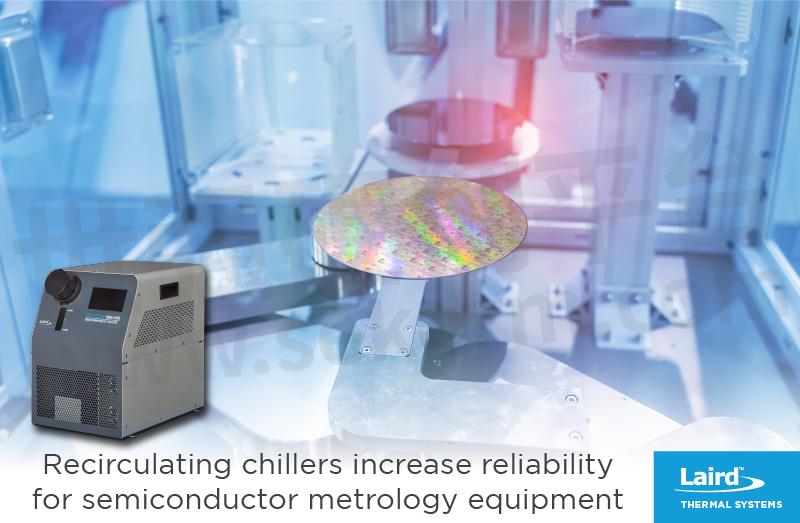

OEM Perspectives: Recirculating Chillers for Semiconductor Metrology & Inspection Systems

Introduction

Semiconductor metrology is critical in the semiconductor fabrication process. The complex nature of semiconductor fabrication now requires multiple test stages in between processing steps. Thin film semiconductor wafers are tested using several techniques including ellipsometry and reflectometry. Sophisticated optical equipment is used to inspect for defects as well as for accurate dimensional measurements. Manufacturers of optical inspection systems must integrate a thermal solution for temperature stabilization of optical components. Thermal noise can impact the imaging system by degrading the quality of the image resolution. Thermal noise fluctuations can also reduce the lifetime of thermally sensitive components, leading to downtime in the inspection system and the semiconductor fabrication process. Downtime of equipment can lead to millions of dollars of lost revenue for manufacturers.

Background

The semiconductor industry has grown into a 500 billion dollar a year industry. Making up more than 99% of the market, the metal-oxide-semiconductor field-effect transistor (MOSFET) is the most popular semiconductor device.

The thin film semiconductor industry has been one of constant process improvement, with each generation of the semiconductor manufacturing process is referred to as process node. Depending on the specific semiconductor process, there are rules on the minimum size and spacing for features on each layer of the chip. With advancements in manufacturing processes, several fabrication plants can now produce 5 nm semiconductors. Other common sizes are 10 nm and 12 nm. Constant process improvement is necessary in order to establish cost effective high yielding production lines as they struggle to keep pace with Moore’s law. Much of this has been made possible through the integration of automated optical inspection systems.

Enhanced manufacturing processes such as automated optical inspection systems have enabled production of 5 nm semiconductors.

Modern metrology systems

Automated metrology systems are now implemented throughout the manufacturing process. Some of the key parameters measured are thickness, refractive index, resistivity and stress of the thin films. These systems are used to not only characterize all of the physical properties of the device during fabrication including: the electrical, optical and mechanical properties of the material, but to feed this information back into the manufacturing process.

Metrology techniques differ according to the number and type of integrated circuit. Metrology tools that work within one process tend to be more stable. Those that are applied to differing products will require periodic requalification. One example of an evolution in metrology can be found in the measurement of the thickness of a thin film. Various thin film measurement methods, such as surface profilometry and resistivity measurements are very difficult to carry out during processing, and analysis of thin film growth rate is usually performed after the deposition run. Traditionally ellipsometry was used for thin film thickness measurements but it lacks the ability to make measurements when the film is opaque. In this area, ultrasonics are especially valuable for measuring the thickness of various films opaque or transparent.

Though the tooling and strategies may change, some things remain constant. The number of measurement points varies by semiconductor device manufacturer or device. Metrology is undertaken according to the following sampling method: 10 to 100 points for one die, 5 to 20 die taken from one wafer, and 1 to 2 wafers taken from each lot (25 wafers). Newly designed devices may go through several thousand metrological processes for one wafer during the start-up period of manufacture.

