Cooling Particle Accelerators: Linear Accelerators and Cyclotrons

Introduction

Particle accelerators, such as linear accelerator (LINAC) and cyclotron systems, increase the kinetic energy of particles for use in a variety of applications, ranging from scientific studies on particle physics to radiation therapy for cancer patients. Particle accelerators, like most sensitive medical and laboratory equipment, are negatively affected by thermal variations, specifically an increase in heat. Temperature control of vital particle accelerator system components is critical for operational integrity, performance accuracy and system reliability. The increasing intricacy of thermal management means that particle accelerator systems often require custom Liquid Cooling Systems. However, these more advanced liquid cooling systems don’t have to extend the design cycle, or the budget.

LINAC background

LINACs are types of particle accelerators that increase the kinetic energy of particles for use in a variety of applications, ranging from scientific studies on particle physics to radiation therapy for cancer patients. For example, intensity-modulated radiation therapy (IMRT) uses a miniature linear particle accelerator to target tumor cells. While all body cells can be damaged by radiation, tumor cells are even more susceptible to it. Radiation therapy is used to specifically target the tumor while sparing nearby normal tissue. A LINAC is used to produce and deliver the radiation beam to the targeted area through a complex system. Electrons are injected into the waveguide, where the number of electrons is controlled by the temperature of the filament material. A vacuum is created for the waveguide to ensure that the electron beam is not impeded by other particles. Electric fields accelerate the electrons and increase the kinetic energy of the beam. A series of magnets controls the path of electrons through the flight tube, focusing the beam. X-rays are produced as the high-energy electron beam hits a heavy metal target material. Filters, dosimeters and collimators are used to minimize leakage, measure the radiation dose, and direct and shape the X-ray beam so that, on exit from the gantry, its shape matches the shape of the tumor.

Linear Accelerator

Cyclotron background

Two additional imaging techniques for cancer patients using particle accelerator systems are positron emission tomography (PET) and single-photon emission computed tomography (SPECT). These systems use a specific particle accelerator, known as a cyclotron, to create a radio tracer made from glucose, which is drawn to tumors. After this substance is ingested, inhaled or injected into the patient, it concentrates in the tumors within the body, allowing the PET or SPECT system to image the tumor by detecting the gamma rays coming from the patient. The cyclotron creates the radioactive isotopes by accelerating a fluid or gas in an outward spiral path and bombarding it with neutrons to create charged particles. The spiral path is maintained by a magnetic field, and the particles are accelerated by an applied electric field. The advantage a cyclotron is the maximum achievable extracted proton current, which is currently 2.2 mA. The energy and current correspond to 1.3 MW beam power, which is the highest of any accelerator currently existing. The radioactive substance produced for a PET scan has a very short half-life (i.e., a rapid decay time). A SPECT uses a different radioactive substance with a longer half-life and is used for other types of imaging. Because of the half-life of the radioactive material, the cyclotron needs to be installed near the PET or SPECT system, so it can be generated and given to the patient just before the imaging is done.

Cooling systems requirements

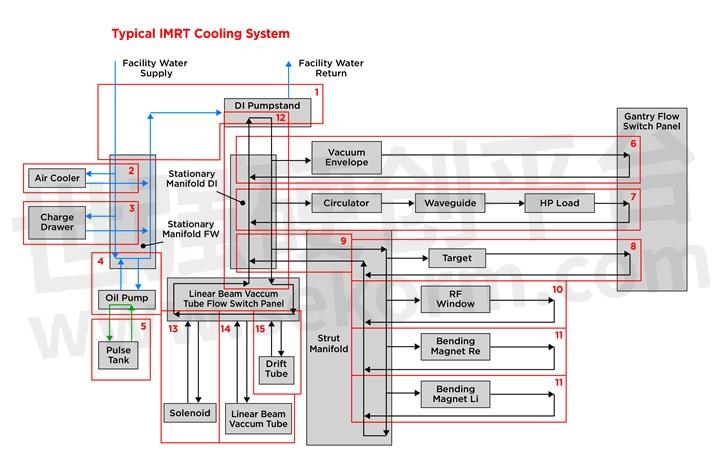

Within the LINAC used in IMRT equipment, thermal consistency is required to maintain beam energy and stability. The tungsten target, the waveguide, the acceleration chamber and the magnets all require precise thermal management to dissipate heat buildup and maintain temperature stability for optimal operation. Certain components in an IMRT system, like the wave guide and filament material, need thermal control within about 0.5℃, thus a liquid cooling system is most likely the best option. Components in the electronic cabinet, like amplifiers and power supplies, may also require cooling from a liquid cooling system if cold plates or heat exchangers cannot offer sufficient or efficient cooling performance. In a standard IMRT system, the cooling path is typically complicated. The facility water cools the charge drawer and oil pump, and then feeds to a liquid cooling system, which basically cools the rest of the system including the linear accelerator.

