120E,WS3A020120J,WM1A045170K,WM1A045170L,WM1A080120K,WS3A020120D,WS3A020120A,WS3A010065J,WM1A045170B,WS4A002065A,WS4A006065E,WM1A080120B,WS3A002330D,WS4A006065A,WS4A010065E,WS4A010065A,WS3A016120K,WM1A080120N,WS3A020120K,WS3A005120A,WS3A008065E,WS3A008065F,WS3A003120J,WS3A012065J,WS3A012065K,WS3A008065A,WM2A025120B,WS3A008065J,WS4A004065A,WS3A004065A,WS3A012065F,WS3A012065D,WS3A012065E,WS3A005170A,WS3A012065A,WS3A020065J,WM1A120065K,WS3A020065F,WS3A020065D,WS3A006065E,WS4A012065WB,WS3A006065F,WS3A020065A,WS3A010120J,WS3A002065A,WS3A010120K,WM1A120065N,WS3A006065J,WS3A015120A,WS3A002065F,WS3A015120D,WS3A002065E,WS3A010065D,WS3A010065E,WS3A002065J,WS3A025650B,WS3A006065A,WS3A010065F,WS3A040065K,WS3A016065K,WS4A008065WB,WS3A010065A,WS3A001330D,WS3A020065K,WS3A012120K,WS4A010065WB,WM1A017065L,WM1A017065K,WS3A004065J,WS3A030330K,WM2A030065B,WM2A060065B,NSD10220S,WS3A004065E,WS3A004065F,WM1A060065L,WM1A060065K,WM1A060065N,WMXAXXXXXX0,WM1A01K170N,WM1A040120L,WM1A040120K,WS3A002120A,WS3A006120E,WS3A002120E,WM1A01K170K,WS3A006120J,WS3A015065A,WS3A015065D,WM1A160120B,WS3A010120D,WS3A002120J,WS3A010120E,WS3A015120E,WM1A160120N,WS3A024065K,WS3A006120A,WS3A015120J,WM2A120065B,WM1A160120K,WS3A040120K,WS3A010120A,WM1A040120B,WS3A030065A,WS3A005330D,WS4A020065K,WS3A030065J,WS4A006065WB,WS3A030065K,WS4A016065K,WS3A030065D,WS3A030065F,WS3A060065K

WACKER(瓦克)固体和液体硅橡胶产品选型指南

描述- 瓦克是一家全球运营的特种化学品公司,产品的技术含量高且发展成熟,被广泛应用于人类日常生活的各个领域,上至太阳能电池,下至瓷砖胶粘剂,一应俱全。瓦克为100 多个国家和地区供应3000多种产品。

