Laird Thermal Systems Custom Solutions for Cooling Medical X-ray Imaging Equipment

Introduction

Designed to take pictures inside a patient’s body, medical X-ray imaging systems are a vital piece of detection equipment. Medical X-ray imaging equipment can be used to detect and diagnose a wide range of injuries or diseases. In X-ray-based imaging techniques, an X-ray beam is projected through a patient to a recording medium. The generation and projection of an X-ray beam is highly inefficient and produces a large amount of waste heat. The heat load can be as much as 5KW. Temperature stability within medical imaging systems is critical to enhance imaging performance, increase system reliability, and maximize equipment uptime. Medical imaging systems require conflicting requirements of increased heat pumping performance with lower power consumption. As a result, Liquid Cooling Systems are often the preferred choice to move heat away from the X-ray tube to ensure quality images are produced. Thermal management systems that feature liquid cooling offer higher efficiencies than air-based heat transfer mechanisms. This translates into higher reliability, reduced field maintenance, greater system uptime and lower total cost of ownership.

Application Overview

Simply put, a medical X-ray system includes an X-ray generator, an X-ray tube and gantry, and a recording medium. To generate an X-ray beam, an electrode pair, an anode and a cathode, are inside of a vacuum tube that is typically made of glass. The cathode is usually a heated filament, while the anode is a flat disc made of tungsten.

In computed tomography (CT) X-Ray systems, the tube and the detector are both rotating around the body during the examination.The flat panel detector technique requires the CT scanner to take many scans of the body, which is then put together layer by layer to create the 3D image.

In CT-scanners, both the tube and detector rotate around the body during X-ray examination.

Often referred to as interventional imaging, C–arm X-ray machines create continuous, real time X-ray images of the movement of a body part, instrument, or contrast agent. C-arm X-ray machines use an image intensifier technology that delivers superior imaging quality compared to flat panel detector technology used by CT scanners. Image intensifier technology enables C-arm X-ray machines to be used for imaging during surgical, orthopedic, and emergency care procedures. Compared to CT scanners, C-arm machines require significantly less space in an often crowded operating room.

Key components of a C-arm X-ray Machine

Thermal Challenges

Medical X-ray manufacturers are tasked with developing new designs that increase scan speeds while improving image quality. Many manufacturers are working towards designing equipment that can scan entire organs in 4D. This can only be achieved by reducing thermal noise in the system to enhance imaging quality. Only a small portion of the energy generated by the system is emitted as X-rays, the balance is released as heat. X-ray systems have a heat load range of 1~5KW that must be efficiently dissipated. Temperature fluctuations not only impact image resolution, but also long-term operation of key components. The X-ray tube, and specifically the anode, must be cooled for optimized X-ray performance and a longer operation life.

On the other end of the X-ray generator, the detector must also be cooled. Usually requiring a low heat load of <300 Watts, cooling systems must provide precise temperature control for X-ray detectors to enhance image resolution.

The trend is to reduce the size of X-ray machines and increase power densities as product form factors continue to shrink. Simple thermal management solutions, such as adding a fan or heat sink, are typically no longer viable to meet required performance and reliability specifications. To meet the required cooling capacity in a more compact form factor, cooling systems must have a high coefficient of performance. Waste heat must be managed and dissipated efficiently in order to increase performance while reducing power consumption and providing quieter operation. Low noise operation is required as to not disturb the patient during the X-ray imaging procedure.

Further complicating liquid cooling designs, X-ray machines utilize gantry systems that house the temperature sensitive components. These gantry systems spin rapidly as the X-ray machine takes images of a patient. Gantry systems and the electronics inside are subjected to tremendous rotational speeds and acceleration forces (G-forces). Liquid pumps must be able to maintain pressure and a constant liquid flow while under high stress caused by these high g-forces. The pump is one of the most critical components in a liquid cooling system. Pumps are in constant operation when the unit is turned on and typically have the shortest mean time between failure (MTBF) of all components due to friction wear of bearings, pump blades and seals. If poorly chosen, the pump will fail prematurely and the liquid cooling system will fail and cause the end instrument to stop working. This can be a problem for expensive medical X-ray machines where downtime not only means a significant loss of revenue, but potential life or death for a patient.