One major change in the semiconductor industry has been the introduction and use of real time process control. Sensors within automated optical inspection systems are used to provide live feedback of local process conditions to the process tool. This data can be used to modify the process parameters of the tool or to stop the line. This type of test characterization is referred to as in-situ process measurements.

Application challenges

The need for higher throughput, higher packaging density and repeatability combined with a high speed optical measurement system places ever increasing demands on the thermal management system associated with metrology tools. Furthermore, the lack of precise temperature control will lead to bad data, incorrect decisions, conclusions and significant yield loss.

Temperature control

No matter the type of automated optical inspection method, tight temperature regulation is required for the proper performance and long-term operation of optical components. Many modern semiconductor automated optical inspection systems, like ultrasonics, now use lasers as the source for testing speed and accuracy. If the optical source is a laser, it inherently generates heat during operation and must be precisely cooled to maintain the desired wavelength. Lasers will pulsate with change in temperature, effecting the testing accuracy.

Metrology imaging techniques using a CCD- or CMOS-based camera also require tight temperature tolerances as resolution degrades with increasing temperatures. Depending on the design of the automated optical inspection (AOI) tool, the system may contain several imaging sensors creating high quality 3D images. The imaging sensors must be kept below room temperature with a temperature stability of ± 0.5℃ or better. Precise temperature control is needed to keep the imaging sensor stable to maintain high image resolution. Cooling laser optics and key components also helps increase equipment uptime, reduces maintenance and lowers total cost of ownership by extending the mean time between failures (MTBF).

Semiconductor automated optical inspection (AOI) systems often require removal of up to 100 Watts or more and temperature stability at 20℃ or below with stability greater than 0.01℃.

Semiconductor optical inspection must be kept at 20℃ or below with a temperature stability of 0.01℃.

Reliability

Many semiconductor automated optical inspection systems operate 24/7. One key cooling system requirement is high reliability with minimal down time. The cooling system must maximize equipment uptime, reduce maintenance and lower the total cost of ownership by increasing the mean time between failure (MTBF). This combined with temperature stability of temperature control to as tight a tolerance as possible.

Thermal load typically increases with more electronics inside smaller housings. As automated optical inspection (AOI) tool imaging systems commonly feature small housings, cooling solutions must offer design flexibility in addition to superior cooling performance. To meet the required cooling capacity in a more compact form factor, the thermal management solution must have a high coefficient of performance (COP) for cooling well below ambient temperatures.

Space Constraints

The complexity of metrology systems can increase the heat flux density as more optoelectronics are packed into smaller footprints. Dissipating heat away from the sensitive components with air-based heat exchangers will raise the temperature of surrounding electronics. By using a recirculating chiller, waste heat can be routed out more efficiently and dissipated into the surrounding environment.

Noise & Vibration

Cooling systems for automated optical inspection (AOI) tools must continuously deliver a steady flow coolant to the temperature sensitive components without pulsation. Pulsation can distort measurement resolution quality from fluctuations in temperature control. This will not only degrade ability to measure, but also the operational lifetime of components.

Cooling systems must also be quieter (both lower noise and vibration) during operation. Larger compressor-based systems can be distracting and disruptive for operators. Thermoelectric-based chillers are designed with smaller fans and pumps providing a lower decibel level in a semiconductor fabrication facility.

Condensation

It is also important to protect optoelectronics against condensation. Even for applications where the set point temperature is at 20⁰C, the cold side of the thermoelectric cooler can be at 10℃ or colder to maintain that set point temperature. This will most likely be below the dew point temperature and cause moisture in the air to condense. Sealing the perimeter of the thermoelectric cooler with RTV is not sufficient. It is recommended to have a second insulation barrier to protect the thermoelectric cooler cavity. All surfaces that go below dew point will require some type of insulation to keep moisture from condensing on those surfaces. This is usually a close cell foam or other type of insulation that does not absorb moisture and has good thermal insulating properties.

Environmental Regulations

Environmental regulations continue to phase out the use of destructive refrigerants tied to ozone depletion and global warming. Older compressor-based systems utilize environmentally harmful HFC refrigerants including R134a and R404A. Modern compressor-based systems now use a variety of natural refrigerants: R744 (carbon dioxide), R717 (ammonia), R290 (propane), R600a (Iso-Butane), and R1270 (propylene). Although they have their own complications, including flammability, these natural refrigerants are significantly better for the environment.

