Multistage Micro Thermoelectric Coolers for Miniature Optical Image Sensing Applications

Introduction

Miniature optical packages provide a robust hermetic seal to protect small image-sensing components, including CMOS, CCD, IR, and X-ray detectors. Optical packages, like Transistor Outline (TO) Cans, are widely used for image-sensing applications. For high-end image sensing, micro thermoelectric coolers (TECs) can be integrated into optical packages called Optical Thermoelectric Assemblies (TEAs). This will provide deep cooling to temperatures well below ambient to minimize thermal noise and capture maximum light spectrum. To achieve precise temperature control, cooling image sensors requires highly engineered micro Multistage TECs.

Miniature Optical Image Sensing Application Challenges

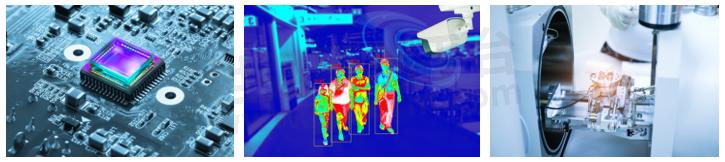

Miniature Optical TEAs are used in a wide variety of applications including thermal imaging, high-performance cameras, gas detectors, spectrometers, border security, digital microscopes, metrology, and defense applications to name a few. For these types of applications, Optical TEA designs present several challenges. These include thermal management, size constraints, optomechanical stability, manufacturing consistency, and cost optimization.

Optical Image Sensing Applications

Mechanical stresses and vibrations can significantly influence the alignment and stability of miniature Optical TEAs, which can impact the alignment and stability of optical components. Designers need to select optimal bonding methods and ensure robust process controls are in place during the manufacturing stage to assure strong bonding adhesion between components in assembly with overall tight tolerances.

Miniature optical packages, which are the key components of optical TEAs, are typically made from materials with low thermal conductivity, such as Kovar. This limits heat dissipation, which can affect the performance and reliability of the imaging sensor.

To ensure that the deep cooling temperature minimizes thermal noise, designers need to implement active cooling devices, such as micro TECs, as they adhere to size and cleanliness requirements. Form factors continue to shrink into smaller packages, requiring higher precision assembly methods to pack smaller thermoelectric elements into tighter densities. TECs can withstand rigorous cleanliness methods and harsh solvents to assure no degradation occurs that can impact reliability.

Multistage TECs can achieve higher temperature differentials between the hot and cold sides compared to single-stage TECs, providing greater cooling or heating capabilities. Careful design consideration of the multistage TEC is needed to balance cooling capacity requirements against temperature differential to maintain the highest coefficient of performance, (COP).

The main type of thermoelectric coolers used in optical packages are multistage micro TECs.

Multistage TECs

A multistage micro thermoelectric cooler, or cascade thermoelectric module, consists of multiple single-stage thermoelectric TECs connected in series electrically and thermally. Each stage of the TEC has its own set of thermoelectric couples, and the stages are arranged in a cascaded configuration. Offering application-specific configurability, a multistage TEC delivers a higher temperature differential compared to a single-stage thermoelectric cooler. By cascading stages, the temperature difference can increase with each stage, allowing it to reach colder temperatures. Multistage thermoelectric devices can provide cooling capacities ranging from milli-watts to watts, depending on the specific configuration and design.

In general, simple image-sensing applications would normally not require a TEC. However, as the importance of image resolution increases for high-performance applications, the more critical multistage micro TECs become.

The selection of multistage micro TECs for optical packages is based on several key factors.

1. Optimized TEC Design: application requirements need to be thoroughly understood at the desired operating point. The geometry factor, number of couples and number of stages should be optimized to match heat removal requirements from the image sensor plus passive heat losses. Thermal resistances of the hot and cold sides need to be accounted for as they will reduce temperature differential across the thermoelectric cooler. Power consumption is an important consideration, especially in applications that require portable battery operation. The following is an approximation of micro TEC cooling temperatures that can be achieved by stage:

• 1 stage micro TEC down to -20℃ below ambient

• 2-stage micro TEC down to -40℃ below ambient

• 3-stage micro TEC down to -60℃ below ambient

• 4-stage micro TEC down to -80℃ below ambient

2. Package Design: the least expensive package in the smallest form factor is often chosen. However, the package is the key heat dissipation mechanism, and may not have the best thermal conductivity. As the form factor of the package shrinks, the heat flux density increases and poor heat dissipation can lead to thermal runaway. This can be avoided by sizing the package and thermal conductivity of the material to accommodate the total heat that needs to be rejected from the TEC, image sensor and parasitic heat losses.

