Smiths Interconnect is Transforming New Product Development with “CAD-to-FAB“

When Henry Ford reimagined the manufacturing process with interchangeable parts and a ‘continuous flow’ through specialist operators, he cut motor car production from 12 hours to 93 minutes. Replicated by manufacturers globally, this new production paradigm not only made cars affordable for the masses but also drove huge social and industrial change.

A century on, by channelling Ford’s pioneering approach to processes as well as products, engineers are continuing to find solutions for today’s pressing challenges.

One of these is ‘CAD-to-FAB’ - CAD stands for ‘computer-aided design’ and FAB for ‘digitised fabrication.’ This process can streamline and clean up the entire production line, from concept to customer-ready unit.

Old ways

The production of satellite communications components provides a useful modern illustration of the step-change CAD-to-FAB represents. Like the motor car, these items were until recently, highly customized and used sparingly for only the largest and most expensive projects. However, with the growth of low orbit satellites and other infrastructure to deliver ‘anywhere/anytime’ communications, they’ve gained a ‘mass production’ imperative – in terms of volume, cost, and pace of delivery.

Not only is this impossible to achieve with traditional component development processes, but unjustifiable given their associated environmental impact.

Take Smiths Interconnect’s original route for prototyping one such component: an isolator, which is used in satellite and radar systems to ‘quarantine’ signals from electrical and environmental interference.

Post-design production began with 2x2-inch, unmarked ceramic, wafer-thin bases – known as wafers - similar to what’s used in your phone chip. After a quality check in Dundee, Scotland they shipped to Dallas, Texas for perforation with the tiny holes that will later ‘ground’ the electrical signals moving through them – something that’s essential for the isolator to do its job, but a time-consuming, manual task.

Next, the wafers were shipped to our site in San Jose in Costa Rica where we applied the conductive ‘thread’ through which the signals flow (typically gold or silver for their superior conductive quality).

But, because we, like all other manufacturers, lacked technology precise enough to ‘draw’ the required pattern onto the wafer, we coated all of it - using the slow, wasteful process of blasting a gold or silver ingot with a high-voltage charge until it shed sufficient tiny particles to cover both sides – before the excess material was finally etched off with acid.

Between coating and etching, the wafers were diced into individual 13x13mm isolators, ready for final assembly in Dundee. This involved the fiddly process of manually adding a magnetic circuit to each isolator. Because any imprecision undermines performance, each item had to undergo an additional manual inspection before being performance-tested in our Space Test Lab.

With new products requiring an average of 2.1 design iterations before finalisation, in total this process could see them travel some 36,000 air miles over a lengthy 26 weeks - not something we could or wanted to scale up.

“FAB” idea

Instead, we’ve developed a revolutionary ‘CAD-to-FAB’ process which has been successfully trialed on a customer order for isolators for a radar system.

It began in much the same way with Dundee and Dallas doing what they had always done; but then the Costa Rica team devised a new, speedier, and cleaner way to apply the conductive material: using a high-end screen stencil to uniformly coat it. Although it still coats the whole surface, it takes just one hour per round instead of several days and wastes far less material.

The Dundee team then used patent-pending digital patterning to remove excess material – a far faster and cleaner technique than acid-etching. And final assembly is performed by COBOTs (collaborative robots) – which are far quicker and more precise than humans. Due to the tight controls embedded throughout this digitized process, the customer only required final testing of 0.1% of samples, saving further time.

The impressive outcome of the trial not only attracted a major new contract but also match-funding from the UK Space Agency that’s now enabling the establishment of a £3.8m single-site CAD-to-FAB facility in Dundee. This final improvement means that all steps in the new process will now be performed in Scotland – removing the need to send to other international locations and saving some 25,000 air miles, 8 months, and 46% of the cost of the average new product development cycle.

Grant Robertson, an engineer at Smiths Interconnect, explains: ‘This ground-breaking facility allows us to eliminate all mid-production shipping, waste and the use of acid. ‘Plus, by making design and production cheaper and more repeatable, it enables us to handle more - and larger orders with the same resource, and target higher risk/reward opportunities.’

With a patent pending for the proven CAD-to-FAB process, the team is already working to fully automate other stages of assembly and inspection. It’s this kind of drive that will help reduce our industry’s impact on the planet while scaling up innovation that improves lives. We’re pretty sure Henry Ford would approve.