Comparing technologies

Direct cooling

Stages upon which the semiconductor wafers are placed for measurement can be temperature controlled using a thermoelectric cooler. Thermoelectric coolers can be used for precise temperature control as they have the ability to change the heat pumping direction through the device under test by reversing the current flow through the device. This allows the thermoelectric cooler to deliver precise temperature stability to within ±0.01C under steady state conditions. For this type of cooling application thermoelectric coolers from tens of watts to more than 300 Watts of cooling capacity can be required.

Liquid cooling

The water-cooled stainless-steel measurement stage can also be cooled using a water-glycol coolant mixture. The channeled cold plate is directly attached to the measurement stage and a chiller provides a cooling fluid to maintain precise temperature control. Highly reliable thermoelectric-based chillers with capacity up to 400 W are typically used. Units such as these are designed for bench-top or rack mount configurations.

Thermoelectric solutions

With the ability to cool to well below ambient, thermoelectric Recirculating chillers are a better option than passive solutions such as heat sinks and fans or ambient liquid cooling systems. Thermoelectric-based recirculating chillers are compact and have few moving parts. This offers high reliability with minimal maintenance throughout the product life cycle. Thermoelectrics are able to achieve very precise temperature control which is required for spot cooling of metrology inspection systems.

This illustration shows how a thermoelectric chiller pumps heat from a metrology imaging tool down to 18℃, while room temperature may fluctuate between 20 and 30℃. Heat from the camera system is absorbed by the liquid coolant and flows to a reservoir tank by a pump.

Cooling of CMOS/CCD sensors in semiconductor metrology systems.

The pump pushes coolant thru the Liquid-to-Air thermoelectric engine, which then cools the temperature of the coolant circuit while exhausting waste heat into the surrounding environment. The coolant then flows back to the camera system at a set point temperature where the cold plate is mounted. The system is semi-closed which makes it difficult for air to seep into the liquid circuit and reduces algae growth. An ethanol glycol water mixture is recommended to use as coolant since it prevents algae growth from building up over time. The recirculating chiller can be designed to cool multiple critical optoelectronic components in series beyond the metrology camera system, such as a detector or/and FPGA’s.

Integrated inside the camera is a thermoelectric cooler that is soldered to the cold plate and cools the CCD or CMOS sensor housing down further to -20 or -30℃ depending on the imaging resolution required. The combination of a recirculating chiller and thermoelectric cooler keeps thermal noise down and maximizes image resolution.

Laird Thermal Systems Solution

The NRC400 Nextreme Performance Chiller offers OEMs a premium thermoelectric-based chiller featuring high performance Peltier coolers and heat exchanger technology. By utilizing next-generation thermoelectric coolers, it achieves 400 Watts of cooling capacity and a temperature control stability of ±0.05°C under steady state conditions.

Compared to previous models, the NRC400 offers a higher coefficient of performance (COP) and quieter operation for semiconductor fabrication facilities. Solid-state thermoelectric technology reduces the number of moving parts, minimizing maintenance requirements throughout the life of the product.

Traditional compressor-based systems are often large and heavy. Modern cooling systems such as thermoelectric-based chillers are designed with portability in mind, which means that it can be used to cool multiple pieces of equipment in the facility.

The NRC400 features an intuitive easy-to-use LCD touch screen display that allows users to easily control temperature setpoints and alarm features. The semi-closed system is equipped with a larger reservoir tank, requiring less refilling during operation and better temperature stability.

This product has been approved by UL for industrial lab use, reference UL 61010-1 and has CE marking. The NRC400 is RoHS compliant and environmentally friendly as no harmful HFC refrigerants are being used. It operates on a universal power supply, making it easy to source one-part number for global use.

Conclusion

Complex wafer processing has increased the demand for metrology in between the various processing steps. Semiconductor automated optical inspection (AOI) systems require highly reliable cooling systems that can operate 24/7 and deliver precise temperature control. Recirculating chillers assisted by thermoelectric coolers are becoming more popular among OEMs due to higher reliability and lower operating costs compared to traditional compressor-based recirculating chillers. In addition, a recirculating chiller system that uses thermoelectric coolers can heat and cool to offer more advanced temperature stability for critical components. Recirculating chillers with thermoelectric coolers increase performance, reduce maintenance, and lower the overall cost of ownership for semiconductor automated optical inspection systems.