型号- R 701/80,R PLUS 4370/50,ELASTOSIL® R PUS 4001/40,R PLUS 4001/90,LR 3023/60,R PLUS 4020/50,LR 3271/45,R PLUS 4305/70,LR 3071/30,LR 3070/60,R 780/80 OH,LR 3093/65,LR 5040/30,R PLUS 4020/60,R 701/70,R 861/60 S,R 402/75 S,R PLUS 4066/60,R PLUS 4370/40,R PLUS 4001/80,LR 3844/30,6700/60,ELASTOSIL® LR 6320 F,R 401/10 OH,LR 3005/70,R PLUS 4305/80,LR 3003/20 TR,R 401/55 S,ELASTOSIL® LR 3003/30,R 420/70 S,R 755/60 OH,LR 5040/20,LR 3071/40,R 401/70 S,ELASTOSIL® LR 6250 F,LR 3092/65,R PLUS 4020/70,R PLUS 4050/55 MH,R 701/60,R 861/70 S,R PLUS 4001/70,ELASTOSIL ® RD 6620 F,LR 3842/60,LR 3843/30,R 756/60 OH,LR 3005/60,R PLUS 4806/20,R PLUS 4305/90,R PLUS 4060/50,LR 3070/40,R 401/60 S,R 701/50,R 752/70 OH,LR 3065/30,LR 3016/65,R 700/80,R 401/60 KX S,R 760/70 MH,R 781/80,LR 3842/70,LR 3005/50,LR 3022/60,R PLUS 4001/60,LR 34004/50,R PLUS 4060/60,LR 3070/50,R 701/40,LR 3040/40,LR 3834/50 ULTRA,ELASTOSIL ® 47007,R PLUS 4305/30,LR 3025/40,LR 3074/60,ELASTOSIL ® E50 N,LR 5040/70,6610/60,6760/50,R 402/65 OH,ELASTOSIL ® RD 3151 F,R 401/20 OH,R 401/80 S,LR 3003/25,LR 3070/20,R 510/70 S,LR 3040/50,ELASTOSIL® LR 6360 F,R 401/30 S,R PLUS 4305/40,R PLUS 573/70,6610/50,R 752/50 OH,LR 5040/60,LR 3070/30,LR 3011/50 FR,ELASTOSIL® LR 6200 A/B,ELASTOSIL® LR 6260 A/B,R 510/60 S,LR 3844/40,LR 3040/60,6000/05,R 865/40 S,R PLUS 4846/30,6610/40,R 101/25 OH,R PLUS 4305/50,LR 3003/03,LR 3003/05,AUX 8251 RO,LR 3856/20,LR 5040/50,R PLUS 4070/60,WACKER ® FINISH CT 51 L,R 570/70 OH,LR 3844/50,R PLUS 573/50,6400/40,LR 3040/70,R PLUS 4020/40,R 756/70 OH,LR 5040/45,LR 3856/30,LR 5040/40,R PLUS 4070/30,LR 3066/70,6000/20,LR 3043/70,6400/50,R 401/30 OH,R PLUS 4000/40,ELASTOSIL ® RD 6600 F,LR 3003/60,LR 3004/30,R 750/50 0H,LR 3675/30,LR 3078/60,R 101/65 OH,6600/60,R PLUS 4361/60,R PLUS 4070/20,R 401/40 S,LR 3852/50,6000/10,R PLUS 4366/60,R PLUS 4350/55,R 512/70 OH,LR 3066/60,LR 3020/60,6400/60,LR 3003/50,R 865/50 S,R PLUS 4303/60,LR 3078/70,6600/50,ELASTOSIL® R 401/40,R 750/40 OH,LR 3851/50,6000/40,LR 3170/40,LR 3675/50,LR 3846/20,LR 3003/40,R PLUS 4303/70,LR 3078/40,LR 7601/60,R 420/40 S,6600/40,R 101/35 OH,LR 3040/30,LR 7601/50,6000/30,ELASTOSIL ® E91,LR 3066/80,LR 3846/30,R 770/75 OH,R 770/50 OH,LR 3003/30,LR 3078/50,R PLUS 4360/60,R PLUS 4303/80,R 570/60 OH,AUX 8250 RO,LR 3066/30,ELASTOSIL® LR 3003/20 TR,LR 3004/70,LR 3005/40,ELASTOSIL ® E43 N,ELASTOSIL ® E92 N,LR 3842/40,R PLUS 4001/50,6740/40,LR 3078/20,R 865/60 S,LR 3671/30,R 420/60 S,LR 3072/40,LR 7601/80,6000/60,R 756/40 OH,LR 3065/50,R 501/75 OH,6000/50,R 420/30 OH,LR 3003/10 TR,ELASTOSIL® LR 3001/55 FR A/B,LR 3043/40,LR 3003/90,LR 3842/50,R PLUS 4001/40,R PLUS 4000/70,LR 3004/60,LR 3001/55 FR,LR 3841/50,LR 3005/30,LR 3078/30,LR 3671/40,R 401/90 OH,LR 3094/60,ELASTOSIL® NT 76,LR 7601/70,ELASTOSIL® LR 6240 A/B,LR 3072/50,LR 3015/70,LR 3066/50,R 502/75 OH,LR 3003/80,R PLUS 4001/30,6700/50,LR 3043/50,LR 3004/50,R 416/70 MH,R PLUS 4000/60,LR 3003/85,LR 3671/50,R 570/50 OH,LR 3162,R PLUS 4061/60,LR 3071/50,R 756/50 OH,R 700/40,R 770/60 OH,R PLUS 4050/55,LR 3066/40,R PLUS 4001/20,LR 3043/60,R PLUS 4000/50,LR 3003/70,6700/40,LR 3004/40,R 865/70 S,R 101/45 OH,LR 3076/70,LR 3153,R 420/50 S,LR 3072/30,6000/70,LR 3071/60,R 490/55 OH,R 401/50 S,R PLUS 4305/60 S,LR 3015/50