Liquid Cooling Systems

Offering optimal temperature stabilization and precise temperature control, liquid cooling systems are self-contained units that recirculate coolant to a predefined set-point temperature. Liquid cooling systems are able to dissipate a large amount of heat generated by the medical X-ray system. Liquid cooling systems offer many advantages over conventional air-cooled systems. Liquid cooling systems provide higher heat pumping capacity, better ability to direct the heat away from the source, more rapid cool down time, and are much quieter. In addition to higher efficiency, liquid cooling systems provide more reliable operation and require less maintenance.

Depending on the medical scanner, two different types of liquid cooling systems can be utilized:

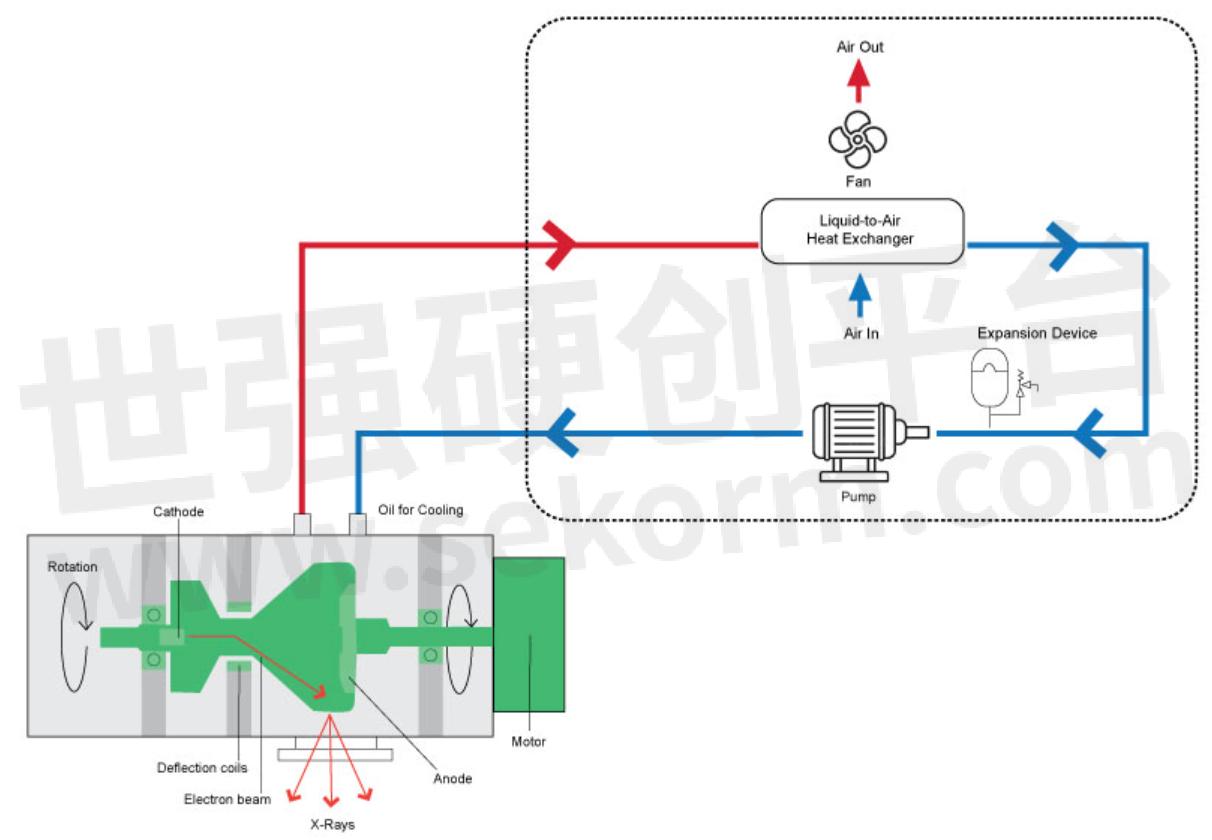

·Liquid-to-air heat transfer configuration: a high-pressure pump recirculates the liquid coolant, while an air heat exchanger removes the heat from the liquid circuit, dissipating it into the ambient environment by means of a fan. The coolant can be water, a water-glycol mixture, or transformer oil, depending on the temperature at the heat source; an oil-cooled system is used when the temperature exceeds the operational temperature limit of the water-based systems.

·Liquid-to-liquid configuration: a pump recirculates the coolant and ambient-temperature water is used in a liquid heat exchanger to dissipate heat on the hot side. The liquid-to-liquid system increases cooling capacity compared with the liquid-to-air system. These systems can be designed to operate with either water or oil as the coolant liquid, depending on the temperature environment.

Medical X-ray systems may utilize two different types of X-ray tubes that impacts the type of coolant used in the liquid cooling system. With bipolar tubes, the cooling fluid around the anode is in contact with the electrical potential, so it must be a liquid that does not conduct electricity, such as oil. For a monopole tube, the anode side is grounded and there is no electrical potential, so a water-based coolant, typically a mixture of water and glycol, can be used. Monopole X-ray tubes are more common in industrial applications.