Illustration of cooling loops for a typical IMRT system.

Cyclotron systems require cooling of the components that generate the radioactive substance, including the magnets, ion sources, cryopump, and the water circuitry. In addition, the amplifiers, power supplies, and vacuum chamber also need cooling. Cold plates and heat exchangers are typically used to cool amplifiers, power supplies and the vacuum chamber in a cyclotron system. A liquid cooling system is vital to cooling tubing connections, solenoid valves, beam stops, and electrically isolated collimators.

Types of liquid cooling systems

Liquid cooling systems, which are self-contained units that recirculate coolant to a predefined set-point temperature, allow for optimal temperature stabilization for more precise temperature control. Liquid cooling systems are able to dissipate the large amount of heat generated in the densely packed electronic environment of linear accelerators and cyclotron systems. The introduction of a liquid coolant into a system of electronics need not be an item of concern as long as the liquid cooling system is designed and assembled properly. Liquid cooling systems offer higher efficiency than air-based heat exchangers, and provide more rapid cooling, quieter operation, higher reliability and more system uptime. One type of liquid cooling system uses a liquid-air heat transfer configuration, whereby a high-pressure pump recirculates the liquid coolant and an air heat exchanger removes the heat from the liquid circuit, dissipating it to the ambient environment by means of a fan. The coolant can be water, a water-glycol mixture, or transformer oil, depending on the temperature at the heat source; an oil-cooled system is used when the temperature exceeds the operational temperature limit of the water-based systems. A second type of liquid cooling system uses a liquid-liquid configuration, whereby the pump recirculates the coolant and ambient-temperature facility water is used in a liquid heat exchanger to dissipate heat on the hot side. The liquid-liquid system increases cooling capacity compared with the liquid-air system. These systems can be designed to operate with either water or oil as the coolant liquid, depending on the temperature environment. A third type of liquid cooling system is a compressor-based chiller system, whereby the pump recirculates coolant that is chilled to well below ambient temperature. Heat from the coolant is absorbed by the compressor-based system and is dissipated to the outside environment. The increasing complexity of thermal management means that IMRT and cyclotron system manufacturers often rely on external companies for temperature control solutions. Manufacturers like Laird Thermal Systems’ offer a series of standard and custom liquid cooling systems that provide liquid-to-air, liquid-to-liquid, or chiller-based systems in various sizes and cooling capacities. Its experience in the design, manufacture and servicing of liquid cooling systems, as well as expertise in pumps, compressor technology, evaporators and heat exchangers, allows IMRT and cyclotron manufacturers to focus on end product designs, while leaving the thermal management issues to the experts. For all types of liquid cooling systems, additional features can add precise temperature control, variable coolant flow rate, coolants with corrosion inhibitors and coolant filtration, as needed. Temperature control of multiple liquid circuits is often required, as is high operational temperature. Control of multiple pressure drop settings to accommodate both low and high-pressure conditions may be needed. Given the intricacy of some IMRT linear accelerator and cyclotron systems, usage of a custom designed liquid cooling system with plug-and-play components may be a good solution. For example, quick connect fittings to allow easy service and maintenance, such as a bottom drain for removing the coolant by gravity, or a pump that is easy to swap out if necessary, add to the system’s ease-of-use. Custom housing configurations for unique environments may be required. Laird Thermal Systems has the knowledge to custom design liquid cooling systems for these specific applications, as well as the experience to support and service them.

Looking ahead

Depending on the particular IMRT system, stationary cooling systems can be used, while other IMRT systems place the cooling system on the moveable gantry. One advancement in IMRT technology is the movement from analog to digital processing in order to image the tumor and treat the patient at the same time, thereby presenting additional cooling complexities. Cyclotron systems require a significant amount of cooling. Manufacturers are looking to reduce the size of cyclotrons and the cooling system so that the unit occupies a smaller footprint and a lesser amount of valuable floor space, which presents further cooling challenges due to the increase in the density of the electronics. As a result, many thermal management experts are looking to utilize a combination of liquid cooling systems and/or thermoelectric cooler assemblies, to cool cyclotron systems and in particular the detector arrays.