WACKER胶粘剂选型表

WACKER胶粘剂选型表,提供有机硅灌封胶、有机硅密封胶、三防漆、导热密封胶、导热硅酮填隙剂、导热硅胶粘合剂六种品类,具有多种导热系数、粘度、固化类型等参数可供选择。

|

产品型号

|

品类

|

Thermal Conductivity([W/mK])

|

Curing Type

|

Curing Initiated by

|

Product Type

|

Viscosity D=0.5 1/s[mPa·s]

|

Hardness

|

Density[g/cm^3]

|

Curing

|

Features

|

|

WACKER SilGel® 612

|

有机硅灌封胶

|

0.2

|

Addition

|

RT or heat

|

2-part ,1:1,long potlife

|

1000

|

Pen 70 mm / 10

|

0.97

|

8h/25°C,15min/100°C

|

Very soft,clear,low bleed,general purpose,UL-94 HB

|

选型表 - WACKER 立即选型

【材料】瓦克车载充电机用高导热有机硅灌封胶ELASTOSIL® RT 7640 TC CN,满足下一代车载充电机复杂结构导热需求

为了满足下一代车载充电机中复杂结构的导热需求,WACKER瓦克推出具有高导热率和高流动性的导热灌封胶ELASTOSIL® RT 7640 TC CN。产品具有良好的抗沉降性,可广泛适配现有的真空点胶设备,满足大流量、高速点胶的应用需求,提高生产效率。

产品 发布时间 : 2024-04-25

汽车行业的合作伙伴:瓦克与CFP复合材料公司如何联手革新电池组防火技术?

瓦克正与汽车行业合作,为电动汽车安全运行寻找创新型防火方案,最新的一个例子是:用碳纤维和硅树脂制成新型复合材料,对电动汽车电池进行被动防火保护。英国新创CFP Composites有限公司CEO Simon Price先生和WACKER瓦克德国博格豪森纤维复合材料创新中心负责人Christoph Briehn博士向我们介绍这种材料的功能、防火性能及部分应用领域。

产品 发布时间 : 2024-10-15

瓦克根据工业标准制定出一套瓦克可持续发展方案,并以此对产品组合的可持续发展性进行评估

瓦克根据工业标准制定出一套瓦克可持续发展方案,并以此对产品组合的可持续发展性进行评估。集团的努力目标是,至2030年,让90%的产品对可持续发展做出积极贡献,或至少不对环境造成负面影响。瓦克旗下拥有3000多种标准产品和一系列特种产品,其中有些特种产品可根据客户需求提供定制化服务。那么,瓦克产品的生态平衡情况如何?生命周期分析是评估一款产品可持续发展性的最客观、最公允的方法。“

原厂动态 发布时间 : 2024-07-09

【材料】瓦克新型硅橡胶buff叠满,助力汽车连接器的密封应用升级!

WACKER瓦克推出新型即用型硅橡胶ELASTOSIL® R plus 4805/30和液体硅橡胶ELASTOSIL® LR 3814,以匹配UL 94 V0阻燃工程塑料。即使高温环境下长时间接触这类无卤阻燃型塑料,ELASTOSIL® R plus 4805/30 CN仍具有良好的力学性能,其硅橡胶制品能够维持无卤阻燃型高压连接器的更长效密封。

产品 发布时间 : 2024-04-29

电子商城

登录 | 立即注册

提交评论