More information on the NRC400 can be found by visiting https://www.lairdthermal.com/nextreme-nrc400

Applications

Industrial

Semiconductor Fabrication Equipment

Product Section

Nextreme™ Series, Recirculating Chillers

- |

- +1 赞 0

- 收藏

- 评论 0

本文由Ray转载自Laird Thermal Systems Official Website,原文标题为:OEM Perspectives: Recirculating Chillers for Semiconductor Metrology & Inspection Systems,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Laird Thermal Systems’ PowerCycling PCX Series Thermoelectric Cooler Features a Unique Construction That Reduces Thermal Stresses in Thermal Test Sockets

Thermal cycling exposes thermoelectric coolers to mechanical stresses as the module contracts and expands from repeated cooling and heating cycles. Laird Thermal Systems’ PowerCycling PCX Series features a unique construction that reduces thermal stresses, providing optimal performance and long-life operation. Assembled with next generation materials, the PCX Series achieves faster ramp rates when compared to standard thermoelectric cooler offerings.

应用方案 发布时间 : 2024-10-25

Security Cameras‘ Cooling Solution : Laird Thermal Systems™ HiTemp ETX Series of thermoelectric coolers

To ensure high-resolution images and prevent system failure, active cooling of sensitive camera components is required. Laird Thermal Systems™ HiTemp ETX Series of thermoelectric coolers can survive temperatures up to 150⁰C and is ideal for cooling outdoor security cameras. The module is assembled with advanced thermoelectric materials, offering a 10% boost in cooling capacity compared to standard thermoelectric coolers.

应用方案 发布时间 : 2024-10-21

OEM Perspectives: Value Chiller provides Economical, Reliable Cooling for Mass Spectrometry

Compressor-based chillers with integrated temperature control offer mass spectrometer OEMs an advanced thermal management solution for maintaining the system’s optimum operating temperature. The ideal solution for such environments is an eco-friendly, efficient, and maintenance-free compressor-based chiller, such as the Nextreme™ Value Chiller, which quietly cools temperature-sensitive components below ambient temperature to help ensure accurate testing results.

应用方案 发布时间 : 2024-10-10

Laird Thermal Systems(莱尔德热系统)液体冷却系统产品选型指南

目录- Introduction Benefits & Applications of Liquid Cooling Systems Nextreme™ Recirculating Chillers Liquid Heat Exchangers Custom Liquid Cooling Systems Featured Application: Medical Imaging

型号- 1510.00,WL1500,385901-001,VRC2400,VRC4500,NRC5000,WL3004,387008451,1550.00,LA5000,WL1000,385911-015,1520.00,387009925,OW4002,385910-043,387010178,387010179,NRC2400,1505.00,38701 0181,1264.00,1155.00,1104.00,VRC1200,WW5001,387002779,NRC400,WW3001,1515.00,WL500,WL2000,387005774,387005598,OL4503,385912-029,NRC1200,385910-015

Laird Thermal Systems(莱尔德热系统)热电冷却器选型指南(英文)