For all types of liquid cooling systems, additional features can add precise temperature control, variable coolant flow rate, coolants with corrosion inhibitors and coolant filtration, as needed. Temperature control of multiple liquid circuits is often required, as is high operational temperature. As with most gantry systems, control of multiple pressure drop settings to accommodate both low and high-pressure conditions may be needed.

System Flow Diagram

Liquid cooling systems are able to dissipate a large amount of heat generated by the X-ray system. A liquid heat exchanger system cools the coolant in a liquid circuit by the use of a liquid-to-air heat exchanger. The system contains of a pump that circulates coolant and a liquid circuit to transfer coolant from the heat source to the liquid cooling system. The expansion device enables the cooling circuit to be completely sealed from the outside environment and compensates for the thermal expansion of the fluid over its wide operating temperature range.

Liquid flow in a typical cooling system for medical X-ray equipment

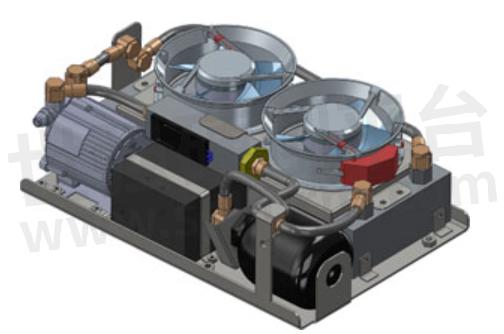

Laird Thermal Systems Custom Solutions

Liquid cooling systems offer a high coefficient of performance (COP) that delivers efficient, low power operation to maximize uptime and optimize performance of medical X-ray imaging equipment. This efficiency optimizes heat transfer delivery away from thermally sensitive components to the ambient environment.

A liquid cooling system offers higher efficiency than air-based heat exchangers and provides more rapid cooling, quieter operation, higher reliability, and increased system uptime. Compared to conventional air heat transfer mechanisms, liquid cooling systems offer cooling up to 5X higher per square area. Laird Thermal Systems’ liquid cooling systems feature high thermal conductivity of coolants to remove bulk heat in Kilowatts with rapid cool down.