Conclusion

In today’s complex operating environment, liquid cooling systems are required to dissipate a large amount of heat in a densely packed electronic environment. Maximum operational life is required to keep particle accelerator system maintenance and repair down time to a minimum. Temperature stabilization has especially become critical, as next generation LINAC and cyclotron systems require more precise temperature control.

Applications

Medical

Medical Imaging

- |

- +1 赞 0

- 收藏

- 评论 0

本文由Ray转载自Laird Thermal Systems Official Website,原文标题为:Cooling Particle Accelerators: Linear Accelerators and Cyclotrons,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Common Coolant Types and Their Uses in Liquid Cooling Systems

This paper mainly introduces the common coolant types of Laird thermal system and its application in liquid cooling system, and analyzes the advantages and disadvantages of specific applications

Liquid to Liquid Ambient Cooling Systems for Semiconductor Tools

A semiconductor fabrication facility’s unique environment makes designing and building a liquid based cooling system one of the most challenging environments.In this paper, Laird Thermal Systems introduces the technical requirements for these systems, including material compatibility with semiconductor processes, the importance of stainless steel for wetted parts to prevent galvanic corrosion, and the use of special fluids like di-electric coolants.

Introduction to Thermal Management: Keeping Devices Cool

Effective thermal management techniques, like heat sinks, fans, liquid cooling systems, and thermal interface materials, enable devices and systems to operate safely, perform at their best, and have a longer lifespan.

Laird Thermal Systems(莱尔德热系统)液体冷却系统产品选型指南

目录- Introduction Benefits & Applications of Liquid Cooling Systems Nextreme™ Recirculating Chillers Liquid Heat Exchangers Custom Liquid Cooling Systems Featured Application: Medical Imaging

型号- 1510.00,WL1500,385901-001,VRC2400,VRC4500,NRC5000,WL3004,387008451,1550.00,LA5000,WL1000,385911-015,1520.00,387009925,OW4002,385910-043,387010178,387010179,NRC2400,1505.00,38701 0181,1264.00,1155.00,1104.00,VRC1200,WW5001,387002779,NRC400,WW3001,1515.00,WL500,WL2000,387005774,387005598,OL4503,385912-029,NRC1200,385910-015

What is the Thermal Wizard?

The Thermal Wizard is a product search and selection tool that helps engineers find the optimal thermal management solution for thermoelectric coolers, thermoelectric cooler assemblies and liquid cooling systems.

Laird Thermal Systems(莱尔德热系统)TEA和温度控制器选型指南

描述- Thermoelectric cooler assemblies are compact units that control the temperature of a wide variety of applications, such as laser diode packages in active optics, lasers in medical and industrial instrumentation, electronic enclosures, sample storage chambers in medical diagnostics and analytical instruments and batteries in various automotive and telecom applications.