型号- 430478-502,HTX20-31-F2A-0909-11-W2.25,64979-501,CP085-127-06-L1-W4.5,UTX15-24-F2-5252-TA-W6,CP14-31-10-L1-W4.5,ETX7-3-F1-2020-TA-RT-W6,9360001-301,7050045-502,71061-504,ETX14-12-F1-6262-TA-W6,PCX SERIES,UTX6-24-F1-5555-TA-W6,HTX15-31-F2A-0909-TB-W2.25,PCX7-156-F2-1672-TA-RT-W6,387008429,SH08-28-05-L1-W4.5,PCX6-12-F1-4040-TA-RT-W6,CP14-71-10-L1-W4.5,ULTRATEC™ UTX SERIES,PCX8-12-F1-4040-TA-W6,9340006-301,71092-501,ETX4-7-F1-2323-TA-W6,PCX7-16-F1-4040-TA-W6,ETX15-28-F2-5252-TA-RT-W6,387008431,CP14-127-10-L1-W4.5,387007103,CP14-35-045-L1-W4.5,430705-503,ETX4-7-F2-3030-TA-RT-W6,387007106,387007227,387007108,HTX12-65-F2A-1312-TB-RT-W2.25,OPTOTEC™ HTX,430874-503,71062-514,387007231,CP08-63-06-L1-W4.5,387007112,387007113,9350004-301,387007115,430052-501,387007117,MS5-257-10-15-11-W8,ETX2.5-12-F1-3030-TA-RT-W6,CP08-127-05-L1-W4.5,PCX10-223-F1-3172-TA-RT-W6,CP14-127-045-L1-W4.5,HITEMP ETX SERIES,430922-501,387007120,387007123,387007122,9320002-301,MS3-119-20-15-11-W8,ETX11-12-F1-4040-TA-RT-W6,MS SERIES,56760-505,ETX15-12-F2-4040-TA-RT-W6,MS2-192-14-20-11-18-11-W8,ETX6-12-F1-4040-TA-RT-W6,56590-502,SH10-23-06-L1-W4.5,71036-505,56610-502,MS4-108-10-20-11-W8,ETX4-12-F1-3030-TA-W6,430027-501,PCX12-248-F1-5040-TA-RT-W6,PT4-7-F2-3030-TA-W6,430848-502,OTX12-65-F2A-1312-11-W2.25,430848-504,PCX8-7-F2-3030-TA-RT-W6,MS2-068-14-14-15-15-11-W8,CP14-71-045-L1-W4.5,PCX,OTX20-66-F0-1211-11-W2.25,PCX4-6-F1-2040-TA-RT-W6,HTX,PCX5-16-F1-4040-TA-W6,56430-501,OTX19-23-F1N-0608-11-W2.25,HTX SERIES,UTX9-28-F2-4040-TA-W6,PCX15-7-F1-4040-TA-RT-W6,PT4-12-F2-3030-TA-W6,CP12-161-04-L1-W4.5,16506-302,430875-503,PCX8-6-F1-2040-TA-RT-W6,ETX4-3-F1-2020-TA-RT-W6,43280-503,66100-501,66156-505,71063-505,44440-501,71020-505,56550-501,MS3-052-10-17-11-W8,387004692,387005660,71012-506,SH10-125-05-L1-W4.5,387005662,ETX2.3-4-F1-1919-TA-RT-W6,ETX5-6-F1-2040-TA-RT-W6,387005663,ETX4-12-F2-4040-TA-RT-W6,387005664,387004697,387005665,387005667,387005669,OTX12-66-F0-1211-11-W2.25,430097-507,ETX2.6-12-F1-2525-TA-W6,PCX9-3-F2-2525-TB-RT-W6,387005671,387005672,MS2-102-22-22-17-17-11-W8,387005673,387005674,387005676,387005677,387005678,387005679,387005318,CP10-254-06-L1-W4.5,ETX9-3-F2-2525-TA-W6,CP10-71-05-L1-W4.5,430026-503,430511-504,56910-502,OTX20-66-F0-1211-11-EP-W2.25,387005681,387006650,56995-501,387006891,387005683,CP10-31-05-L1-W4.5,ETX6-19-F1-4040-TA-RT-W6,387006893,387005685,387005686,387006534,387006897,HTX15-30-F2A-0610-11-W2.25,OTX12-65-F2A-1312-TB-W2.25,RH14-14-06-L1-W4.5,ETX2-12-F2-3030-TA-W6,PCX8-