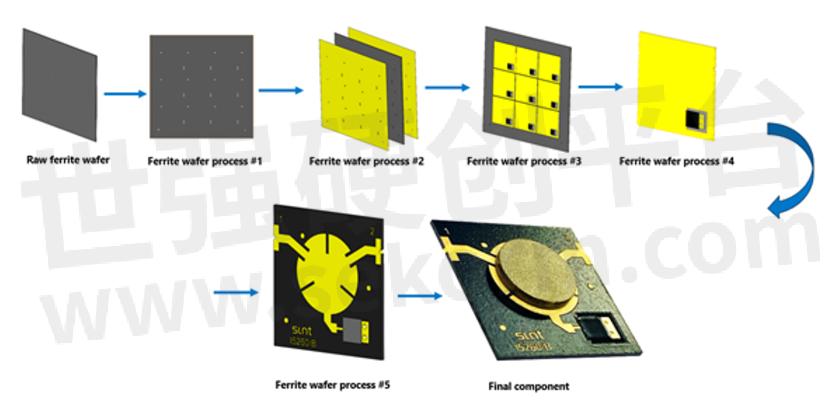

How the CAD 2 FAB process works.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由Lluvia转载自Smiths Interconnect Official Website,原文标题为:Transforming new product development with "CAD-to-FAB",本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

The Anatomy of a Microstrip Isolator and Circulator: Understanding the Basics of Microwave Microstrip Isolator and Circulator Technologies

Smiths Interconnect has produced almost 700,000 microstrip isolators and circulators over the past 2 decades from 300 portfolio products. The innovation continues and on average 12 new designs being added to the portfolio each year. Today automation is used to produce a large proportion of the devices supplied with robot assembly working had in hand with human operators to bring unheard of device consistency and quality.

Smiths Interconnect Has Invested in A Comprehensive Range of Environmental Tests at Dundee Facility to Replicate Deep Space Environment

Smiths Interconnect, a global supplier of cutting-edge connectivity solutions, has invested in a comprehensive range of environmental tests at their Dundee facility. This offers an important capability to customers not prepared to negotiate on fundamental reliability and insist on demonstrable compliance.

X-band RF Isolator and Circulator

The X-band belongs to the microwave frequency range. There are two versions of X-band: one refers to the radio wave band with a frequency of 8-12GHz, and the other refers to the frequency range of X-band with a frequency of 7-11.2GHz. This artical introduces some X-band RF isolators and circulators.

The Main Application of RF Circulator

In this article UIY will introduce two common applications of circulators: duplexer and RF isolators.

Smiths Interconnect Offered Isolators to Support NASA’s Europa Clipper Mission to Explore Jupiter’s Moon

Smiths Interconnect is proud to support NASA and the Johns Hopkins Applied Physics Laboratory in providing key components for use in the forthcoming Europa Clipper mission to explore one of Jupiter’s moons.

Smiths Interconnect Has a Very Large Portfolio of Existing Coaxial Isolators and Circulators for Space or Defence Applications

As it is impractical to solder the piece parts externally and pass the assembly into the cavity, Smiths Interconnect uses a contactless induction soldering and inspect the resultant solder joints using a Smiths Interconnect in-house 3D x-ray machine, whose 160keV beam makes short work of up to 5mm of steel.

SWaP challenges in the defence industry: How Smiths Interconnect rises to the challenge

The defence industry has exceptionally high connectivity demands, especially when it comes to size, weight and power (SWaP). Smiths Interconnect is an industry-leading provider of cutting-edge connectivity solutions to the defence sector for applications such as guidance systems, data links, manpack radios, radar systems (ground, air and shipboard), antenna systems and drones.

L, S & X-Band High Power Circulators and Isolators

型号- IA10001200P3KS,CB800012000P300S,CA31003500P3KS,IB800012000P300S,CA10001200P3KS,IA31003500P3KS

K-BAND PASSIVE COMPONENTS Space Qualified Coaxial and WR51 Isolators, Circulators and Iso-adapters, Waveguide Loads and Microstrip Isolators

型号- 19TE110,I190220/A,I233236/A,I190220/B,19HD353,I177220/H,I255270/A,C173202/C,19TE111,I173220/A,19TM107,19TM106,I173220/C,I235240/A,19TE109,19CD328,19HD359,19HD358,I178202/J,I178202/H

Smiths Interconnect’s Isolator is Connecting with (Potential) Life on Jupiter’s Moons

It was a galactic effort. No surprise, then, at the site’s pride in knowing JUICE’s first transmission was successfully made and received. Nor that the team saved JUICE’s July 2031 date of arrival at Jupiter, after which Smiths Interconnect’s isolator will be helping to relay data that is highly relevant to Earth’s immediate future.

From the Clouds of Everest to the Surface of Other Planets, Smiths Kits and Components Are Widely Used

Smiths kit is reckoned to be on half of the geostationary satellites orbiting the Earth at present, allowing us to drive by sat-nav, get reasonably accurate weather forecasts, receive 400 television channels, trade financial instruments in milliseconds and shoot first when opponents on the other side of the world converge on your position in Call of Duty.

Introduction to Common Frequency Band of Satellite Communication (C / Ku / KA Band)

UIY Inc. specializes in RF and microwave passive components, integrating R &D, production, sales and service. In this paper,UIY will introduce Common frequency band of satellite communication (C / Ku / KA band).

New X-band passive components for Space and Defence

Smiths Interconnect has launched its broad range of microstrip isolators, circulators and coaxial components in X-band.

电子商城

品牌:数明半导体

品类:High Speed Six Channel Digital Isolator

价格:¥3.4118

现货: 1,500

现货市场

登录 | 立即注册

提交评论