3. Interface between TEC and Package: The solderability of the TEC to the optical package is critical to assure proper heat rejection from the TEC. Poor solder adhesion leads to solder voiding and this increases the hot side thermal resistance. Proper plating materials need to be specified on ceramic substrate surfaces of the TEC in combination with optimal solder construction to assure a thin bond layer is achieved with minimal solder voiding. This will have maximum impact by increasing the operating efficiency of the TEC.

4. Parasitic Losses: Passive heat losses can occur from a thermal short between the hot and cold side of the TEC. Most packages are hermetically sealed in a vacuum or gas, so this minimizes thermal losses from passive heat in the surrounding environment. However, lead attachments to the TEC, imaging sensor, and NTC thermistor on the cold side substrate of the TEC are susceptible to heat transfer from the lead wires. This will cause the TEC to consume more input power to achieve the same cooling power required. It is ideal to design the TEC to operate at a lower current since this will reduce the gauge thickness of the lead wire and reduce heat transfer from the lead wires.

5. Form Factor: The size and form factor of multistage micro TECs are important, particularly in space-constrained TO-39 packages. Micro TECs with smaller footprints down to 2.0mm x 4.0mm allow for easier integration into optical packages without compromising the performance of other devices. Height is particularly critical as the imaging sensor is mounted on top resulting in tight tolerances.

6. Outgassing: Managing outgassing is crucial in thermal management solutions for imaging systems to prevent contamination on the optical lens and reduction of image resolution. The impact of outgassing on the imaging system can be minimized by selecting materials that do not outgas, applying appropriate treatments or coatings, considering design aspects, and conducting thorough testing. This will ensure optimal performance and reliability.

Once the main design variables have been determined, the TEC is controlled by a temperature control circuit, which adjusts the current supplied to the TEC to maintain the imaging sensor at the desired control temperature. Other variables to consider are substrate materials and solder construction of the TEC. Materials exist with higher thermal conductivity and solder adhesion, which boost performance, heat spreading and reliability, but they must be weighed against cost targets of the end application.

MSX Series

The MSX Series utilizes advanced ceramic materials, proprietary solder bonding technics and next-generation thermoelectric materials to boost cooling capacity by as much as 10% – all in a micro footprint.

Multistage MSX Series micro TECs offer footprints on the cold side down to 2.0 x 4.0 mm with thicknesses down to:

• 3.3 mm for 2 stages

• 3.8 mm for 3 stages

• 4.9 mm for 4 stages

The packing fraction for thermoelectric elements enables a high heat pumping capacity of up to 5 Watts, with lower operating currents than traditional multistage coolers. Featuring solid-state construction for long-life reliability and no maintenance, the Micro multistage thermoelectric coolers deliver reliable temperature stabilization from room temperature down to 180 Kelvin with no outgassing.

Advanced Process Automation

Manufactured in the USA, Laird Thermal Systems has invested in advanced automation equipment in-house, to integrate multistage micro thermoelectric coolers into miniature Optical TEAs. This saves customers the burden of integrating TECs into their optical packages, thereby reducing assembly time and cost, and improving repeatability. Additional benefits to OEMs and their design engineers include:

Simplified Integration - design engineers can easily integrate the cooling solution into their existing imaging system without the need for significant modifications or customizations. This simplifies the design process and reduces time-to-market.

Quality Assurance - Combining proprietary optical thermoelectric assembly capabilities with minimal solder voiding ensures customers receive high-quality cooling devices with consistent and repeatable performance.

Reliable Supply Chain - results in reduced lead times, easier procurement, and facilitates fulfilling production demand schedules.