6-F1-3518-TA-RT-W6,MS2-102-14-14-17-17-11-W8,387006784,UTX15-288-F2-5252-TA-W6,387005696,387006544,387005698,387005699,ETX4-12-F1-4040-TA-RT-W6,SH14-125-10-L1-W4.5,CP14-71-06-L1-W4.5,9340001-301,HTX12-18-F2A-0606-11-RT-W2.25,ETX,387006791,387006795,CP2-127-10-L1-W4.5,387006798,63604-511,CP14-199-06-L1-W4.5,PCX6-24-F1-5555-TA-RT-W6,OTX20-65-F2A-1312-11-W2.25,PCX5.6-19-F1N-3030-TA-RT-W6,ETX15-24-F2-5252-TA-W6,MS3-231-10-15-11-W8,SH14-125-045-L1-W4.5,62910-510,POWERCYCLING PCX,387005354,PCX24-128-F2-5555-TA-RT-W6,HTX15-65-F2A-1312-TB-W2.25,POWERCYCLING PCX SERIES,CP10-131-04-L1-TOW-W4.5,OTX08-18-F0-0505-11-W2.25,HTX12-18-F2A-0606-GG-W2.25,CP14-199-045-L1-W4.5,CP2-71-06-L1-W4.5,ETX4-6-F2-2143-TA-RT-W6,OTX20-68-F1A-1313-11-W2.25,71212-502,OPTOTEC™ OTX SERIES,CP SERIES,CP2-31-06-L1-W4.5,63595-501,POLARTEC™ PT SERIES,PCX4-4-F1-1515-TA-RT-W6,ETX8-12-F2-2525-TA-RT-W6,HTX12-65-F2A-1312-11-W2.25,OTX08-31-F1-0707-11-RT-W2.25,PT8-12-F2-4040-TA-W6,ETX4-12-F2-3030-TA-RT-W6,CP10-71-06-L1-W4.5,OTX08-66-F0-1009-11-RT-W2.25,CP14-17-10-L1-W4.5,ETX11-12-F2-3030-TA-RT-W6,ETX3-3-F2-1518-TA-W6,PCX4-7-F1-2020-TA-RT-W6,387004970,MS2-190-10-10-12-12-11-W8,387005700,CP10-127-06-L1-W4.5,ETX2.5-12-F1-4040-TA-RT-W6,9340002-301,MS2-065-04-04-11-11-11-W4,71049-501,9350007-301,POLARTEC™ PT,387006926,PT4-12-F2-4040-TA-W6,387006928,387006927,PCX11-12-F2-3030-TA-RT-W6,RH14-32-06-L1-W4.5,MS2-051-22-25-22-25-11-W8,ETX14-3-F1-3030-TA-RT-W6,MS4-115-14-15-11-W8,PCX8-176-F2-7528-TA-RT-W6,SH14-15-06-L-W4.5,PCX7.5-13-F1-4023-TA-RT-W6,OTX15-68-F1A-1313-11-W2.25,CP2-127-06-L1-W4.5,ETX6-7-F2-3030-TA-RT-W6,OTX08-08-F0-0303-11-W2.25,PCX6-28-F2-4040-TA-RT-W6,44530-501,MS2-049-10-10-15-15-11-W8,16503-310,475010-313,ETX3-48-F1-1212-GG-W6,UTX8-288-F2-5252-TA-W6,ETX2.6-6-F1-1225-TA-W6,UTX6-19-F1-4040-TA-W6,430436-504,OPTOTEC™ OTX,387006832,387006834,387006836,387006837,9350006-301,387006839,HTX20-65-F2A-1312-11-W2.25,9380001-301,MS3-070-20-25-11-W8,9340003-301,MS2-192-14-20-15-25-11-W8,MS4-129-10-15-11-W8,PCX2-12-F1-3030-TA-RT-W6,ETX2-6-F1-1225-TA-RT-W6,ETX4-3-F1-1515-TA-RT-W6,387005513,387006845,387005514,387005515,387006847,387005516,ETX25-12-F1-6262-TA-W6,ETX1.6-12-F2-3030-TA-RT-W6,OTX12-66-F0-1211-TB-RT-W2.25,430023-507,9350001-301,HITEMP ETX,387004679,57180-501,CP10-63-06-L1-W4.5,71035-505,PCX4-139-F1-1850-TA-RT-W6,ETX SERIES,UTX8-12-F2-2525-TA-W6,430474-501,MS2-107-10-10-12-12-11-W8,ETX8-12-F1-4040-TA-RT-W6,UTX11-12-F2-3030-TA-W6,387004680,ETX6-3-F1-2020-TA-RT-W6,OTX SERIES,387004685,387005659,PCX15-128-F