Since medical X-ray equipment features many unique cooling challenges, a custom liquid cooling system configuration is often required to optimize performance and long-life operation. The type of coolant used will depend on the desired control temperature. Laird Thermal Systems has the experience to design cooling systems that are compatible with water, water-glycol, dialectric oil or various corrosion inhibitors. Liquid cooling systems can also be quite complex and require temperature control of multiple liquid circuits or multiple pressure drop settings in order to accommodate low and high-pressure conditions. From simple cooling systems to complex and precise temperature control systems with multiple liquid circuits or multiple pressure drop settings, Laird Thermal Systems offers dynamic solutions that meet medical X-ray application requirements. They offer engineering design services with a global presence that supports onsite concept generation, thermal modeling, mechanical and electrical design and rapid prototyping. The company also offers validation test services to meet unique compliance standards for the medical industry.

Because medial X-ray equipment features many unique cooling challenges, a custom liquid cooling system may be the optimal solution.

Liquid Cooling System Pump

Laird Thermal Systems has developed a spindle screw pumps featuring a simple construction that is ideal for high vibration, high G-force applications like rotational medical X-ray equipment. Compared to centrifugal pumps, spindle screw pumps provide higher reliability, performance and efficiency for liquid cooling systems. The fluid delivered by a screw pump does not rotate radially, but moves linearly. The rotors work like endless pistons, which continuously move forward. Flow through a screw pump is axial and in the direction of the power rotor. The inlet hydraulic coolant that surrounds the spindles is trapped as the spindles rotate. The coolant is pushed uniformly with the rotation of the spindles along the axis and is forced out the other end. This results in reduced power consumption, higher efficiency and a smaller motor size. It also enables the spindle screw pump to move fluids of higher viscosity without losing flow rate, and pressure changes have little impact on spindle screw pumps. Vital to the performance of rotating applications like a CT scanner gantry system, screw pumps are able to maintain constant flow and pressure while under high stress caused by high g-forces.

Long life operation is built into the spindle screw design due to no metal-to-metal contact between moving components. This minimizes friction wear and abrasions that can cause cavitation. The flexible mechanical assembly allows the use of a smaller strainer with higher mesh size that extends maintenance intervals and reduces the overall cost of ownership. No metal-to-metal contact also results in the elimination of pulsations, even at high flow rates, making the unit very quiet during operation. The end result is smooth and quiet operation even at high revolution rates and pressure.

Conclusion

Thermal management of medical X-ray systems is challenging due to the spinning gantry, increasing power densities and shrinking form factors. Heat must be quickly and efficiently moved away from temperature sensitive components inside the gantry system to ensure high quality imaging to detect and diagnose injuries and diseases. Laird Thermal Systems’ custom liquid cooling systems combine high heat pumping capacity and superior heat routing with lower power consumption, low noise operation and reduced footprints compared to competing technologies. With Laird Thermal Systems’ proprietary spindle screw pump technology, pressure changes have little impact on the liquid cooling system performance, as the pump easily moves fluids of higher viscosity without losing flow rate.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由samsara转载自Laird Thermal Systems Official Website,原文标题为:Cooling Medical X-ray Imaging Equipment,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Laird Thermal Systems‘ Nextreme™ Value Chillers Provide Economical, High Reliability OEM Cooling Solution

The Extreme Value Chiller Series uses high-performance components to cool well below ambient temperatures to control processes or dissipate heat away from thermally sensitive equipment.

Laird Thermal Systems‘ Next Generation Heat Exchanger LA5000 Economically Provides Full-Time Operation for Immersion Cooling in Data Centers

Laird Thermal Systems’ LA5000 is a 5000-watt liquid-to-air water heat exchanger designed to operate slightly above ambient temperatures serves as an excellent source of cold water for the system condenser and is ideal for immersion cooling applications.

Laird Thermal Systems Offers MRI Custom liquid Cooling Systems with Cooling Capacities of Hundreds of Kilowatts

This article focuses on Laird Thermal Systems‘ customized liquid cooling solution for the medical MRI product market, which effectively solves the problem of heat generation due to the creation of magnetic fields during the imaging process and solves the problem of image interruption.