OEMs no longer need to be concerned with investing in tooling and process equipment, lowering development costs, or keeping production schedules on track.

Optical TEA package

TO Can with Cap off and on, including Image Sensor and MSX Series Thermoelectric Cooler

Conclusion

Micro multistage thermoelectric coolers offer multiple advantages for advanced image sensing applications. Micro thermoelectric coolers provide precise, localized thermal control in microscale environments, rapid cooling to very low temperatures, high thermal efficiency, solid-state operation, low power consumption, and can be customized to easily scale up or down depending on the specific application requirements. Supplying micro thermoelectric coolers in Optical TEAs provides additional benefits including ease of integration, space-efficient design, optimized thermal performance, quality assurance, cost-effectiveness, and improved product performance.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由Ray转载自Laird Thermal Systems Official Website,原文标题为:Multistage Micro Thermoelectric Coolers for Miniature Optical Image Sensing Applications,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Laird Thermal Systems Offers Ultra-Compact Coolers for Next-Generation Optical Transceivers

In this application note, we will discuss laser diodes commonly used in telecom applications, and how ultra-small thermoelectric coolers (TECs) can remove the heat generated in the laser diode package to optimize overall performance.

Laird Thermal Systems OptoTEC™ MBX,用于下一代光模块的微型热电制冷器

本文讨论了半导体激光器在通讯应用中的重要性,以及Laird Thermal Systems OptoTEC™ MBX系列微型热电制冷器(TEC)如何帮助散热以优化性能。介绍了激光器的类型、封装、性能挑战和制冷方法,强调了微型TEC在提高激光器性能和可靠性中的作用。

Laird Thermal Systems Produces a Wide Array of Thermoelectric Coolers, Assemblies and Temperature Controller Combinations Optimized for Incubator Chambers

Laird Thermal Systems introduces thermoelectric solutions for incubator chambers, emphasizing precise temperature control without refrigerants. The HiTemp ETX Series and SuperCool X Series provide efficient heating and cooling, crucial for cell culture in labs. These systems offer a compact, reliable, and low-maintenance alternative to traditional incubator thermal management.

【材料】莱尔德热系统新推用于小型光学图像感测应用的多级微型热电制冷器MSX系列,冷侧面积最小可做到2x4mm

莱尔德新推出MSX系列多级微型热电制冷器,采用高级陶瓷材料、专有的焊接工艺和下一代热电材料,可将制冷能力提高10%,而所有这些都是通过微小面积实现。多级MSX系列微型TEC在冷侧的面积最小可做到2x4mm。

莱尔德热系统将在2024 CIOE中国光博会上展出下一代主动制冷技术

莱尔德热系统(Laird Thermal Systems)将于9月11日至13日在深圳国际会展中心参加2024年中国国际光电博览会(简称:CIOE中国光博会),展位位于12号馆信息通信展的12A69。

【IC】莱尔德热系统全新OptoTEC™ MSX系列微型多级热电制冷器,专为微型光电封装设,制冷能力可提高10%

Laird Thermal Systems已经开发出全新OptoTEC™ MSX系列微型多级热电制冷器,和将它集成在各种光学封装中的能力,包括广泛使用的TO-39、TO-46以及TO-8等规格,能够构建出更为先进的光学热电模组。

Laird Thermal Systems Unveils Micro Multistage Thermoelectric Cooler & Optical TEAs Integration Capability

“Advanced process automation has enabled a new level of miniaturization for our MSX multistage series to support next-generation imaging solutions that require smaller optical packages,” said Andrew Dereka, Thermoelectrics Product Director at Laird Thermal Systems.

Laird Thermal Systems MSX Series: Advanced Thermoelectric Cooling Solutions for High Performance Imaging Sensing Applications

The MSX Series utilizes advanced ceramic materials, proprietary automation and next-generation thermoelectric materials to boost cooling capacity by as much as 10% and assure high process repeatability.The compact MSX Series is used to deliver deep cooling to well below ambient in high-performance imaging sensing applications including:Infrared (IR) Detectors,Charge-Coupled Devices (CCD),Complementary Metal Oxide Semiconductors (CMOS),X-Ray Detectors.