型号- LA-045,DA-075-24-02-00-00,DA-034-24-02-00-00,AAC-050,LA-160,DA-014-12-02-00-00,AA-150-48-44-00-XX,AA-200-48-22-00-00,DAT-105-24-02-00-00,SLA-400,AA-200,DAT-040-12-02-00-00,AA-060-12-22-00-00,AA-100-,AAT-032-12-22-00-00,AA-040-24-22-00-00,DAT-065-24-02-00-00,DA-115-24-02-00-00,LL-120-24-00-00-00,AA-200-24-22-00-00,SDAX-135-24-02-00-00,Q SERIES,AA-150-24-44-00-XX,SLA-400-24-02-00-00,SAAX-215,DA-044-24-02-00-00,DL-210,DL-120-24-00-00,DA-045-24-02-00-00,SLAX-140,AA-150-24-22-00-00,385901-001,DA-024-24-02-00-00,AAT-027,SAAX-175,LA-115-24-02-00-00,AA-250-24-44-00-XX,ATT-027-12-22-00-00,AAT-085-12-22-00-00,LA-024-12-02-00-00,LA-045-12-02-00-00,QE-50,SAAX-175-24-22-00-00,DL-060,DA-280-48-02-00-00,NRC400,AA-480,SDAX,DA-160-24-02-00-00,387006702,AA-230,387006704,387006703,387006706,SR-54,387006708,SAAX-115-24-22-00-00,DA-075-12-02-00-00,LL-060-12-00-00-00,387006707,ATT-055-24-22-00-00,AA-024-12-22-00-00,LA-075-24-02-00-00,DAT-029-12-02-00-00,DAC-035-12-02-00-00,SLAX-215-24-02-00-00,AAT-055-12-22-00-00,DA-033-12-02-00-00,AA-100-24-22-00-00,DA-034-12-02-00-00,387004253,DL-060-24-00-00,DA-025,DAT-065-12-02-00-00,AA-230-48-D44-00-XX,DAT-105-12-02-00-00,AA-040-12-22-00-00,DA-280-24-02-00-00,AA-070-24-22-00-00,QC-50,DA-135-24-02-00-00,AA-060-24-22-00-00,DAC-060-24-02-00-00,NRC400-T0-00-PC1,AA-250-48-44-00-XX,AA-250,SDAX-220-24-02-00-00,AA-019-12-22-00-00,LL-210-24-00-00-00,AA-100-48-44-00-XX,PR-59,PR SERIES,DA-044-12-02-00-00,DA-045-12-02-00-00,AAC-050-24-22-00-00,X SERIES,AA-150,DA-024-12-02-00-00,AA-100-24-44-00-XX,DA-045,AAT-085-24-22-00-00,AA-230-24-D44-00-XX,AA-200-48-44-00-XX,DA-011-05-02-00-00,DA-280,LA-024-24-02-00-00,LA-160-24-02-00-00,LL-060,AA-480-24-44-00-XX,SLAX-215,SDAX-220,SAAX-140,AA-040,LA-045-24-02-00-00,SLAX-145-24-02-00-00,AA-200-24-44-00-XX,LL-210,AA-024-24-22-00-00,DL-210-24-00-00,AA-034-12-22-00-00,AA-480-48-44-00-XX,DL-060-12-00-00

What's the difference between standard and custom products?

Our standard products can be found in our product portfolio: Thermoelectric Coolers, Thermoelectric Cooler Assemblies, Liquid Cooling Systems, Temperature Controllers. These units have specific heat transfer methods, cooling capacity ranges or size constraints and can be ordered upon request from our distribution partners. If the capacity, size or other parameters of our standard products do not meet your application requirements you may need a customized solution. Laird Thermal Systems has the ability to customize our entire product range, however MOQ’s apply. To optimize performance and long-life operation, an application could require a customized thermal management solution. Also cooling capacities above 5 kW typically require a custom solution. Laird Thermal Systems designs and manufactures customized, thermal management solutions for performance-critical applications to optimize your product’s performance. Laird Thermal Systems offers strong engineering design services with a global presence that supports onsite concept generation, thermal modeling, mechanical and electrical design and rapid prototyping. The company also offers validation test services to meet unique compliance standards for each industry, such as UL, Telcordia, or a unique standard specific to a medical, industrial or semiconductor application.

Laird Thermal Systems Offers Thermoelectric Coolers, Thermoelectric Cooler Assemblies and Temperature Controllers for Refrigerated Centrifuges

Centrifuges are crucial for separating mixtures in medical and food processing labs. They face thermal challenges like temperature stability and noise levels. Thermoelectric coolers, like those from Laird Thermal Systems, offer an efficient and reliable solution for precise temperature control in centrifuges, reducing power consumption and maintenance costs. Laird‘s CP Series and temperature controllers provide stable cooling capacities and accurate control, making them ideal for various centrifuge applications.

Does LTS offer standalone cooling systems?

Yes, Laird Thermal Systems offers self-contained Liquid Cooling Systems. liquid cooling systems (LCS) that recirculate a coolant to a preprogrammed temperature setpoint.

Laird Thermal Systems‘ Nextreme™ Value Chillers Provide Economical, High Reliability OEM Cooling Solution

The Extreme Value Chiller Series uses high-performance components to cool well below ambient temperatures to control processes or dissipate heat away from thermally sensitive equipment.

How do I determine the best thermal solution for my application?

Laird Thermal Systems has developed the Thermal Wizard — a quick and easy selection tool helping customers determine the optimum cooling solution. To begin the selection process, users can input two application performance requirements; the required cooling power (Qc) and the desired temperature change (ΔT). If you know these specifications the Thermal Wizard product search will show thermoelectric coolers, thermoelectric cooler assemblies or liquid cooling systems that meet your application demands.