日本电产集团综合产品目录(Nidec Group Products Catalog)

描述- 日本电产集团发布第10版产品目录,涵盖从精密小型马达到超大型电机的全系列产品。产品应用于信息技术、办公自动化、汽车、机器人、家电、物流、农业等多个领域。公司致力于成为全球领先的驱动技术企业,并积极应对汽车电动化、机器人应用扩展等五大技术创新浪潮。

型号- PM4系列,H300,D SERIES,NRFEIS-5060,DFS,GATS-2000 SERIES,TPI SERIES,GATS-7800 SERIES,R-6100,TVX,GATS-6300,GATS-8600,SX-20,RWI SERIES,ZI20A,GATS-7500系列,LSR-3230,BP100,RSH,GATS-7700 SERIES,K-MC1000,P2H系列,E300,GATS-2000系列,GATS-6300系列,NVM-6060GCP,VL-H系列,GATS-7500,MH3NCV,VL SERIES,GATS-7800系列,SS-SV,DEWE3-A4,TPI,TVX SERIES,RGA20,NRTES-1000 SERIES,FCPL,ΜV1,RSH系列,ZG SERIES,ID300,FMD,TPI系列,GATS-8600系列,S-CART,GATS-6300 SERIES,KS,CM,R-580,SS-SV SERIES,ANEX SERIES,LD SERIES,VP600GC,GE15FR PLUS,MD2,ANEX系列,NRTES-1000,P2H SERIES,FFB,VL系列,LS,RSH SERIES,RVL,VL-H SERIES,RVP,F600,SS-SV系列,S-FLAG,GATS-7500 SERIES,REC-92FT,DEWE3-PA8,ECO-KA,KCV1000-5AX,S-CART-V1000-LFT,RVL SERIES,RVP SERIES,R-700 SERIES,P2H,ZE16C,CPLS,S-CART-V500,HM500S,VM53RⅡ,GATS-7700,ANEX,NRTES-1000系列,HM-X6100,RWI,TVX系列,KA SERIES,S-CART-MINI,GATS-2000,PM4,VL-H,GATS-7700系列,CBZ,GH,GATS-8600 SERIES,R-700,R-5920系列,NRFEIS-3570,DFS SERIES,MVR-HX,MAF130EⅡ,BL-V20,ECO-KA SERIES,SERIES S-FLAG,RWI系列,HE,GATS-7800,R-5920

Laird Thermal Systems(莱尔德热系统)液体冷却系统产品选型指南

目录- Introduction Benefits & Applications of Liquid Cooling Systems Nextreme™ Recirculating Chillers Liquid Heat Exchangers Custom Liquid Cooling Systems Featured Application: Medical Imaging

型号- 1510.00,WL1500,385901-001,VRC2400,VRC4500,NRC5000,WL3004,387008451,1550.00,LA5000,WL1000,385911-015,1520.00,387009925,OW4002,385910-043,387010178,387010179,NRC2400,1505.00,38701 0181,1264.00,1155.00,1104.00,VRC1200,WW5001,387002779,NRC400,WW3001,1515.00,WL500,WL2000,387005774,387005598,OL4503,385912-029,NRC1200,385910-015

What are the benefits of using liquid instead of air cooling systems?

Liquid heat exchangers can reduce the thermal resistance of conventional heat sink fan dissipation mechanisms by a factor of 10 or more, which makes it much more efficient. This is due to the poor thermal properties of air versus coolants such as water. Liquid cooling systems have a more rapid cool down time, which means less time to reach the desired temperature. While conventional air cooling systems push air all around the system, and can potentially add heat from surrounding hot electronics, liquid cooling systems are equipped with a heat exchanger that routes heat away through a liquid circuit. Air-cooling systems in the higher capacity range often require larger fans, which can increase noise as well as the size of the system.