Laird Thermal Systems to Showcase Next Generation Active Cooling Technologies at CIOE 2024 - China International Optoelectronic Exhibition

Laird Thermal Systems will be exhibiting its newest active thermal products that solve thermal problems in applications including optical transceivers, imaging sensors, lasers and autonomous systems at the 2024 China International Optoelectronic Exhibition from September 11th through the 13th.

用于小型光学图像感测应用的多级微型热电制冷器

描述- 本文主要介绍了用于小型光学图像感测应用的多级微型热电制冷器(TEC)的设计和应用。文章阐述了微型光学TEA在热成像、高性能相机等领域的应用挑战,如热管理、尺寸限制等。重点介绍了多级TEC的优势,包括实现更高温差、提供更大制冷或加热能力等。同时,文章还详细说明了选择多级微型TEC的关键因素,如TEC设计、封装设计、TEC和封装之间的接口、寄生损耗、外形尺寸、释气等。最后,介绍了MSX系列微型TEC的特点和优势,以及莱尔德热系统在自动化制造方面的投资和优势。

型号- MSX,MSX系列

热电手册

描述- 本资料主要介绍了热电制冷器(TEC)的相关知识,包括其工作原理、结构、功能、应用场景、性能参数、设计选择、组装技巧以及可靠性测试等。资料详细阐述了热电制冷器的优势,如紧凑的尺寸、无运动部件、长寿命、环境友好等,并提供了不同系列热电制冷器的性能参数和应用案例。此外,资料还介绍了热电制冷器的温度控制、热电阵列设计、密封剂选择、多级制冷器应用以及组装注意事项等内容。

型号- PCX,ULTRATEC™ UTX,ETX,HTX,OPTOTEC™ OTX,OTX,UTX SERIES,MS SERIES,HITEMP ETX,OPTOTEC™ HTX,UTX,HTX SERIES,OPTOTEC™ OTX SERIES,ANNULAR SERIES,ETX SERIES,CP SERIES,PCX SERIES,MULTISTAGE MS,POWERCYCLING PCX,OTX SERIES,POWERCYCLING PCX SERIES,MULTISTAGE MS SERIES,ULTRATEC™ UTX SERIES,OPTOTEC™ HTX SERIES,HITEMP ETX SERIES

Laird Thermal Systems(莱尔德热系统)热电冷却器选型指南(中文)