Thermoelectric Cooler Assemblies & Temperature Controllers

型号- TUNNEL SERIES,DA-075-24-02-00-00,POWERCOOL SERIES,DA-034-24-02-00-00,POWERCOOL,AAC-050,SUPERCOOL SERIES,DA-014-12-02-00-00,AA-150-48-44-00-XX,AA-200-48-22-00-00,DAT-105-24-02-00-00,SLA-400,AA-200,DAT-040-12-02-00-00,SLA-140-24-02-00-00,AA-060-12-22-00-00,AA-100-,AAT-032-12-22-00-00,AA-040-24-22-00-00,DAT-065-24-02-00-00,DA-115-24-02-00-00,CASCADE SERIES,387000639,LL-120-24-00-00-00,AA-200-24-22-00-00,AA-150-24-44-00-XX,SLA-400-24-02-00-00,SAA-170-24-22-00-00,DA-044-24-02-00-00,DL-210,DL-120-24-00-00,DA-045-24-02-00-00,AA-150-24-22-00-00,387000624,DA-024-24-02-00-00,OUTDOOR COOLER SERIES,AAT-027,LA-115-24-02-00-00,AA-250-24-44-00-XX,ATT-027-12-22-00-00,AAT-085-12-22-00-00,LA-024-12-02-00-00,LA-045-12-02-00-00,QE-50,387000612,DL-060,DA-280-48-02-00-00,NRC400,387003326,387003325,AA-480,387003324,DA-160-24-02-00-00,TUNNEL,AA-230,SR-54,DA-075-12-02-00-00,LL-060-12-00-00-00,ATT-055-24-22-00-00,AA-024-12-22-00-00,LA-075-24-02-00-00,DAT-029-12-02-00-00,DAC-035-12-02-00-00,AAT-055-12-22-00-00,DA-033-12-02-00-00,AA-100-24-22-00-00,SDA-195,DA-034-12-02-00-00,SAA-170,387004253,DL-060-24-00-00,DA-025,SAA-110-24-22-00-00,DAT-065-12-02-00-00,AA-230-48-D44-00-XX,DAT-105-12-02-00-00,AA-040-12-22-00-00,DA-044 -12-02-00-00,DA-280-24-02-00-00,AA-070-24-22-00-00,LIQUID SERIES,QC-50,DA-135-24-02-00-00,AA-060-24-22-00-00,DAC-060-24-02-00-00,NRC400-T0-00-PC1,AA-250-48-44-00-XX,AA-250,AA-019-12-22-00-00,SDA-195-24-02-00-00,LL-210-24-00-00-00,AA-100-48-44-00-XX,PR-59,OUTDOOR COOLER,DA-045-12-02-00-00,DA-044-12-02-00-00,AAC-050-24-22-00-00,AA-150,DA-024-12-02-00-00,AA-100-24-44-00-XX,DA-045,SUPERCOOL,AAT-085-24-22-00-00,AA-230-24-D44-00-XX,SLA-205-24-02-00-00,SDA-130-24-02-00-00,CASCADE,AA-200-48-44-00-XX,DA-011-05-02-00-00,DA-280,LA-024-24-02-00-00,LA-160-24-02-00-00,LL-060,AA-480-24-44-00-XX,AA-040,LA-045-24-02-00-00,AA-200-24-44-00-XX,LL-210,LIQUID,AA-024-24-22-00-00,DL-210-24-00-00,AA-034-12-22-00-00,AA-480-48-44-00-XX,DL-060-12-00-00

电子商城

品牌:Laird Thermal Systems

品类:半导体制冷模组(TEA)

价格:¥2,569.5300

现货: 0

品牌:Laird Thermal Systems

品类:半导体制冷模组(TEA)

价格:¥3,679.8700

现货: 0

品牌:Laird Thermal Systems

品类:半导体制冷模组(TEA)

价格:¥1,878.4300

现货: 0

品牌:Laird Thermal Systems

品类:半导体制冷模组(TEA)

价格:¥1,547.6100

现货: 0

品牌:Laird Thermal Systems

品类:半导体制冷模组(TEA)

价格:¥1,280.6700

现货: 0

服务

使用FloTHERM和Smart CFD软件,提供前期热仿真模拟、结构设计调整建议、中期样品测试和后期生产供应的一站式服务,热仿真技术团队专业指导。

实验室地址: 深圳 提交需求>

提供稳态、瞬态、热传导、对流散热、热辐射、热接触、和液冷等热仿真分析,通过FloTHERM软件帮助工程师在产品设计初期创建虚拟模型,对多种系统设计方案进行评估,识别潜在散热风险。

实验室地址: 深圳 提交需求>

登录 | 立即注册

提交评论