The Nextreme™ Performance Chiller Series from Laird Thermal Systems Offers Reliable Temperature Control for Laboratory Equipment

Modern lab equipment is getting smaller and more efficient, with chillers like the Nextreme series providing precise temperature control for various applications. These chillers are compact, portable, use eco-friendly refrigerants, and meet global safety standards, helping labs save costs, space, and ensure reliable results.

产品 发布时间 : 2024-10-26

Laird Thermal Systems(莱尔德热系统)TEA和温度控制器选型指南

描述- Thermoelectric cooler assemblies are compact units that control the temperature of a wide variety of applications, such as laser diode packages in active optics, lasers in medical and industrial instrumentation, electronic enclosures, sample storage chambers in medical diagnostics and analytical instruments and batteries in various automotive and telecom applications.

型号- LA-045,DA-075-24-02-00-00,DA-034-24-02-00-00,AAC-050,LA-160,DA-014-12-02-00-00,AA-150-48-44-00-XX,AA-200-48-22-00-00,DAT-105-24-02-00-00,SLA-400,AA-200,DAT-040-12-02-00-00,AA-060-12-22-00-00,AA-100-,AAT-032-12-22-00-00,AA-040-24-22-00-00,DAT-065-24-02-00-00,DA-115-24-02-00-00,LL-120-24-00-00-00,AA-200-24-22-00-00,SDAX-135-24-02-00-00,Q SERIES,AA-150-24-44-00-XX,SLA-400-24-02-00-00,SAAX-215,DA-044-24-02-00-00,DL-210,DL-120-24-00-00,DA-045-24-02-00-00,SLAX-140,AA-150-24-22-00-00,385901-001,DA-024-24-02-00-00,AAT-027,SAAX-175,LA-115-24-02-00-00,AA-250-24-44-00-XX,ATT-027-12-22-00-00,AAT-085-12-22-00-00,LA-024-12-02-00-00,LA-045-12-02-00-00,QE-50,SAAX-175-24-22-00-00,DL-060,DA-280-48-02-00-00,NRC400,AA-480,SDAX,DA-160-24-02-00-00,387006702,AA-230,387006704,387006703,387006706,SR-54,387006708,SAAX-115-24-22-00-00,DA-075-12-02-00-00,LL-060-12-00-00-00,387006707,ATT-055-24-22-00-00,AA-024-12-22-00-00,LA-075-24-02-00-00,DAT-029-12-02-00-00,DAC-035-12-02-00-00,SLAX-215-24-02-00-00,AAT-055-12-22-00-00,DA-033-12-02-00-00,AA-100-24-22-00-00,DA-034-12-02-00-00,387004253,DL-060-24-00-00,DA-025,DAT-065-12-02-00-00,AA-230-48-D44-00-XX,DAT-105-12-02-00-00,AA-040-12-22-00-00,DA-280-24-02-00-00,AA-070-24-22-00-00,QC-50,DA-135-24-02-00-00,AA-060-24-22-00-00,DAC-060-24-02-00-00,NRC400-T0-00-PC1,AA-250-48-44-00-XX,AA-250,SDAX-220-24-02-00-00,AA-019-12-22-00-00,LL-210-24-00-00-00,AA-100-48-44-00-XX,PR-59,PR SERIES,DA-044-12-02-00-00,DA-045-12-02-00-00,AAC-050-24-22-00-00,X SERIES,AA-150,DA-024-12-02-00-00,AA-100-24-44-00-XX,DA-045,AAT-085-24-22-00-00,AA-230-24-D44-00-XX,AA-200-48-44-00-XX,DA-011-05-02-00-00,DA-280,LA-024-24-02-00-00,LA-160-24-02-00-00,LL-060,AA-480-24-44-00-XX,SLAX-215,SDAX-220,SAAX-140,AA-040,LA-045-24-02-00-00,SLAX-145-24-02-00-00,AA-200-24-44-00-XX,LL-210,AA-024-24-22-00-00,DL-210-24-00-00,AA-034-12-22-00-00,AA-480-48-44-00-XX,DL-060-12-00-00

PC8-12-F1-4040-TA-RT-W6 PowerCycling PC Series Thermoelectric Cooler

型号- PCX SERIES,108127086001,PCX,PC8-12-F1-4040-TA-RT-W6,PCX8-12-F1-4040-TA-RT-W6,PC SERIES,387005695

Laird Thermal Systems Introduces Eco-Friendly EFC Chiller with Natural Refrigerant R-290

As the EU moves to ban fluorinated refrigerants by 2027 under the F-gas regulation, Laird Thermal Systems product aligns with this environmentally conscious shift. With nearly a decade of experience in developing customer-specific solutions using natural refrigerants, we‘re proud to introduce the EFC, featuring R290.