目录- 公司简介和产品介绍 热电冷却器 表面处理选项和热管理大师

型号- 430478-502,HTX20-31-F2A-0909-11-W2.25,64979-501,CP085-127-06-L1-W4.5,UTX15-24-F2-5252-TA-W6,CP14-31-10-L1-W4.5,ETX7-3-F1-2020-TA-RT-W6,9360001-301,7050045-502,71061-504,ETX14-12-F1-6262-TA-W6,UTX6-24-F1-5555-TA-W6,HTX15-31-F2A-0909-TB-W2.25,PCX7-156-F2-1672-TA-RT-W6,387008429,SH08-28-05-L1-W4.5,PCX6-12-F1-4040-TA-RT-W6,ULTRATEC™ UTX SERIES,CP14-71-10-L1-W4.5,PCX8-12-F1-4040-TA-W6,9340006-301,PCX7-16-F1-4040-TA-W6,ETX4-7-F1-2323-TA-W6,71092-501,ETX15-28-F2-5252-TA-RT-W6,387008431,CP14-127-10-L1-W4.5,387007103,CP14-35-045-L1-W4.5,ETX4-7-F2-3030-TA-RT-W6,430705-503,387007106,387007227,387007108,HTX12-65-F2A-1312-TB-RT-W2.25,OPTOTEC™ HTX,430874-503,71062-514,387007231,CP08-63-06-L1-W4.5,387007112,387007113,9350004-301,387007115,430052-501,387007117,MS5-257-10-15-11-W8,ETX2.5-12-F1-3030-TA-RT-W6,CP08-127-05-L1-W4.5,PCX10-223-F1-3172-TA-RT-W6,HITEMP ETX SERIES,CP14-127-045-L1-W4.5,430922-501,387007120,387007123,387007122,9320002-301,MS3-119-20-15-11-W8,ETX11-12-F1-4040-TA-RT-W6,MS SERIES,56760-505,ETX15-12-F2-4040-TA-RT-W6,MS2-192-14-20-11-18-11-W8,ETX6-12-F1-4040-TA-RT-W6,56590-502,SH10-23-06-L1-W4.5,71036-505,56610-502,MS4-108-10-20-11-W8,ETX4-12-F1-3030-TA-W6,430027-501,PCX12-248-F1-5040-TA-RT-W6,PT4-7-F2-3030-TA-W6,430848-502,OTX12-65-F2A-1312-11-W2.25,430848-504,PCX8-7-F2-3030-TA-RT-W6,MS2-068-14-14-15-15-11-W8,CP14-71-045-L1-W4.5,OTX20-66-F0-1211-11-W2.25,PCX4-6-F1-2040-TA-RT-W6,HTX,PCX5-16-F1-4040-TA-W6,56430-501,OTX19-23-F1N-0608-11-W2.25,HTX SERIES,UTX9-28-F2-4040-TA-W6,PCX15-7-F1-4040-TA-RT-W6,PT4-12-F2-3030-TA-W6,CP12-161-04-L1-W4.5,16506-302,PCX8-6-F1-2040-TA-RT-W6,430875-503,ETX4-3-F1-2020-TA-RT-W6,43280-503,66100-501,66156-505,71063-505,44440-501,71020-505,56550-501,MS3-052-10-17-11-W8,387004692,387005660,SH10-125-05-L1-W4.5,71012-506,387005662,ETX2.3-4-F1-1919-TA-RT-W6,ETX5-6-F1-2040-TA-RT-W6,387005663,ETX4-12-F2-4040-TA-RT-W6,387005664,387004697,387005665,387005667,387005669,OTX12-66-F0-1211-11-W2.25,430097-507,ETX2.6-12-F1-2525-TA-W6,PCX9-3-F2-2525-TB-RT-W6,387005671,387005672,MS2-102-22-22-17-17-11-W8,387005673,387005674,387005676,387005677,387005678,387005679,387005318,CP10-254-06-L1-W4.5,ETX9-3-F2-2525-TA-W6,CP10-71-05-L1-W4.5,430026-503,430511-504,56910-502,OTX20-66-F0-1211-11-EP-W2.25,387006650,387005681,56995-501,387006891,387005683,ETX6-19-F1-4040-TA-RT-W6,CP10-31-05-L1-W4.5,387006893,387005685,387005686,387006897,387006534,HTX15-30-F2A-0610-11-W2.25,OTX12-65-F2A-1312-TB-W2.25,RH14-14-06-L1-W4.5,ETX2-12-F2-3030-TA-W6,PCX8-6-F1-3518-TA-RT-W6,MS2-102-14-14-17-17-11-W8,387006784,UTX15-288-F2-5252-TA-W6,387005696,387006544,387005698,387005699,ETX4-12-F1-4040-TA-RT-W6,SH14-125-10-L1-W4.5,CP14-71-06-L1-W4.5,9340001-301,HTX12-18-F2A-0606-11-RT-W2.25,387006791,387006795,CP2-127-10-L1-W4.5,387006798,63604-511,PCX6-24-F1-5555-TA-RT-W6,CP14-199-06-L1-W4.5,OTX20-65-F2A-1312-11-W2.25,UTX,PCX5.6-19-F1N-3030-TA-RT-W6,ETX15-24-F2-5252-TA-W6,MS3-231-10-15-11-W8,SH14-125-045-L1-W4.5,POWERCYCLING