WL1500 WL系列液体冷却系统

描述- WL1500是一款可靠的液体到空气热交换器,通过高效循环冷却液来移除大量热量。它采用高压泵确保最大流量,并通过辐射式换热器和风扇将热量散发到环境中。该设备包含空气和水过滤器以保持最佳性能,并提供手动调节功能控制液体电路的压力和流量。

型号- WL1500,WL SERIES

Common Coolant Types and Their Uses in Liquid Cooling Systems

This paper mainly introduces the common coolant types of Laird thermal system and its application in liquid cooling system, and analyzes the advantages and disadvantages of specific applications

Does LTS offer standalone cooling systems?

Yes, Laird Thermal Systems offers self-contained Liquid Cooling Systems. liquid cooling systems (LCS) that recirculate a coolant to a preprogrammed temperature setpoint.

Laird Thermal Systems的新一代热交换器可为数据中心的浸没式冷却提供经济的全时运行

描述- Laird Thermal Systems推出新一代LA5000热交换器,专为数据中心沉浸式冷却系统设计。该热交换器可高效散热,降低运营成本,提高能源效率。通过监测系统液体水平、流量和温度,LA5000确保系统稳定运行,减少维护成本。沉浸式冷却利用热交换器将热量传递到冷却液体中,实现高效散热,同时降低能耗。

型号- LA5000

WL500 WL系列液冷系统

描述- 该资料介绍了WL500液体冷却系统,这是一种循环液态空气热交换器,通过高效的热量转移能力,从液体回路中移除大量热量。它具有高泵送能力和紧凑的设计,适用于医疗诊断与治疗、工业仪器和半导体制造等领域。

型号- WL SERIES,WL500

What is the maximum cooling capacity you provide?

Our Liquid Cooling Systems have the highest cooling capacity in our standard product portfolio. The largest capacity is our Ambient Cooling Systems with cooling capacities up to 5 kW. Custom solutions have been designed with capacities greater than 40 kW’s. The largest capacity of a thermoelectric cooler assembly is our Outdoor Cooler Series AA-480 and it has a cooling capacity of 480 Watts. The largest capacity of a thermoelectric cooler is the HiTemp ETX Series ETX15-28-F2-5252-TA-RT-W6 and it has a cooling capacity of 322 Watts.

What's the difference between standard and custom products?

Our standard products can be found in our product portfolio: Thermoelectric Coolers, Thermoelectric Cooler Assemblies, Liquid Cooling Systems, Temperature Controllers. These units have specific heat transfer methods, cooling capacity ranges or size constraints and can be ordered upon request from our distribution partners. If the capacity, size or other parameters of our standard products do not meet your application requirements you may need a customized solution. Laird Thermal Systems has the ability to customize our entire product range, however MOQ’s apply. To optimize performance and long-life operation, an application could require a customized thermal management solution. Also cooling capacities above 5 kW typically require a custom solution. Laird Thermal Systems designs and manufactures customized, thermal management solutions for performance-critical applications to optimize your product’s performance. Laird Thermal Systems offers strong engineering design services with a global presence that supports onsite concept generation, thermal modeling, mechanical and electrical design and rapid prototyping. The company also offers validation test services to meet unique compliance standards for each industry, such as UL, Telcordia, or a unique standard specific to a medical, industrial or semiconductor application.

Aavid‘s Modular Liquid Cooling Systems: Build a semi-custom system with high performance compatible components

Modular Liquid Cooling Systems are a cost-effective and reliable option where precise temperature control and cooling below ambient temperature are not required. These systems consist of a high performance heat exchanger integrated with a fan, pump, and tank in a durable metal chassis. Aavid‘s Modular Cooling Systems have cooling capacities up to 3.5 kW.

电子商城

服务

使用FloTHERM和Smart CFD软件,提供前期热仿真模拟、结构设计调整建议、中期样品测试和后期生产供应的一站式服务,热仿真技术团队专业指导。

实验室地址: 深圳 提交需求>

登录 | 立即注册

提交评论