产品 发布时间 : 2024-06-19

Thermoelectric Cooler Assemblies & Temperature Controllers

型号- TUNNEL SERIES,DA-075-24-02-00-00,POWERCOOL SERIES,DA-034-24-02-00-00,POWERCOOL,AAC-050,SUPERCOOL SERIES,DA-014-12-02-00-00,AA-150-48-44-00-XX,AA-200-48-22-00-00,DAT-105-24-02-00-00,SLA-400,AA-200,DAT-040-12-02-00-00,SLA-140-24-02-00-00,AA-060-12-22-00-00,AA-100-,AAT-032-12-22-00-00,AA-040-24-22-00-00,DAT-065-24-02-00-00,DA-115-24-02-00-00,CASCADE SERIES,387000639,LL-120-24-00-00-00,AA-200-24-22-00-00,AA-150-24-44-00-XX,SLA-400-24-02-00-00,SAA-170-24-22-00-00,DA-044-24-02-00-00,DL-210,DL-120-24-00-00,DA-045-24-02-00-00,AA-150-24-22-00-00,387000624,DA-024-24-02-00-00,OUTDOOR COOLER SERIES,AAT-027,LA-115-24-02-00-00,AA-250-24-44-00-XX,ATT-027-12-22-00-00,AAT-085-12-22-00-00,LA-024-12-02-00-00,LA-045-12-02-00-00,QE-50,387000612,DL-060,DA-280-48-02-00-00,NRC400,387003326,387003325,AA-480,387003324,DA-160-24-02-00-00,TUNNEL,AA-230,SR-54,DA-075-12-02-00-00,LL-060-12-00-00-00,ATT-055-24-22-00-00,AA-024-12-22-00-00,LA-075-24-02-00-00,DAT-029-12-02-00-00,DAC-035-12-02-00-00,AAT-055-12-22-00-00,DA-033-12-02-00-00,AA-100-24-22-00-00,SDA-195,DA-034-12-02-00-00,SAA-170,387004253,DL-060-24-00-00,DA-025,SAA-110-24-22-00-00,DAT-065-12-02-00-00,AA-230-48-D44-00-XX,DAT-105-12-02-00-00,AA-040-12-22-00-00,DA-044 -12-02-00-00,DA-280-24-02-00-00,AA-070-24-22-00-00,LIQUID SERIES,QC-50,DA-135-24-02-00-00,AA-060-24-22-00-00,DAC-060-24-02-00-00,NRC400-T0-00-PC1,AA-250-48-44-00-XX,AA-250,AA-019-12-22-00-00,SDA-195-24-02-00-00,LL-210-24-00-00-00,AA-100-48-44-00-XX,PR-59,OUTDOOR COOLER,DA-045-12-02-00-00,DA-044-12-02-00-00,AAC-050-24-22-00-00,AA-150,DA-024-12-02-00-00,AA-100-24-44-00-XX,DA-045,SUPERCOOL,AAT-085-24-22-00-00,AA-230-24-D44-00-XX,SLA-205-24-02-00-00,SDA-130-24-02-00-00,CASCADE,AA-200-48-44-00-XX,DA-011-05-02-00-00,DA-280,LA-024-24-02-00-00,LA-160-24-02-00-00,LL-060,AA-480-24-44-00-XX,AA-040,LA-045-24-02-00-00,AA-200-24-44-00-XX,LL-210,LIQUID,AA-024-24-22-00-00,DL-210-24-00-00,AA-034-12-22-00-00,AA-480-48-44-00-XX,DL-060-12-00-00

Nextreme™ Value Chiller Specification and User Manual

型号- 387008803,VRC1200,VRC4500,VRC2400,VRC2400-A1-20-BT1

PC12-199-F1-4040-TA-W6 PowerCycling PC Series Thermoelectric Cooler

型号- PCX SERIES,387004355,PC12-199-F1-4040-TA-W6,PCX,387005516,PC SERIES,PCX12-19-F1-4040-TA-RT-W6

PT4-12-F2-4040-TA-W6 PolarTEC™ PT Series Thermoelectric Cooler

型号- PT SERIES,PT4-12-F2-4040-TA-W6,430023-507

Laird Thermal Systems Introduces 5000 Watt Heat Exchanger for Industrial Applications

Laird Thermal Systems has expanded its line of water heat exchangers with the introduction of the LA5000 Liquid Cooling System. As a water heat exchanger, the 5000-watt unit offers dependable compact performance while removing large amounts of heat from a liquid circuit. Designed to maximize system uptime, the LA5000 heat exchanger is ideal for immersion cooling and bulk heat removal in particle accelerators, linear accelerators, cyclotrons, semiconductor fabrication equipment, medical X-ray, and industrial X-ray scanners.

产品 发布时间 : 2024-09-30

电子商城

服务

使用FloTHERM和Smart CFD软件,提供前期热仿真模拟、结构设计调整建议、中期样品测试和后期生产供应的一站式服务,热仿真技术团队专业指导。

实验室地址: 深圳 提交需求>

提供稳态、瞬态、热传导、对流散热、热辐射、热接触、和液冷等热仿真分析,通过FloTHERM软件帮助工程师在产品设计初期创建虚拟模型,对多种系统设计方案进行评估,识别潜在散热风险。

实验室地址: 深圳 提交需求>

登录 | 立即注册

提交评论