PCX,62910-510,PCX24-128-F2-5555-TA-RT-W6,387005354,HTX15-65-F2A-1312-TB-W2.25,POWERCYCLING PCX SERIES,CP10-131-04-L1-TOW-W4.5,OTX08-18-F0-0505-11-W2.25,HTX12-18-F2A-0606-GG-W2.25,CP14-199-045-L1-W4.5,CP2-71-06-L1-W4.5,ETX4-6-F2-2143-TA-RT-W6,OTX20-68-F1A-1313-11-W2.25,OPTOTEC™ OTX SERIES,71212-502,CP SERIES,CP2-31-06-L1-W4.5,POLARTEC™ PT SERIES,63595-501,PCX4-4-F1-1515-TA-RT-W6,ETX8-12-F2-2525-TA-RT-W6,HTX12-65-F2A-1312-11-W2.25,OTX08-31-F1-0707-11-RT-W2.25,PT8-12-F2-4040-TA-W6,ETX4-12-F2-3030-TA-RT-W6,CP10-71-06-L1-W4.5,OTX08-66-F0-1009-11-RT-W2.25,CP14-17-10-L1-W4.5,ETX3-3-F2-1518-TA-W6,ETX11-12-F2-3030-TA-RT-W6,PCX4-7-F1-2020-TA-RT-W6,387004970,MS2-190-10-10-12-12-11-W8,387005700,ETX2.5-12-F1-4040-TA-RT-W6,CP10-127-06-L1-W4.5,9340002-301,OPTOTEC HTX 系列,MS2-065-04-04-11-11-11-W4,9350007-301,71049-501,POLARTEC™ PT,387006926,PT4-12-F2-4040-TA-W6,387006928,387006927,PCX11-12-F2-3030-TA-RT-W6,RH14-32-06-L1-W4.5,MS2-051-22-25-22-25-11-W8,MS4-115-14-15-11-W8,ETX14-3-F1-3030-TA-RT-W6,PCX8-176-F2-7528-TA-RT-W6,SH14-15-06-L-W4.5,PCX7.5-13-F1-4023-TA-RT-W6,OTX15-68-F1A-1313-11-W2.25,CP2-127-06-L1-W4.5,ETX6-7-F2-3030-TA-RT-W6,OTX08-08-F0-0303-11-W2.25,PCX6-28-F2-4040-TA-RT-W6,44530-501,MS2-049-10-10-15-15-11-W8,16503-310,UTX8-288-F2-5252-TA-W6,475010-313,ETX3-48-F1-1212-GG-W6,ETX2.6-6-F1-1225-TA-W6,OPTOTEC HTX,UTX6-19-F1-4040-TA-W6,OPTOTEC OTX 系列,430436-504,OPTOTEC™ OTX,387006832,UTX SERIES,387006834,387006836,387006837,9350006-301,387006839,HTX20-65-F2A-1312-11-W2.25,9380001-301,MS3-070-20-25-11-W8,9340003-301,MS2-192-14-20-15-25-11-W8,MS4-129-10-15-11-W8,PCX2-12-F1-3030-TA-RT-W6,ETX2-6-F1-1225-TA-RT-W6,ETX4-3-F1-1515-TA-RT-W6,387006845,387005513,387005514,387006847,387005515,387005516,ETX25-12-F1-6262-TA-W6,ETX1.6-12-F2-3030-TA-RT-W6,OTX12-66-F0-1211-TB-RT-W2.25,430023-507,9350001-301,HITEMP ETX,387004679,57180-501,CP10-63-06-L1-W4.5,PCX4-139-F1-1850-TA-RT-W6,71035-505,UTX8-12-F2-2525-TA-W6,430474-501,MS2-107-10-10-12-12-11-W8,UTX11-12-F2-3030-TA-W6,ETX8-12-F1-4040-TA-RT-W6,387004680,ETX6-3-F1-2020-TA-RT-W6,387004685,38700

电子商城

服务

使用FloTHERM和Smart CFD软件,提供前期热仿真模拟、结构设计调整建议、中期样品测试和后期生产供应的一站式服务,热仿真技术团队专业指导。

实验室地址: 深圳 提交需求>

提供稳态、瞬态、热传导、对流散热、热辐射、热接触、和液冷等热仿真分析,通过FloTHERM软件帮助工程师在产品设计初期创建虚拟模型,对多种系统设计方案进行评估,识别潜在散热风险。

实验室地址: 深圳 提交需求>

登录 | 立即注册

提交评论